Patents

Literature

76results about How to "Short ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

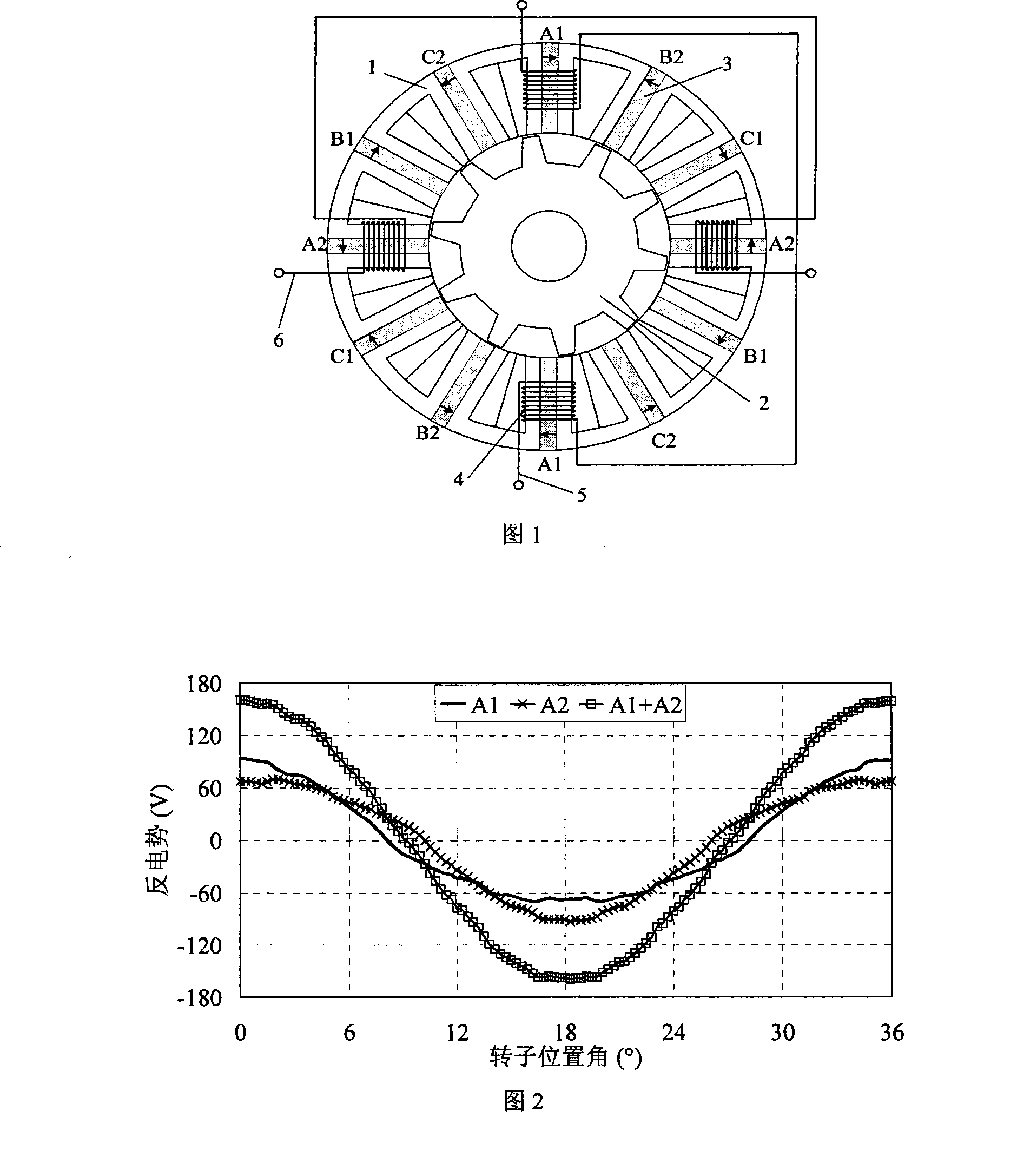

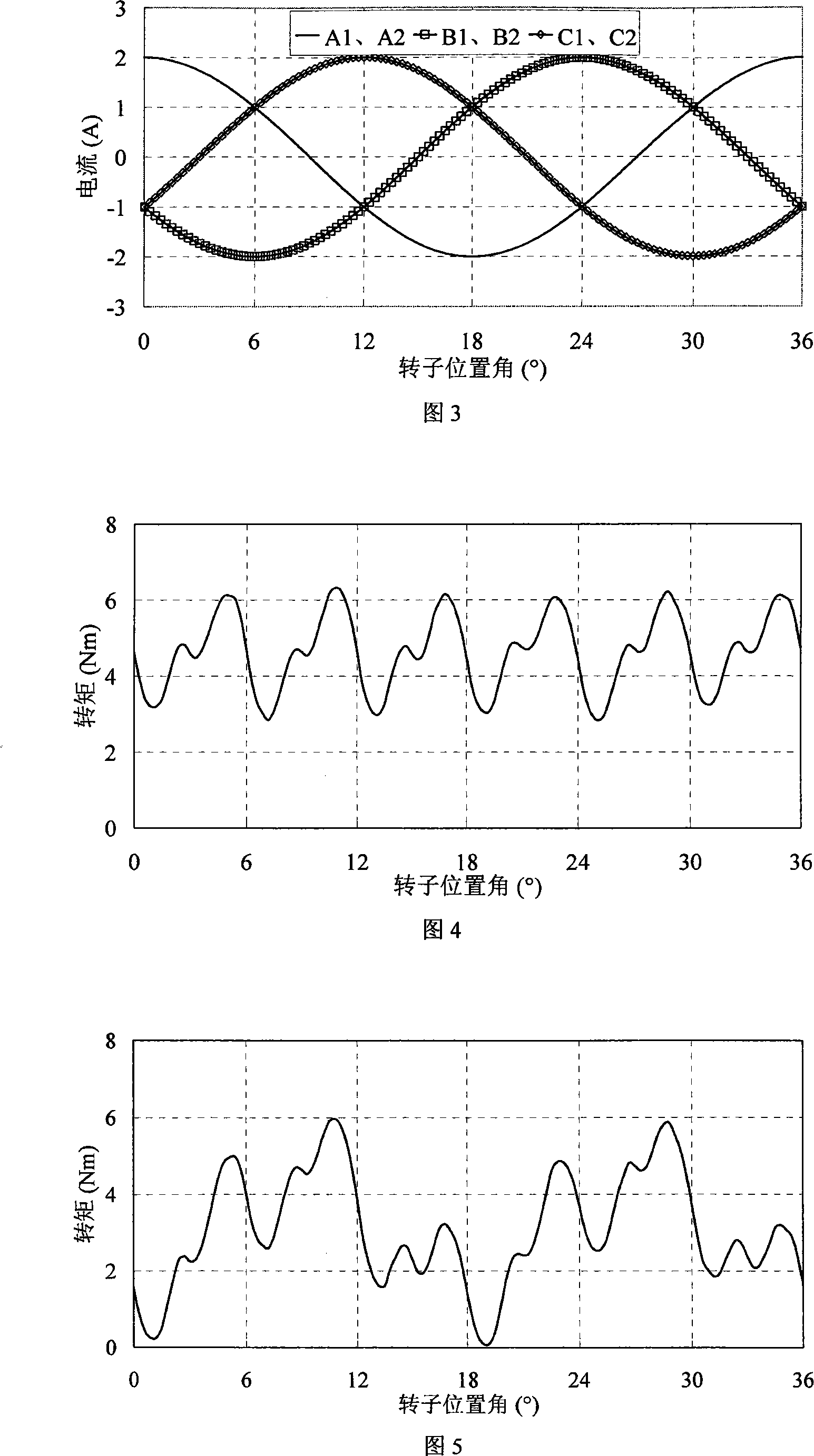

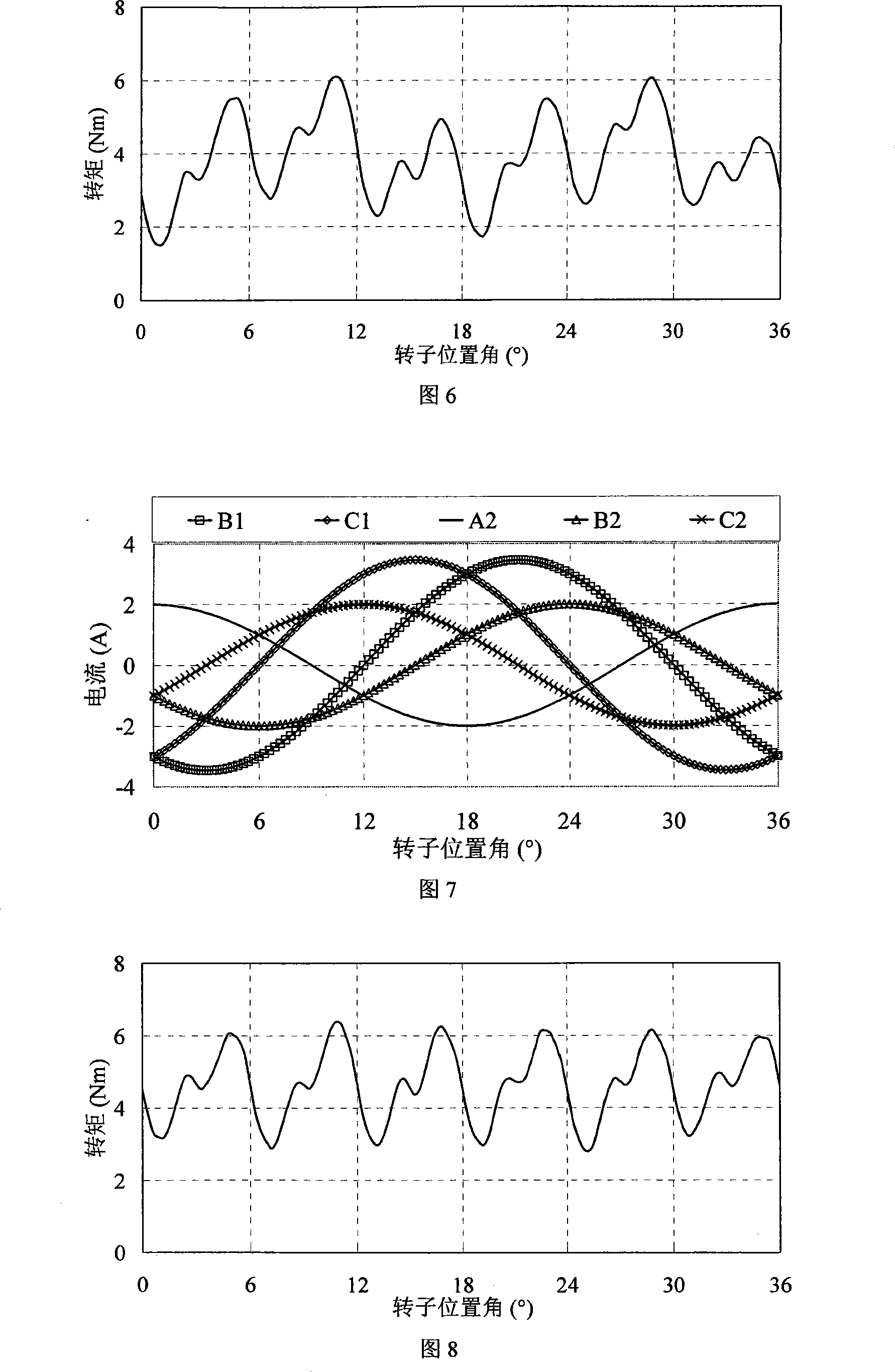

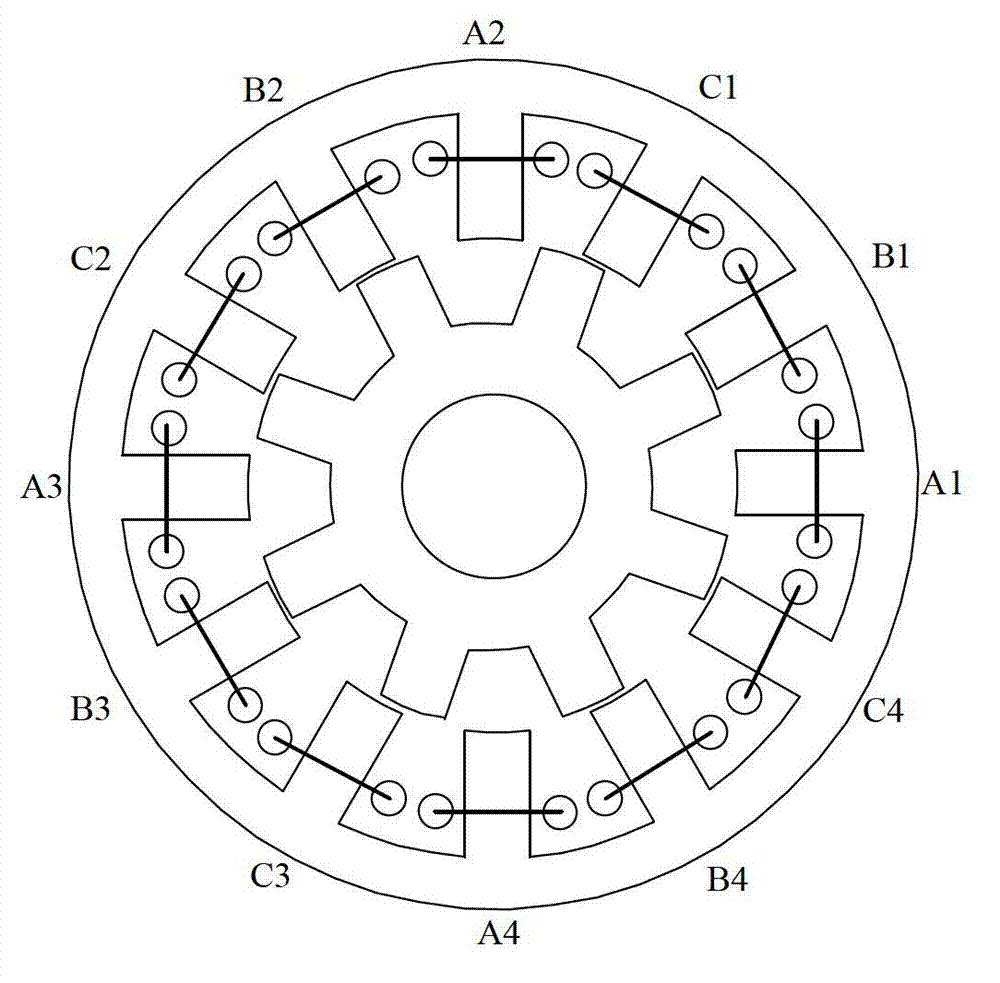

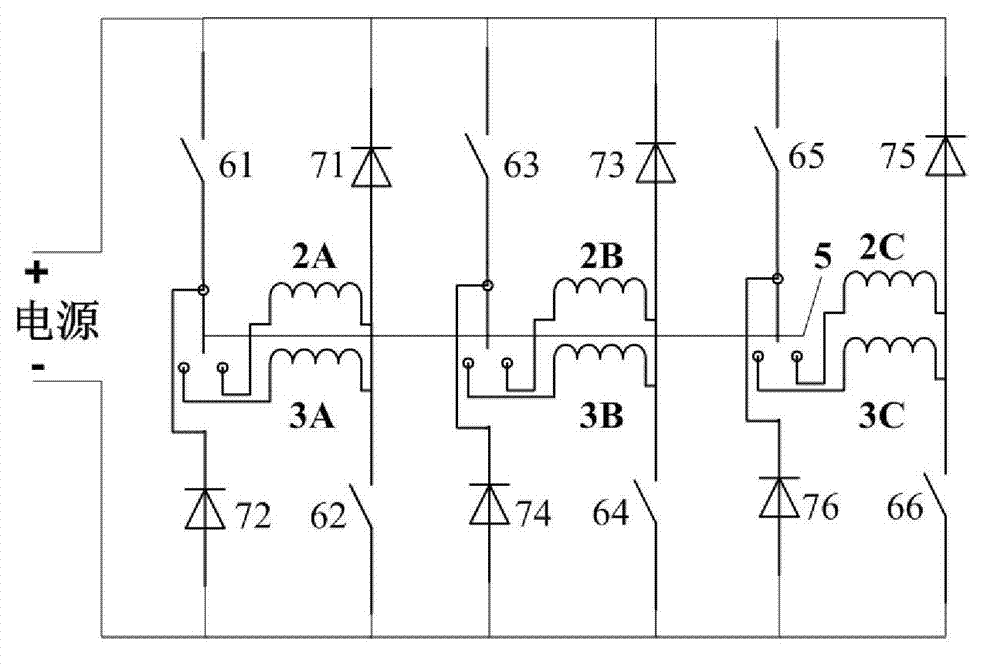

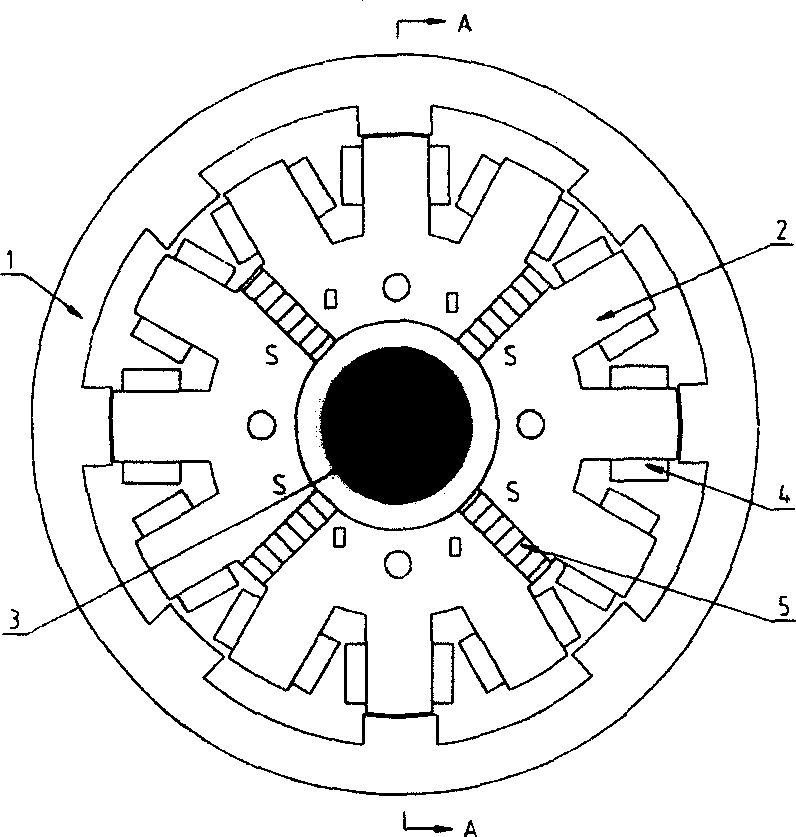

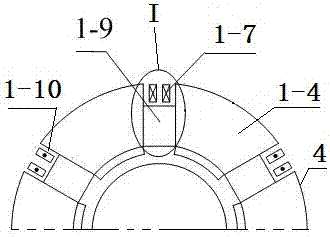

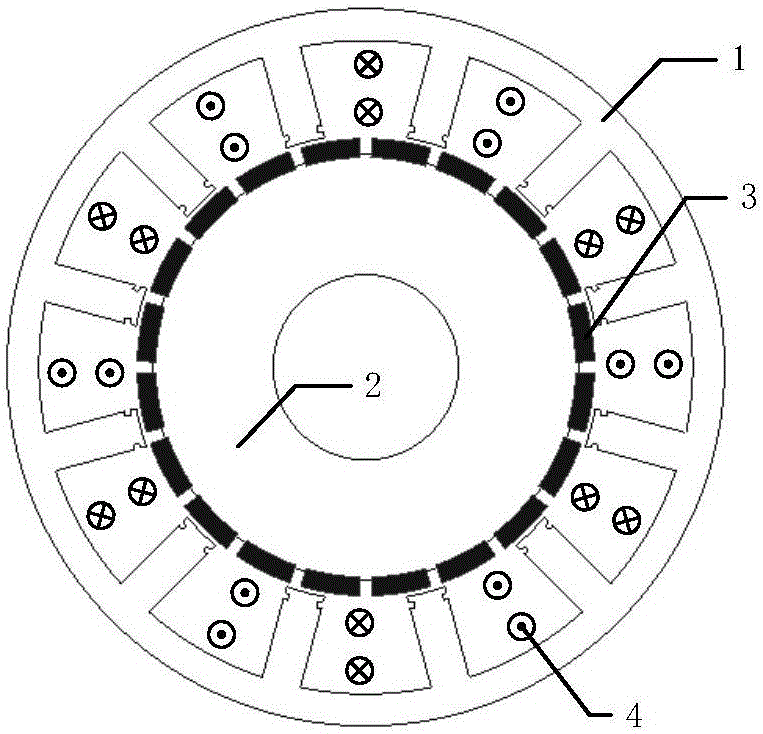

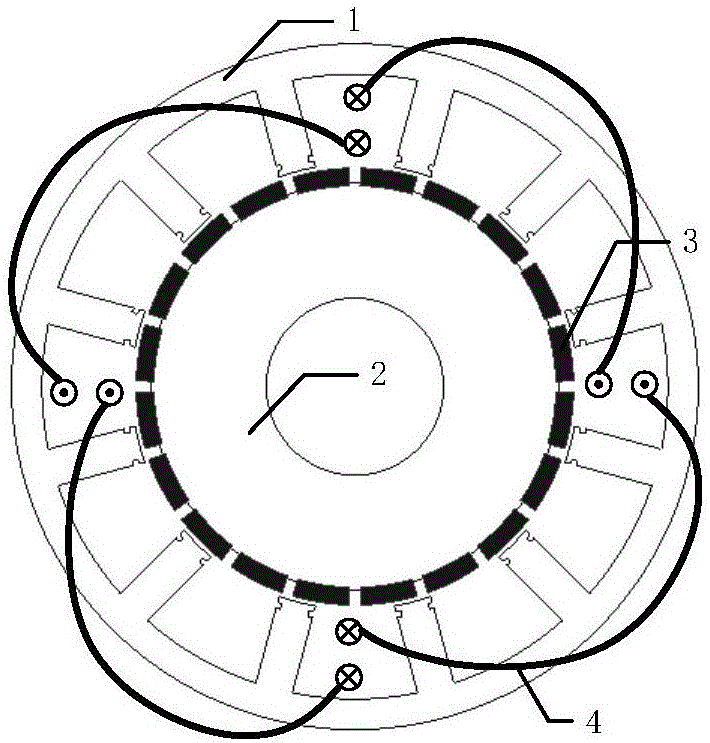

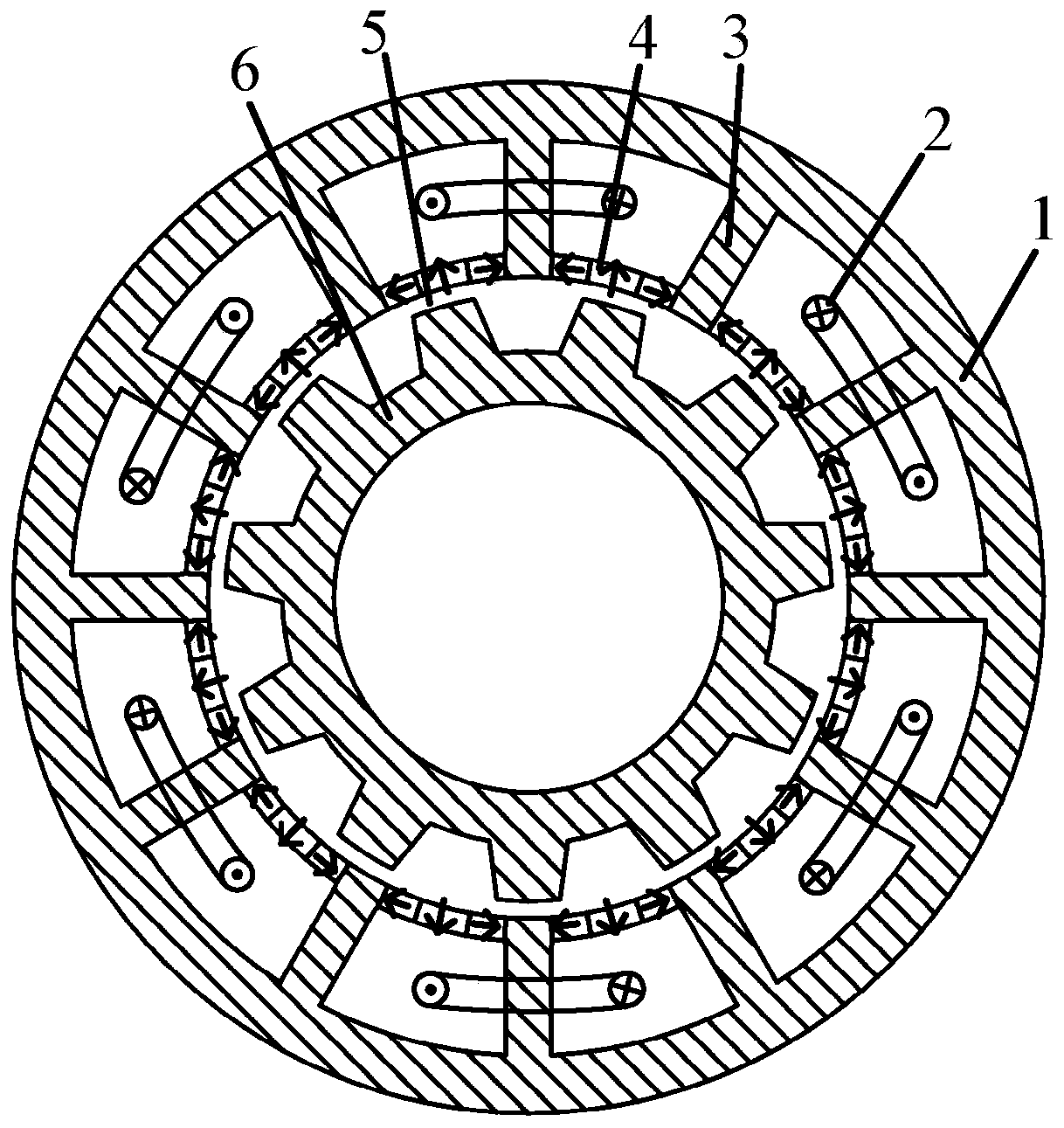

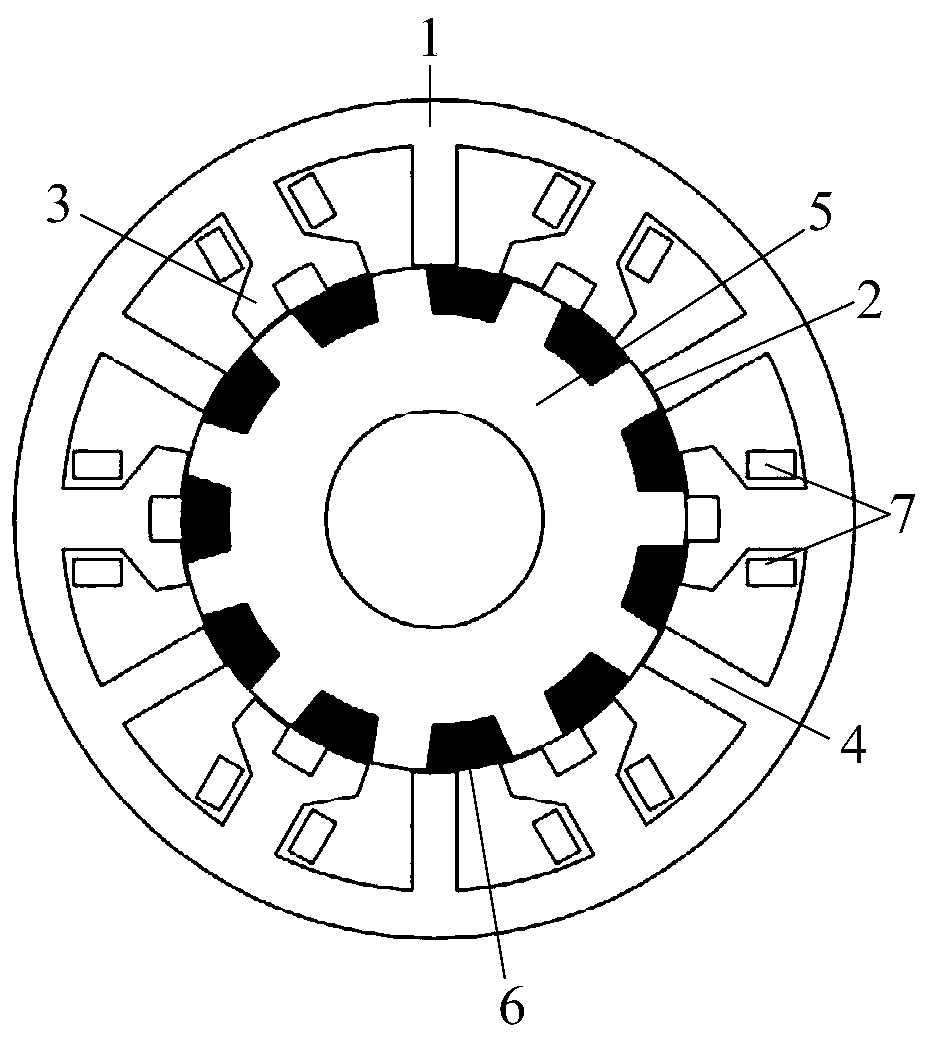

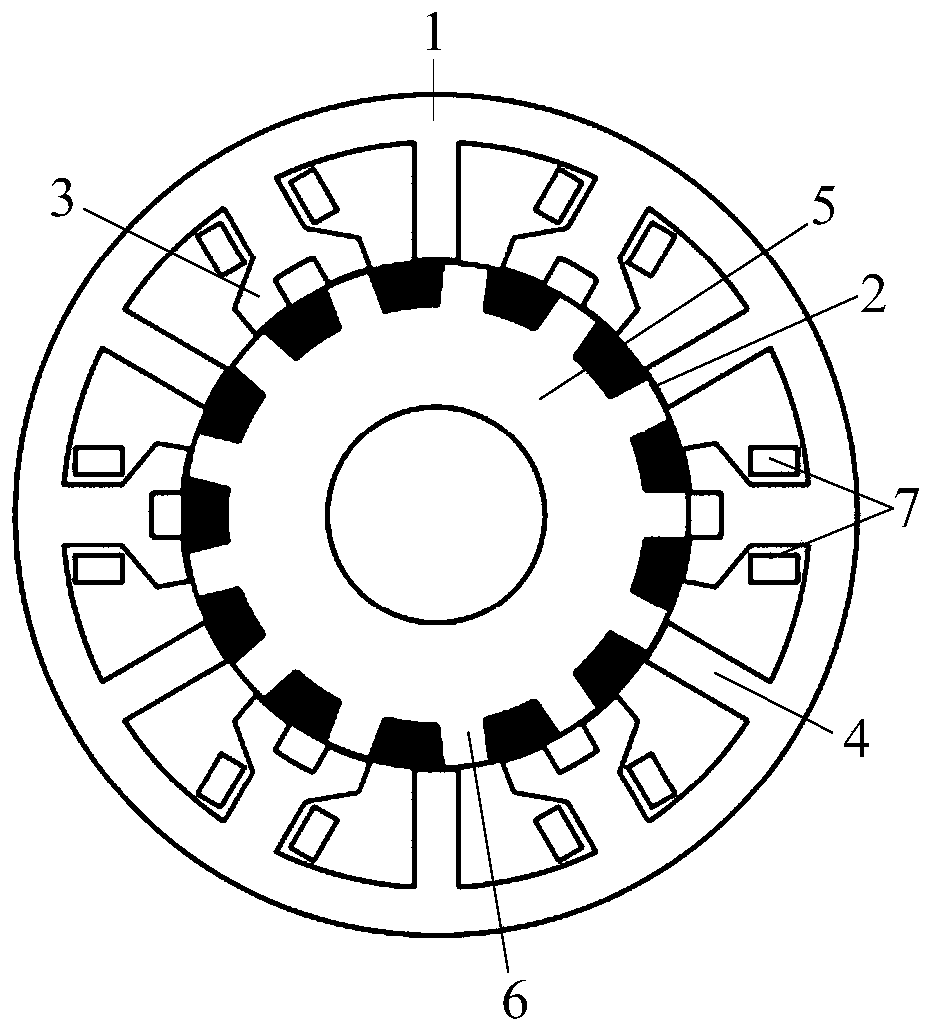

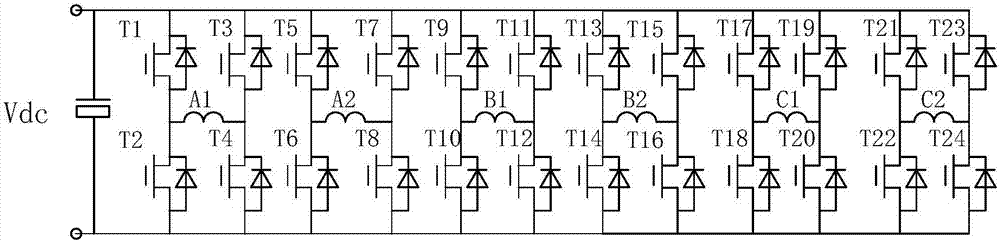

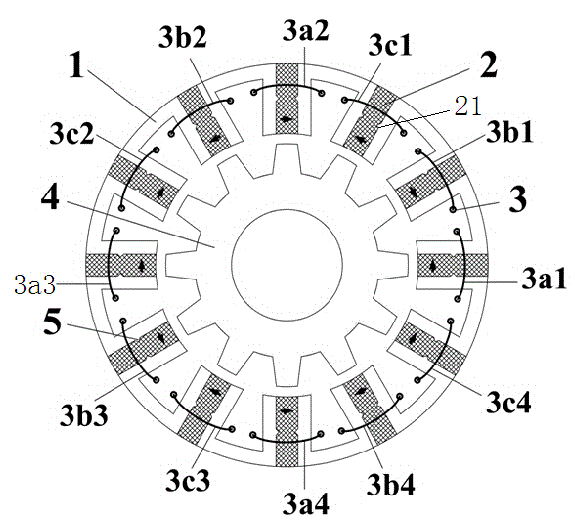

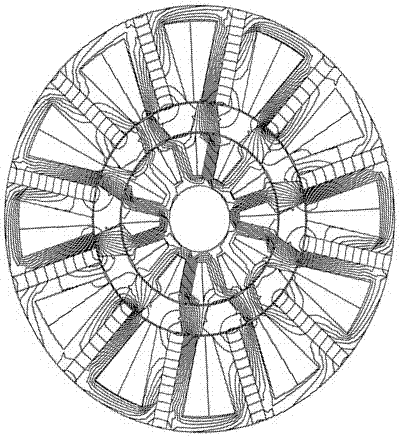

Double-channel fault tolerant type flux switch permanent magnet motor and control method thereof

InactiveCN101159391AImprove reliabilityImprove power densityTorque ripple controlMagnetic circuit rotating partsFault tolerancePhase currents

