Patents

Literature

76 results about "Winding factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In power engineering, winding factor is a technique that is employed to improve the rms generated voltage or electromotive force (EMF) in a three-phase AC electrical machine so that the output voltage and hence torque does not have any harmonics in it which may reduce efficiency. This is because the armature winding of each phase is distributed in a number of slots. Since the EMF induced in different slots are not in phase, their phasor sum is less than their numerical sum. This reduction factor is called distribution factor Kd. Another factor that can reduce the winding factor is when the slot pitch is smaller than the pole pitch, called pitch factor Kₚ.

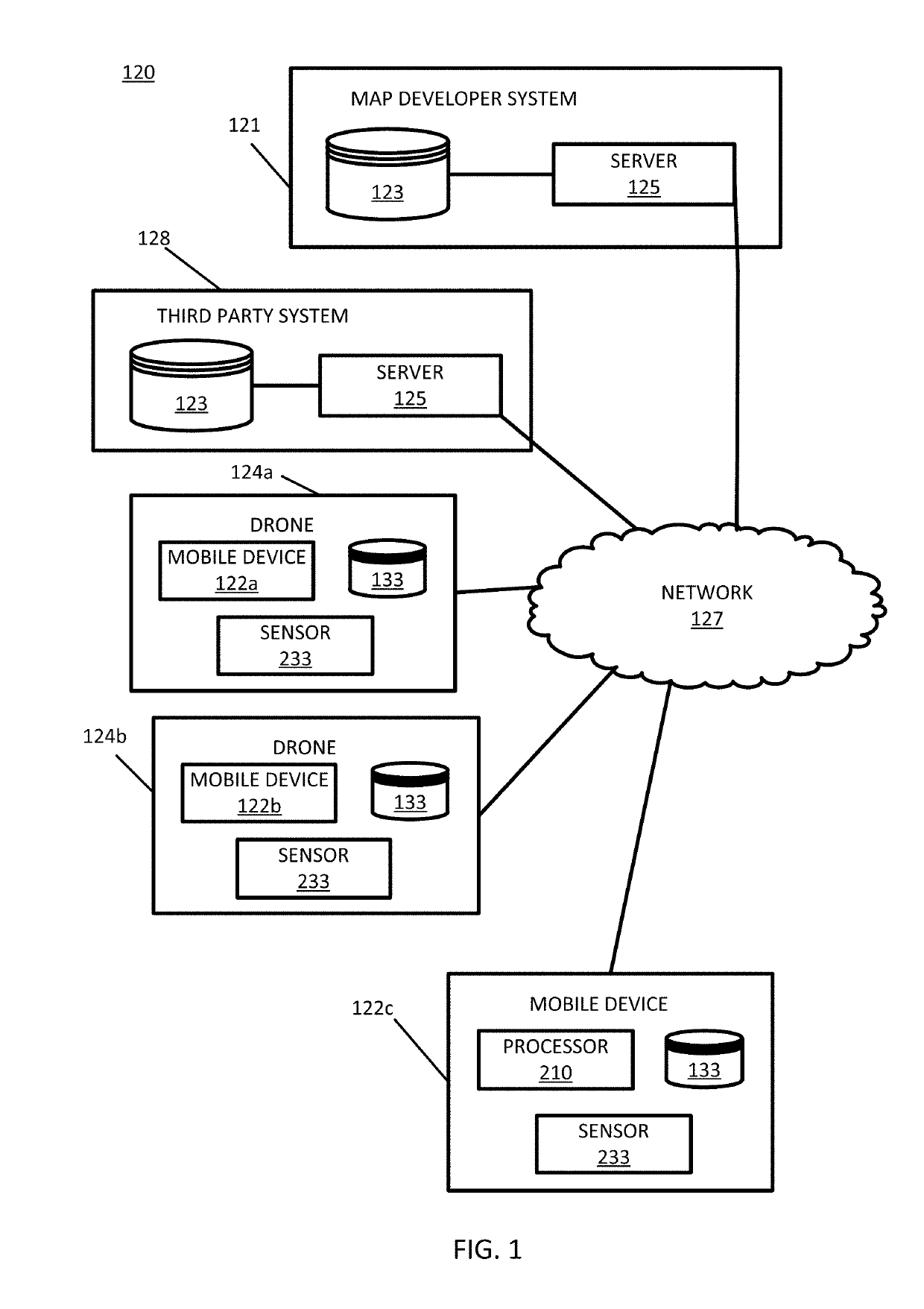

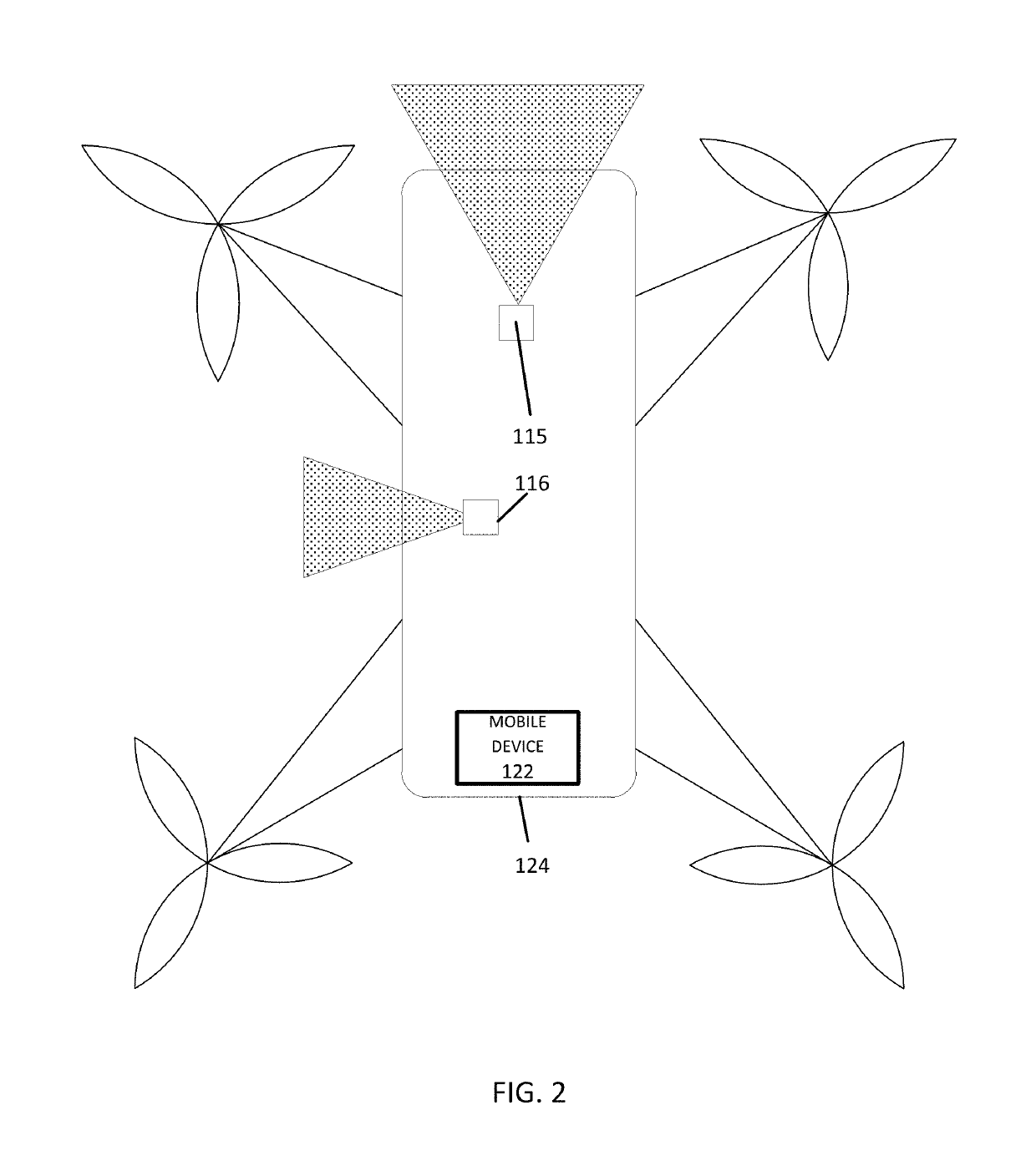

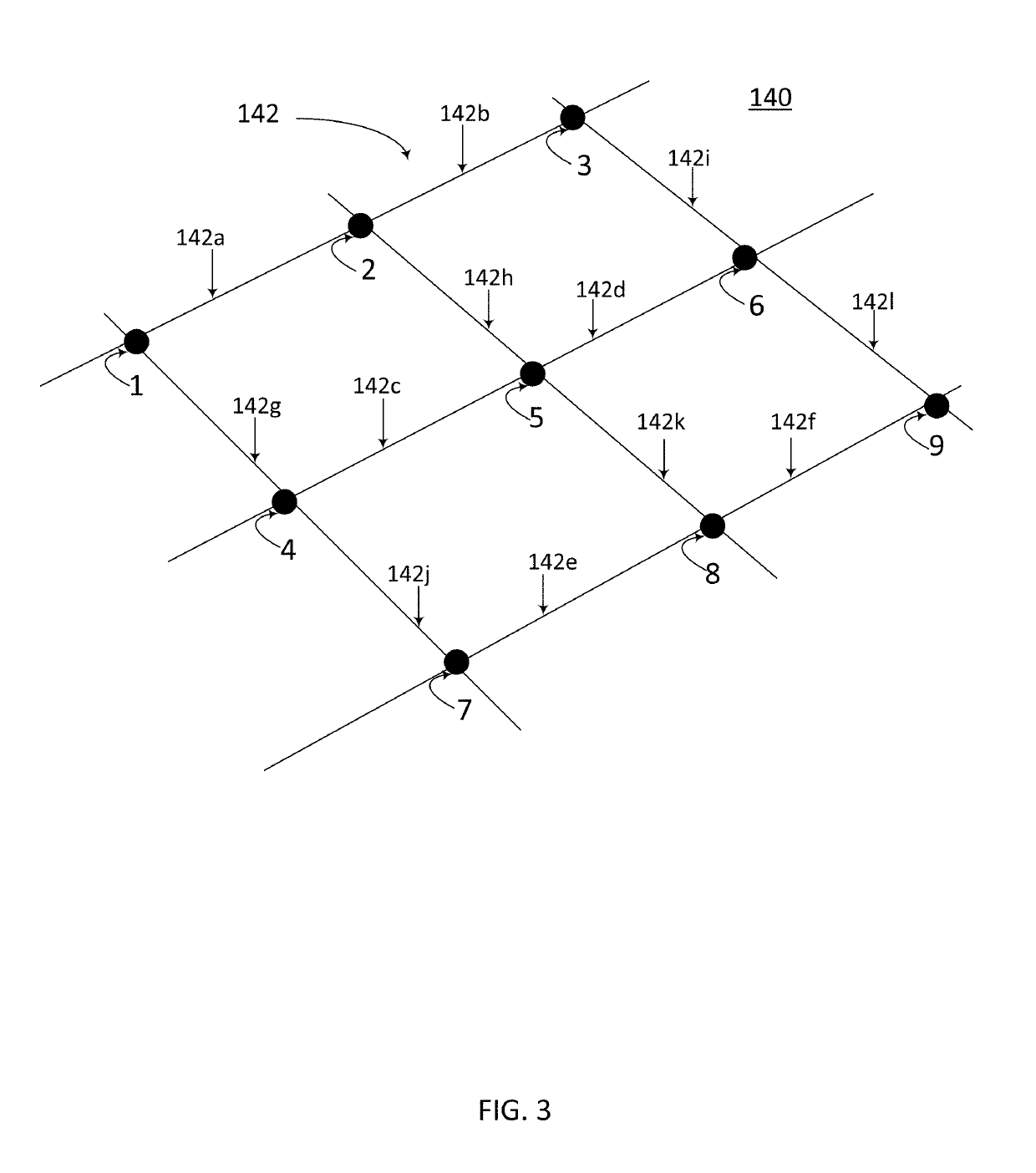

Link level wind factor computation for efficient drone routing using 3D city map data

ActiveUS20190101934A1Instruments for road network navigationNavigational calculation instrumentsPosition dependentRoad networks

Embodiments include apparatus and methods for determining link level wind factors and providing routes for drones based on the wind factors. At least a portion of the route corresponds to airspace above a road network. Wind factor values are assigned to a range of altitudes of drone air space above a road link of the road network based on a wind model and stored in a database. The wind model is applied to a location based on wind condition data and three-dimensional (3D) features from 3D map data associated with the location. The route is optimized based on the determined wind factors.

