Bearingless permanent magnet sheet motor

A bearingless, thin-film technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of large volume and insufficient axial rigidity, and achieve the effect of high system power, compact mechanical structure, and solving operation drawbacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

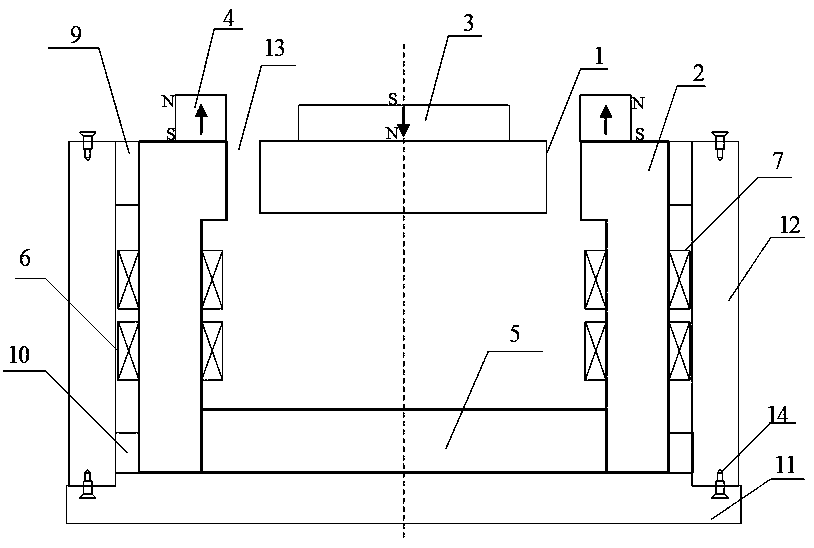

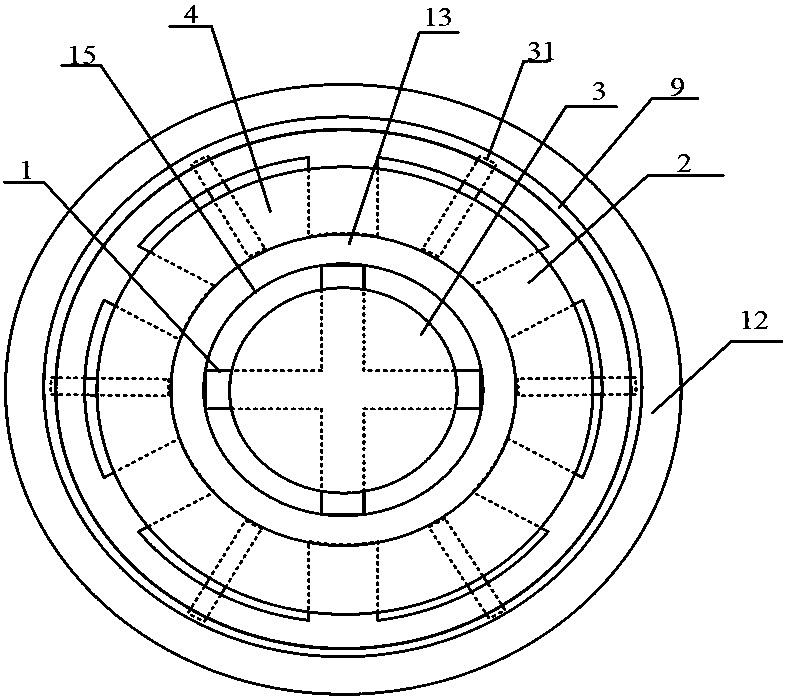

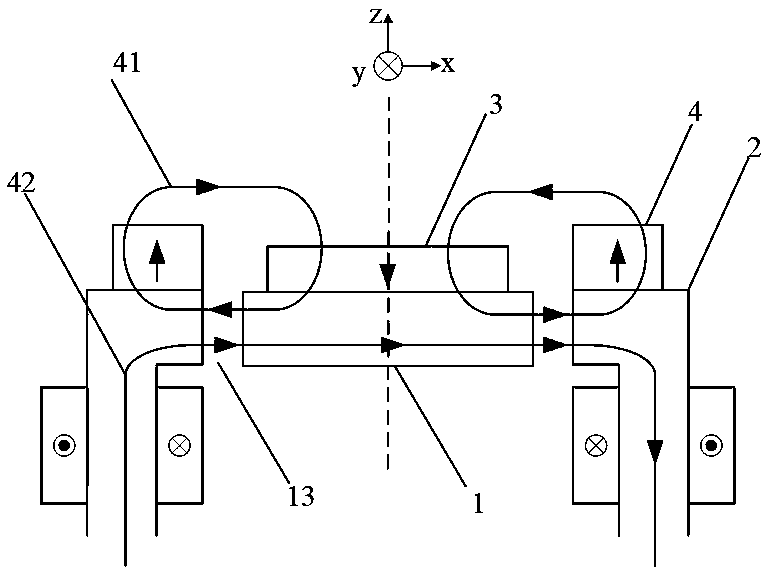

[0016] see figure 1 and figure 2 , in the axial direction, the axial bottom of the motor is a steel chassis 11, and the top surface of the steel chassis 11 is fixedly connected with an iron core yoke 5 in the middle, and the two are on the same axis line. A cross-shaped thin-plate rotor 1 and a rotor permanent magnet 3 are coaxially arranged directly above the core yoke 5 , and the rotor permanent magnet 3 is in the shape of a round pie, coaxially and fixedly connected to the top surface of the cross-shaped thin-plate rotor 1 . The outer diameter of the rotor permanent magnet 3 is smaller than that of the cross-shaped sheet rotor 1, and the two form a whole. The rotor permanent magnet 3 is axially magnetized, and the bottom end close to the cross-shaped sheet rotor 1 is an N pole, and the top end is an S pole.

[0017] The radial section of the cross-shaped thin-plate rotor 1 is cross-shaped and has a 4-pole salient-pole structure. An annular aluminum alloy ring 15 is tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com