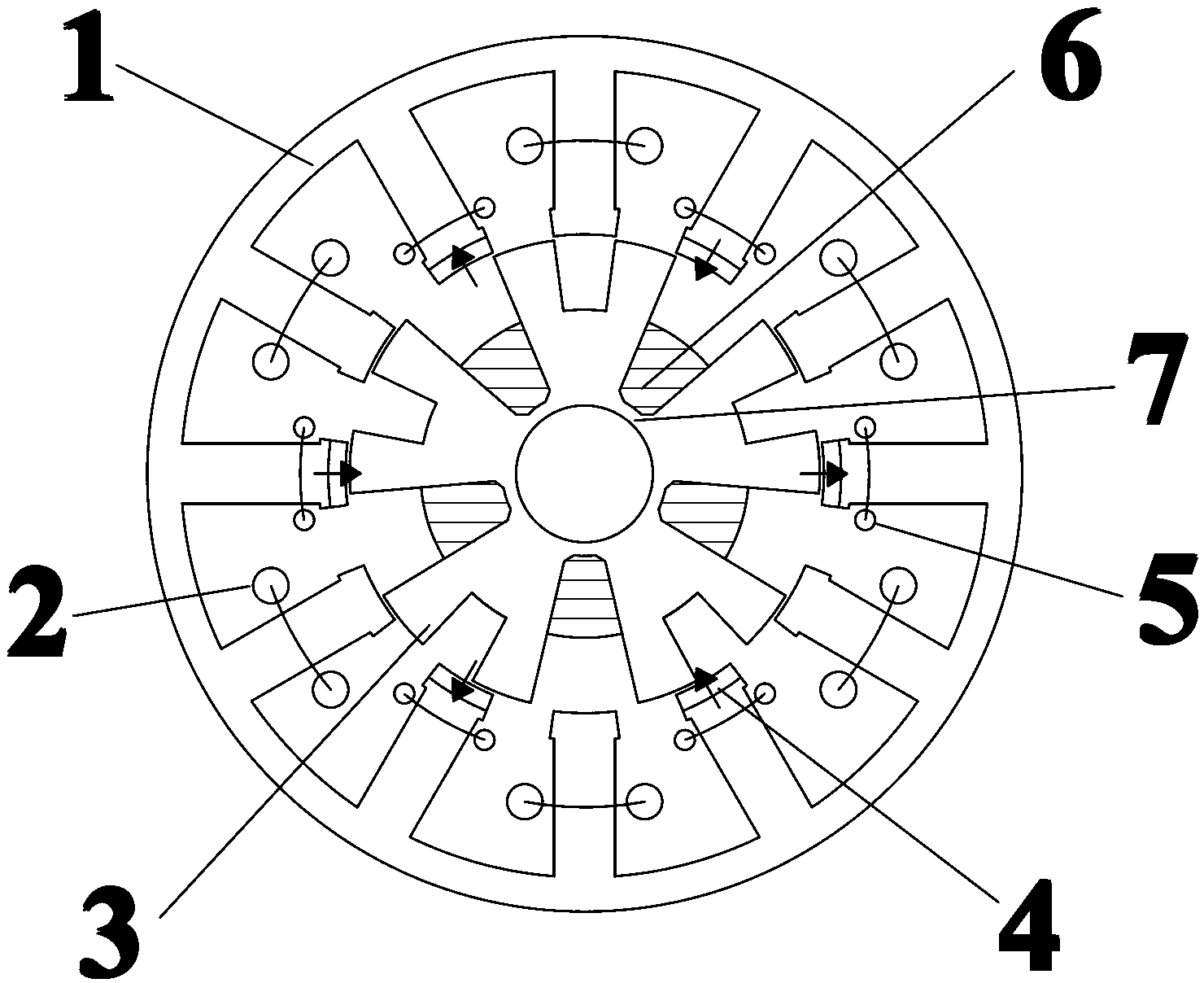

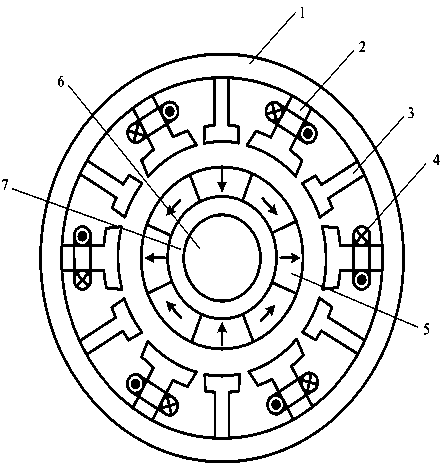

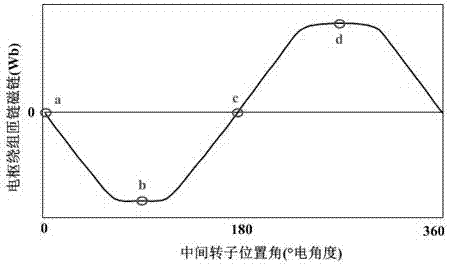

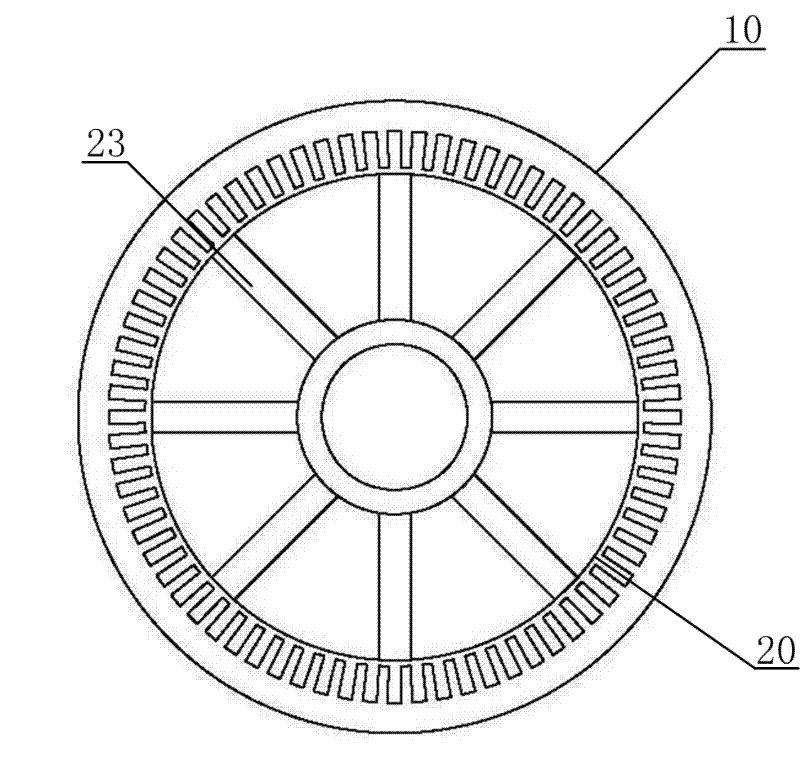

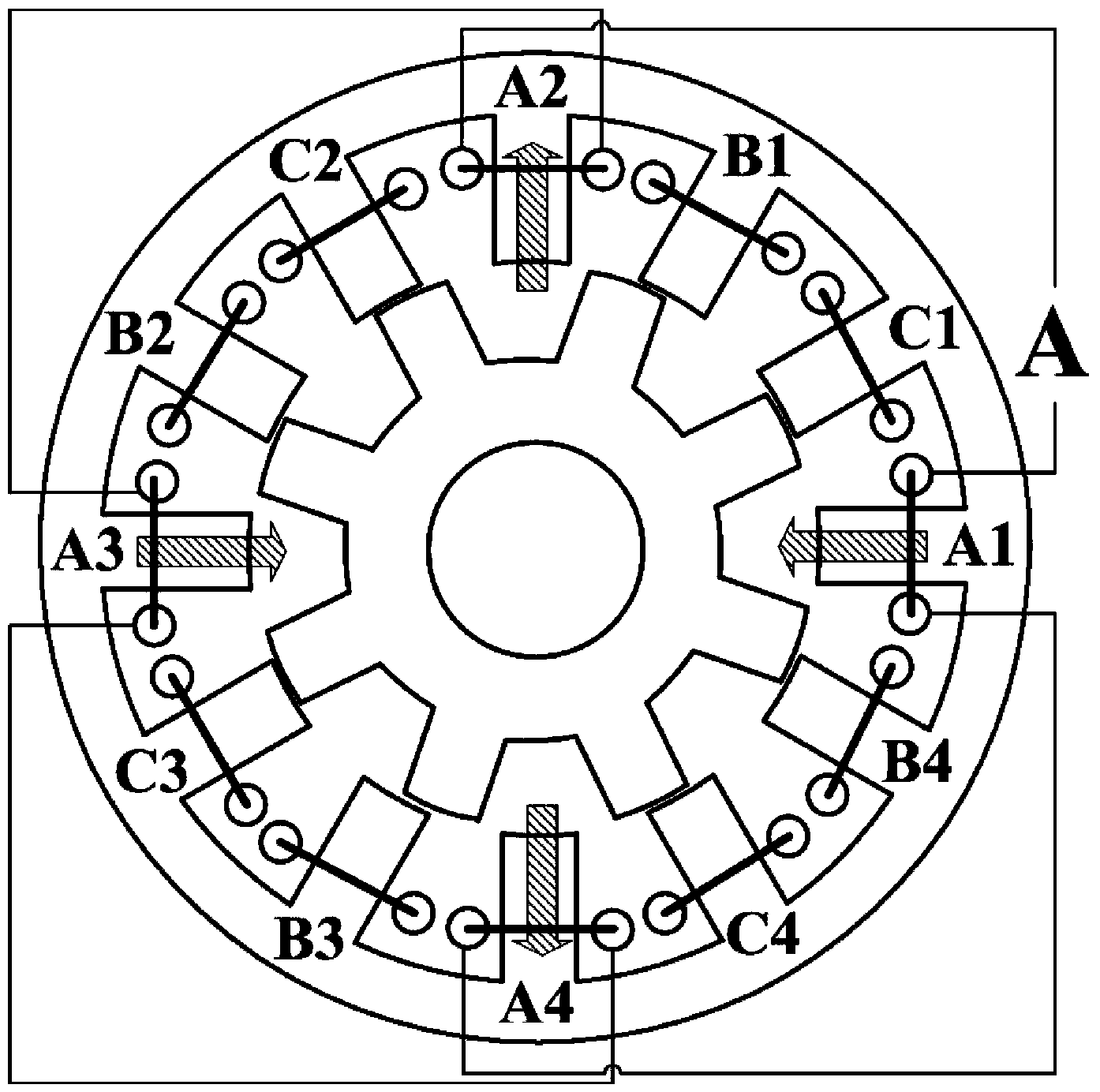

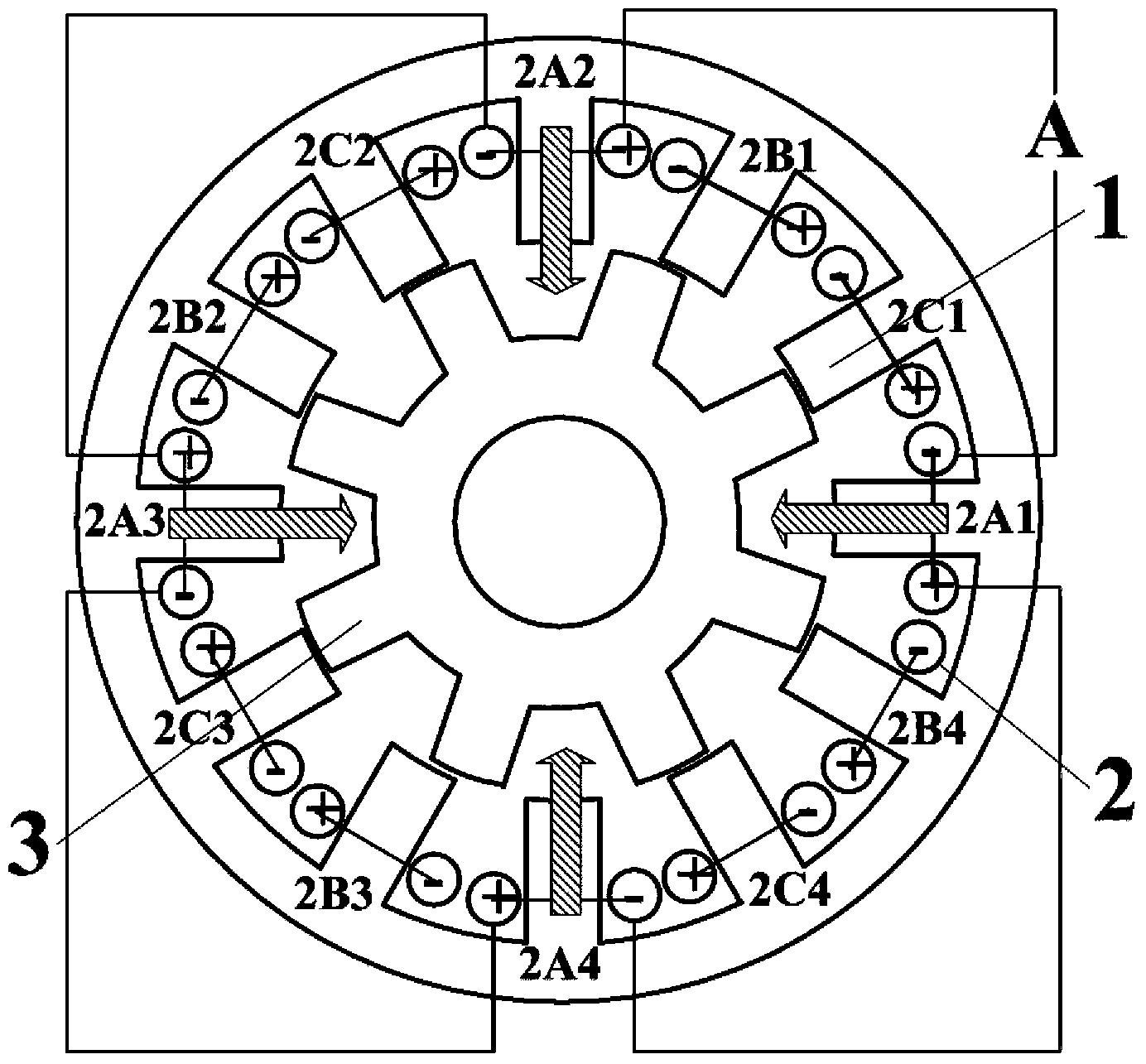

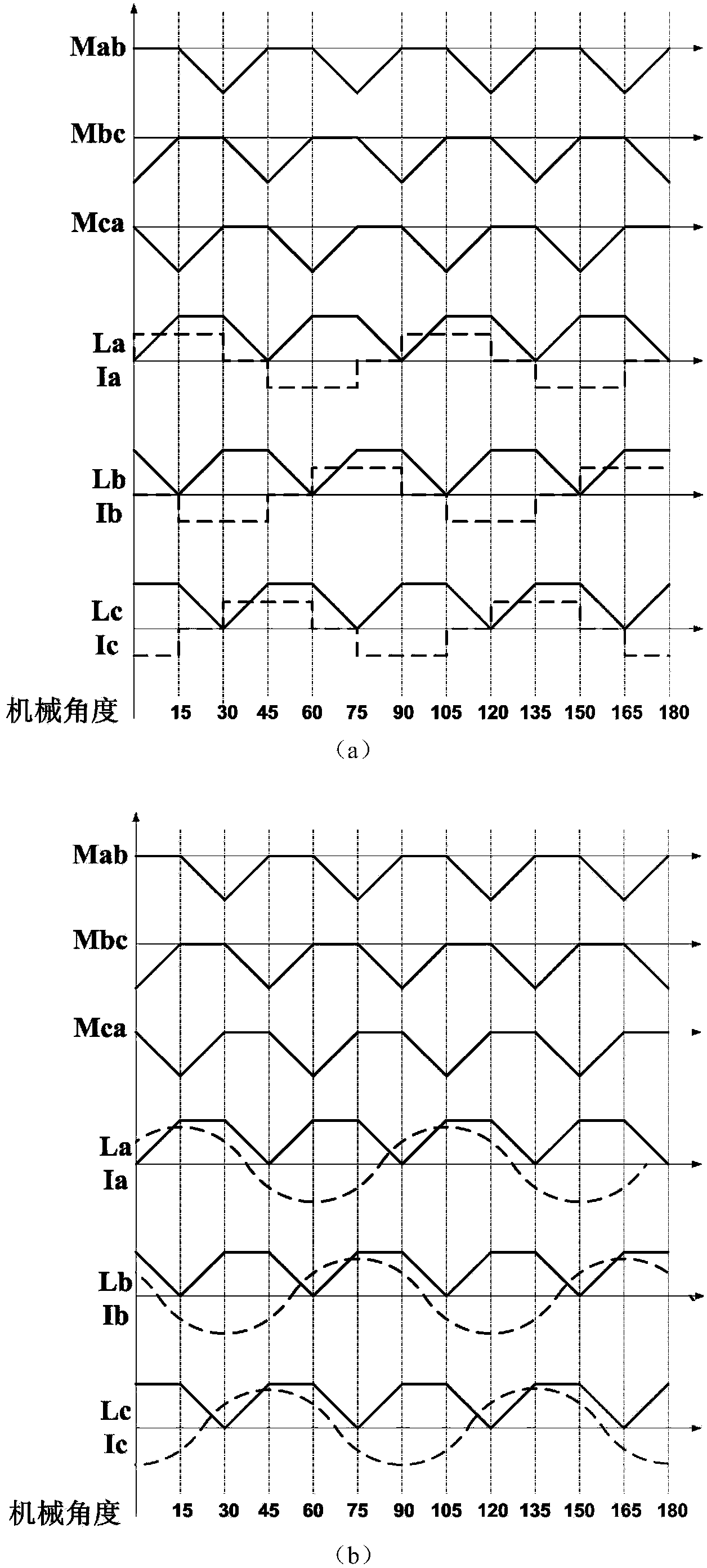

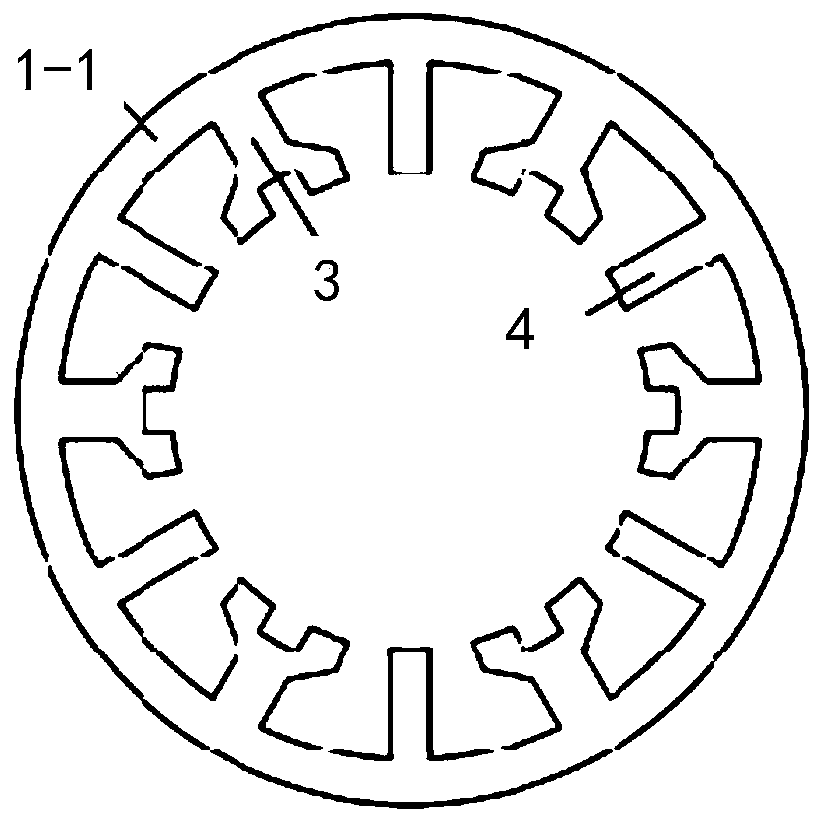

A dual-channel fault tolerant flux switch permanent magnet motor is a novel stator permanent magnet motor. The fault tolerant motor adopts a doubly salient structure, and the inner loop of the stator (1) is provided with salient poles evenly. Permanent magnets (3) are arranged onto the circle of the stator in pairs, which can be cooled easily; the rotor (2) adopts a simple salient structure, without windings nor permanent magnets. The fault tolerance motor integrates the advantages of a switch magnet resistance motor and a rotator permanent magnet fault tolerance motor, and has the advantages of high credibility, high power density, and preferable operating capacity when a failure occurs. The invention provides a fault tolerance strategy, and can improve the electromagnetic performance of the motor when a failure occurs by adjusting the phase and amplitude of non-fault phase current; the invention can accomplish the torque output in the approximately normal running status and have high theory and practical value.

Owner:SOUTHEAST UNIV

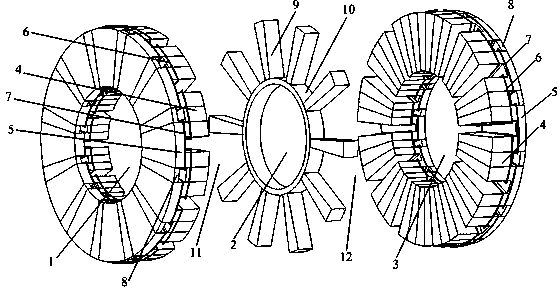

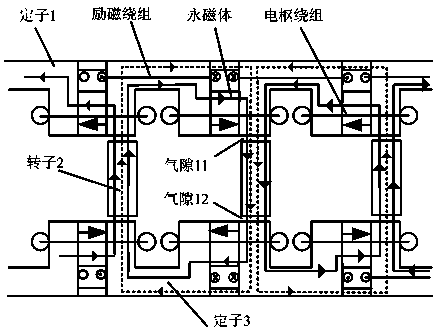

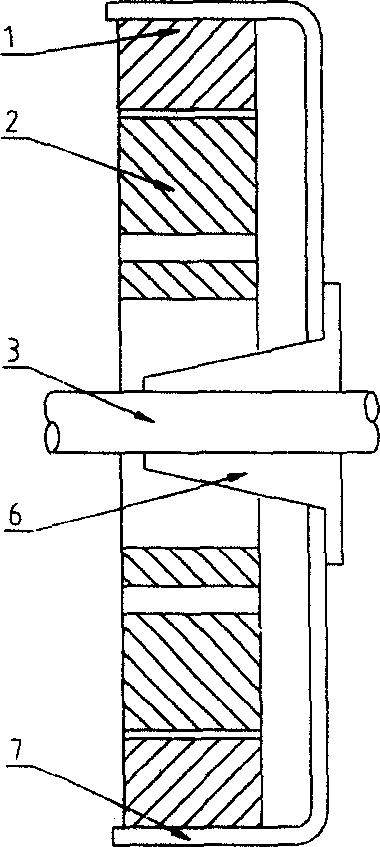

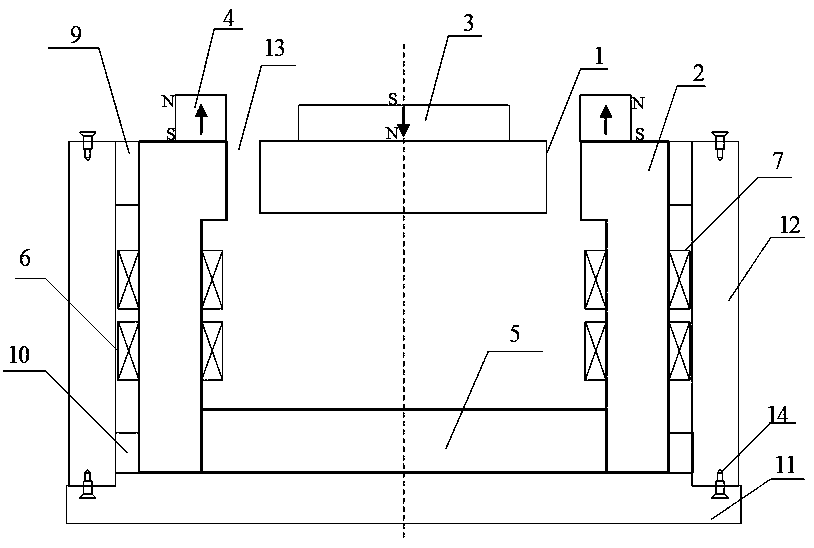

Double-stator disc type mixed excitation motor

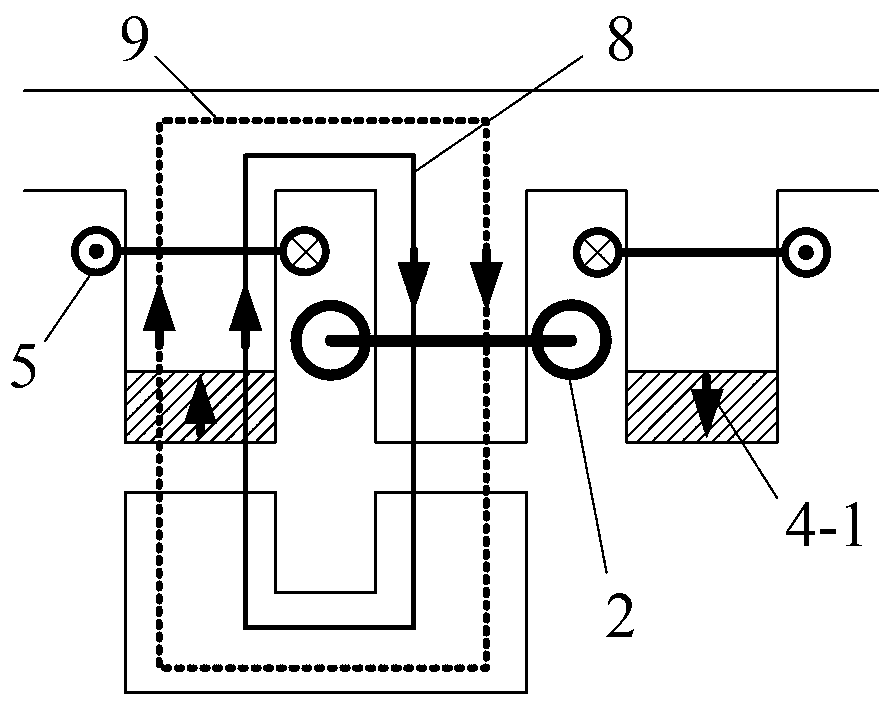

InactiveCN103390978ASimple structureAdjusting the air gap magnetic fieldElectric machinesMagnetic circuit stationary partsElectric machineExcitation current

The invention discloses a double-stator disc type mixed excitation motor which comprises two stators, a permanent magnet, a three-phase concentrated armature winding, a single-phase concentrated excitation winding and a rotor. The stators and the rotor are arranged coaxially, and the rotor is arranged between the two stators. The permanent magnet, the armature winding and the electric excitation winding are all located on the stators. The rotor is free of the permanent magnet or the windings and simple in structure. An air-gap magnetic field is formed by an electric excitation magnetic field generated by the electric excitation winding and a permanent magnetic field generated by the permanent magnet, and adjusting of the air-gap magnetic field is achieved by changing electric excitation current. The motor structurally reserves the characteristics of a disc type magnetic flux switching permanent magnetic motor of being compact, simple and suitable for high-speed operation, can achieve a mixed excitation function without increasing the motor size additionally and guarantees good torque output capacity and high power density. The motor is small in axial size and suitable for strict and thin type installing in places of a hub driving motor for electromobile and the like.

Owner:SOUTHEAST UNIV

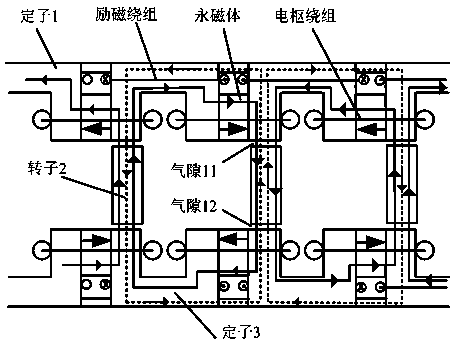

Electric vehicle hybrid excitation hub motor

ActiveCN105914981AAchieve integrationReduce volumeSynchronous machine detailsLow speedElectric machine

The invention provides an electric vehicle hybrid excitation hub motor which is composed of a shaft, a hub, rotor poles, stator poles, two sets of armature windings, stator iron cores, excitation windings, permanent magnets and a hub cap. The fan-shaped stator iron cores are fixed in the middle of the shaft in a back-to-back way. The two sides of the stator iron cores are provided with the protruding stator poles. The rotor poles are fixed on the internal walls of the two end surfaces of the hub. One permanent magnet is clamped between every two stator iron cores which are aligned in a circumferential direction. A groove is arranged between the two opposite stator iron cores and used for embedded arrangement of the excitation windings. Each stator pole is provided with the armature windings in a winding way. Integration of the hub and a driving motor is effectively realized by the technology so that the size and the weight of a driving system can be reduced; the rotor has no permanent magnet or excitation winding so that the possibility of demagnetization of the permanent magnets caused by impact can be reduced; a permanent magnetic field can be enhanced by an electric excitation magnetic field at low speed so that high-torque output can be realized; and the permanent magnetic field can also be weakened at high speed so that high-speed weak magnetic control can be realized.