Owner:HERE GLOBAL BV

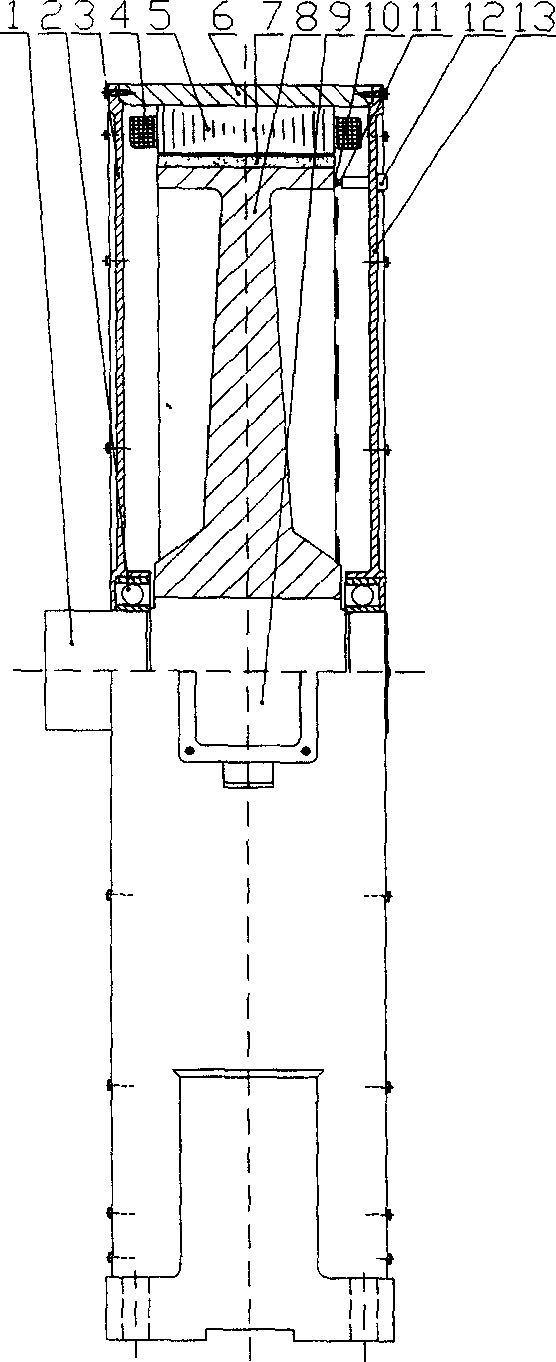

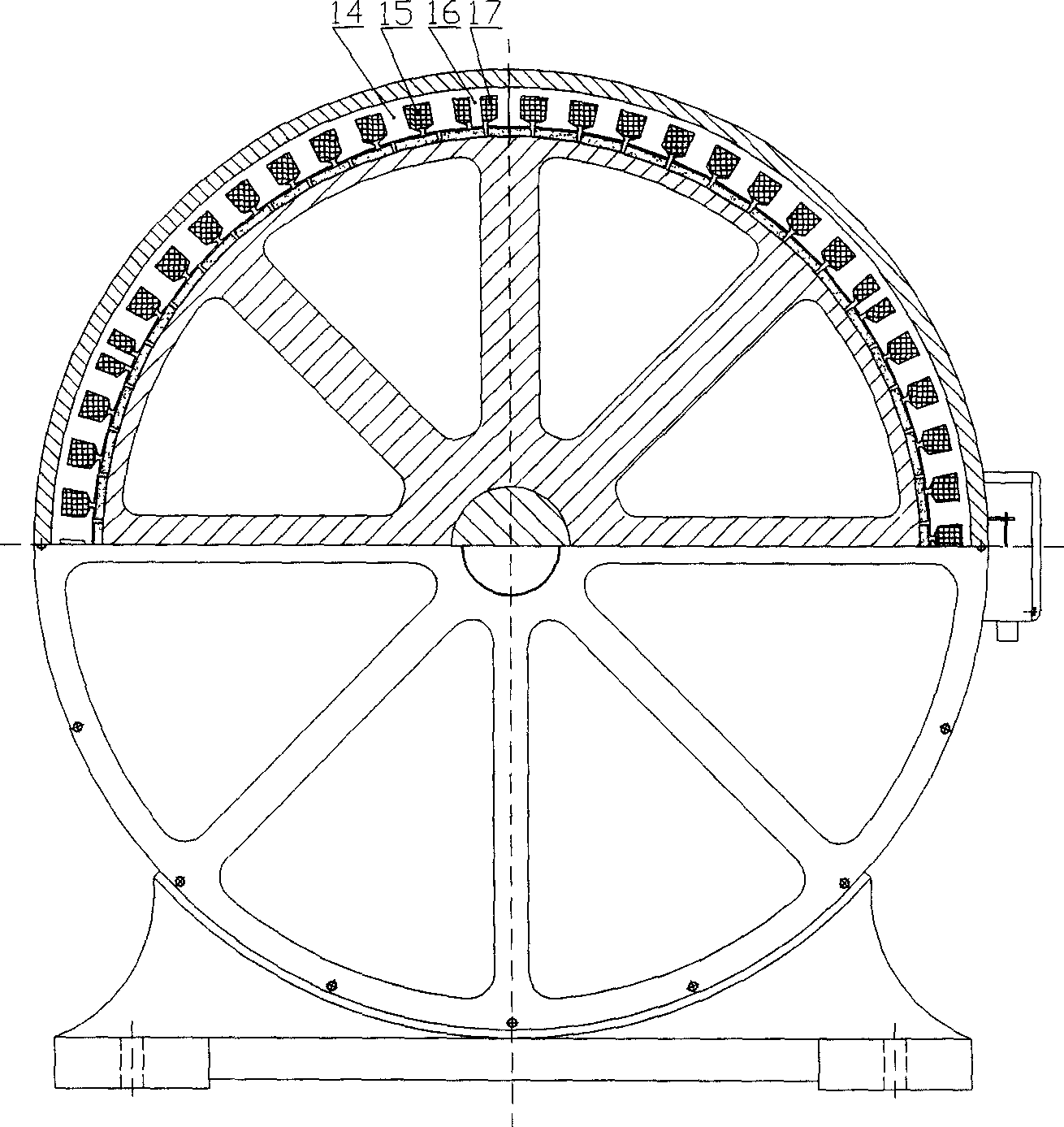

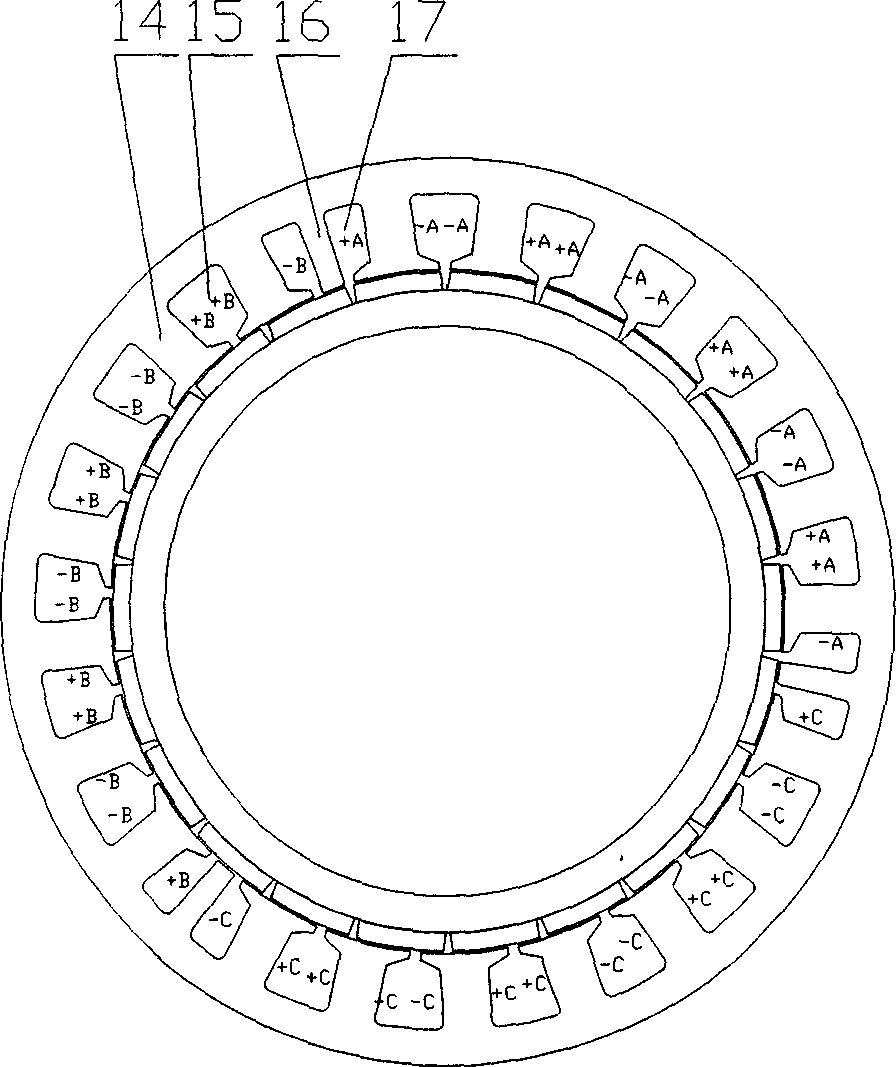

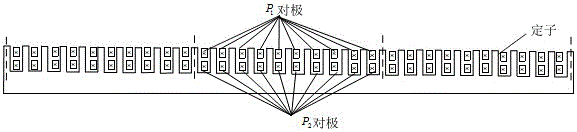

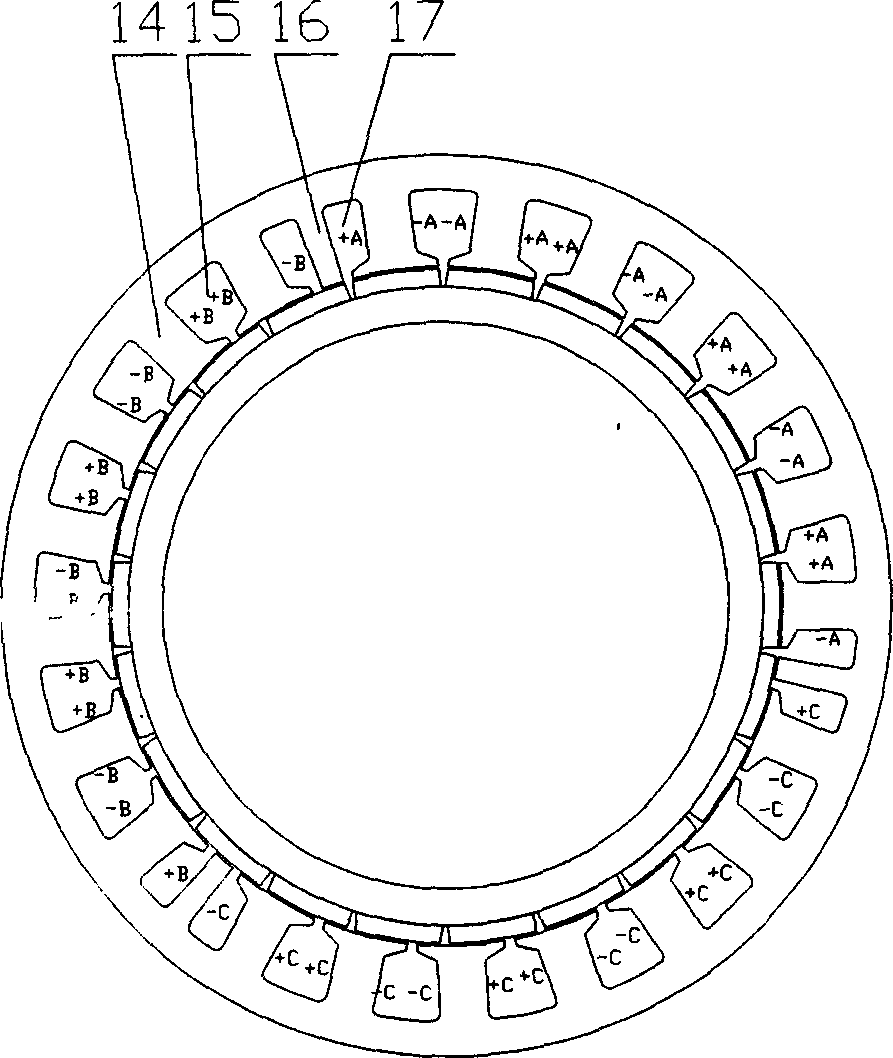

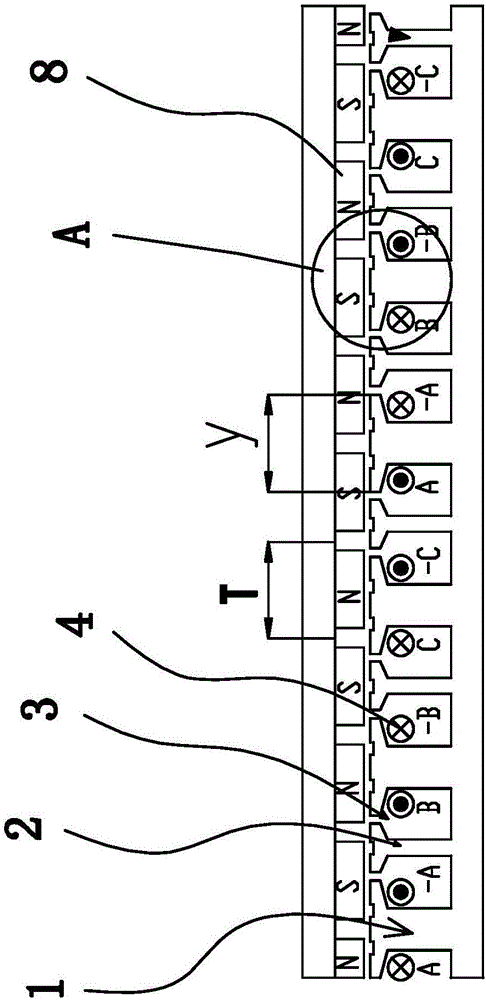

Modularized stator structure low-speed DC brushless motor

InactiveCN1862928AImprove efficiencySimple winding processMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsLow speed

The invention discloses the blocking stator structure low speed direct current brushless motor. It divides evenly the inner diameter circle of the stator iron core into the K1 fan section group, the A, B, C three phases of each fan section group accounts for the same superficial one fan section respectively, the stator iron core of each fan section are mounted with K2 canine tooth, the tooth distance between the border canine tooth is one polar distance, the stator iron core between the said border two fan sections are mounted with one the small slot respectively, one small tooth is mounted between the said two small slots, the settling distance collecting loop are coiled on each canine tooth, the poles of the electric machine of the invention can be designed largely, the ends of the electric machine stator winding don't fold each other, the ends are shorter, the winding modulus is one, the process of the coiling is easy, and the stator iron core of the electric machine can depress the permanent magnet guiding humorous wave torque availably without the flume, the efficiency of the electric machine is high.

