Thin-film capacitor for automobile

A technology of film capacitors and capacitors, applied in the direction of film/thick film capacitors, capacitors, laminated capacitors, etc., can solve the problems of reducing the interior space of the car, unable to withstand large currents, and high ambient temperature, so as to reduce ESL and reduce Small size, enhanced heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

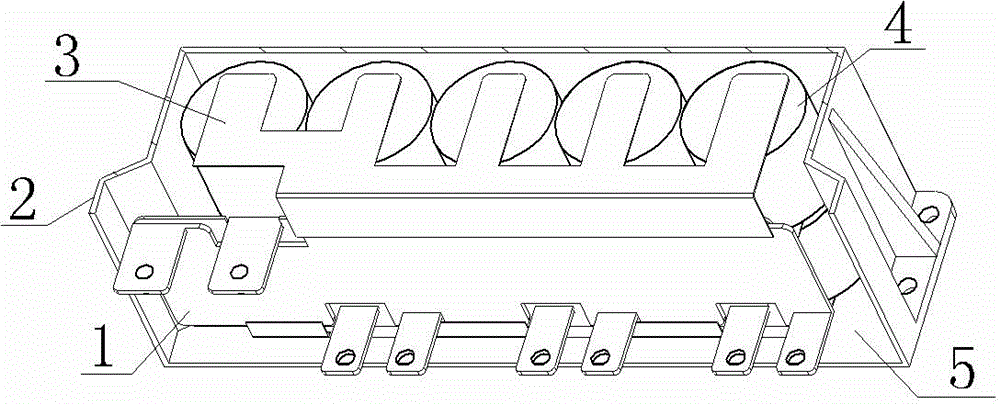

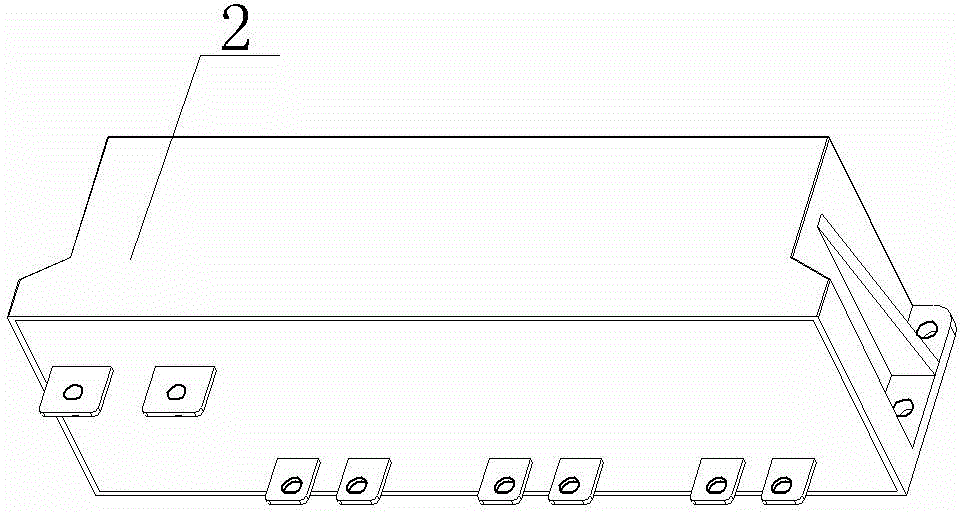

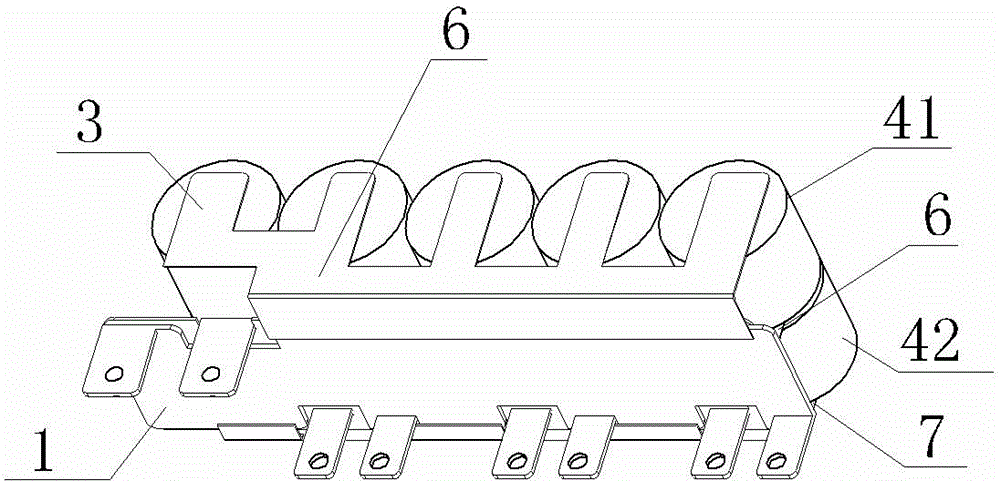

[0022] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a film capacitor for automobiles includes a housing 2, and a lead-out composite copper bar 1 is arranged inside the shell 2. The lead-out composite copper bar 1 includes an upper layer copper bar 11, an intermediate insulating plate 13, and a lower layer copper bar 12. , the capacitor core 4 is a two-layer core group, namely the core group 41 and the core group 42, the two-layer core group 4 is connected by the middle copper plate 6, the middle copper plate 6 is connected to the upper copper bar 11, and the two-layer core The two ends of group 4 are respectively connected to the lower copper bar 12 through the outer edge copper plate 7; or the two are exchanged, the middle copper plate 5 is connected to the lower layer copper bar 12, and the two ends of the two-layer core group 4 are respectively connected to the upper layer copper bar 11 through the outer edge copper plate 7 ;See F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com