Owner:SHANDONG UNIV OF TECH

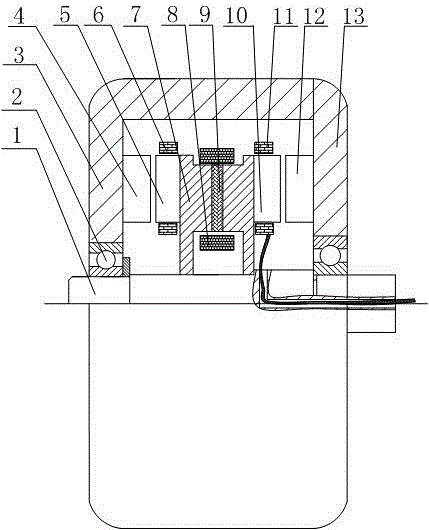

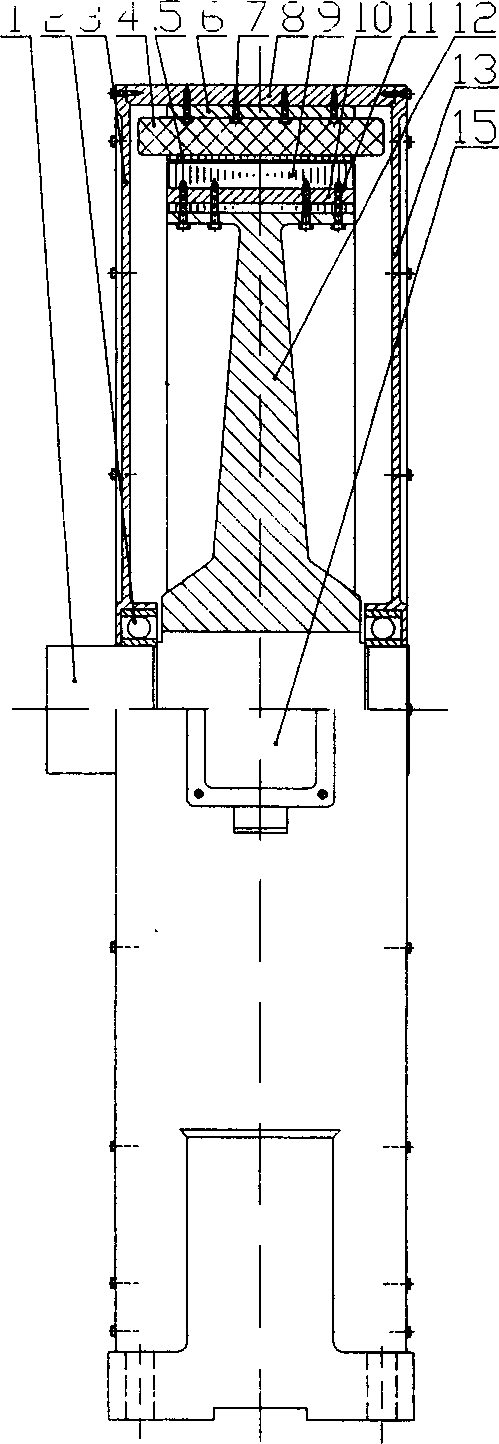

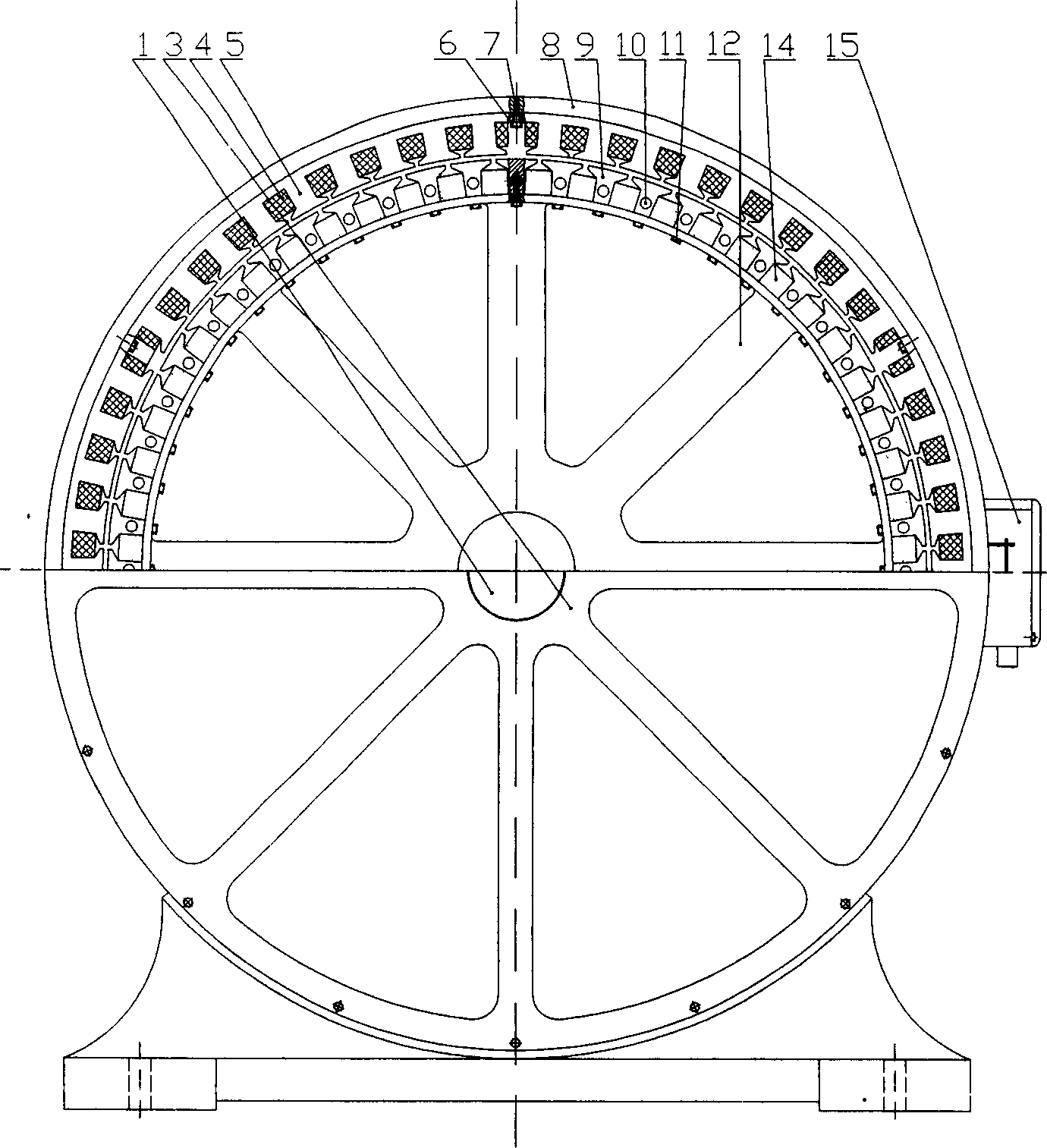

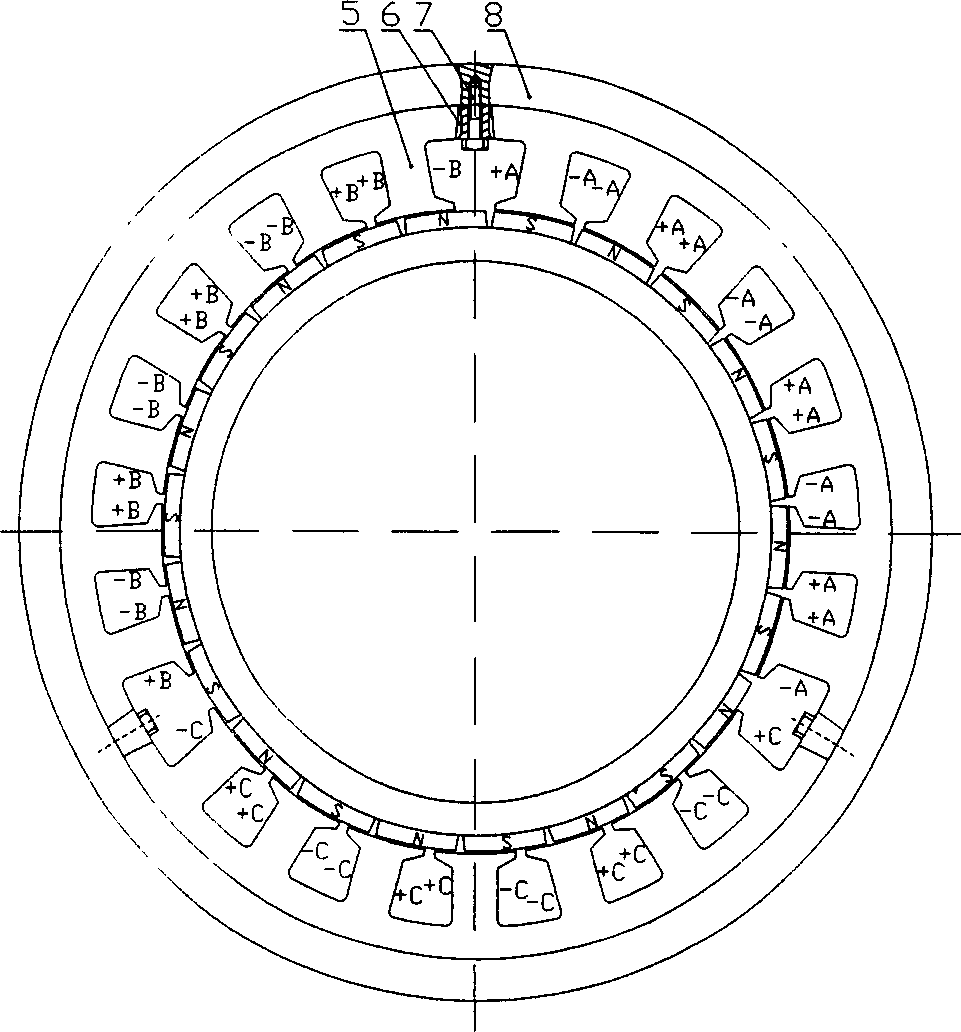

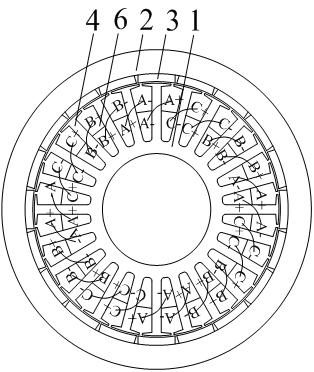

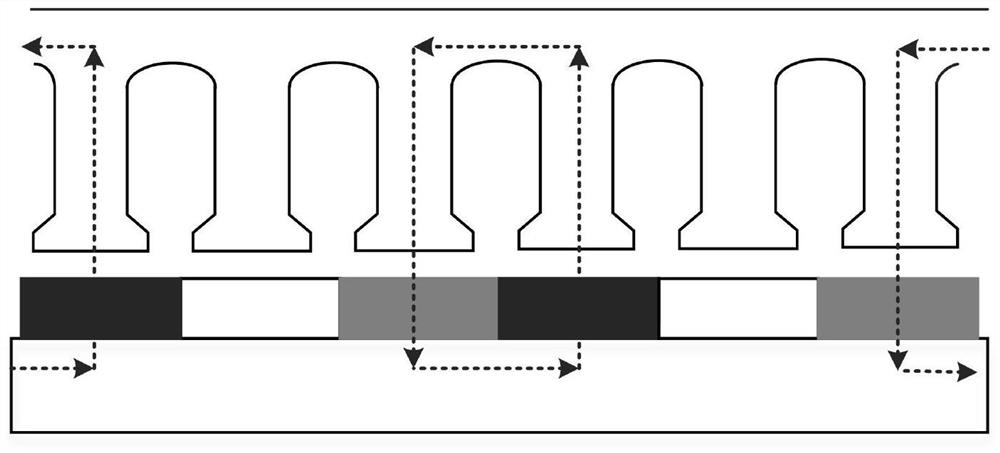

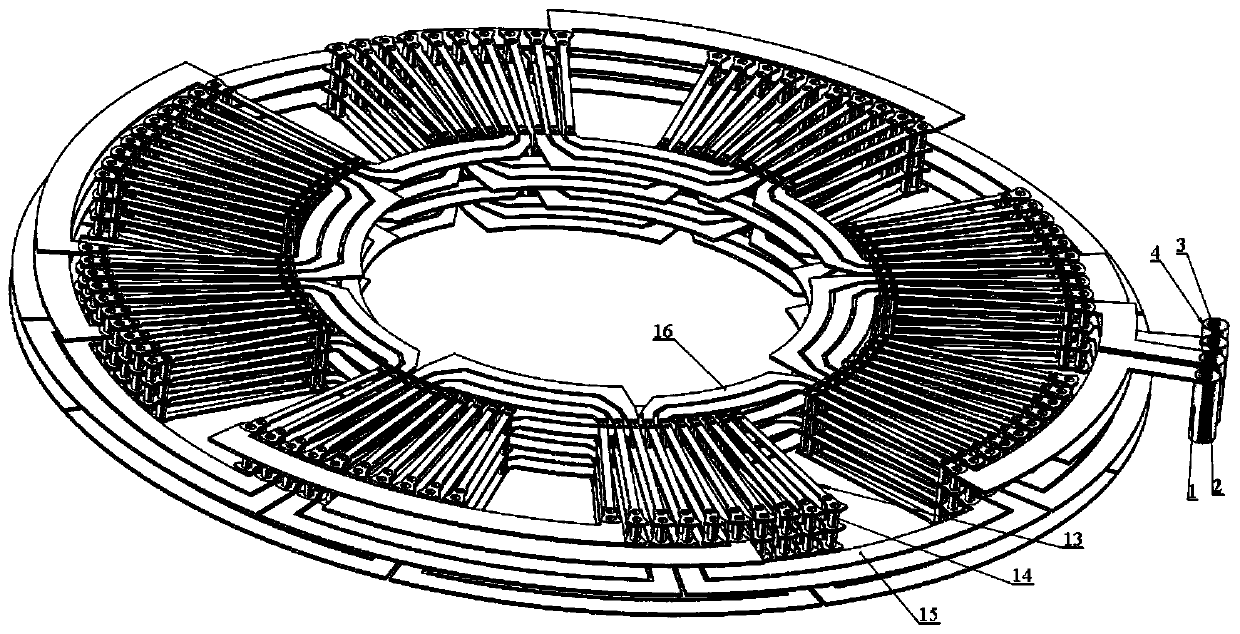

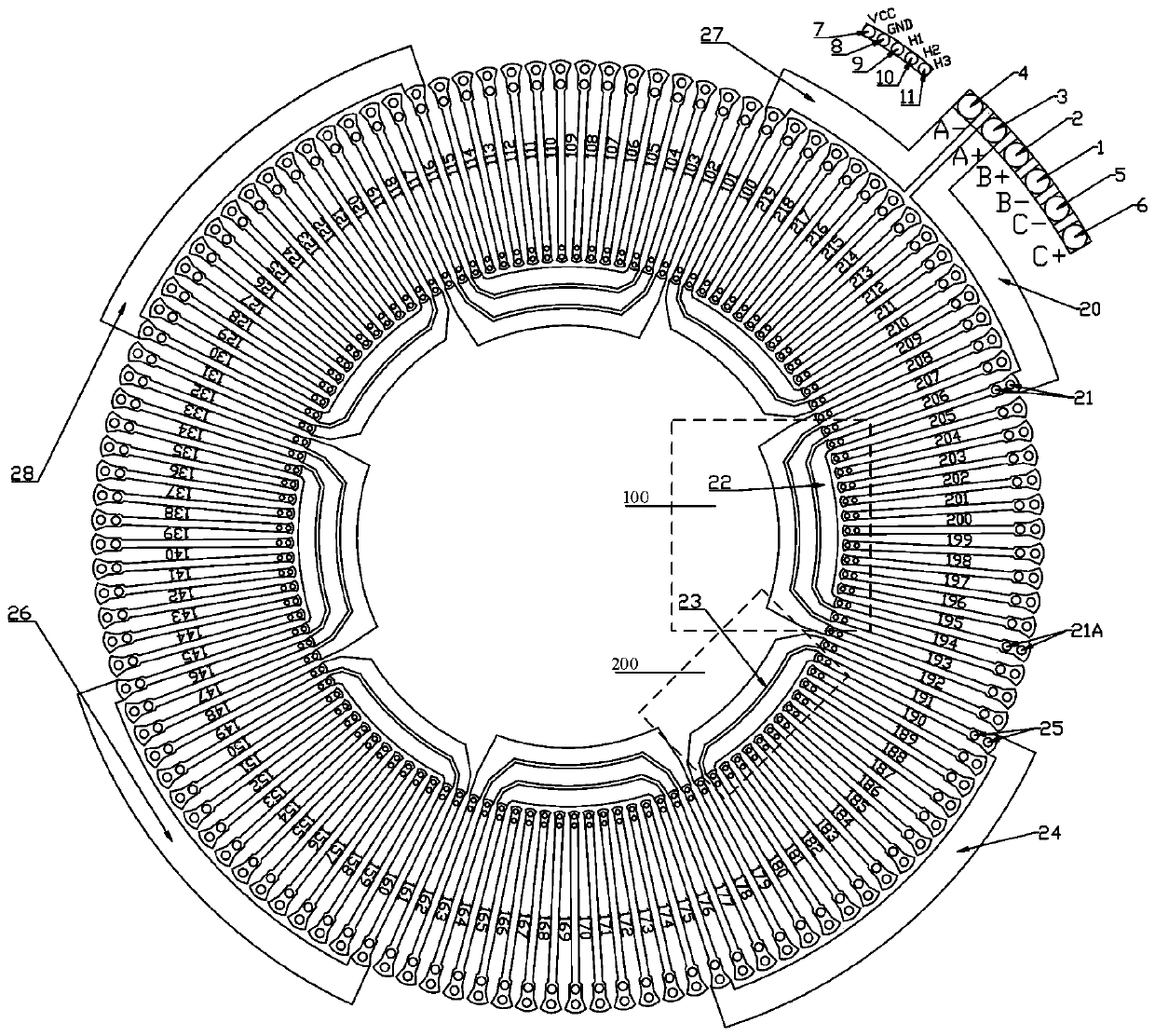

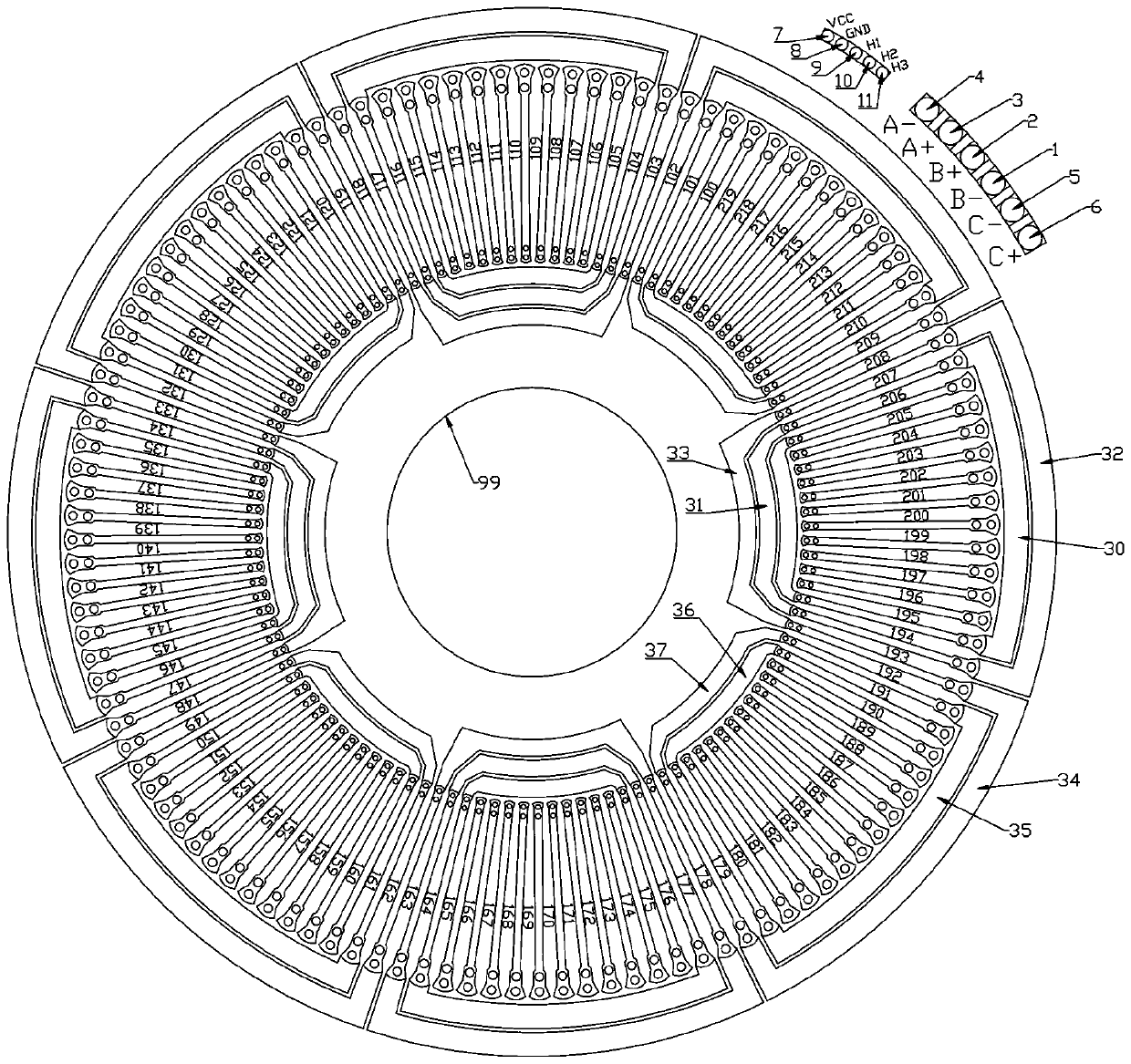

Sectional modular stator structural direct-driving permanent magnetic synchro wind generator

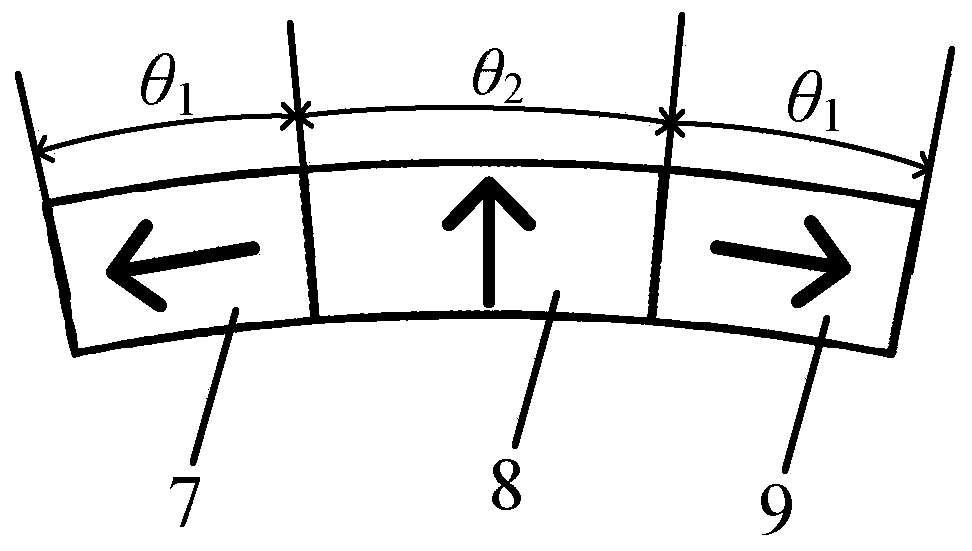

InactiveCN1889338AShort endsEasy mechanical continuous windingMagnetic circuit rotating partsSynchronous machine detailsWind forceWinding factor

This invention discloses a direct-drive low speed magnetic synchronous wind generator with a sectional module stator structure including a stator core set in sections, in which, the internal circle of the core is divided into k1 fan zone sets uniformly and three phases of A, B and C in each set are in three fan zones in same area, each zone belongs to one phase, K2 teeth are set on the stator core of a zone uniformly, a groove is opened between adjacent two teeth, the teeth distance of which is a pole distance, a holddown is set between the two adjacent stator cores and a full-pitched centralized coil is winded on each tooth of the stator cores, the winding coefficient of the motor is 1, the end of the stator winding is short and easy to be winded mechanically and continuously, the core sections are independent to each other on the base and easy to be exchanged.

Owner:TIANJIN UNIV

Five-phase permanent magnet fault-tolerant motor with magnetic congregating effect for electric vehicle

InactiveCN102130559AEffective combinationImprove reliabilityMagnetic circuit rotating partsElectric machinesElectric machineElectric vehicle

The invention discloses a five-phase permanent magnet fault-tolerant motor with a magnetic congregating effect for an electric vehicle. An outer rotor is arranged on a stator outer ring, armature teeth and fault-tolerant teeth are uniformly distributed at intervals along the circumferential direction of the stator outer ring, permanent magnets are uniformly and radially embedded in the direction of the circumference in the outer rotor, a single-layer concentrated winding is wound on the armature teeth, radially opposite dipolar single-layer concentrated windings are serially connected to form one phase; total tooth quantity of the armature teeth and the fault-tolerant teeth is a multiple of 10 and is not equal to the quantity of permanent magnets, and the difference of the total tooth quantity of the armature teeth and the fault-tolerant teeth does not exceed + / -4; rotor grooves with same quantity as the permanent magnets are arranged on the outer rotor and positioned between each of the permanent magnets and the stator; and the width of the armature teeth is two times of that of the fault-tolerant teeth. The flux leakage of the permanent magnets is reduced while a magnetic-gathering effect is generated, the consumption of the permanent magnets is reduced, the motor cost is saved, the motor weight is reduced, and the reliability and the failure operation capacity of the motor is improved.

Owner:JIANGSU UNIV

Mixed excitation stator surface-mounted double-salient motor

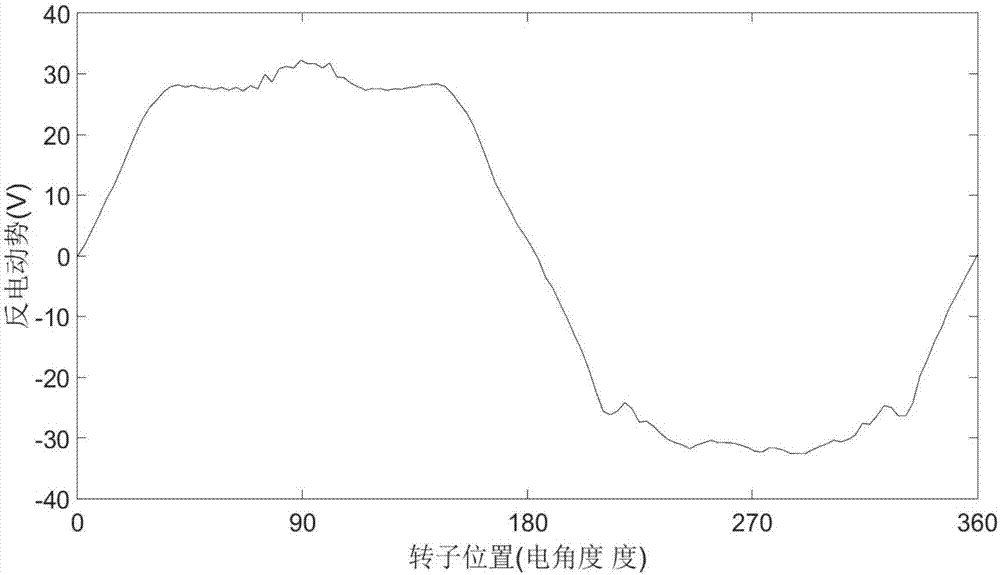

InactiveCN103248148ASinusoidal back emfImprove cooling conditionsMagnetic circuit rotating partsMagnetic circuit stationary partsConstant powerPermanent magnet motor

The invention relates to a mixed excitation stator surface-mounted double-salient motor adopting a modularized rotor, which is characterized in that a stator part adopts a centralized armature winding and a centralized excitation winding, stator teeth are divided into two groups, i.e. a group of stator teeth with permanent magnets and a group of stator teeth being sleeved with armature winding coils, and the armature teeth and the permanent magnetic teeth are alternately distributed. The permanent magnets which are alternately magnetized in the radial direction are respectively mounted on the surface, facing a rotor, of the stator permanent magnetic tooth. Each coil of the armature winding is respectively sleeved on one stator armature tooth, and each coil of the centralized excitation winding is respectively sleeved on one stator permanent magnetic tooth. The structural advantages of the stator surface-mounted double-salient permanent magnet motor such as compact structure and easiness in heat radiation are maintained, a mixed excitation function can be realized without additionally increasing the size of the motor, the strong torque output capacity and high power density of the motor can be guaranteed, the motor is particularly suitable for the application occasion requiring small size and large output torque, and the large torque of a constant-torque area and a wide speed regulation function of a constant-power area can be realized.

Owner:SOUTHEAST UNIV

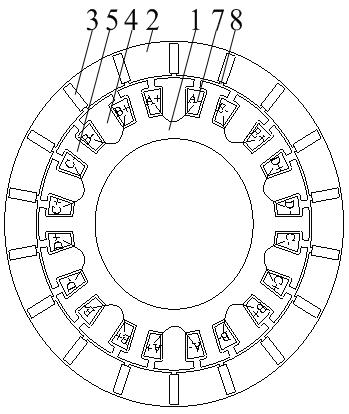

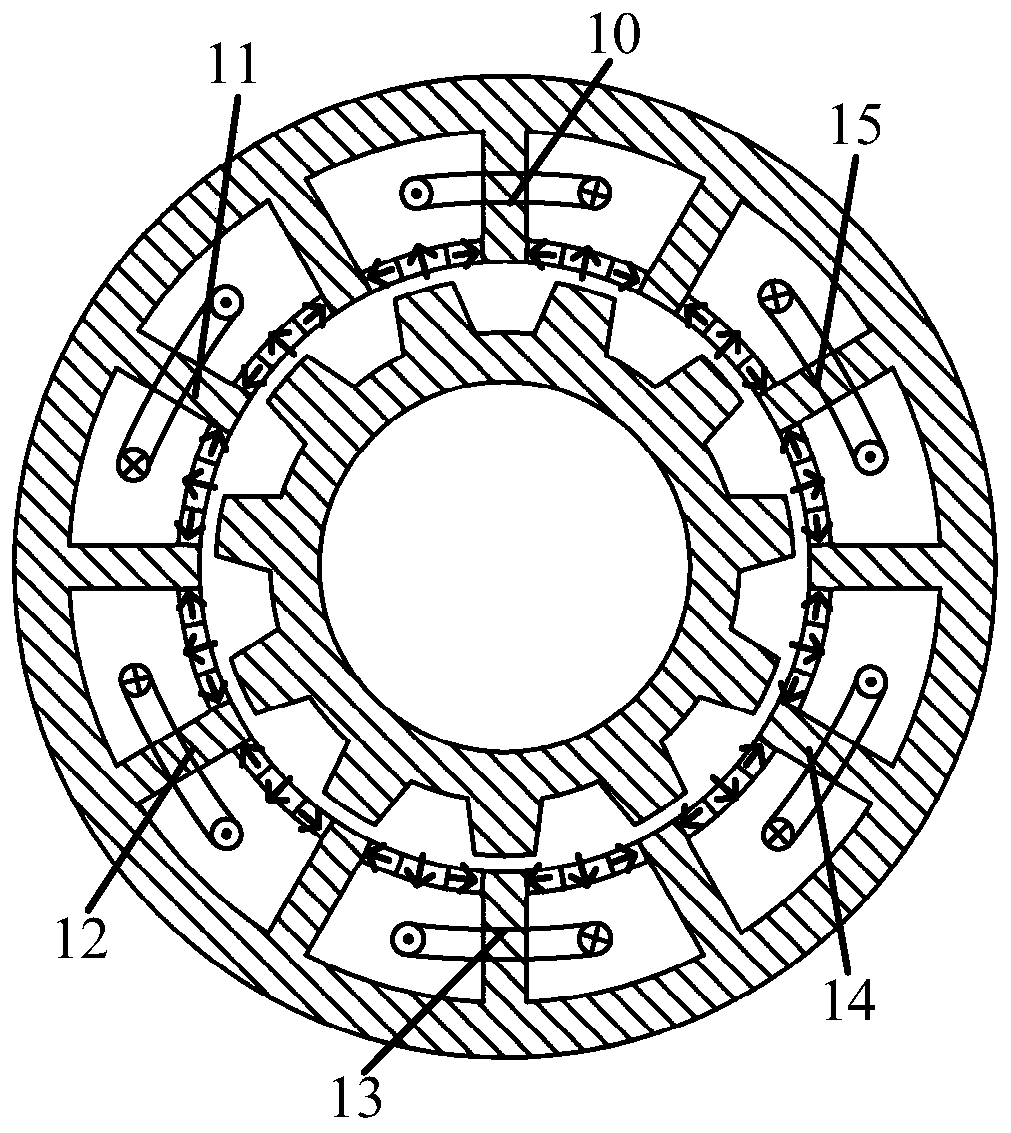

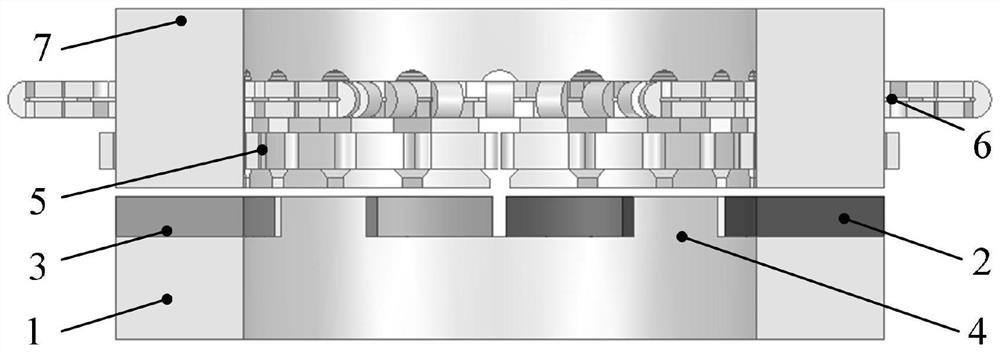

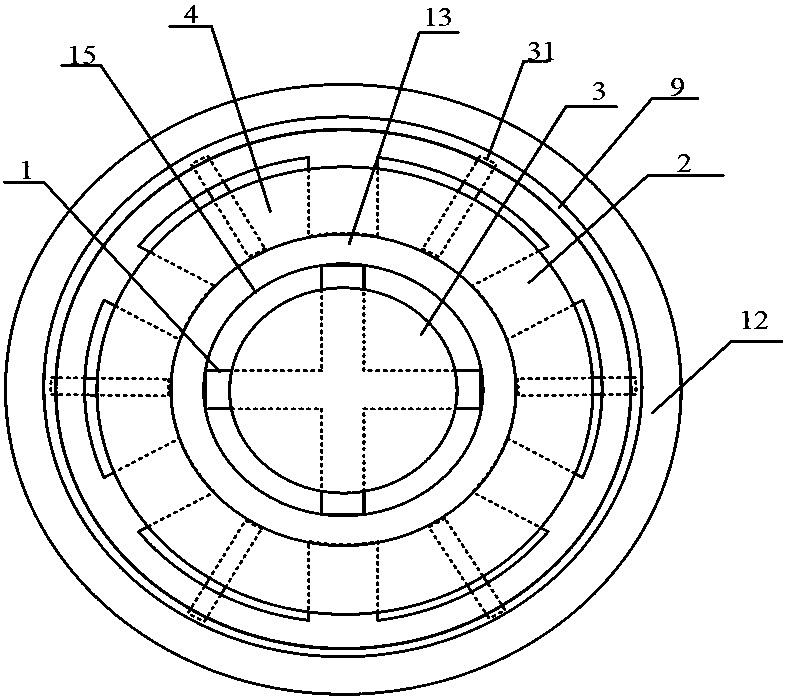

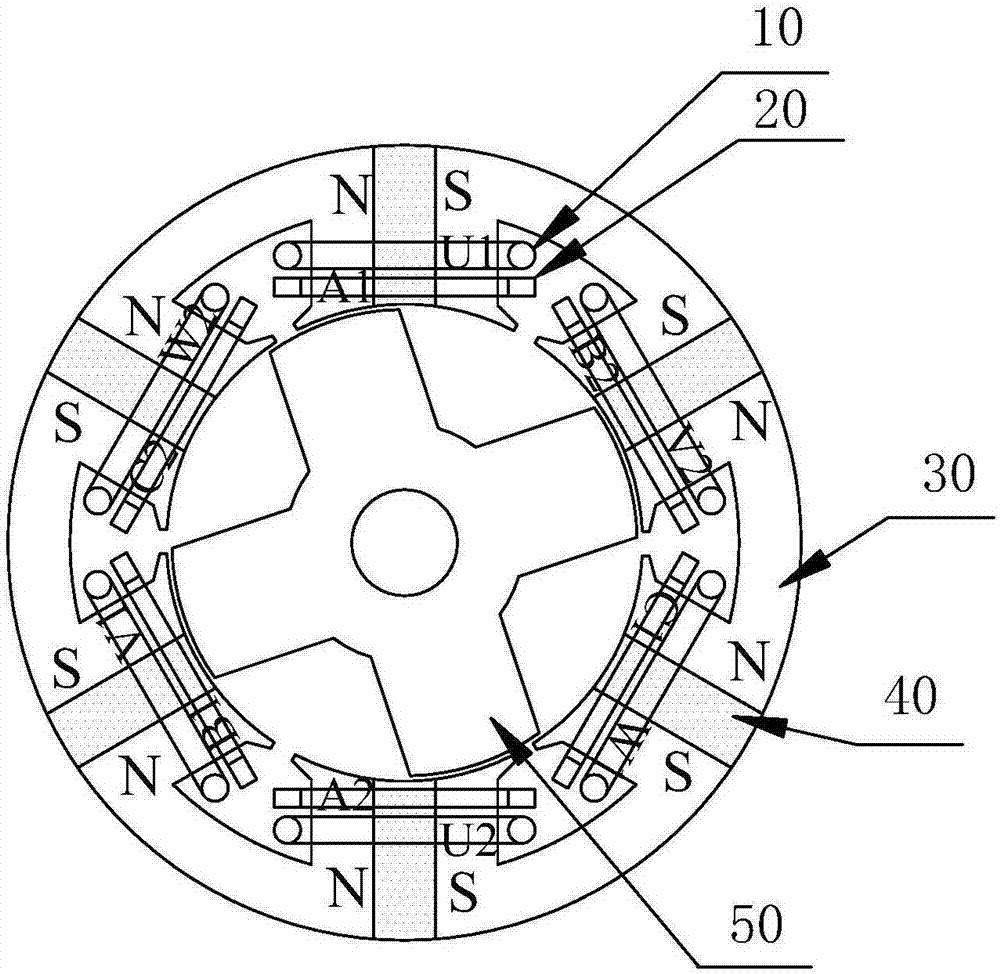

Hybrid excitation flux switching motor

ActiveCN105553128AImprove power densityIncrease electromagnetic loadMagnetic circuit stationary partsWindings conductor shape/form/constructionThree-phaseAlternating current

The invention discloses a hybrid excitation flux switching motor. The motor comprises an outer stator, a rotor and an inner stator. The rotor coaxially sheaths outside the inner stator. The outer stator coaxially sheaths outside the rotor. The outer stator comprises an outer stator iron core, permanent magnets and a three-phase armature winding. A three-phase alternating current excitation winding sheaths on convex pole teeth of an inner stator iron core. The quantity of the convex pole teeth of the inner stator iron core is equal to the quantity of the permanent magnets. The radial central axes of the convex pole teeth of the inner stator iron core and the radial central axes of the permanent magnets coincide. In the prior art, the excitation winding is placed by reducing the volume of the permanent magnet or reducing the number of turns of the armature winding. Through adoption of the hybrid excitation flux switching motor, the problem in the prior art is solved, the electromagnetic load of the motor is increased, a symmetrical three-phase alternating current with adjustable amplitude accessed to the inner stator excitation winding can generate a rotating magnetic field with adjustable amplitude and polarity, and the rotating magnetic field and an effective air gap magnetic field in a permanent magnetic field are overlaid, so that effective harmonic component in the permanent magnetic field is enhanced or weakened, so as to realize magnetic shunt operation.