Owner:TIANJIN UNIV

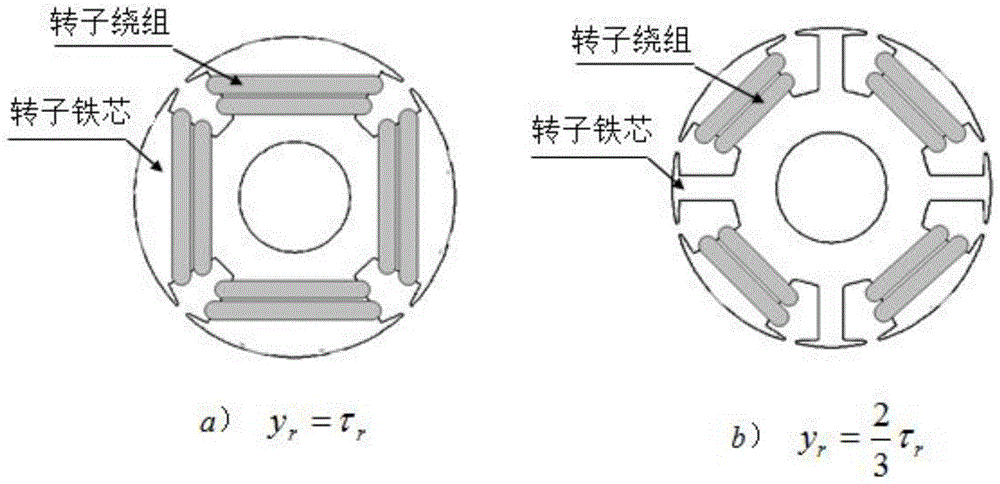

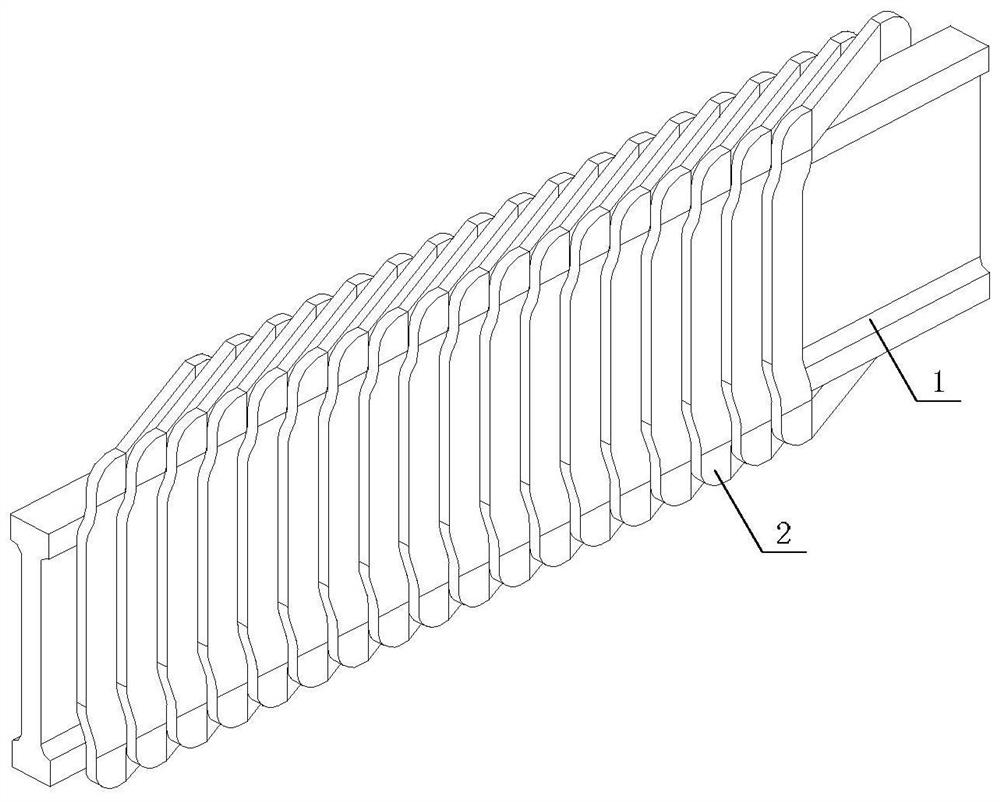

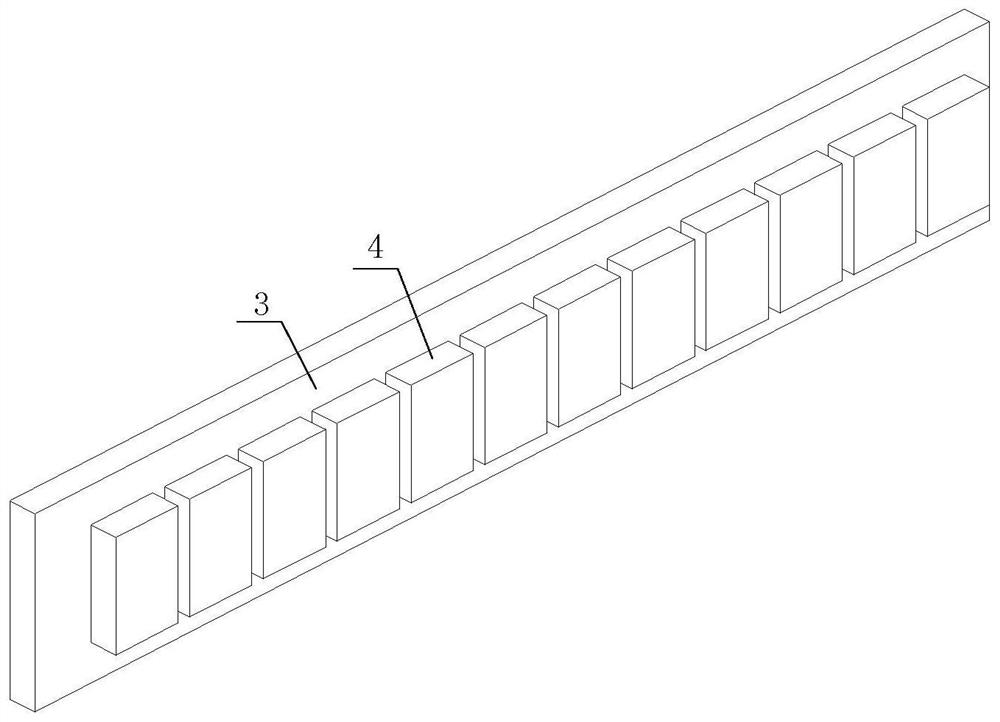

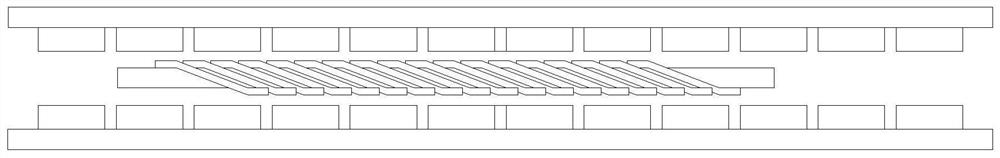

Winding-type linear brushless doubly-fed generator

ActiveCN104993629AImprove power densityLow failure rateWindings conductor shape/form/constructionFailure rateEngineering

The invention discloses a winding-type linear brushless doubly-fed generator, and proposes a unit motor according to a unit motor concept, wherein the total number of pole-pairs of a stator power winding and a control winding of the unit motor is N times. Meanwhile, a rotor winding employs a mode of symmetric distribution like a sine rule according to the principle of tooth harmonic, thereby reducing coils of different phases of a power winding P1 and a control winding P2. The rotor winding can achieve the coupling of a control winding and another winding well, and the air-gap magnetic density harmonic is lower. The generator can enable a magnetic field with a lower moving speed to be modulated into a high-speed magnetic field, and effectively improves the power density. The control winding is placed at a stator side, and a sliding ring and a brush are removed. The generator is low in motor failure rate, is long in service life, eliminates the higher harmonic of a magnetomotive force of a rotor to the maximum degree through the adjustment of the span and turns of a rotor coil, achieves the higher winding coefficients of the pole pairs of power windings P1 and P2, and achieves the high efficiency and energy saving.

Owner:黄山市开发投资集团有限公司

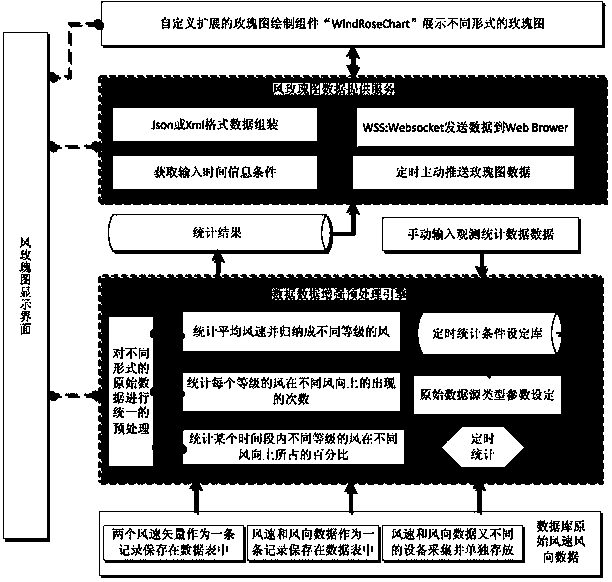

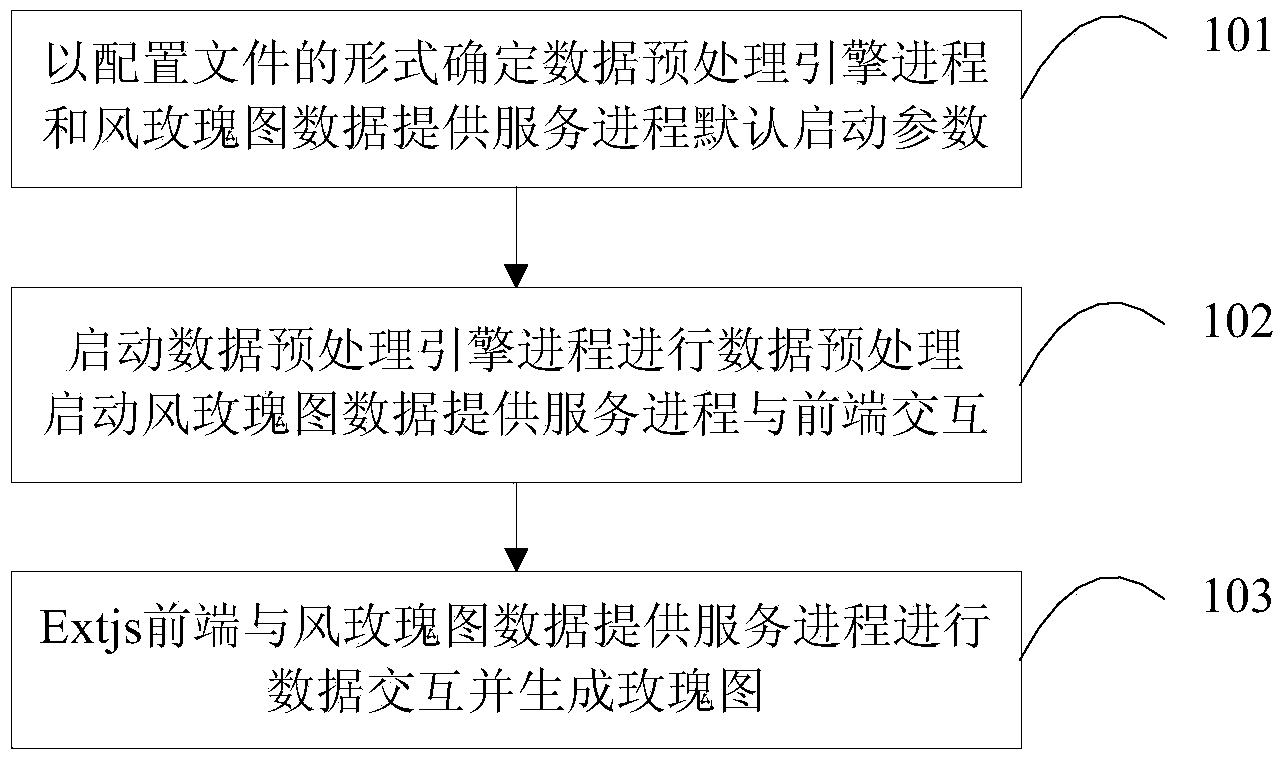

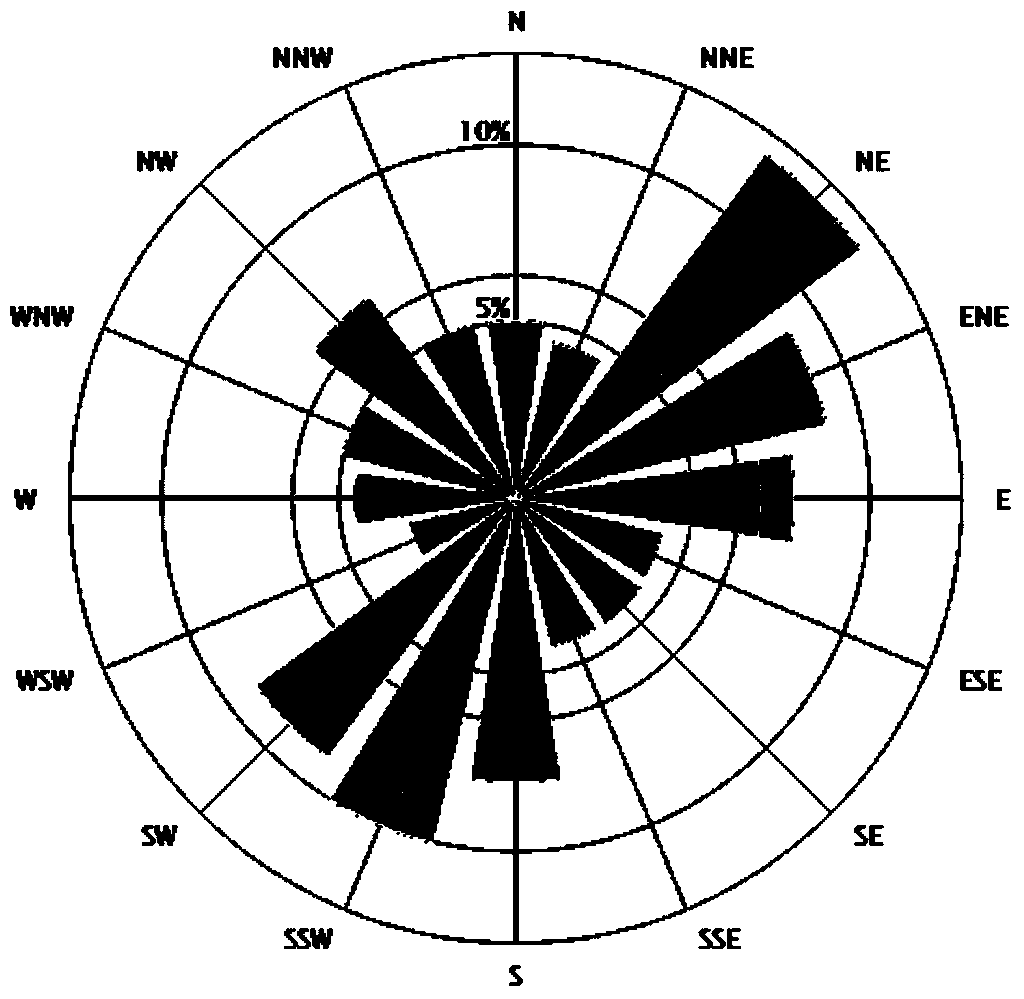

Method for drawing wind-rose chart based on ExtJs

ActiveCN103714209AEasy to transplantEasy accessSpecial data processing applicationsData setChart datum