Owner:JIANGSU UNIV

Double-speed winding switch reluctance motor

ActiveCN103166337AWide speed rangeReduce the number of turnsMagnetic circuit stationary partsWindings conductor shape/form/constructionLow speedEngineering

Owner:SOUTHEAST UNIV

Fault-tolerant type single-winding bearing-less permanent magnet motor

InactiveCN103929035ACompact structureShort endsMagnetic holding devicesSynchronous machines with stationary armatures and rotating magnetsShortest distancePermanent magnet motor

The invention discloses a fault-tolerant type single-winding bearing-less permanent magnet motor. A stator magnet yoke is in a cylinder shape and is placed on the outermost portion of the permanent magnet motor. A rotating shaft and the stator magnet yoke are coaxial, the rotating shaft is placed in the middle in the stator magnet yoke, a rotor iron core coaxial with the rotating shaft is fixed on the outer periphery surface of the rotating shaft, and a plurality of permanent magnets which are evenly distributed on the outer surface of the rotor iron core in a Halbach array structure to form a cylinder shape are fixed on the outer periphery surface of the rotating shaft. Six armature teeth and six fault-tolerant teeth which are arranged in an alternating mode in the periphery direction are fixed evenly on the inner periphery face of the stator magnet yoke. Each armature tooth is provided with a set of an armature winding which generates torque and radial suspension force at the same time in a winding mode. Each set of armature winding is of a concentrating short-distance winding structure. Each phase control current is formed by overlapping of a torque winding control current component and a suspension force winding control current component. According to the fault-tolerant type single-winding bearing-less permanent magnet motor, only one set of armature winding is needed, the structure is simple, motor weight is lowered, and the suspension operation capacity with fault of the motor is improved.

Owner:JIANGSU UNIV

Less-rare-earth multi-excitation-source double-stator flux-switching memory motor

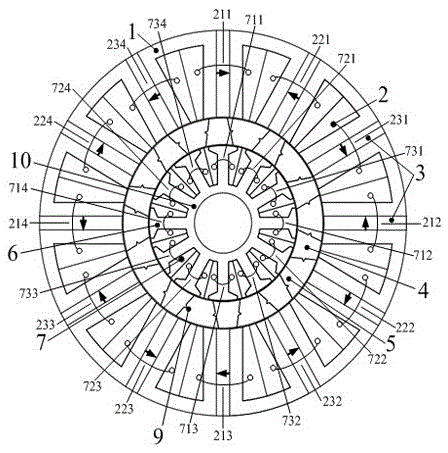

InactiveCN106911237AAchieve separationSolve mutual problemsMagnetic circuit rotating partsMagnetic circuit stationary partsRare earthEngineering

The invention discloses a less-rare-earth multi-excitation-source double-stator flux-switching memory motor, which belongs to the technical field of motor body design and operating principles. Coaxial outer stators, rotors and inner stators are sleeved together in turns from outside to inside to compose the memory motor, wherein a radial air gap exists between the outer stators and the rotors, the rotors and the inner stators, the outer stators are composed of armature core teeth, fault-tolerant teeth and stator yokes, and the rotors are composed of a rotor support, a magnetic silicon steel block and a magnetic insulation block, and meanwhile, the inner stators are composed of the inner stator core and a combined permanent-magnet cell block. The double-stator structure of the motor realizes the separation of armature winding and permanent magnet and solves the problem that multiple excitation sources inside the traditional flux-switching permanent magnet motors restrain each other, thereby easily increasing motor power density and torque density. The memory motor maintains high air-gap flux density and ensures of the motor power density and the torque density, meanwhile, the consumption of rare-earth permanent-magnetic materials is effectively lowered. On the other side, the memory motor can realize flexible adjustment of a motor air-gap field and expand the range of speed operation.