The invention provides a method for drawing a wind-rose chart based on the ExtJx. The method comprises the steps that original wind factor data of different modes are processed in a unified mode and stored in a database through a data enhancing preprocessing engine process; data analysis and assembly are conducted on wind-rose chart data obtained from the database by a wind-rose chart data service providing process according to a timing condition and wind-rose statistical data are provided for a front platform; different display modes of the wind-rose chart are configured by a rose chart drawing assembly 'Wind Rose Chart', the display modes are configured to a Panel assembly of the ExtJs and are bound with a data set of the wind-rose chart; after an ExtJs event mechanism asynchronously judges that the data arrive, the rose chart is updated. The method is convenient to deploy and capable of rapidly and accurately conducting rendering at the front end and updating the wind-rose chart in time and providing full support for development of the rose chart at the front end of a Web information system, and can be conveniently and rapidly connected to the Web information system needing rose chart drawing.

Owner:GUODIAN NANJING AUTOMATION

Method for researching influence of micro-landform strong wind area on safety operation of electric transmission line

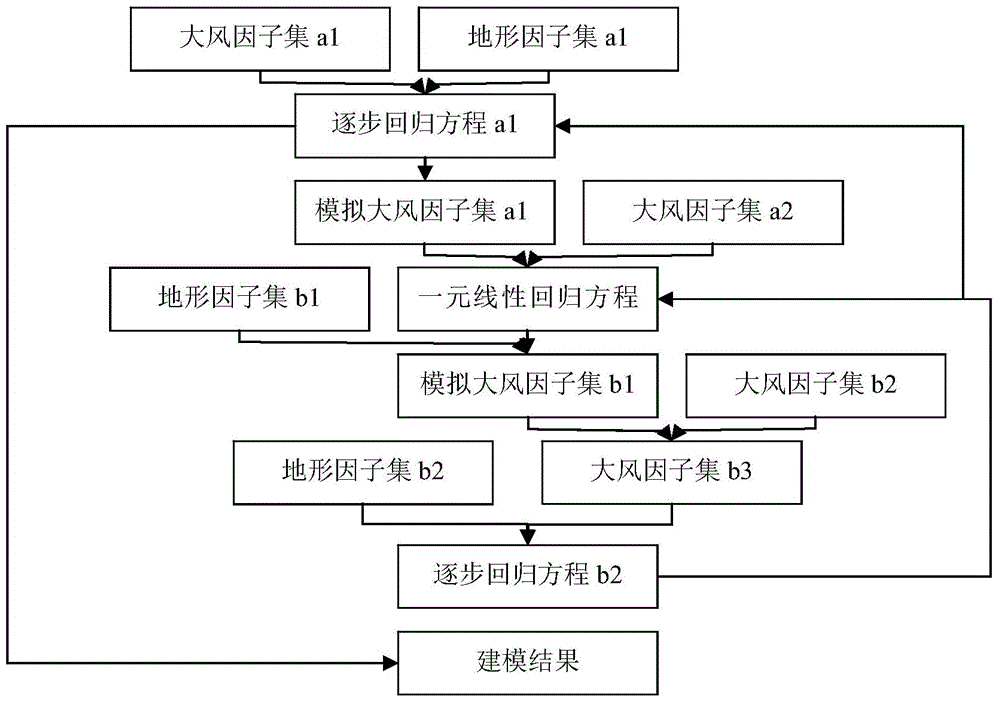

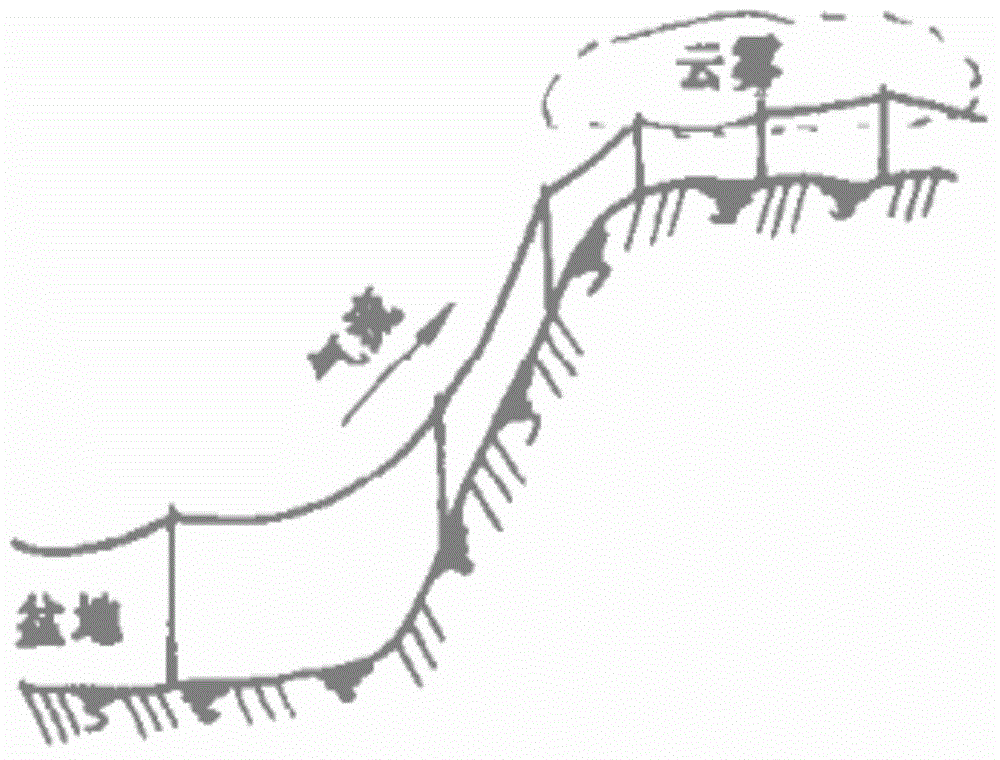

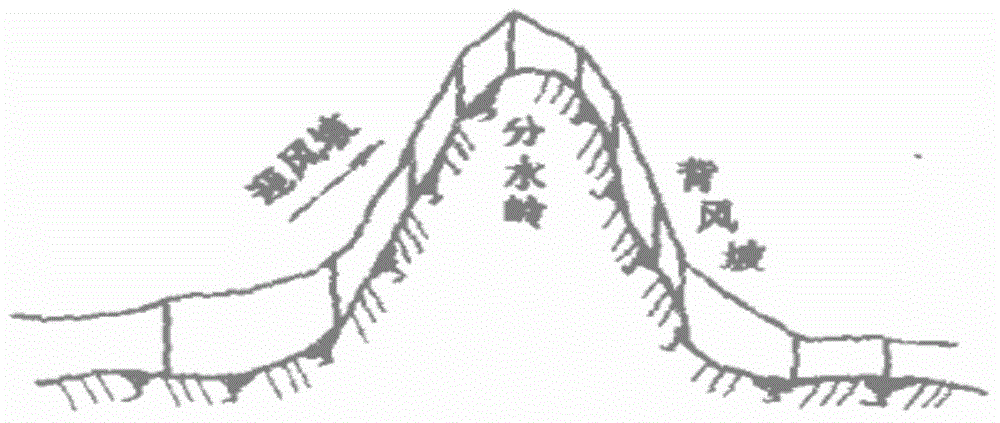

The invention discloses a method for researching the influence of a micro-landform strong wind area on the safety operation of an electric transmission line. The method for researching the influence of the micro-landform strong wind area on the safety operation of the electric transmission line comprises the steps that (1) a stepwise regression equation a1 is established based on a strong wind factor set a1 and a landform factor set a1; (2) the landform factor set a1 is substituted into the stepwise regression equation a1, so that a simulation strong wind factor set a1 is obtained; (3) based on the linear relationship between the simulation strong wind factor set a1 and a strong wind factor set a2, a unary linear regression equation a2 is established; (4) a landform factor set b1 is substituted into the unary linear regression a2 so that a simulation strong wind factor set b1 is obtained; (5) according to the difference value set between the simulation strong wind factor set b1 and a strong wind factor set b2, a strong wind factor set b3 is obtained; (6) based on the strong wind factor set b3 and a landform factor set b2, a stepwise regression equation b2 is established; (7) a modeling result is obtained, wherein the stepwise regression equation b2 and the unary linear regression equation a2 are back substituted into the stepwise regression equation a1, and then the final modeling result is obtained.

Owner:STATE GRID CORP OF CHINA +1

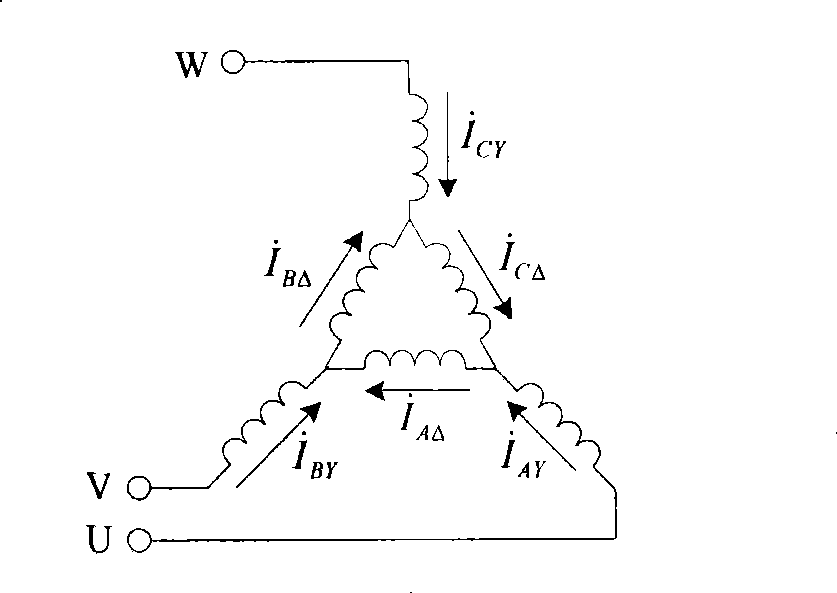

Method for modifying double layer winded performing winding into Y-Delta mixed performed winding

ActiveCN101364751AManufacturing dynamo-electric machinesWindings conductor shape/form/constructionWire gaugeElectrical conductor