Owner:YANGZHOU UNIV

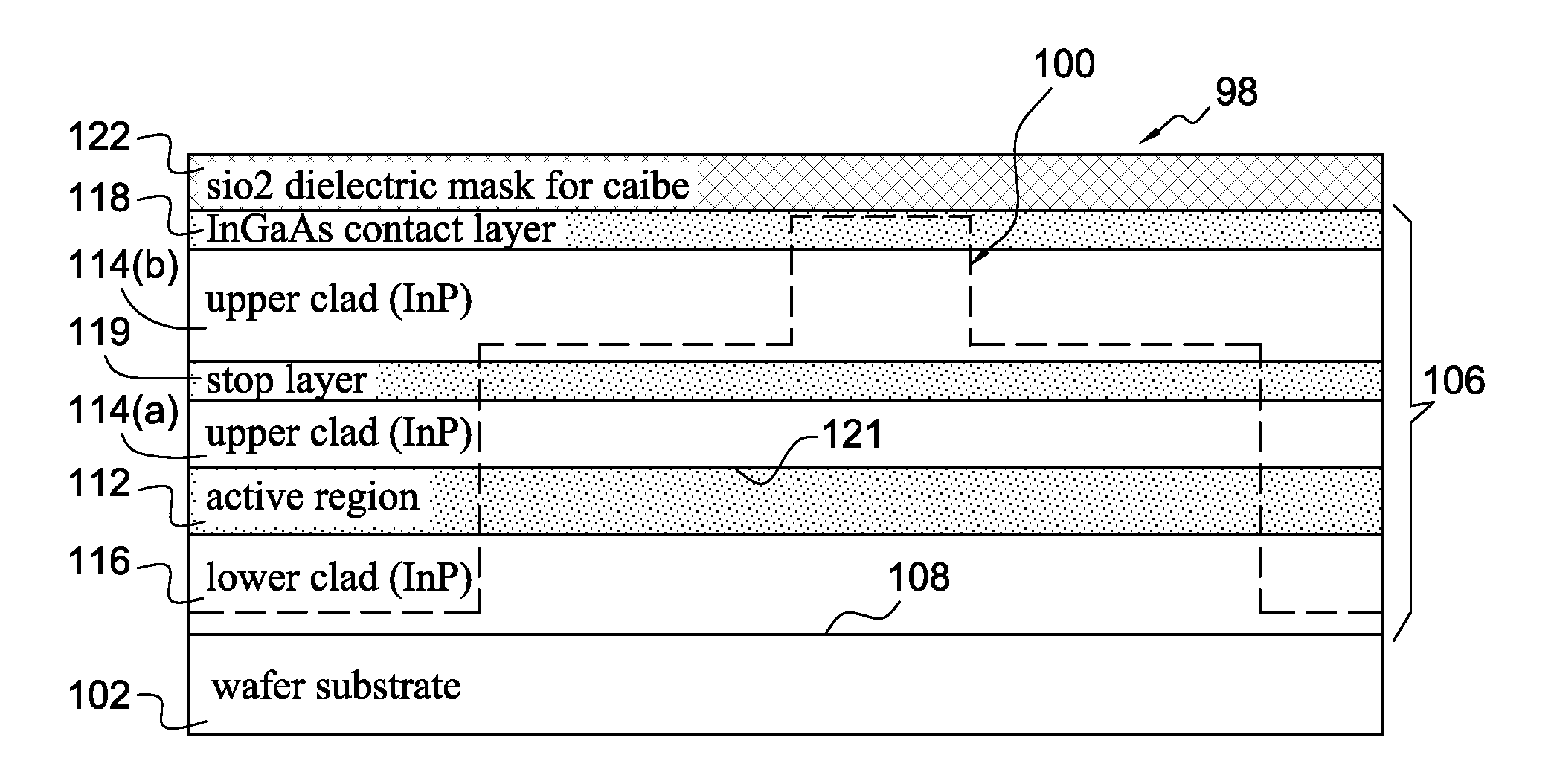

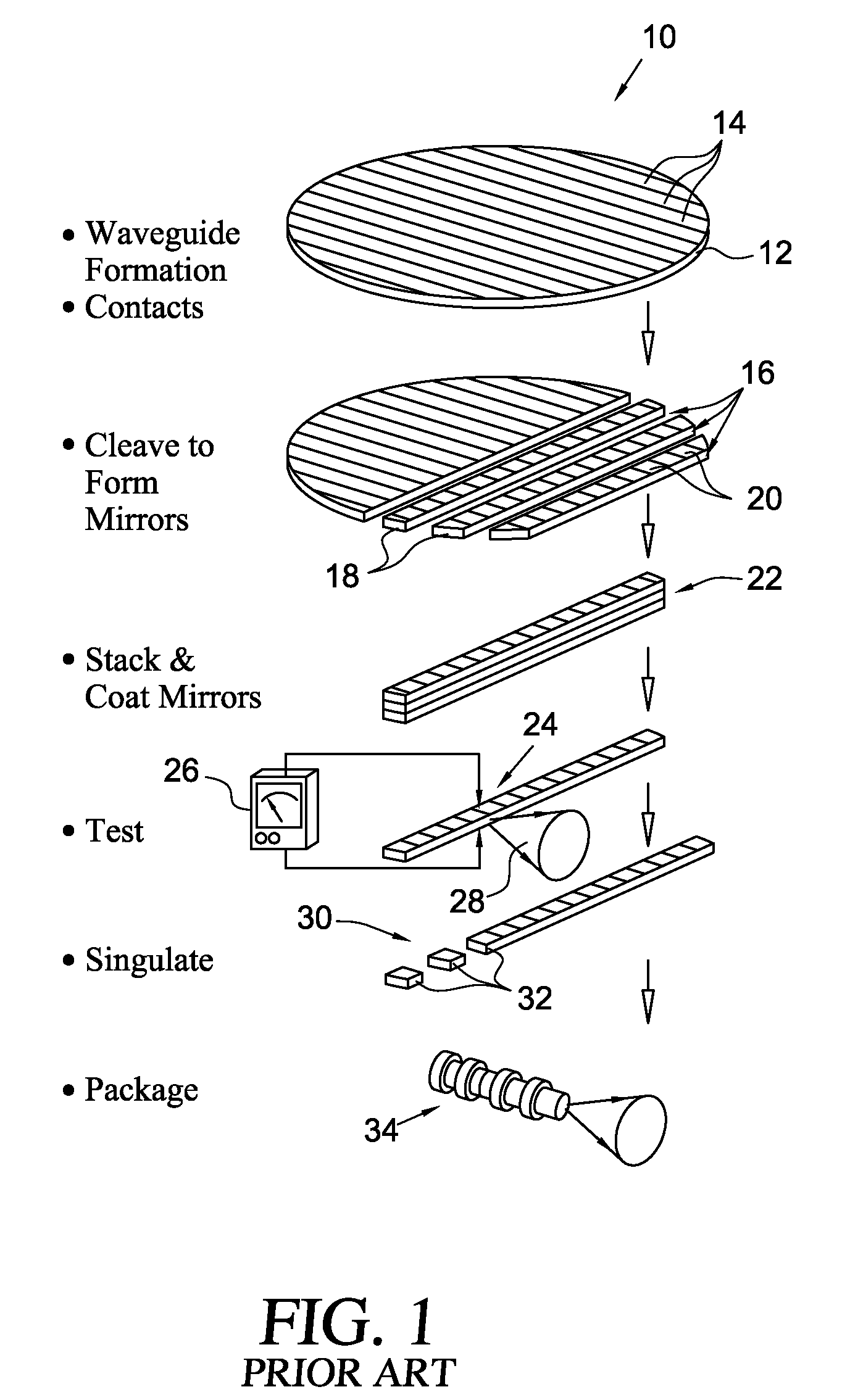

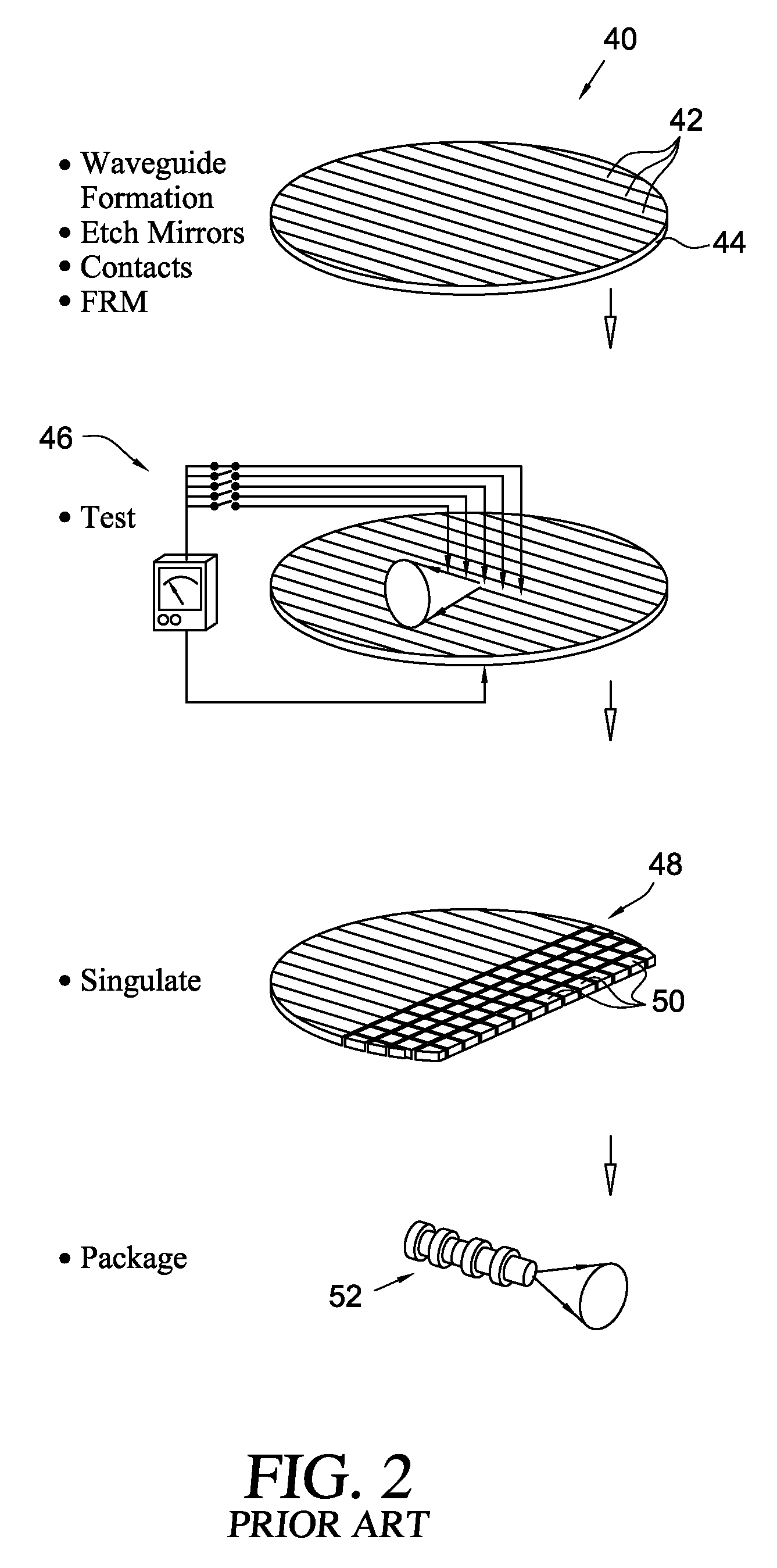

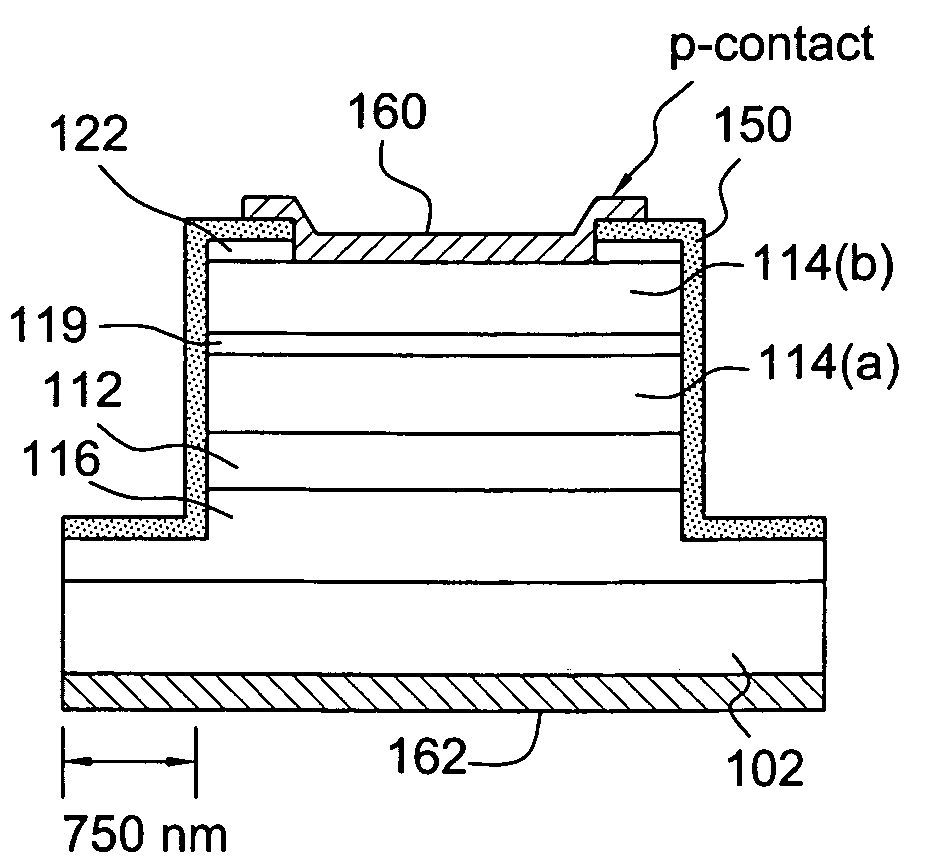

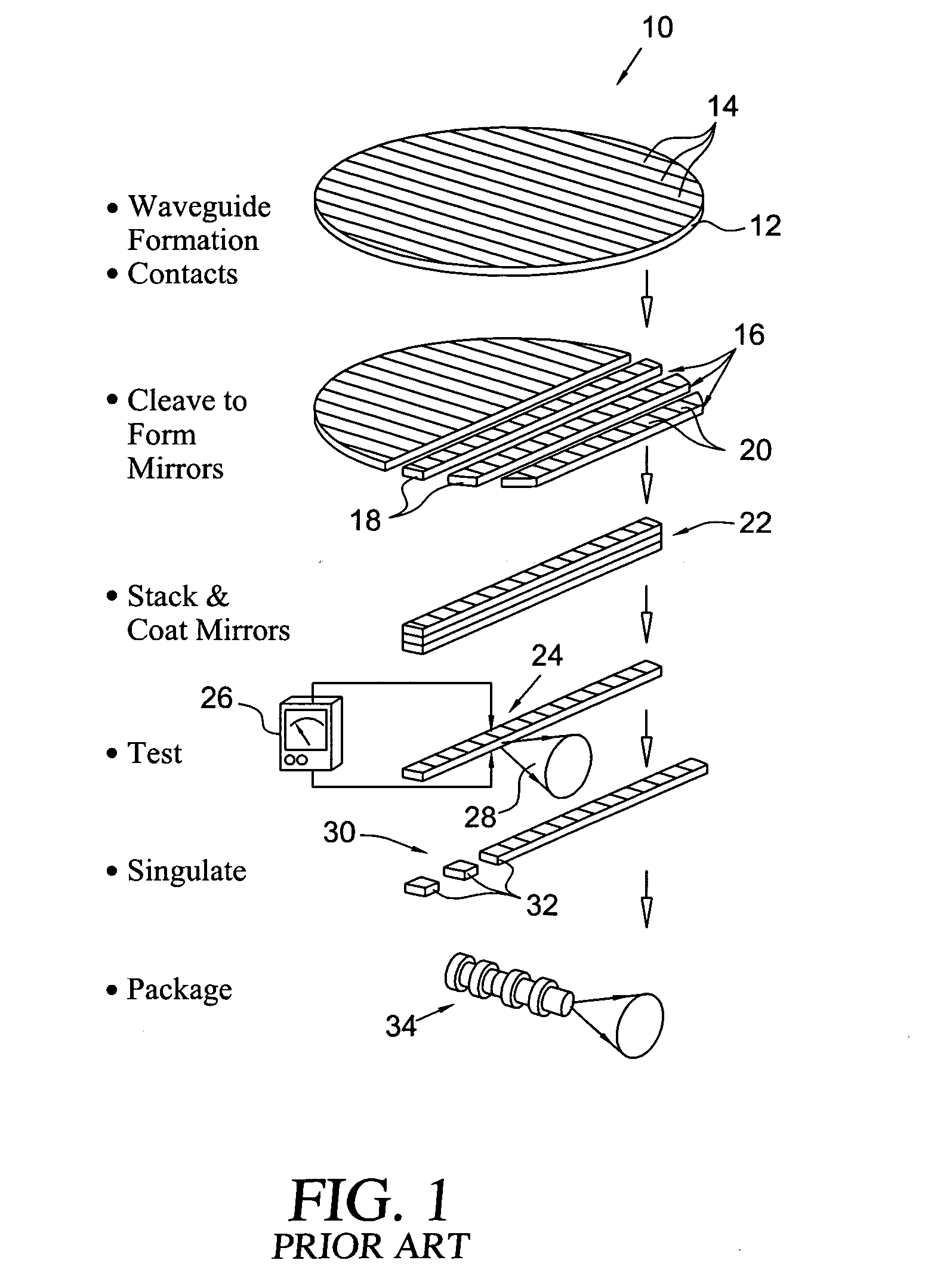

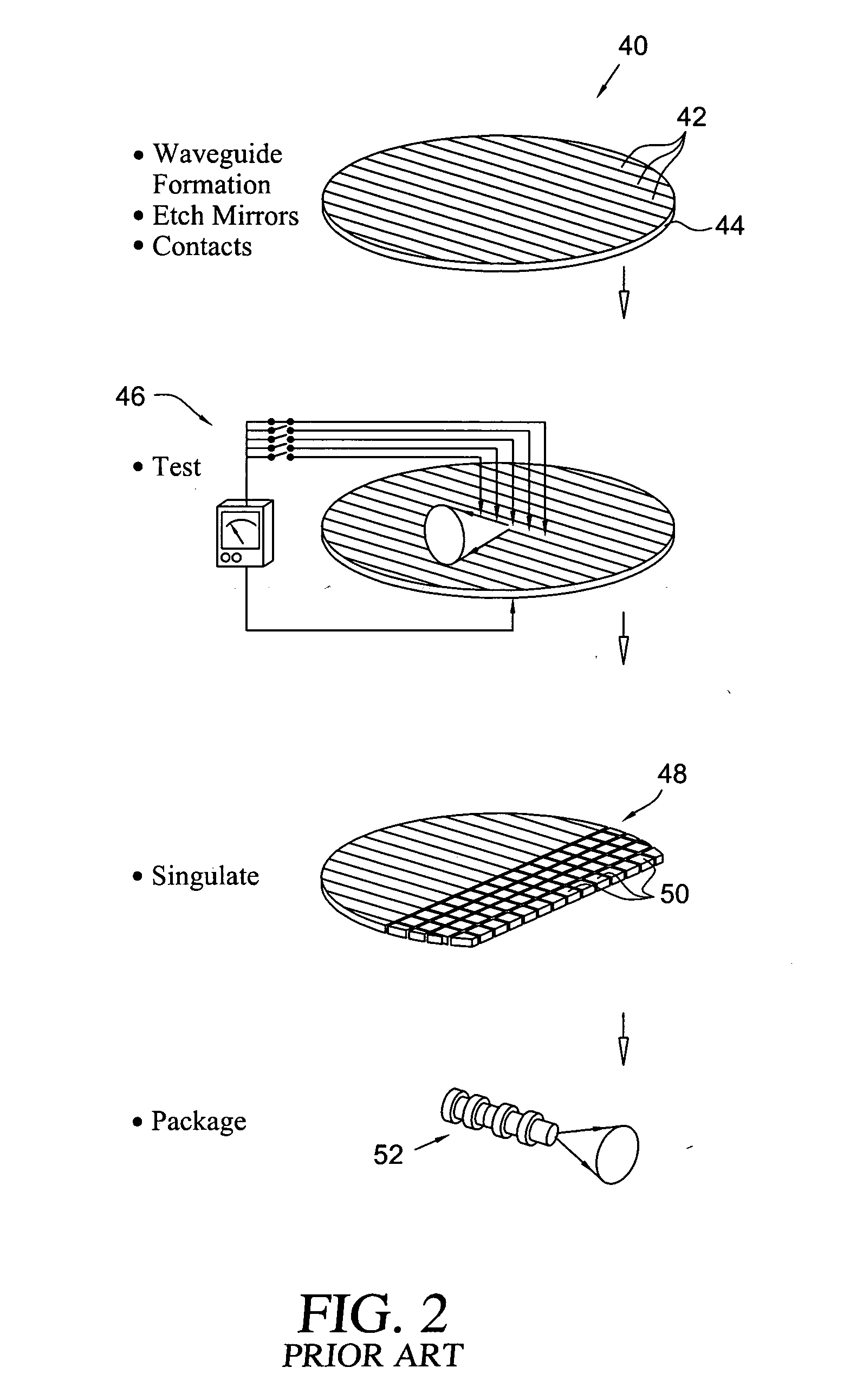

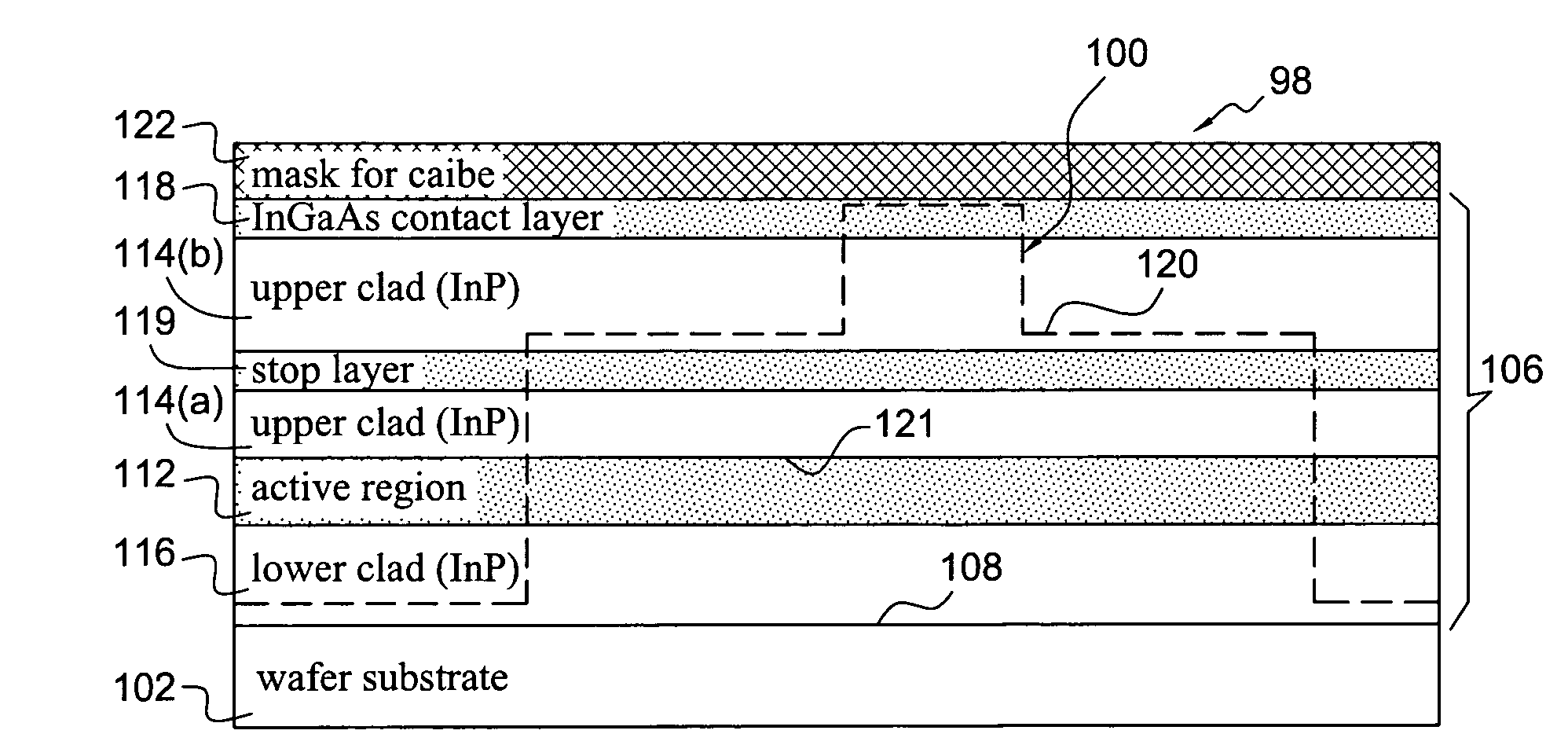

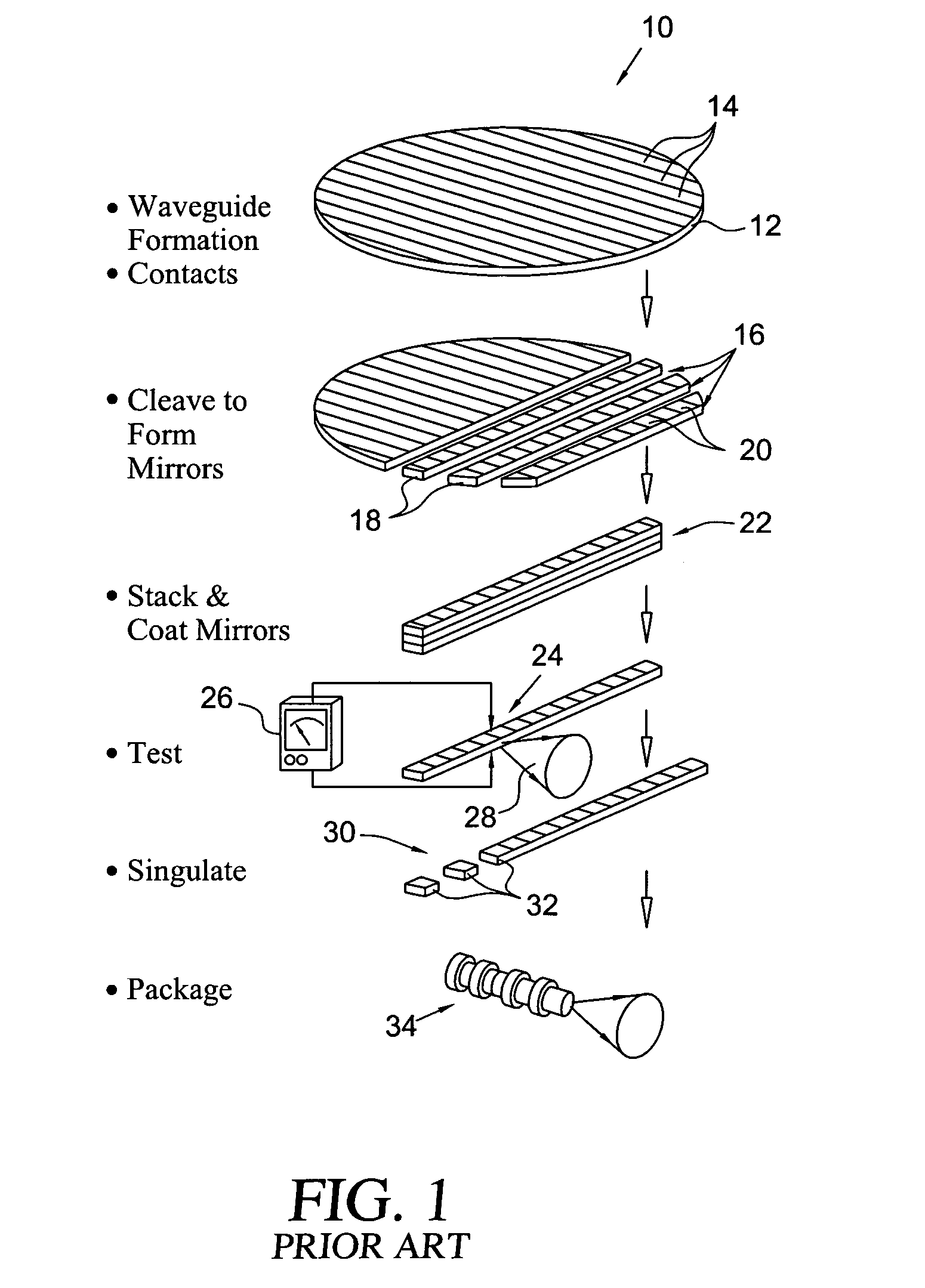

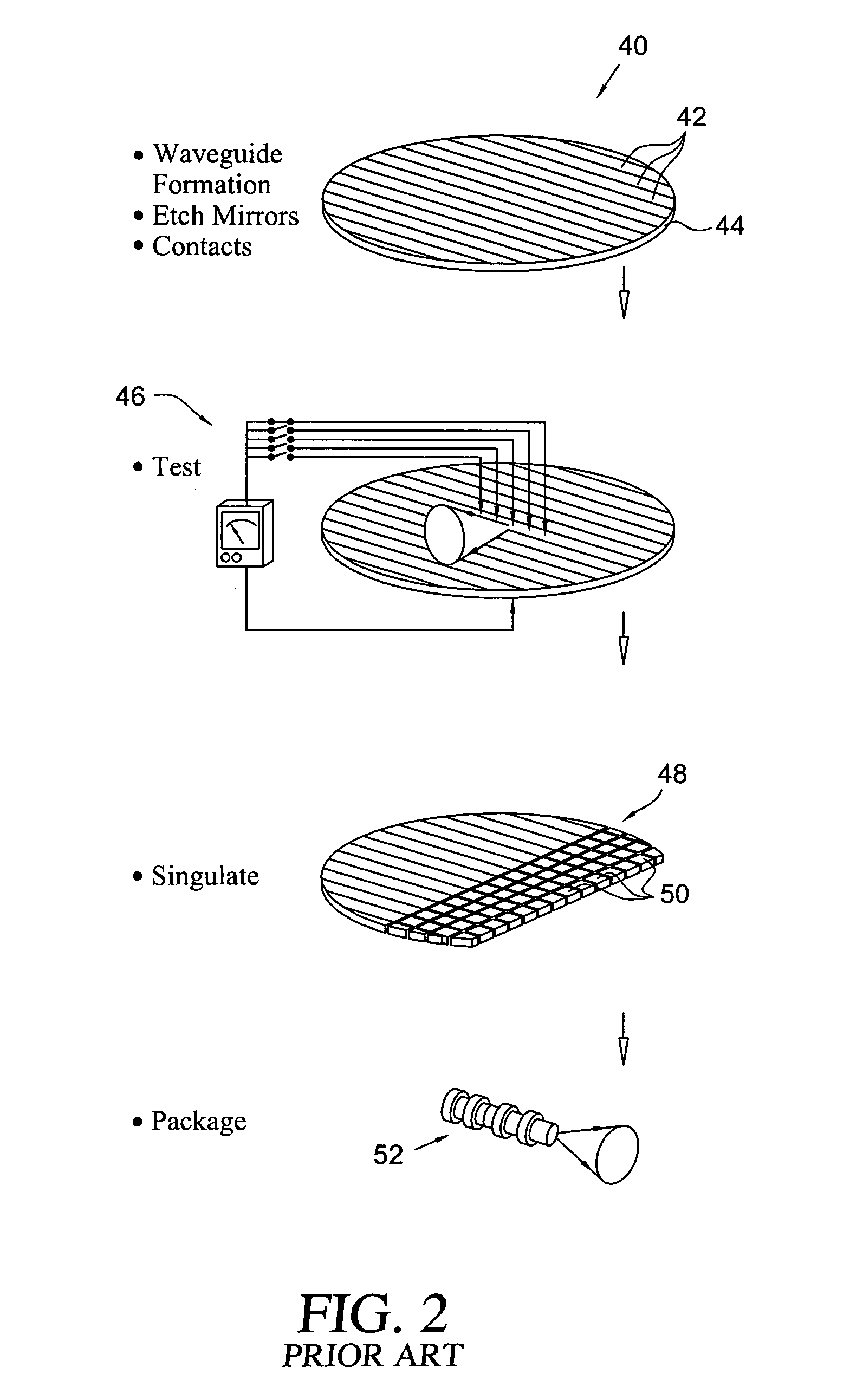

Etched-facet ridge lasers with etch-stop

ActiveUS20100015743A1High uniformity and yieldIncrease productionOptical wave guidanceSemiconductor/solid-state device manufacturingDry etchingRidge

A photonic device incorporates an epitaxial structure having an active region, and which includes a wet etch stop layer above, but close to, the active region. An etched-facet ridge laser is fabricated on the epitaxial structure by dry etching followed by wet etching. The dry etch is designed to stop before reading the depth needed to form the ridge. The wet etch completes the formation of the ridge and stops at the wet etch stop layer.

Owner:MACOM TECH SOLUTIONS HLDG INC

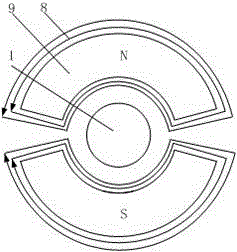

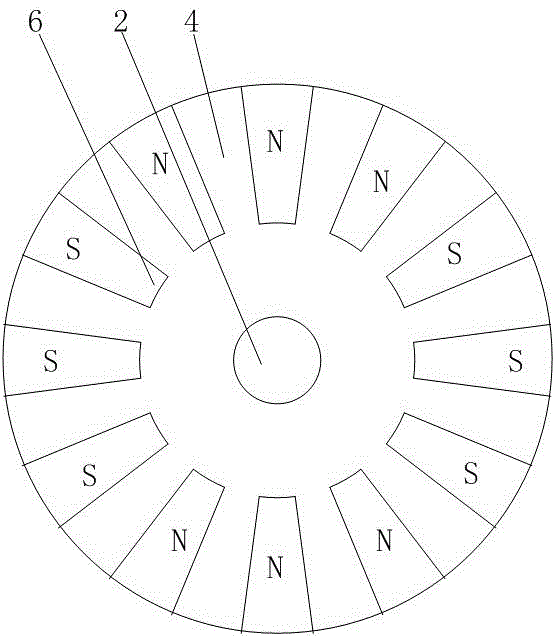

Three phase external rotor double salient pole permanent magnet brushless electric generator

InactiveCN1753287AImprove reliabilityGood high speed performanceSynchronous machinesElectrical polarityThree-phase

A three-phase double convex pole permanent magnet brushless generator is in the structure of a stator inside and a rotor outside, the magnet and an armature winding are set on the stator fixed on the base by four installing holes, the rotor is connected with the shaft by the shell and a shaft sleeve base, four magnets are distributed uniformly along the circum at the yoke of the stator, the poles of which are distributed in N,S,S,N,N,S,S,N, 12 convex poles are uniformly distributed on the outer circum of the stator, 8 convex poles are uniformly distributed on the inner circum of the rotor and placed on the two face to face poles of the stator and two face to face vertical poles connected with them and the centralized windings of the four poles are serial to one three-phase armature winding in 120deg. difference.

Owner:SOUTHEAST UNIV

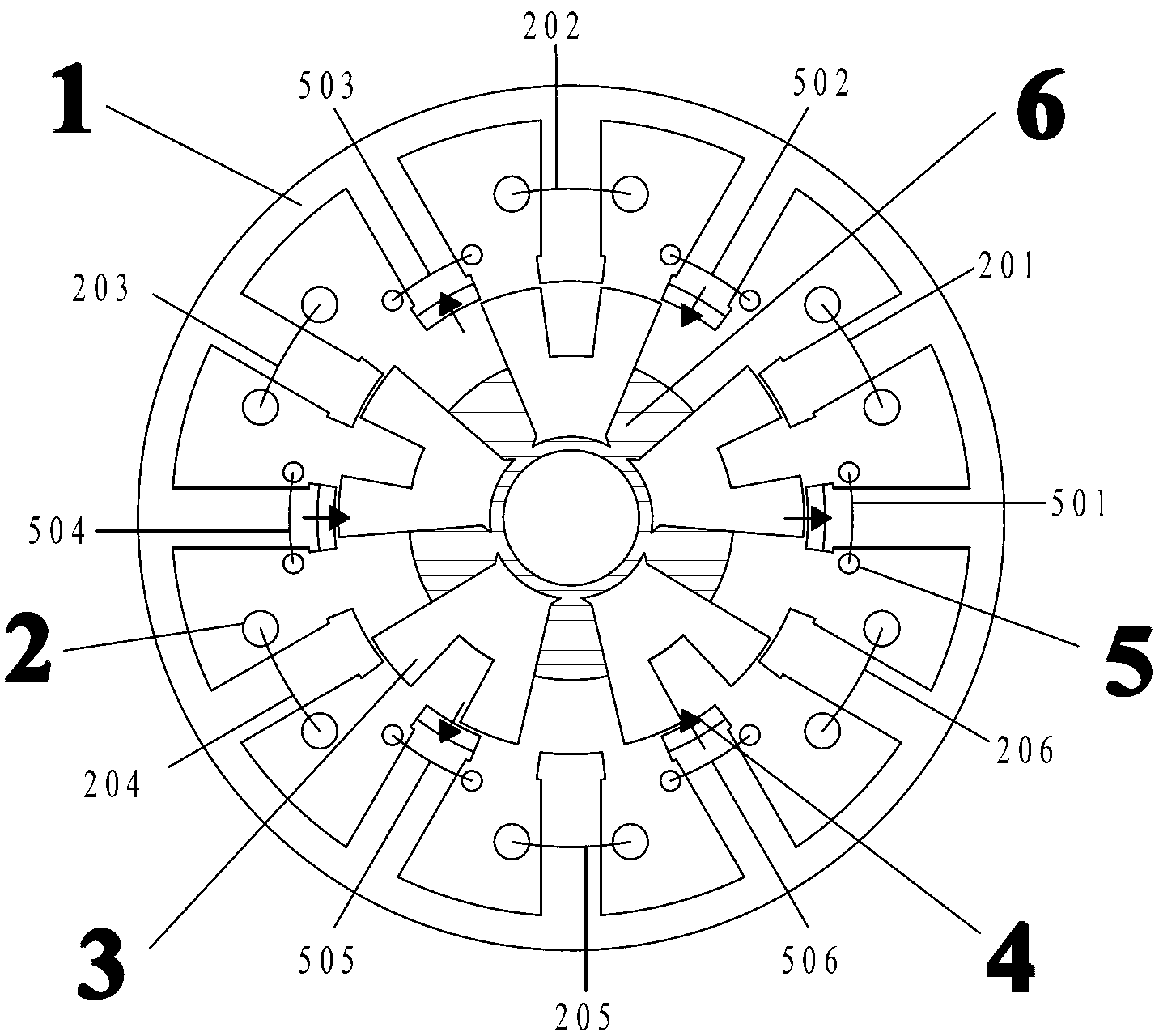

Double-end hybrid excitation stator-partition-type flux switching motor

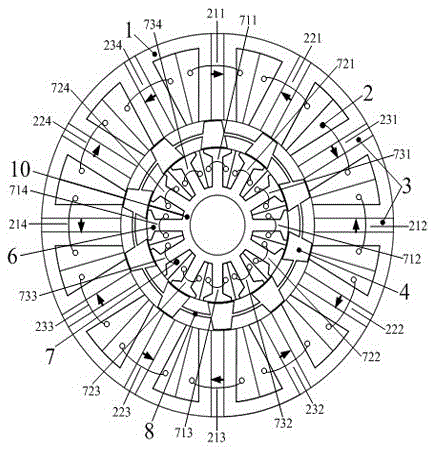

ActiveCN106992650AReduce manufacturing costIncreased torque densitySynchronous machine detailsElectric machinesElectric machineRare earth

The invention discloses a double-end hybrid excitation stator-partition-type flux switching motor. The inner surface of a stator yoke of an external stator is provided with armature teeth and excitation teeth alternately at intervals in circumference direction; each armature tooth is wound by an armature winding, and each excitation tooth is wound by an external DC excitation winding; a stator core of an internal stator is uniformly provided with inner stator slots, the number of which is same with that of the armature teeth, in the circumference direction; the inner side of each inner stator slot is embedded by a non-rare-earth ferrite permanent magnet; the outer side of each inner stator slot is placed by an internal DC excitation winding; a stator core between every two inner stator slots is embedded by a rare-earth neodymium-iron-boron permanent magnet; the external diameter of each rare-earth neodymium-iron-boron permanent magnet is equal to the internal diameter of the non-rare-earth ferrite permanent magnet; and the internal diameter of the rare-earth neodymium-iron-boron permanent magnet is equal to the internal diameter of each inner stator slot. The flux switching motor adopts internal and external stator double-end excitation and realizes flexible control of an air-gap magnetic field, has a broader magnetically-adjusting range and ensures higher torque density and power density of the motor.

Owner:JIANGSU UNIV

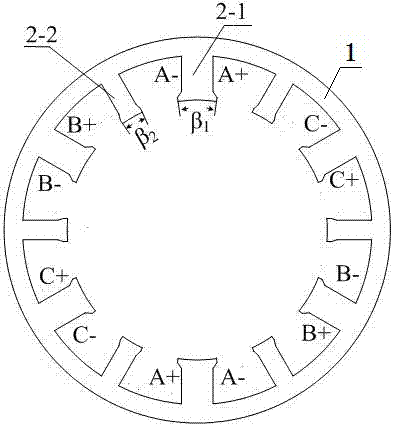

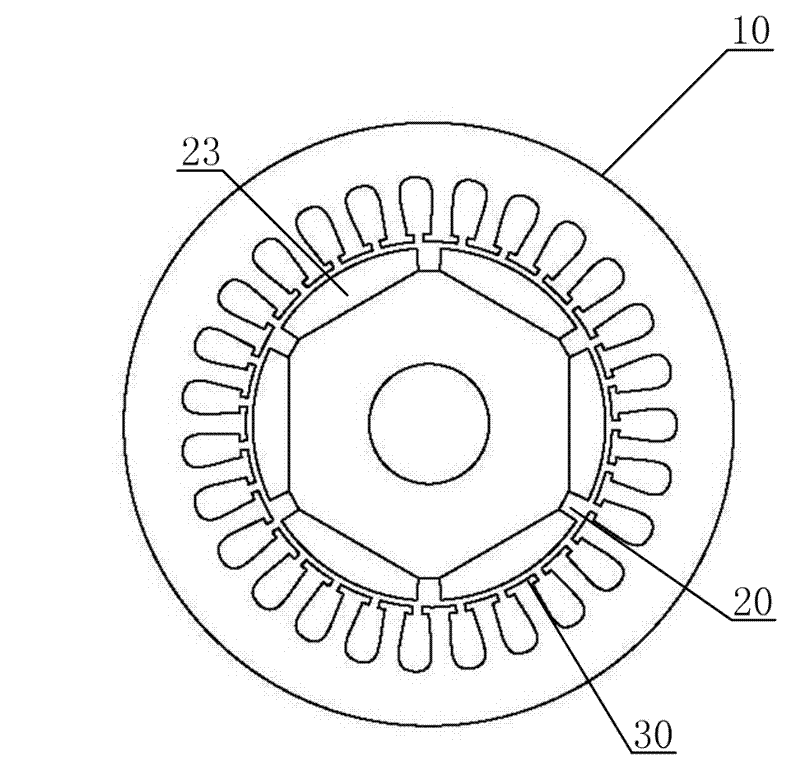

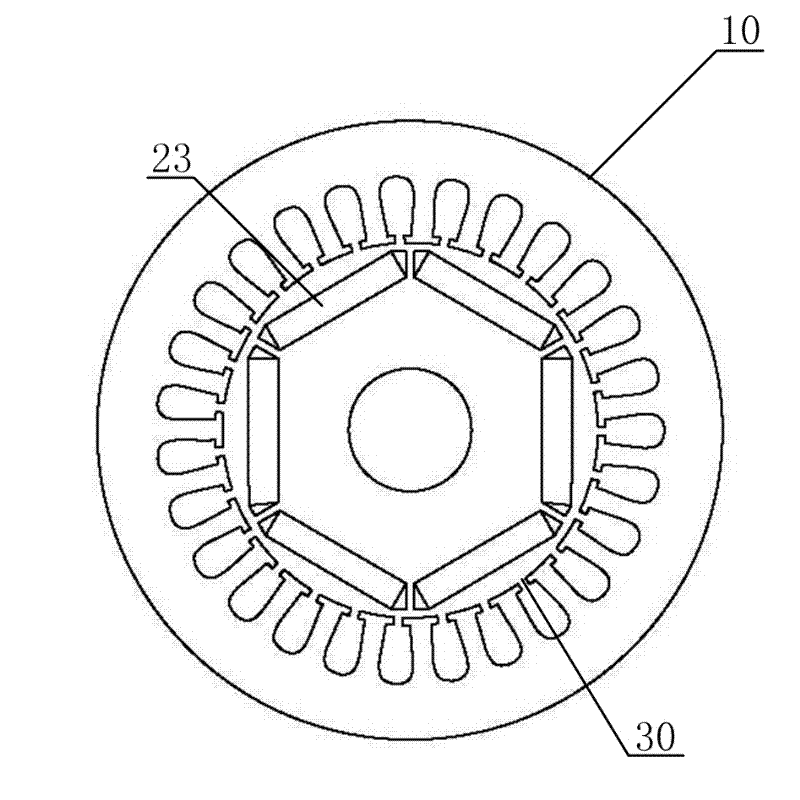

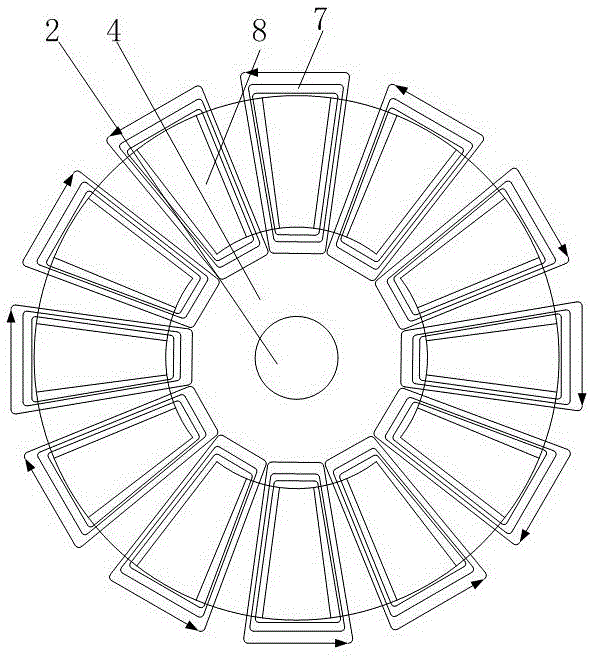

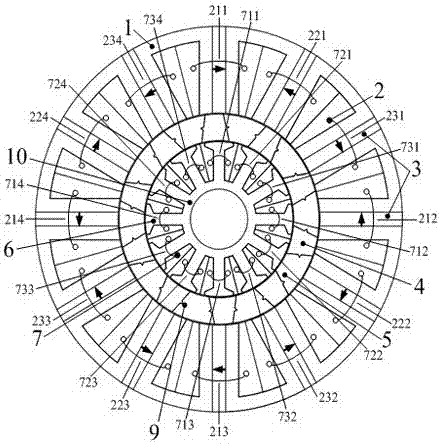

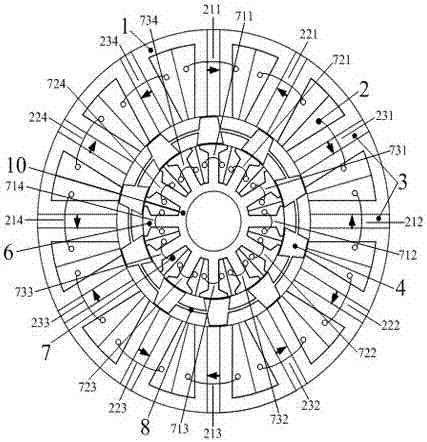

Cross-two-teeth concentrated winding vernier permanent magnetic motor

ActiveCN106253530AReduce copper consumptionReduce volumeWindings conductor shape/form/constructionPower factorCopper

The invention discloses a cross-two-teeth concentrated winding vernier permanent magnetic motor. The cross-two-teeth concentrated winding vernier permanent magnetic motor comprises a stator (1) and a rotor (2), wherein the stator (1) is a cylindrical body, a circumferential wall of the cylindrical body is uniformly distributed with multiple grooves, the grooves are respectively used for accommodating windings, stator teeth are formed at projection portions among the grooves on the circumferential wall of the cylindrical body, the rotor (2) is a circular body, a circumferential wall of the circular body is distributed with multiple permanent magnets with intervals, and an armature winding of the vernier permanent magnetic motor is a concentrated winding crossing two teeth. According to the cross-two-teeth concentrated winding vernier permanent magnetic motor, compared with a traditional vernier motor, a winding crossing distance is substantially reduced , an end portion is shorter, copper consumption of the motor is effectively reduced, a motor volume is reduced, and motor efficiency is improved; the cross-two-teeth concentrated winding is employed, an ultimate ratio of the vernier motor is reduced to be in a range of 2-5, a power factor of the motor can be improved to be greater than 0.8 on the condition that output torque loss is relatively small.