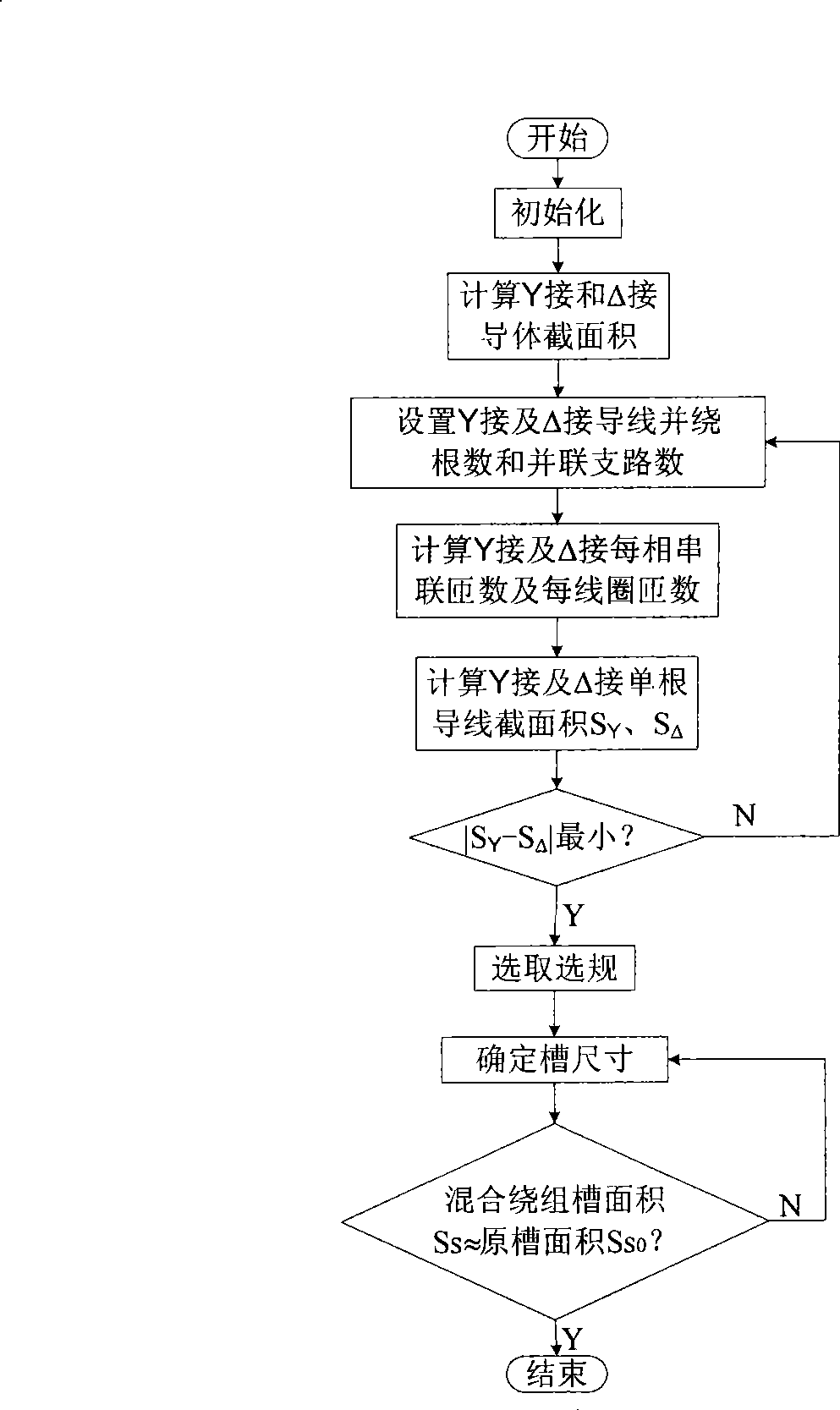

The invention relates to a method for changing a double-layer lap-winding winding to Y-delt connection mixed winding. The method is characterized in that the method comprises the steps of calculating the section areas of a Y-connection winding conductor and a delt-connection winging conductor, and determining the number of branches connected with each other in parallel, the number of turns of the coil and the width and the thickness of a wire on the basis of the prior double-layer lap-winding windings. In consideration of the manufacture cost of the motor, other parameters and the size of the motor are kept original values when changing to the Y-delt connection mixed winding, but the size of a stator groove needs to be adjusted correspondingly according to the wire gauge and the number of turns of the coil without changing the groove area. The winding has improved winding coefficient and can weaken harmonic waves with higher harmonic contents such as the fifth and the seventh harmonic waves, thereby increasing the wire gauge, reducing the number of turns, lowering the motor loss, and improving the motor efficiency and the power coefficient. Additionally, the Y-connection and delt-connection coils are arranged in a non-alternate manner so as to reduce the process difficulty. The method suits the alteration of common double-layer lap-winding winding of high-voltage large and medium asynchronous motor with a power lower than 2,000 kW.

Owner:TSINGHUA UNIV +1

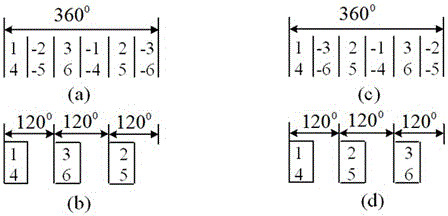

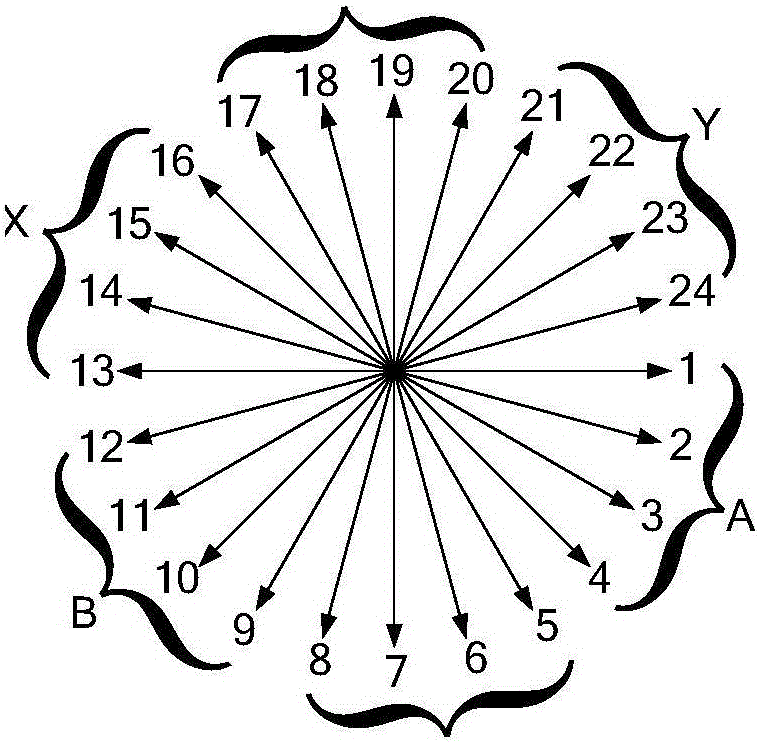

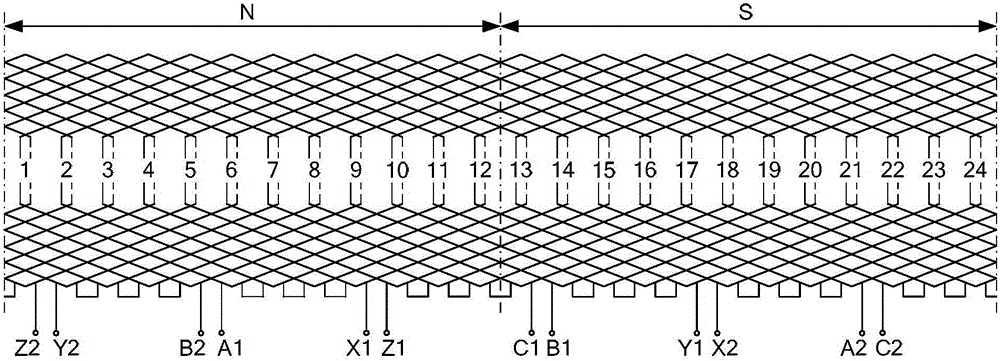

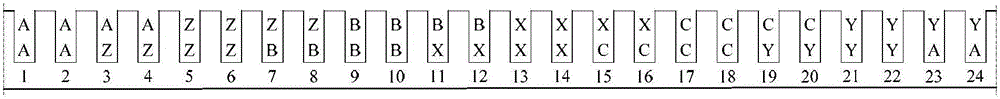

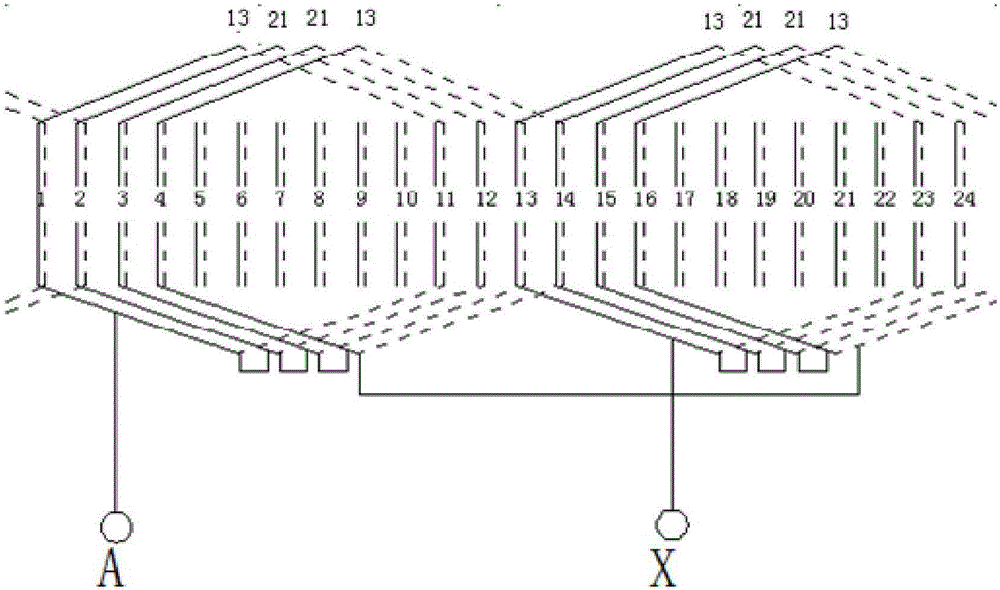

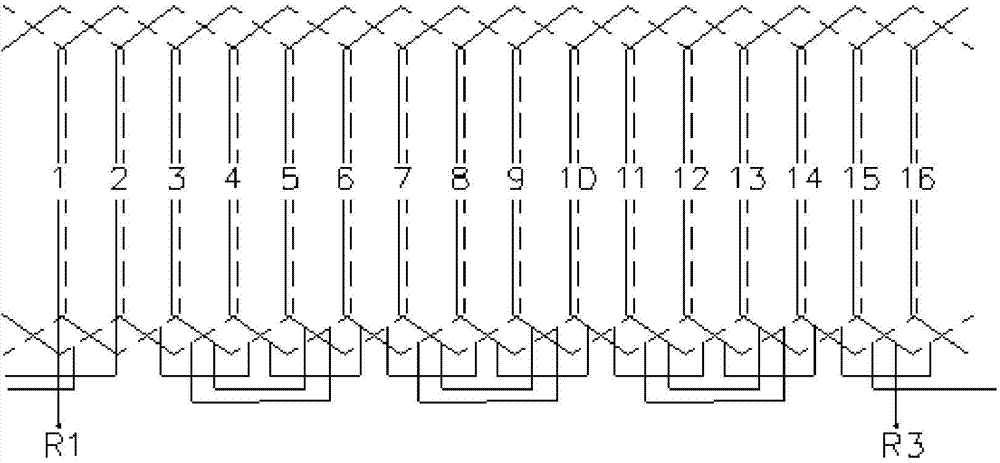

Single/double-layer stator winding for 24-slot 2-pole three-phase alternating current motor

ActiveCN105978202AReduce copper consumptionSave copper wireWindings conductor shape/form/constructionCurrent meterMagnetomotive force

The invention relates to a single / double-layer stator winding for a 24-slot 2-pole three-phase alternating current motor. The single / double-layer stator winding is evolved from a three-phase dual-layer short-distance distribution lap winding in which equal spans among 24-slot 2-pole coils are 10 slots; four coils are arranged in each phase of positive and negative phase belts; in each phase of positive and negative phase belts, upper and lower coil edges of coils in adjacent two slots belong to the phase; the upper coil edge of the coil in a small-number slot in the adjacent two slots is moved into a large-number slot, and the end part length is reduced; the lower coil edge of the coil in the large-number slot is moved into the small-number slot, and the end part length is reduced; the spans among the four coils of which the coil edges are moved in each phase are 9 slots; and the coils of which the four coil edges are moved and the four coils of which the coil edges are not moved construct four groups of coil groups consisting of two inner concentric-like coils and two outer concentric-like coils. Under the situation of not changing an electrodynamic force winding coefficient or a magnetomotive force winding efficient, an end-part copper wire is short; the loss is low; and the efficiency is high. When the total number of turns is constant, the number of turns of the coils which are 10 slots in spans is properly larger than the number of turns of the coils which are 9 slots in spans, and the motor performance can be further improved.

Owner:安徽登冠新能源电动车科技有限公司

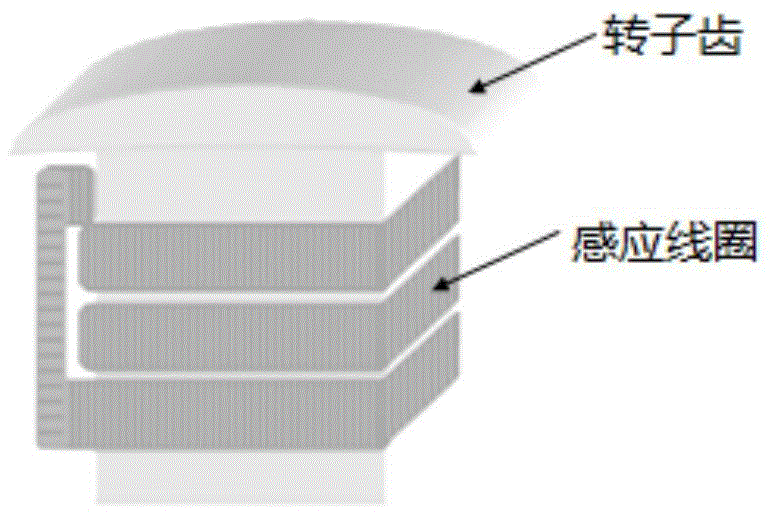

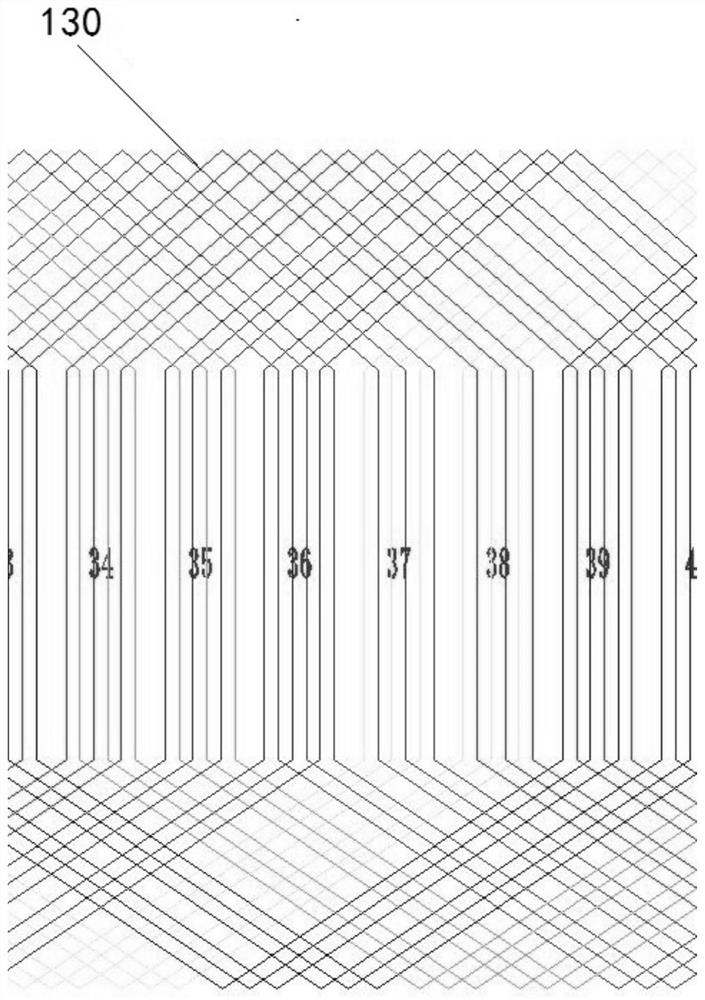

Alternating current brushless double-fed motor and design method for tooth harmonic coil-wound rotor distributed winding therefor

InactiveCN105680653AIncrease profitReduce harmonic contentAsynchronous induction motorsManufacturing dynamo-electric machinesElectrical conductorHarmonic

The invention discloses an alternating current brushless double-fed motor and a design method for a tooth harmonic coil-wound rotor distributed winding therefor. The design method comprises the steps that the number Zr of rotor toothed slots and the phase number mr are preliminarily determined according to stator winding pole pair numbers p1 and p2, wherein Zr is equal to mr at the current moment; each tooth is corresponding to a concentrated coil, so that a tooth harmonic concentrated type winding is obtained; then the number of rotor slots is increased, a coefficient kr is chosen to enable a new number of rotor slots Z to be equal to krZr, wherein the polar distance at the current moment tau r is equal to kr; on the basis, one concentrated coil in each phase is split into nr coils with the equipment pitch of yr, wherein nr is less than or equal to kr, and yr is less than tau r; the nr coils are distributed in the rotor slots in sequence at interval of alpha r slot pitch angle; then the kr, nr and yr are adjusted to enable the winding coefficient of the pole pair numbers p1 and p2 to be as high as possible, and the harmonic content is low; and finally, the winding coils in each phase are wound by adopting a multi-plane concentric type winding method to obtain coils with different pitches and different sizes and with overlaid central lines, and then the obtained coils are put in the rotor slots, connected in series and then linked in a short-circuited manner to obtain the distributed tooth harmonic rotor winding. The distributed tooth harmonic rotor winding has the characteristics of low harmonic content, high conductor utilization ratio and tidy winding end part arrangement.