Owner:HUAZHONG UNIV OF SCI & TECH

Etched-facet ridge lasers with etch-stop

ActiveUS20080151955A1Improve uniformityHigh yieldOptical wave guidanceSemiconductor/solid-state device manufacturingDry etchingLaser

A photonic device incorporate an epitaxial structure having an active region, and which includes a wet etch stop layer above, but close to, the active region. An etched-facet ridge laser is fabricated on the epitaxial structure by dry etching followed by wet etching. The dry etch is designed to stop before reading the depth needed to form the ridge. The wet etch completes the formation of the ridge and stops at the wet etch stop layer.

Owner:MACOM TECH SOLUTIONS HLDG INC

DC bias type flux reverse permanent magnet motor

ActiveCN111181266AReduce the effective air gapIncreased torque densityMagnetic circuit rotating partsElectric machinesDC - Direct currentDc current

The invention discloses a DC bias type flux reverse permanent magnet motor, which comprises a permanent magnet stator and a salient pole iron core rotor. An independent air gap is formed between the permanent magnet stator and the salient pole iron core rotor; the permanent magnet type stator comprises a stator yoke part and a plurality of stator teeth, wherein the stator yoke part and the plurality of stator teeth form a plurality of stator slots; armature windings are placed in the stator slots; bias direct current is injected into the armature windings; a permanent magnet is arranged at theslot opening of each stator slot; the permanent magnets and the adjacent stator teeth form a pair of magnetic poles; and the number and the magnetizing modes of the permanent magnets at the slot openings of the stator slots are the same. Multi-harmonic simultaneous work of the stator armature windings can be achieved, motor magnetic field adjustment is achieved by controlling positive and negative injected direct currents, and the motor is quite suitable for high-power demand occasions such as wind power generation and electric vehicles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

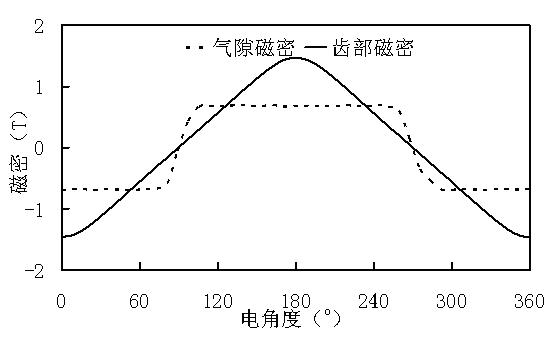

Permanent magnet synchronous machine (PMSM) possessing assembled magnetic effect

InactiveCN102255460AImprove distributionImprove approachMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous machinePermanent magnet synchronous motor

The invention provides a permanent magnet synchronous machine (PMSM) possessing an assembled magnetic effect. The PMSM comprises a stator and a rotor. Air gaps exist between the stator and the rotor. The stator includes a stator core and a stator winding. The rotor includes a rotor core, a rotating shaft and permanent magnet steel. The stator winding is a centralized winding. The rotor is an eccentric rotor. Ends of the permanent magnet steel are directly connected with each other. The air gaps between the stator and the rotor are non-uniform air gaps. The invention has the following positive effects that: (1) distribution of air-gap flux density can be optimized through improving a rotor structure and the air gap flux can be very close to a sinusoidal waveform by using the non-uniform air gaps; (2) magnetic flux leakage on the ends can be effectively reduced because the ends of the permanent magnet steel are directly connected with each other, and simultaneously a magnetic isolation bushing is not needed to be installed on a rotating shaft side so that a requirement of a rotating shaft material can be reduced, wherein the rotating shaft can adopt a magnetic conductive material and / or a non magnetic conductive material.

Owner:SHANGHAI DIANJI UNIV

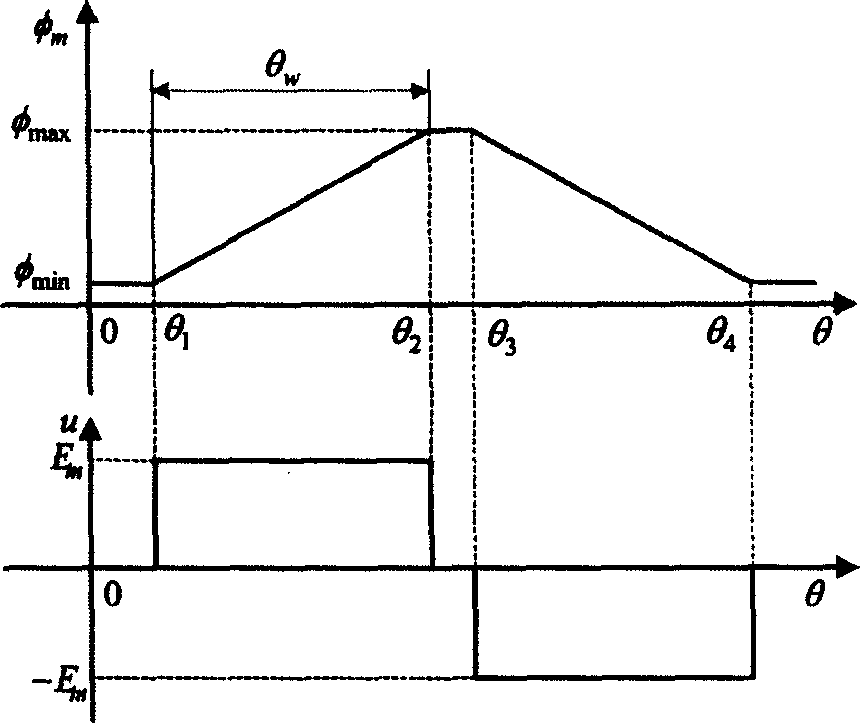

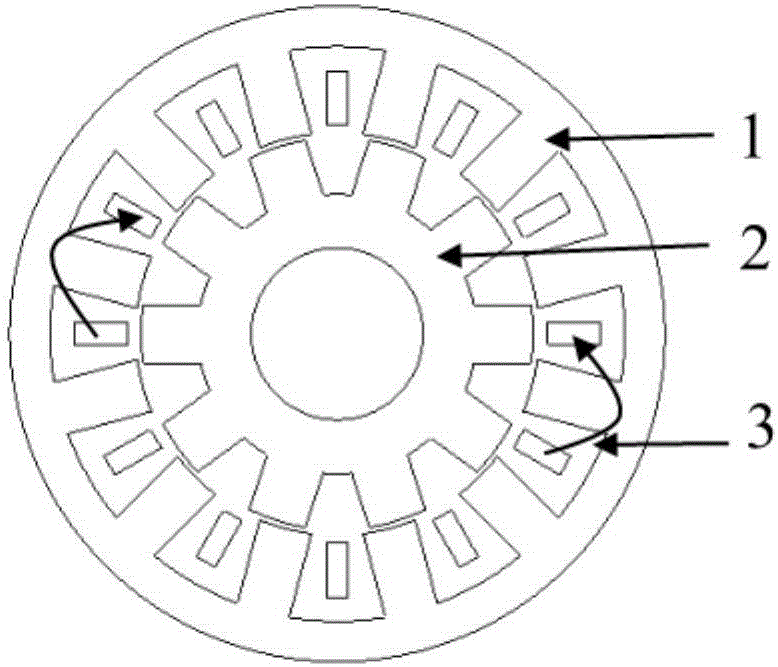

Mutual inductance coupling type switch magnetic resistance motor

InactiveCN103532265AHigh material utilizationReduce torque rippleMagnetic circuit stationary partsWindings conductor shape/form/constructionCouplingElectric machine

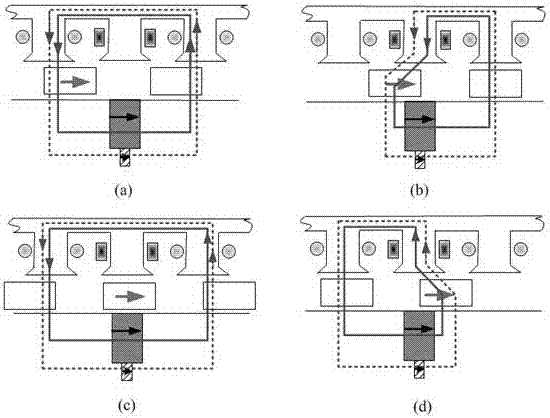

The invention discloses a mutual inductance coupling type switch magnetic resistance motor, which is in a double-salient-pole structure, wherein salient pole teeth are respectively arranged on a stator and a rotor, but the number of the salient pole teeth on the stator and the number of the salient pole teeth on the rotor are different. An integrated winding coil is wound on the stator teeth, a multiphase symmetrical winding structure is formed, the coil adopts double-layer coil edges, i.e., two ring edges belonging to different coils are placed in each stator groove, all of the coils of the winding maintain the same winding direction, i.e. after the introduction of current in the same direction, the polarities of flux linkage of all stator poles are identical, the self inductance and the mutual inductance of each phase of winding of the motor can be periodically changed along with the position change of the rotors, i.e., the motor can work simultaneously through the reluctance torque generated through the self inductance and mutual inductance change. The invention further discloses a control method of the mutual inductance coupling type switch magnetic resistance motor. The mutual inductance coupling type switch magnetic resistance motor has the advantages that the material utilization rate of the motor can be improved, the torque pulse of the motor is effectively inhibited, and the motor control mode is more flexible and diversified.

Owner:SOUTHEAST UNIV

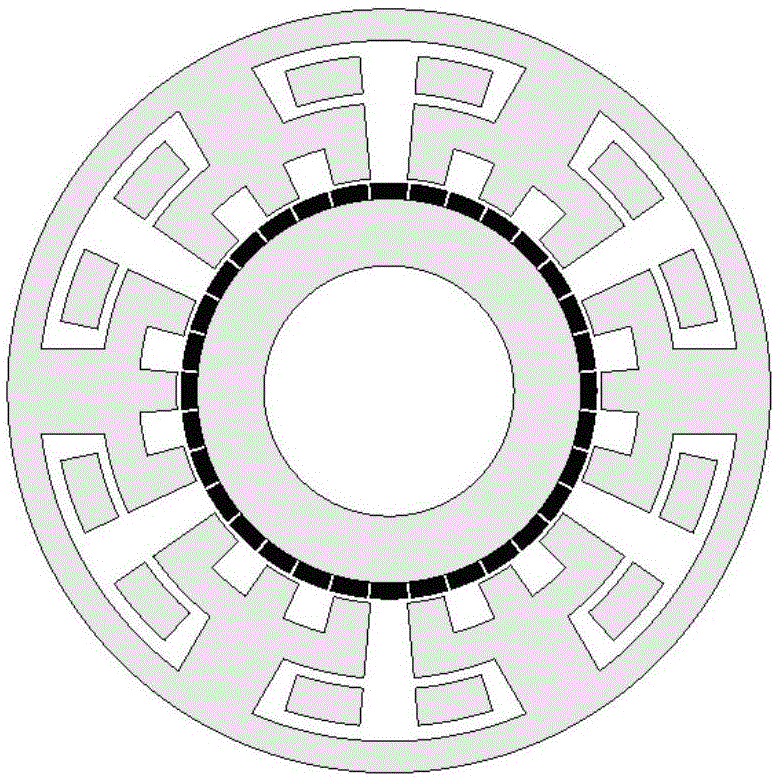

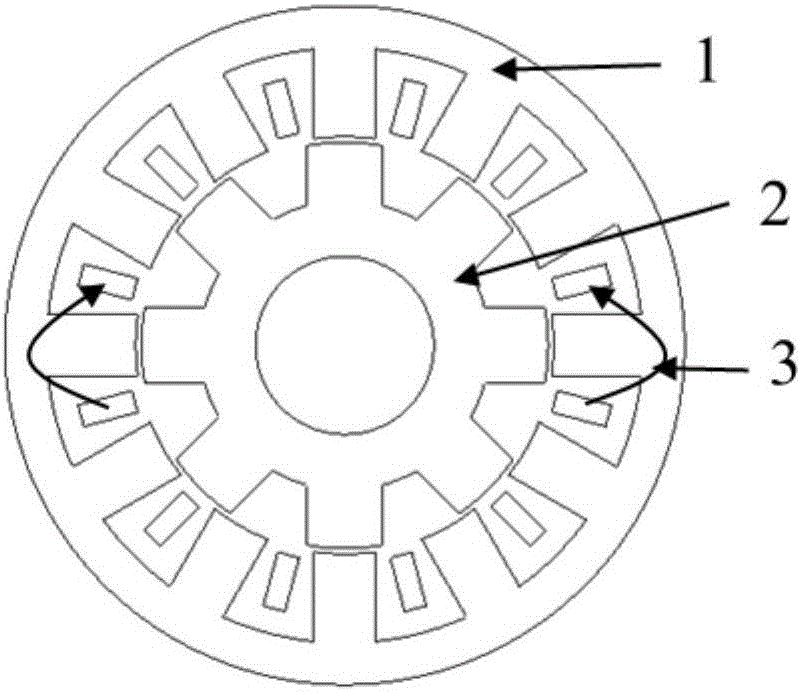

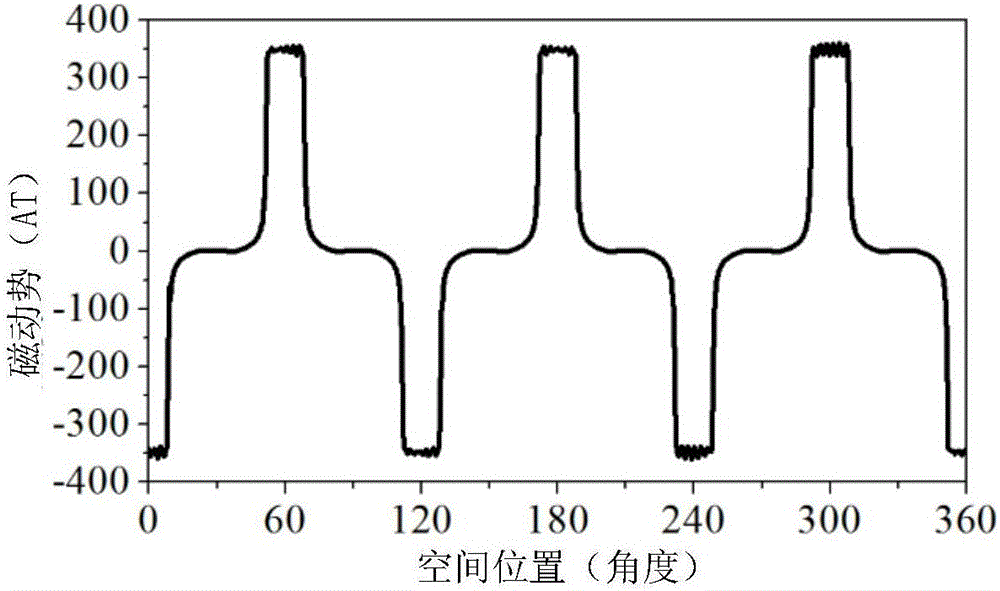

Single-layer concentrated winding DC injection type cursor reluctance machine

ActiveCN106849396AIncreased torque densityIncrease slot fill rateMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineTorque density

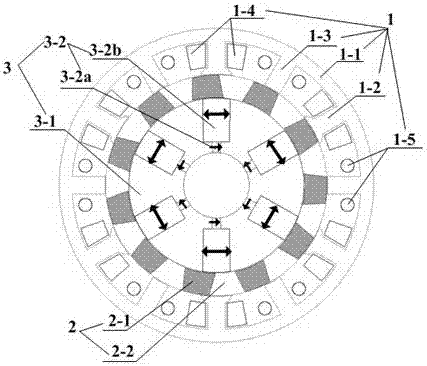

The invention discloses a single-layer concentrated winding DC injection type cursor reluctance machine. The single-layer concentrated winding DC injection type cursor reluctance machine comprise a stator (1), a rotor (2) and windings (3), wherein the stator (1) and the rotor (2) are both of salient pole structures, the single-layer concentrated winding DC injection type cursor reluctance machine is characterized in that the windings (3) are single-layer fractional-slot non-overlapping concentrated windings, a current in each winding comprises a sine AC component and a DC component, the sine AC component is used for generating a rotation magnetic potential, and the DC component is used for generating a rotation magnetic field. The reluctance machine is a single-layer winding, and no inter-insulator is needed. Compared with the prior art, the single-layer concentrated winding DC injection type cursor reluctance machine has the advantages that the space factor can be improved, and the torque density of the machine is further improved; and moreover, compared with the prior art, the single-layer concentrated winding DC injection type cursor reluctance machine has the advantages that the least common multiple of the stator Z1 and the rotor slots Z2 of the reluctance machine proposed by the invention is improved, and the torque pulse is reduced below 30%.

Owner:HUAZHONG UNIV OF SCI & TECH

Axial magnetic field consequent pole brushless hybrid excitation motor

ActiveCN113078792ALow costRealize brushless excitationMagnetic circuit rotating partsSynchronous motorsElectric machineEngineering

The invention discloses an axial magnetic field consequent pole brushless hybrid excitation motor, which comprises an axial rotor, and is characterized in that permanent magnet N poles distributed in an array are fastened in one side of the axial rotor, permanent magnet S poles distributed in an array are fastened on one side of the axial rotor, one side of the axial rotor is fixedly provided with iron core poles which are distributed in an array mode, one side of the axial rotor is provided with an axial stator, the axial rotor and the axial stator are coaxial, an air gap is formed between the axial rotor and the axial stator, one side of the axial stator is provided with an armature winding in a fastening mode, and the armature winding is close to the air gap. An alternating-current excitation winding for realizing brushless excitation is fastened between the armature winding and the axial stator, the armature winding and the alternating-current excitation winding are wound on the axial stator, and the armature winding and the alternating-current excitation winding are coaxial. According to the motor, the alternating-current excitation winding is adopted, an electric brush and a slip ring are omitted, brushless excitation is achieved, the cost of the motor is reduced, and the reliability is improved.

Owner:SOUTHEAST UNIV

Hybrid excitation rotor permanent magnet vernier motor

InactiveCN110880821AImprove power factorReduce riskMagnetic circuit rotating partsMagnetic circuit stationary partsDC - Direct currentElectric machine

The invention discloses a hybrid excitation rotor permanent magnet vernier motor, and belongs to the field of motors. A rotor is sleeved with a stator, and an air gap is formed between the rotor and the stator. The stator comprises a stator iron core and a stator winding, the stator iron core comprises a stator yoke part, first modulation teeth and second modulation teeth, the end parts of the first modulation teeth are two split teeth, and the first modulation teeth and the second modulation teeth are connected with the stator yoke part and are alternately distributed on the circumference ofan upper iron core; the second modulation teeth and the split teeth are the same in width; all phases of windings of the stator winding are connected in a single-tooth concentrated winding manner andare wound on the split teeth at equal intervals; and direct-current bias current is introduced into the stator winding. According to motor topology, the space of an inner cavity of the rotor is fullyutilized, the excitation effect of an excitation magnetic field and direct current is enhanced, and the torque density is greatly improved; direct-current bias current is adopted to flexibly adjust distribution of magnetic loads and electric loads, and the power factor of the motor can be well improved.