Owner:HUAZHONG UNIV OF SCI & TECH +1

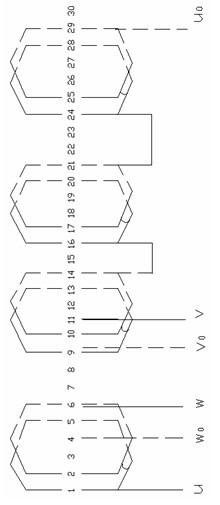

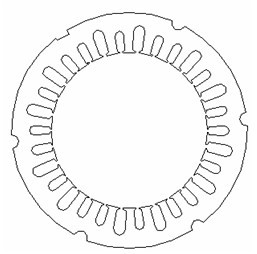

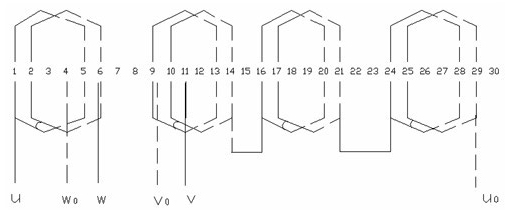

Fractional slot single and double-layer lap winding for servo permanent magnet synchronous motor

ActiveCN101986513AGood sinusoidal magnetic potentialReduce widthWindings conductor shape/form/constructionPunchingPermanent magnet synchronous motor

The invention relates to a fractional slot single and double-layer lap winding structure of a servo permanent magnet synchronous motor, which is characterized in that a stator slot comprises 30 slots, 8 poles and 3 phases, wherein the number of slots of per pole per phase is 5 / 4; the stator winding is designed into a single and double-layer lap winding; each phase comprises 8 coils, the pitch of each coil is 4, wherein the number of turns of each of 4 coils is n; the number of turns of the rest 4 coils is 2n; the ratio of numbers of turns of the two types of coils is 1:2; all opening coils of the 8 coils are connected in series, and the 3 phases are symmetrically distributed to form the single and double layer lap winding; 10 slots of the 30 slots are single lap windings, the rest 20 slots are double-layer lap windings, the 30 slots of a stator punching corresponding to the stator slots are composed of two types of slots, wherein the number of larger slots is 12 and the number of small slots is 18. Compared with the traditional lap winding, the fundamental wave winding coefficient of the special fractional slot single and double layer lap winding is improved by 0.75%, while the magnetic potential harmonic wave is reduced by 60.3%; and the inserting winding process for coil manufacturing is totally the same as that of the traditional lap winding, thereby reducing the vibration, noise and temperature rising of a motor traditionally designed and improving the efficiency and the torque.

Owner:TELLHOW SCI TECH CO LTD

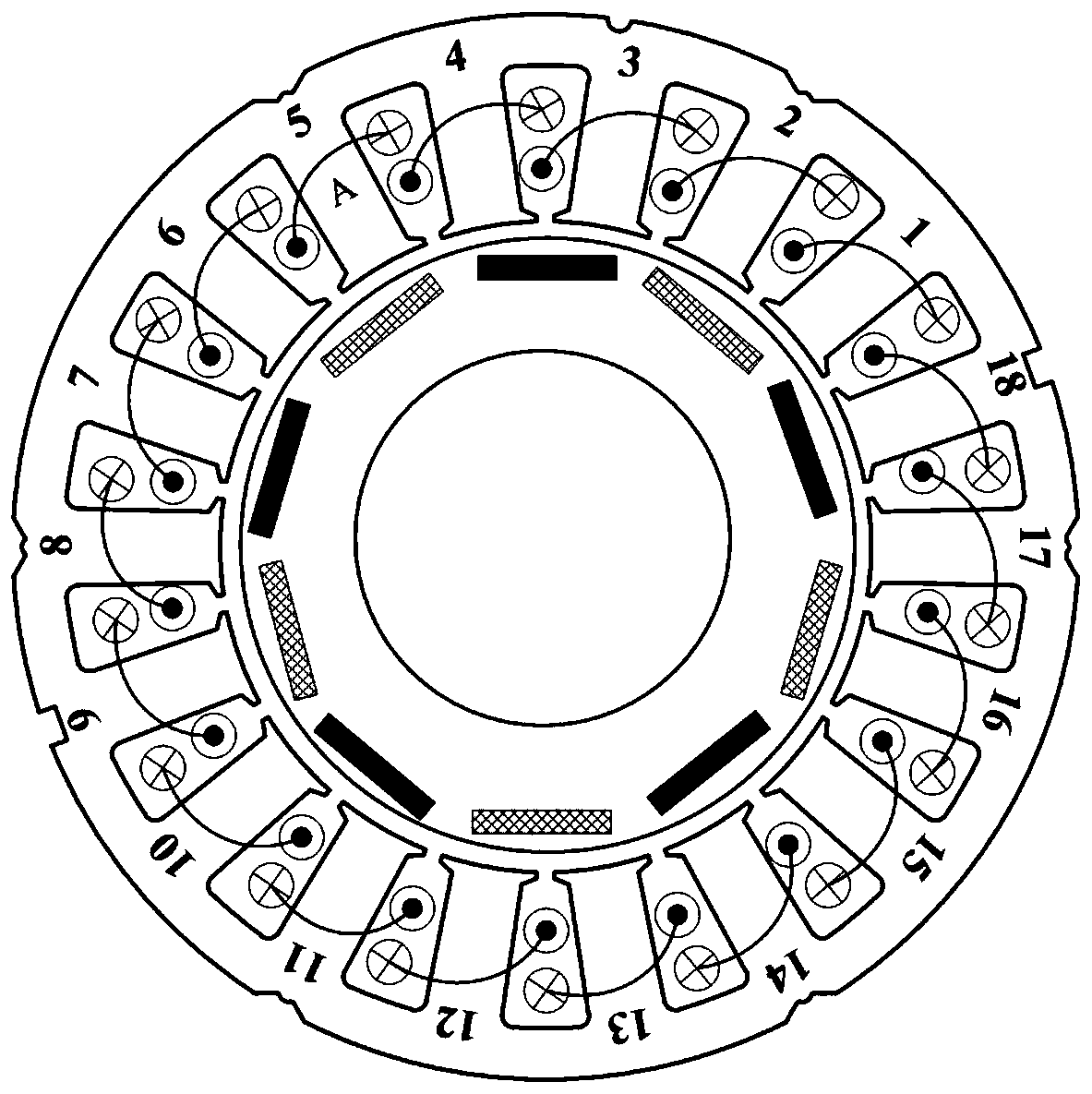

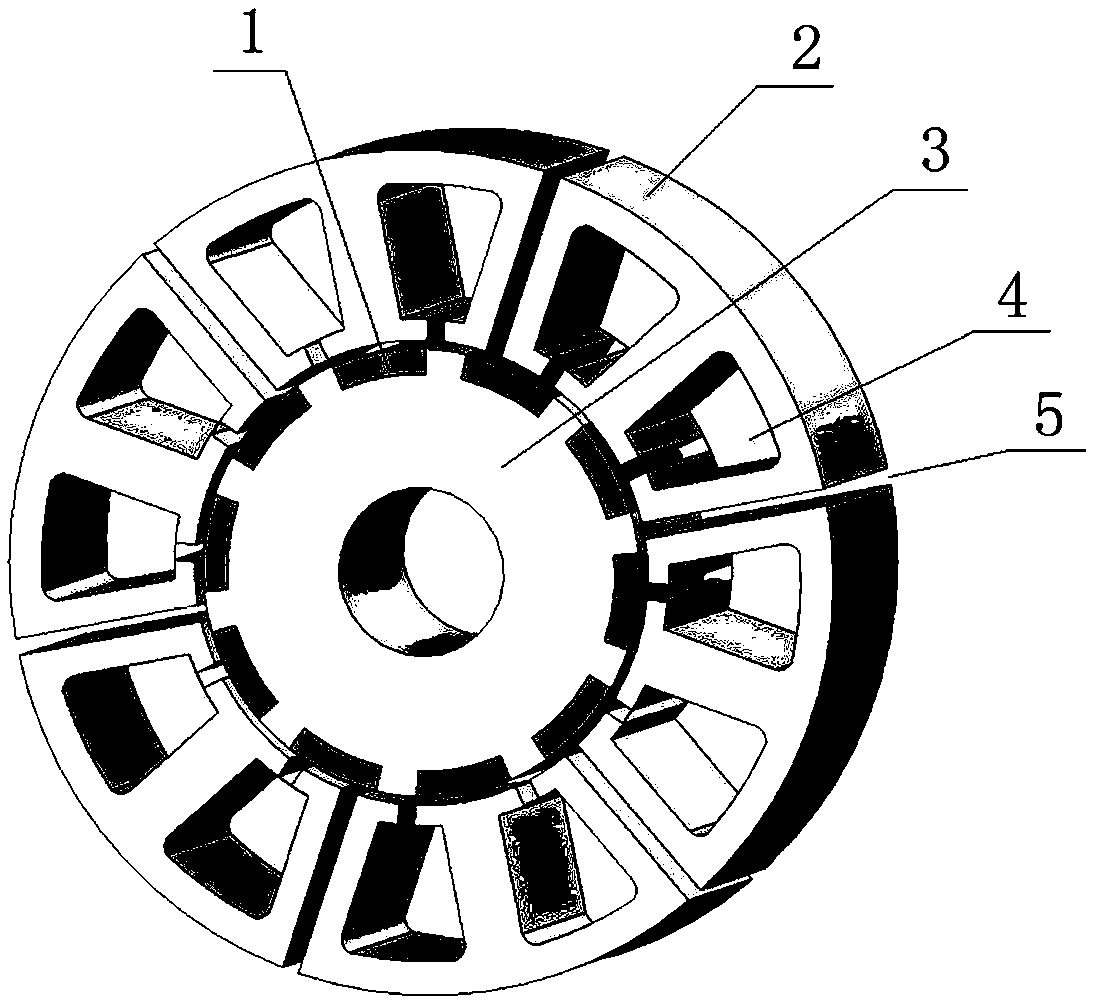

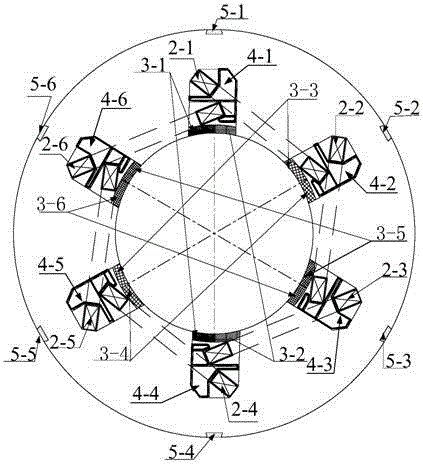

18N-10N structure low-noise fractional slot concentrated winding permanent magnet motor

InactiveCN109888941AReduce vibrationReduce noiseMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseMagnetomotive force

The invention discloses a 18N-10N structure low-noise fractional slot concentrated winding permanent magnet motor. 18N stator teeth are uniformly distributed on a stator; a rotor has 10N poles, the stator teeth are wound with concentrated winding wire packages, and each three adjacent concentrated winding wire packages form one phase so as to form 2N groups of three-phase winding systems. In a fixed three-phase winding, in three adjacent concentrated winding wire packages of one phase, the middle one is A1, and two concentrated winding wire packages at both sides are reversely connected in series to form A2; and the other two phases are also defined to respectively obtain B1, B2, C1 and C2; after A2, B2 and C2 are connected into a triangle shape, a connection point of A2 and B2 is connected into C1, a connection point of B2 and C2 is connected into A1, and a connection point of C2 and A2 is connected into B1. According to the invention, not only is a winding factor guaranteed not to bechanged, but also content of tooth harmonic waves in a winding magnetomotive force in an air gap is reduced, so that vibration and noise of the motor and eddy current loss are reduced; and moreover,a reluctance torque under a magnetic field saturated working condition is improved.

Owner:江苏迈吉易威电动科技有限公司

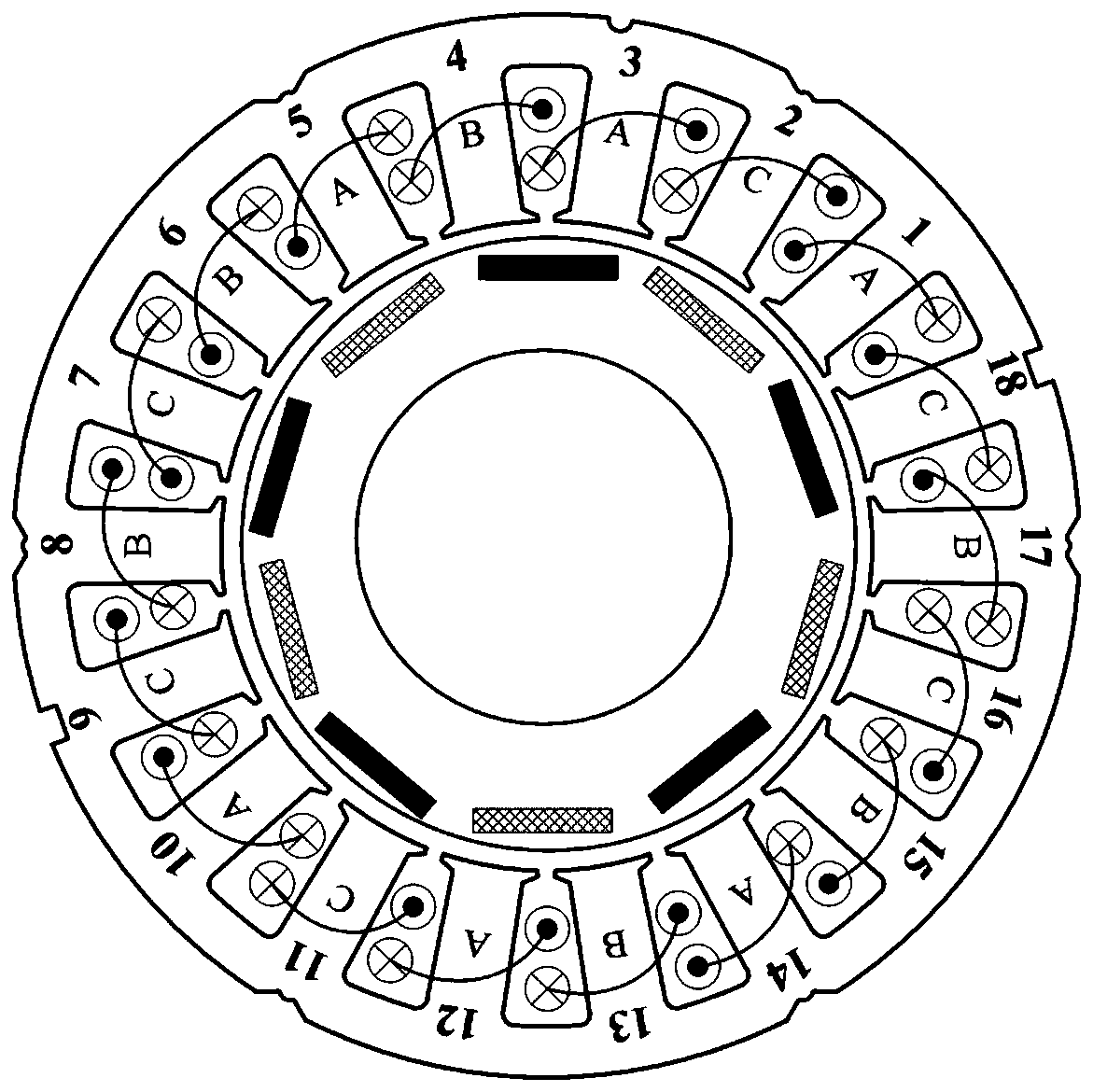

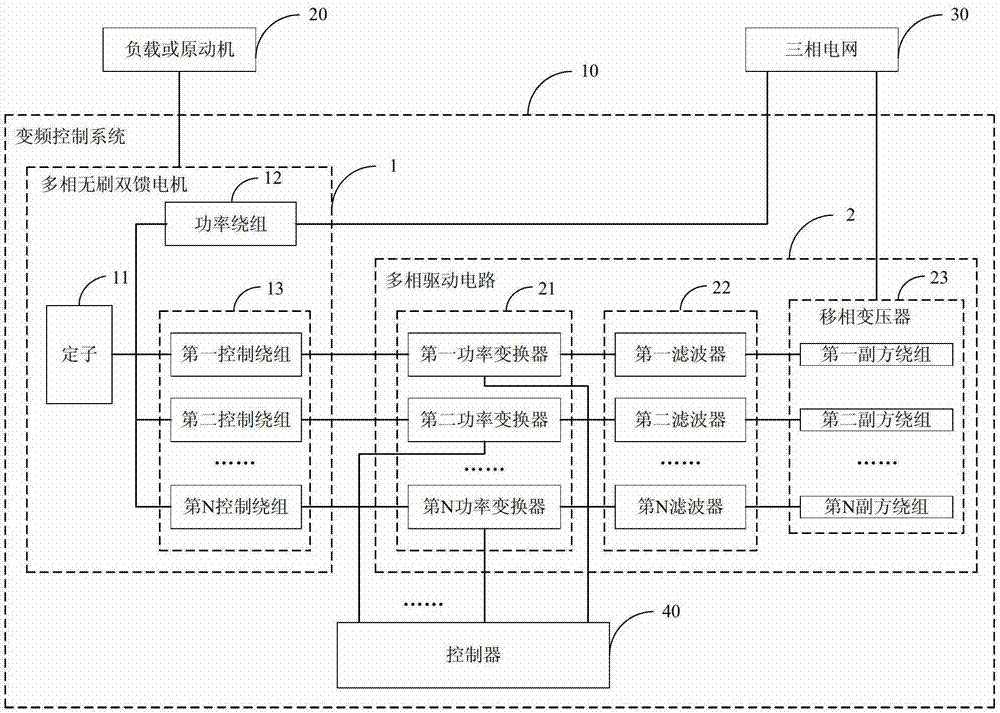

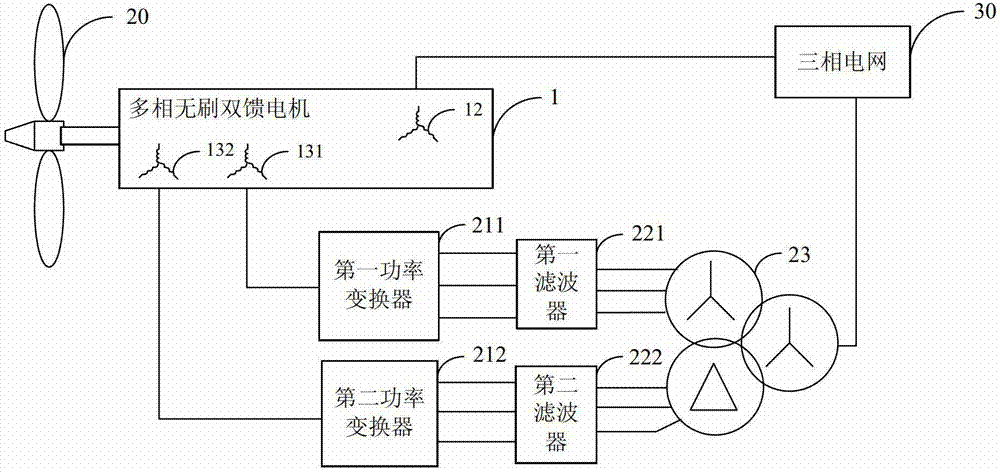

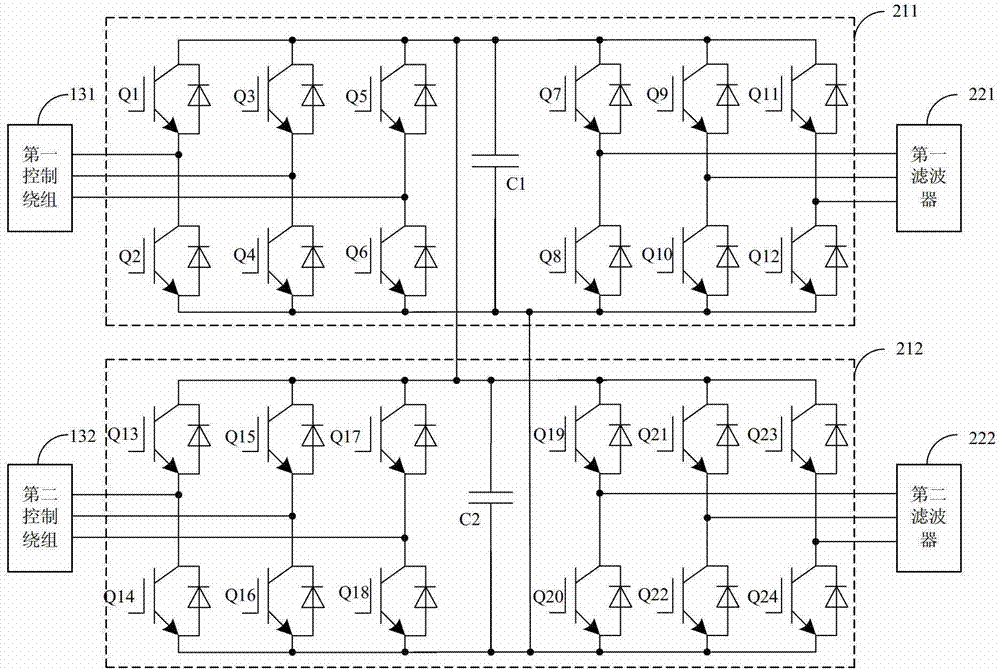

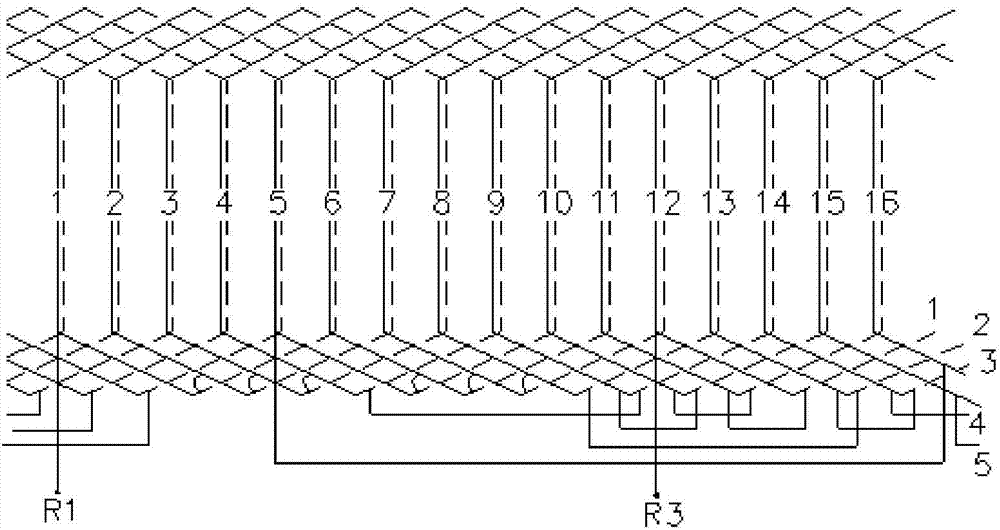

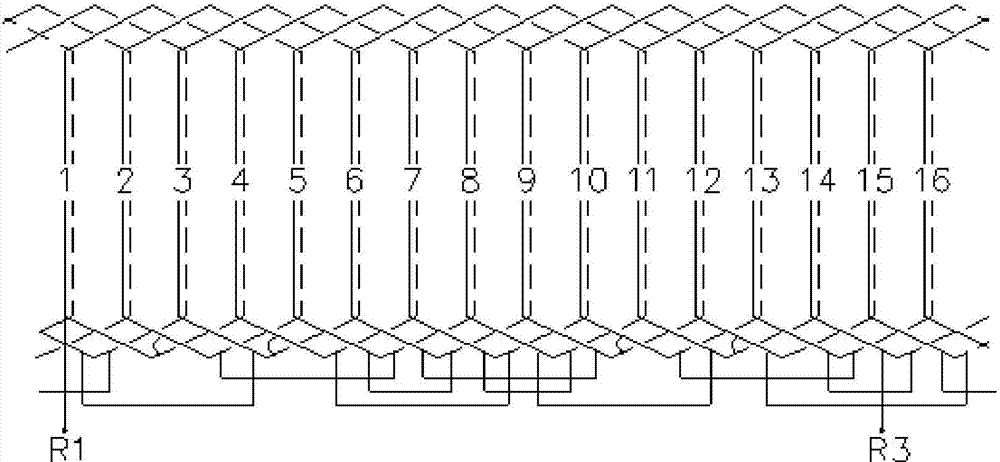

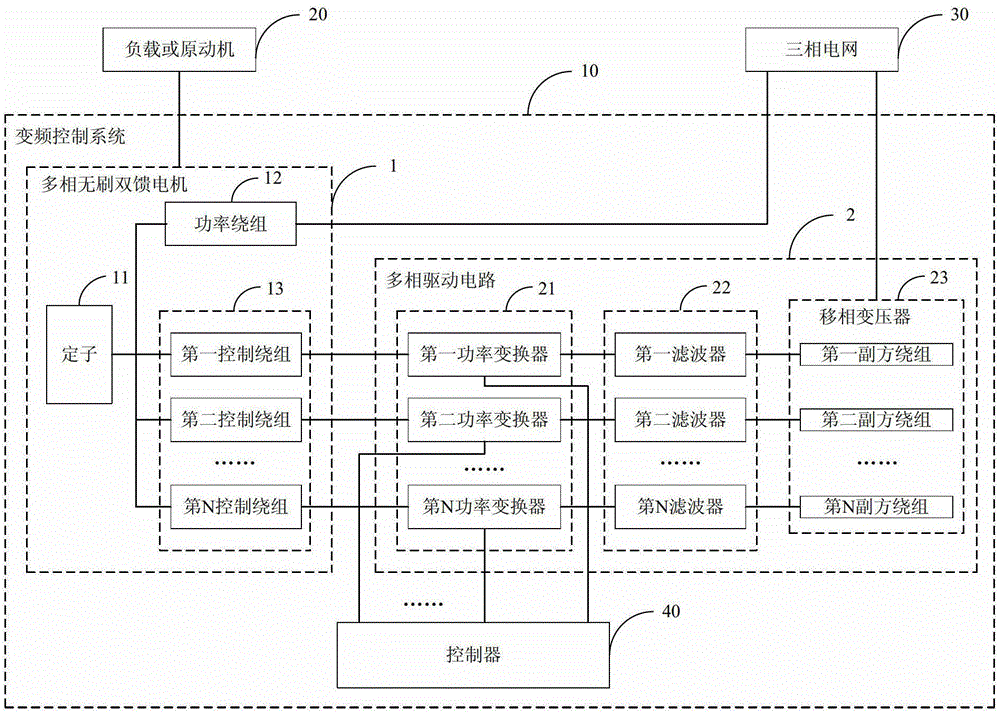

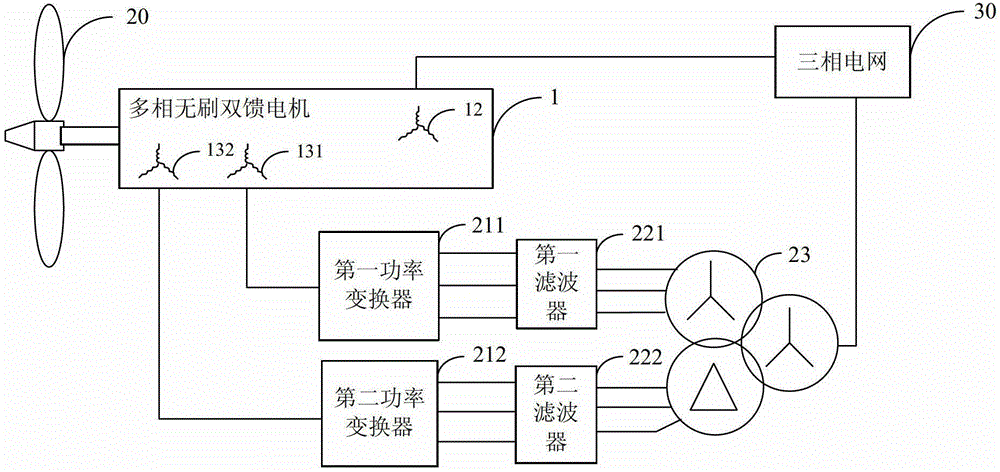

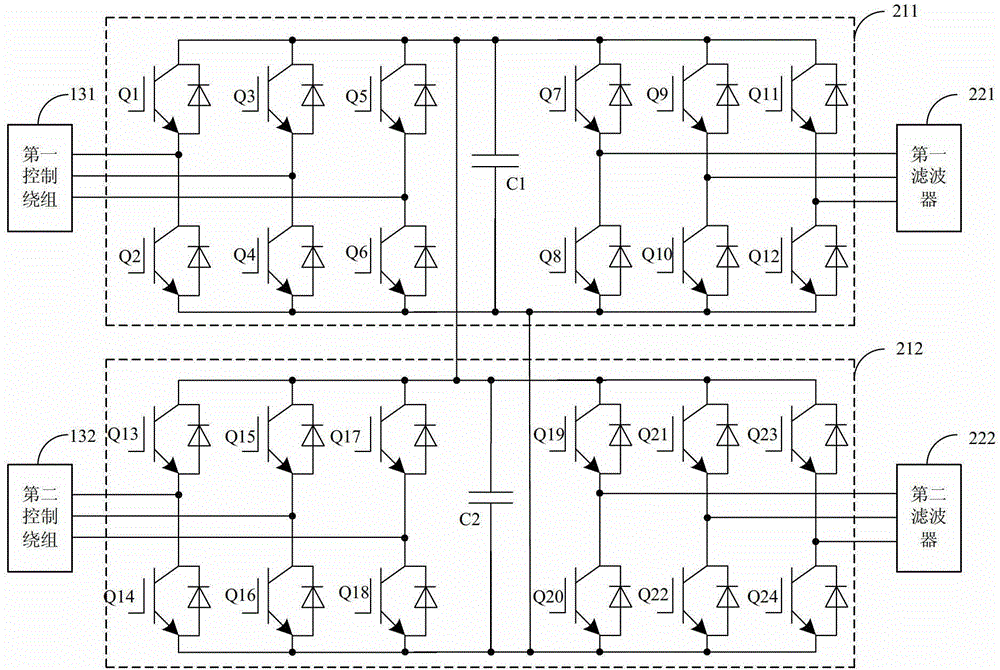

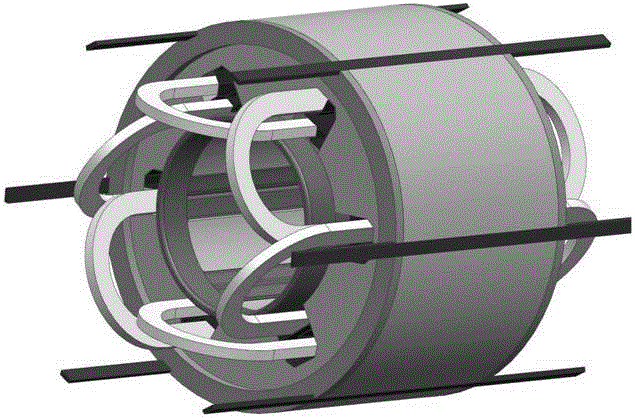

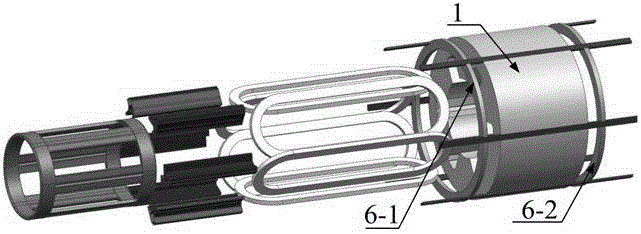

Multi-phase brushless double-fed motor and frequency converting control system

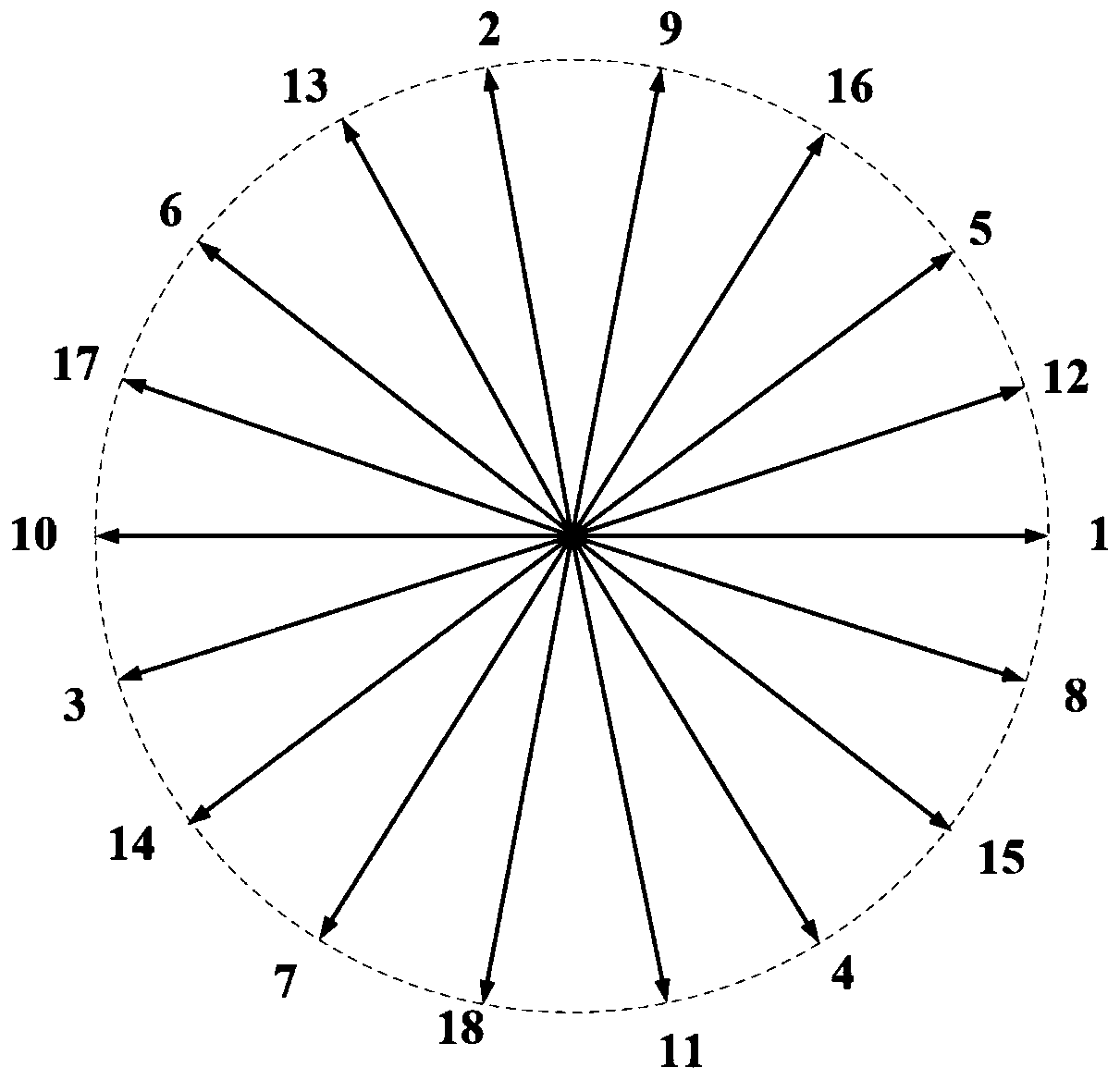

InactiveCN102969860AImprove efficiencyImprove the winding factorAC motor controlWindings conductor shape/form/constructionTransformerConductor Coil

The invention discloses a multi-phase brushless double-fed motor and a frequency converting control system. The frequency converting control system comprises the multiphase brushless double-fed motor and a multi-phase driving circuit, wherein a set of power winding and N sets of control windings are arranged in a stator of a multi-phase brushless double-fed motor, and every set of control winding in the N sets of control windings controls the windings to be distributed with a phase of 60 / N electricity degree. The multi-phase driving circuit comprises N power converters respectively connected with the N sets of control