Owner:XI AN JIAOTONG UNIV

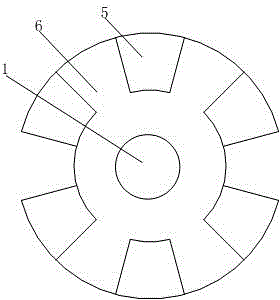

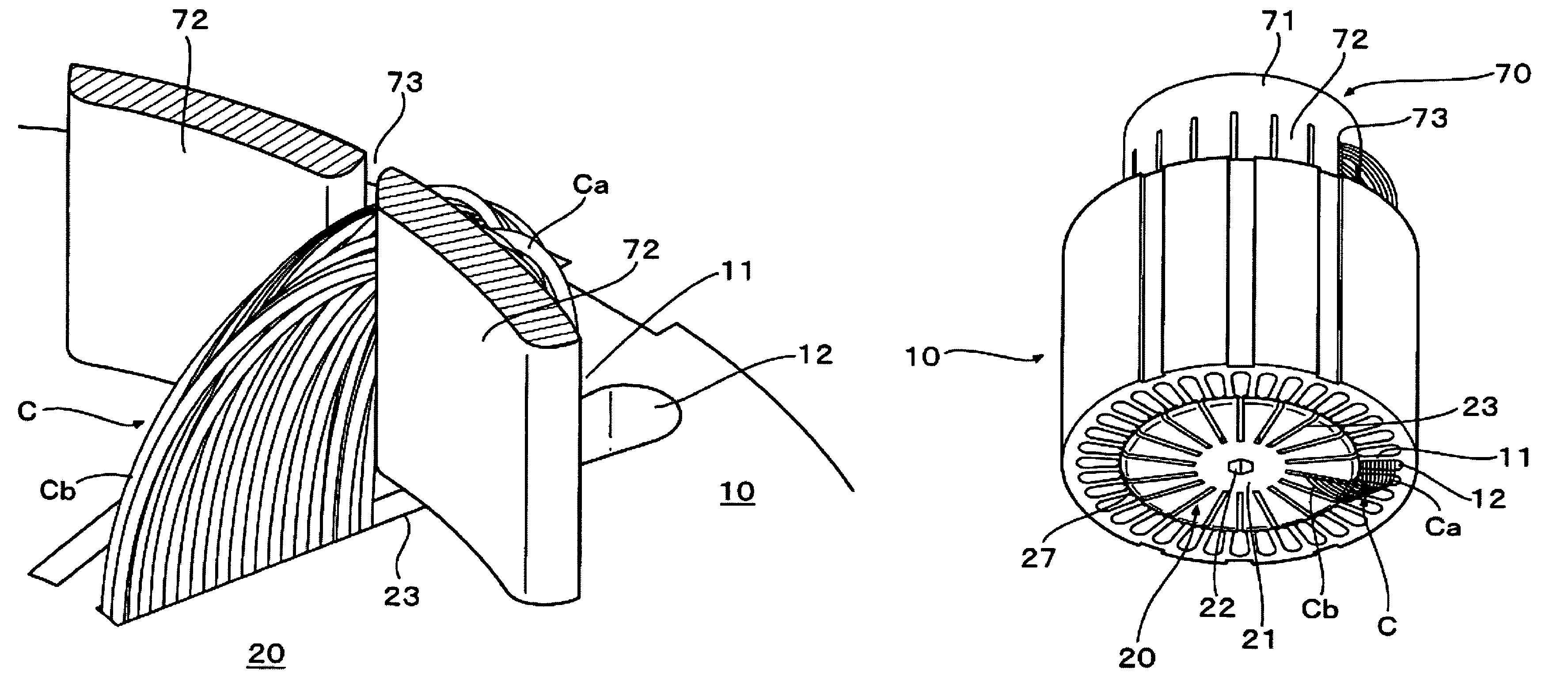

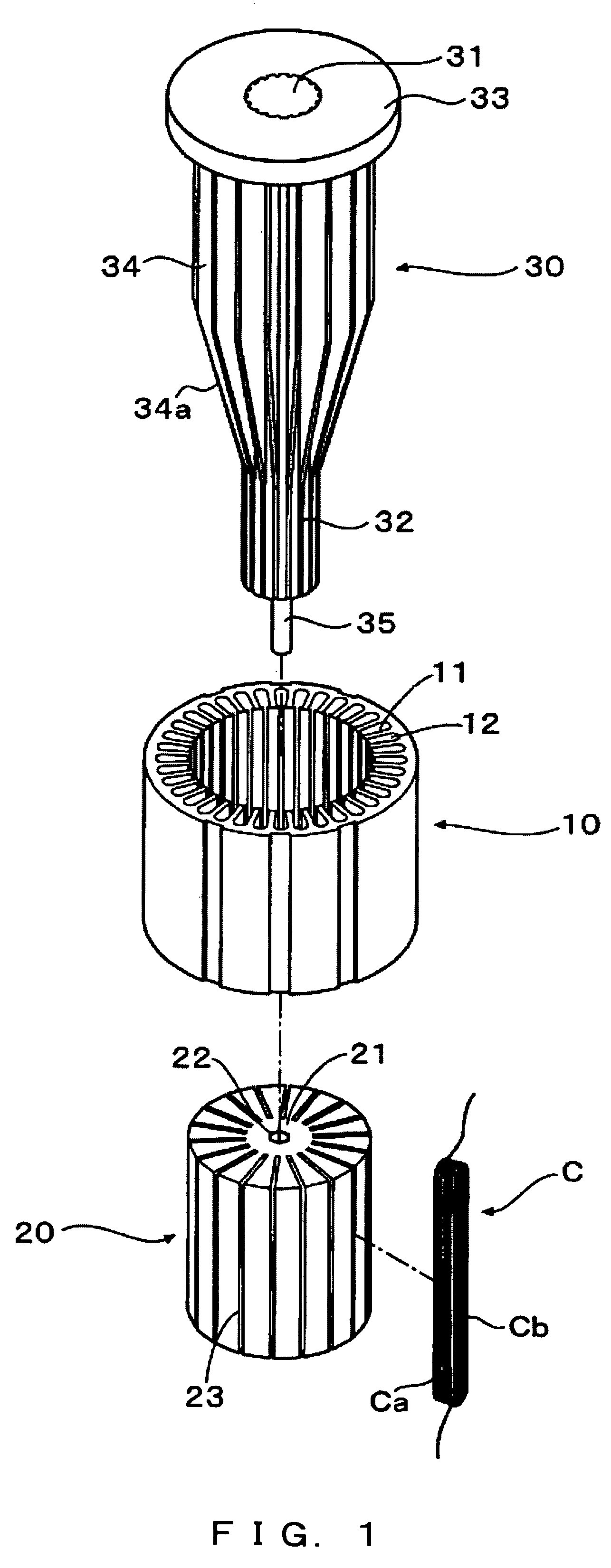

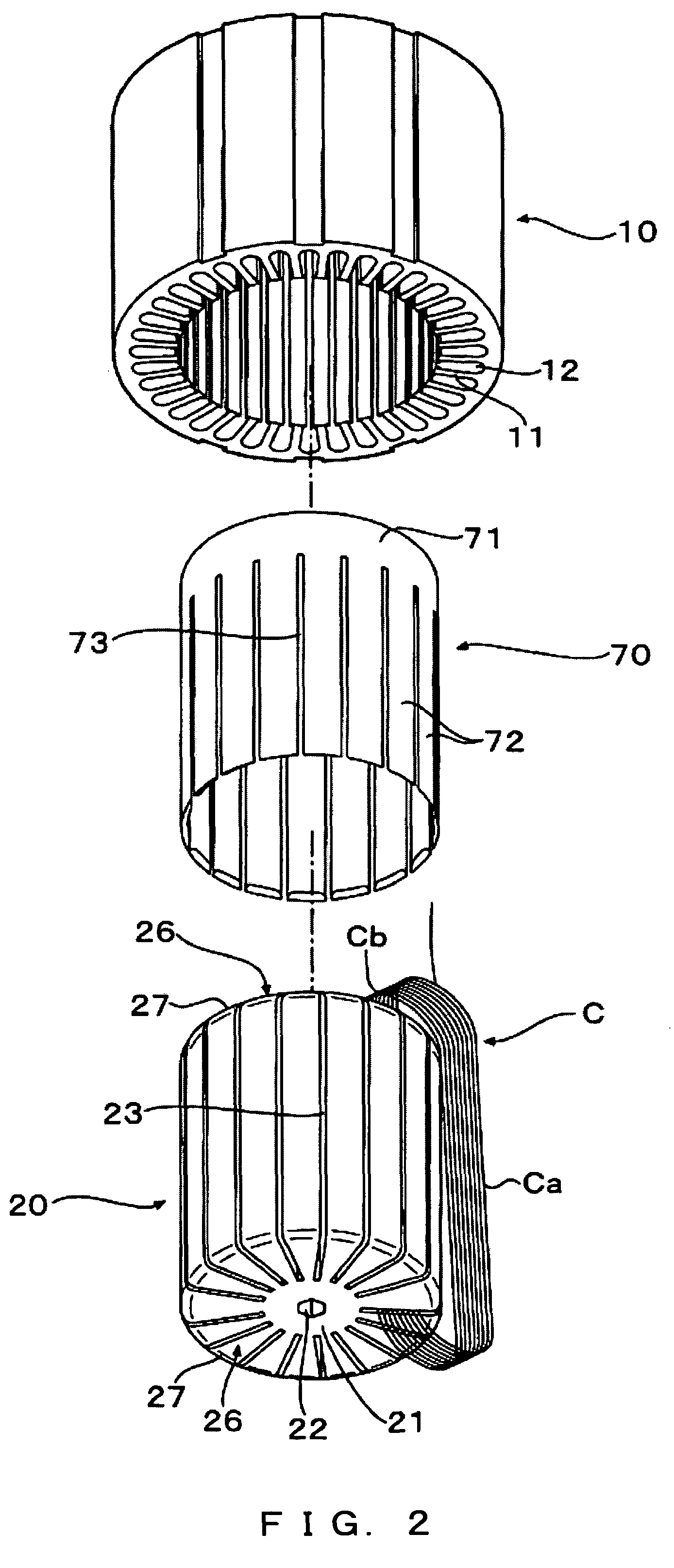

Stator

InactiveUS7923883B2High market shareTorque unevenness is smallMagnetic circuitSynchronous machinesStator coilPhysics

Owner:TOYOTA IND CORP

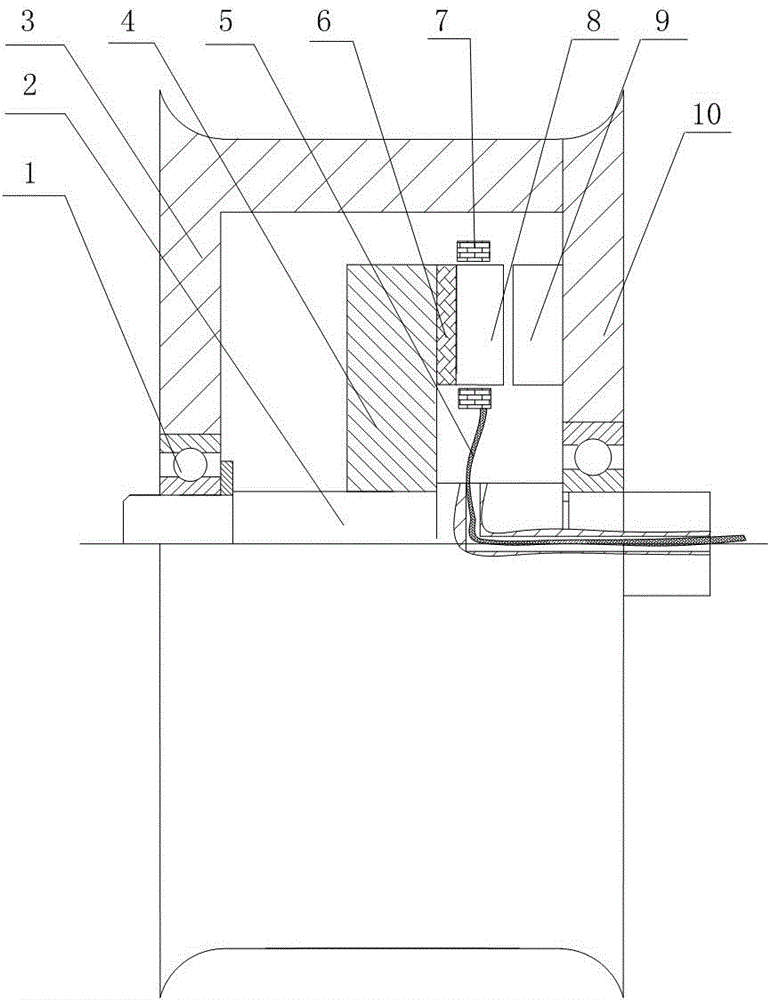

Bearingless permanent magnet sheet motor

ActiveCN109347226AIncreased reliability and axial stiffnessImprove system robustnessMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnet

The invention discloses a bearingless permanent magnet sheet motor. A circular-cake-shaped rotor permanent magnet is coaxially and fixedly connected to the axial top surface of a cross-shaped sheet rotor with a cross-shaped radial section; six identical L-shaped stator iron core columns are uniformly distributed on the periphery of the cross-shaped sheet rotor in the circumferential direction, wherein each L-shaped stator iron core column is composed of an axial stator yoke and radial stator teeth, and the stator teeth and the cross-shaped sheet rotor 1 are arranged in a radial opposite mode,and a radial air gap is formed therebetween; the outside of a disc-shaped iron core magnetic yoke is fixedly sleeved with the bottoms of the stator yokes of the six L-shaped stator iron core columns;the stator yoke of each L-shaped stator iron core column is wound with a set of torque windings and suspension force windings; a ring-shaped stator permanent magnet is coaxially and fixedly arranged on the top surfaces of the stator teeth of the six L-shaped stator core columns; and the stator permanent magnet and the rotor permanent magnet are both magnetized in the axial direction, and the magnetizing directions of the stator permanent magnet and the rotor permanent magnet are opposite. According to the bearingless permanent magnet sheet motor, the reliability and the axial rigidity of the rotor can be improved.

Owner:ZHENJIANG YUANDONG ELECTRIC MOTOR

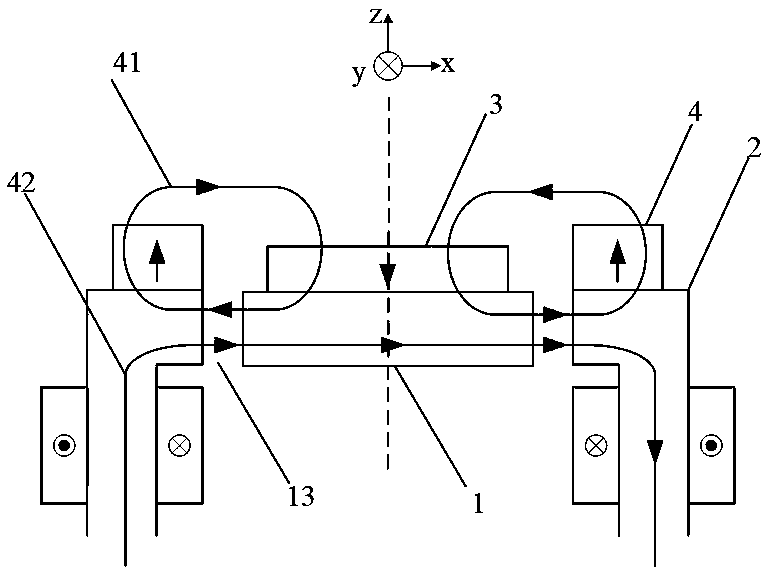

Hub-type axial excitation permanent magnetic motor

InactiveCN105896861AAchieve integrationReduce volumeSynchronous machine detailsDrive motorIntegrated design

The invention provides a hub-type axial excitation permanent magnetic motor. The hub-type axial excitation permanent magnetic motor is formed by bearings, an axle, a hub, a stator core, a permanent magnet, armature windings, stator poles, a rotor pole and a hub cover, wherein the hub and the hub cover can rotate around the axle so as to drive a wheel to rotate; the disc type stator core is fixed at the middle part of the axle; the permanent magnet and the stator poles are successively fixed on the end surface, relative to the hub cover, of the stator core; a corresponding armature winding winds around each stator pole; and the rotor pole which is convex in the axial direction is fixed on the inner wall, facing toward the stator pole, of the hub cover. For the hub-type axial excitation permanent magnetic motor, as both the permanent magnet and the armature windings are arranged on the stator, the rotor structure is simple and works reliably; as the contact surface between the stator and the rotor is large, the conductable maximum magnetic flux is large and the motor power is high; and the integrated design of the drive motor and the hub is realized, so that a decelerator is saved and the transmission efficiency is high.

Owner:SHANDONG UNIV OF TECH

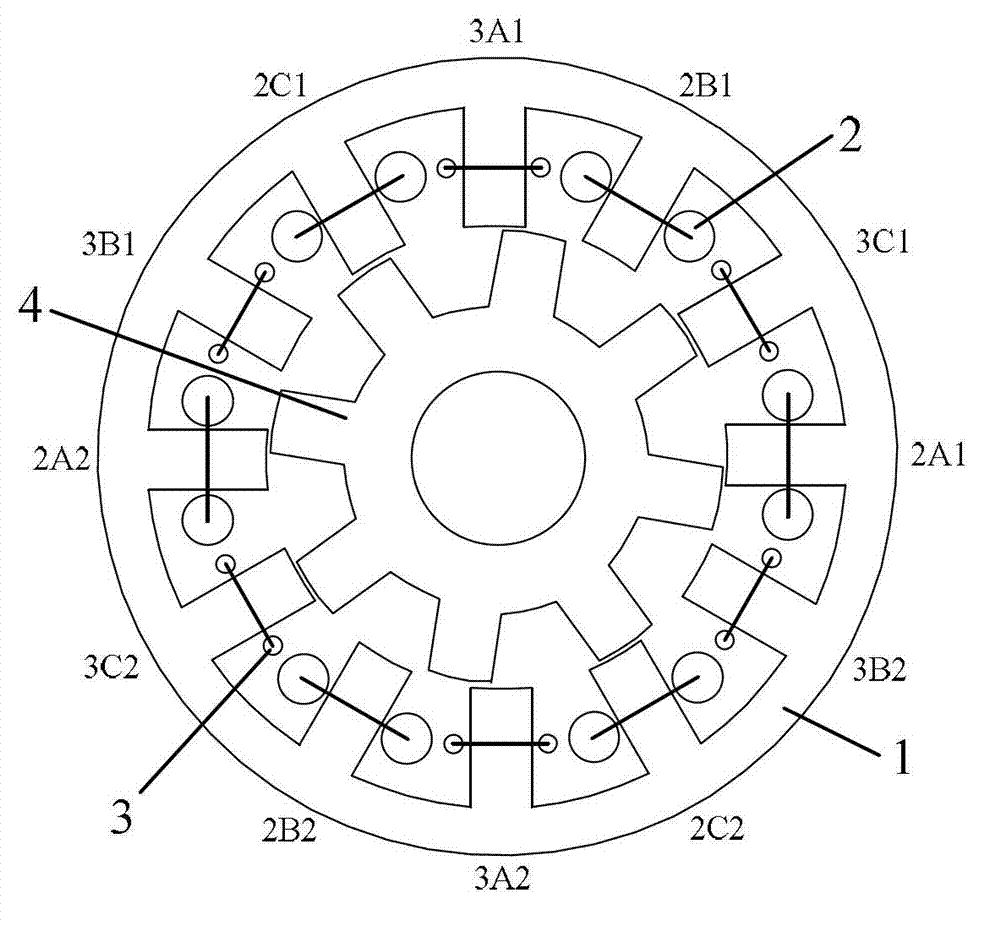

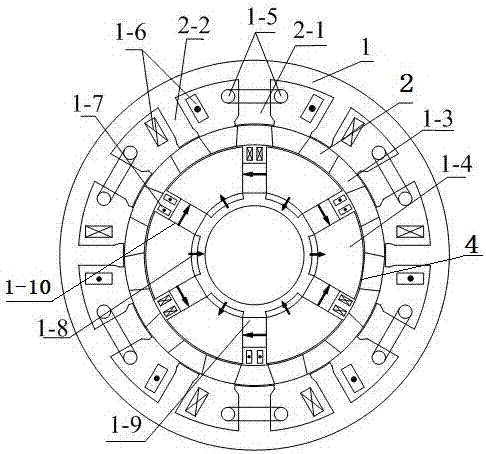

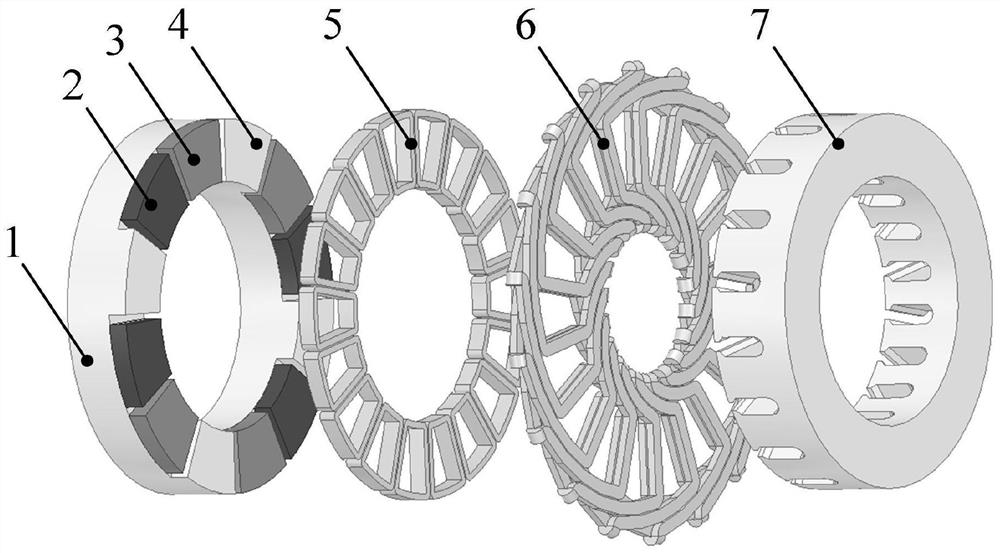

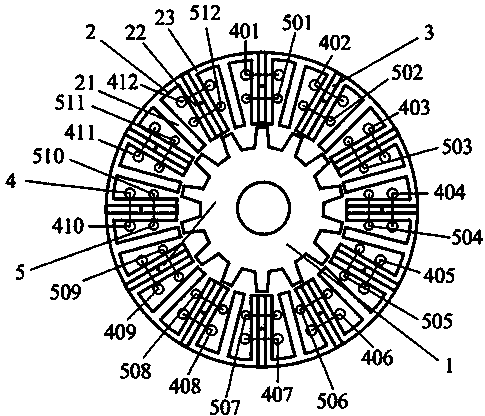

Double-winding modular bearingless magnetic flux switching permanent magnet motor

InactiveCN103683564ASimple structureImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

The invention discloses a double-winding modular bearingless magnetic flux switching permanent magnet motor which comprises a rotor iron core, a stator iron core, permanent magnets, 4m armature coils and 4m suspension coils, wherein m is the phase number of the motor, both the rotor iron core and the stator iron core are salient pole structures, the stator iron core is formed by the alternating splicing of 4m E-shaped iron core units and 4m permanent magnets, the magnetizing directions of the permanent magnets are tangential, the magnetizing directions of the adjacent permanent magnets are opposite, a projected tooth in the middle of each of the E-shaped iron core units is a stator fault tolerance tooth, both the armature coils and the suspension coils are sleeved on stator permanent magnet teeth, and the stator fault tolerance tooth is provide with a coil. The motor has the simple structure of a bearingless switch reluctance motor, the high efficiency and high power density of a bearingless rotor permanent magnet motor, and high theoretical and practical values.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Double-winding bearingless magnetic flux switching permanent magnet motor

InactiveCN107134866AImprove stabilityImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical polarityThree-phase

The invention discloses a double-winding bearingless magnetic flux switching permanent magnet motor comprising a stator, a rotor and windings. The stator and the rotor have a doubly salient structure and have the axial symmetry. The stator and rotor iron cores are formed by silicon steel plates through lamination. The stator iron core is formed by six U-shaped lamination plates. A tangentially and alternately magnetized permanent magnet is embedded between every two U-shaped lamination plates so as to form a stator tooth together. The windings are centralized windings and are installed on the stator teeth, and the end parts of the windings are small. There are two sets of windings. As for one set of windings, the coils on the two spatially opposite stator teeth are successively connected in series in an end-to-end way to form a phase so as to form the three-phase torque control windings; as for the other set of windings, the coils on the two spatially opposite stator teeth are reversely connected in series to form a phase so as to form the suspension force control windings, and the polarity of the adjacent sides of the adjacent permanent magnets is identical. The double-winding bearingless magnetic flux switching permanent magnet motor has the characteristics of high speed, high power, high efficiency, high power density, high operation stability and high reliability.

Owner:TIANJIN UNIV

Flux-switching type permanent magnet motor with permanent magnet fixing bosses

InactiveCN104600887AImprove installation accuracyPerformance is not affectedMagnetic circuit stationary partsFall riskPermanent magnet motor

The invention discloses a flux-switching type permanent magnet motor with permanent magnet fixing bosses and belongs to the technical field of manufacture and applications of motors. The motor is formed by a stator iron core, permanent magnets, an armature winding, a rotor iron core and the permanent magnet fixing bosses; the permanent magnets are fixed on a stator and tangentially magnetize alternately; the permanent magnet fixing bosses are arranged on contact surfaces of the stator iron core and the permanent magnets and towards the permanent magnets; the permanent magnet fixing bosses and the stator iron core are connected into a whole; a groove is formed in the permanent magnet; the size of the groove is matched with that of the permanent magnet fixing bosses. According to the flux-switching type permanent magnet motor with permanent magnet fixing bosses, the installation accuracy of the permanent magnet is greatly improved due to the permanent magnet fixing bosses, falling risks of the permanent magnet along the radial direction of the motor are reduced, and the motor reliability is improved.

Owner:扬州市新港电机有限公司 +1

Stator structure based on disc type permanent-magnetism motor winding

PendingCN109842229ALower resistanceReduce copper consumptionWindings conductor shape/form/constructionEngineeringConductor Coil

The invention discloses a stator structure based on a disc type permanent-magnetism motor winding. The stator structure comprises a PCB with at least 6 or 6N layers, and a Hall sensor; each PCB layeris provided with outer end portions, a winding setting part and inner end portions; each PCB layer is provided with at least three windings, and each winding is provided with two wiring ends correspondingly; the wiring ends are arranged in the outer end portions; each winding coil is printed and arranged in the corresponding outer end portion; the winding coil is uniformly printed on the winding set part along the circumferential direction, and the length of the winding coil is arranged and printed in parallel along the radial direction without overlapping; the same phase of winding coils on the PCB layers are connected via the outer and inner end portions; the Hall sensor is arranged in the outer end portions with an angle; and the layers in the PCB are connected via through holes.

Owner:上海崴崖实业有限公司

A Hybrid Excitation Flux Switching Motor

ActiveCN105553128BImprove power densityIncrease electromagnetic loadMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical polarityThree-phase

The invention discloses a hybrid excitation flux switching motor. The motor comprises an outer stator, a rotor and an inner stator. The rotor coaxially sheaths outside the inner stator. The outer stator coaxially sheaths outside the rotor. The outer stator comprises an outer stator iron core, permanent magnets and a three-phase armature winding. A three-phase alternating current excitation winding sheaths on convex pole teeth of an inner stator iron core. The quantity of the convex pole teeth of the inner stator iron core is equal to the quantity of the permanent magnets. The radial central axes of the convex pole teeth of the inner stator iron core and the radial central axes of the permanent magnets coincide. In the prior art, the excitation winding is placed by reducing the volume of the permanent magnet or reducing the number of turns of the armature winding. Through adoption of the hybrid excitation flux switching motor, the problem in the prior art is solved, the electromagnetic load of the motor is increased, a symmetrical three-phase alternating current with adjustable amplitude accessed to the inner stator excitation winding can generate a rotating magnetic field with adjustable amplitude and polarity, and the rotating magnetic field and an effective air gap magnetic field in a permanent magnetic field are overlaid, so that effective harmonic component in the permanent magnetic field is enhanced or weakened, so as to realize magnetic shunt operation.

Owner:JIANGSU UNIV

Etched-facet ridge lasers with etch-stop

ActiveUS7606277B2High uniformity and yieldIncrease productionOptical wave guidanceSemiconductor/solid-state device manufacturingDry etchingLaser

A photonic device incorporate an epitaxial structure having an active region, and which includes a wet etch stop layer above, but close to, the active region. An etched-facet ridge laser is fabricated on the epitaxial structure by dry etching followed by wet etching. The dry etch is designed to stop before reading the depth needed to form the ridge. The wet etch completes the formation of the ridge and stops at the wet etch stop layer.

Owner:MACOM TECH SOLUTIONS HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com