windings, N filters respectively connected with N power converters and a phase-shifting transformer. The phase-shifting transformer comprises N auxiliary square windings and N original square windings, wherein the N auxiliary winding square windings are respectively connected with the N filters, and the original square windings are connected with a three-phase power grid. The control windings of the multi-phase brushless double-fed motor is demounted into a plurality of sets from one set, the phase belt width is changed into 30 degrees or less from the conventional 60 degrees, therefore, winding coefficients of fundamental waves of the control windings are improved, harmonic wave magnetic potential is reduced, and efficiency of a motor is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

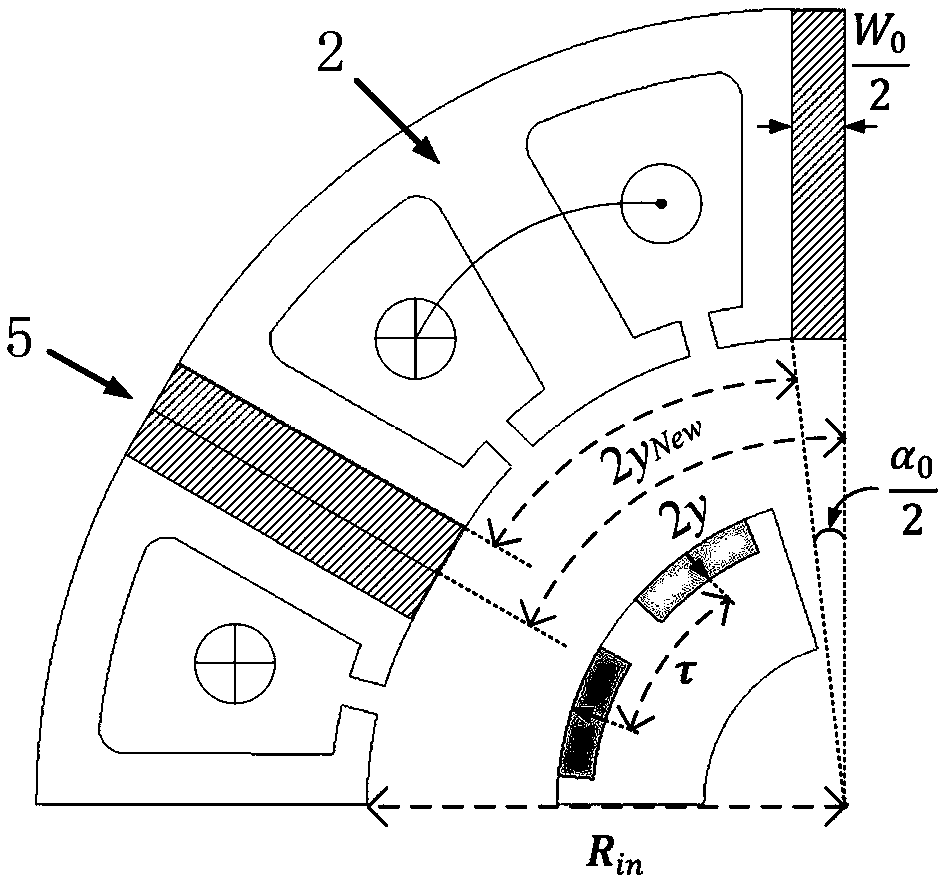

Double-layer long-short-distance hybrid winding suitable for a 36-slot 14-pole three-phase permanent magnet synchronous motor

ActiveCN109194075AReduce the amount of copper used in the tipImprove performance indicatorsSynchronous machine detailsWindings conductor shape/form/constructionElectric machinePermanent magnet synchronous motor

The invention discloses a double-layer long-short-distance hybrid winding suitable for a 36-slot 14-pole three-phase permanent magnet synchronous motor, wherein each phase winding has 12 coils, wherein 8 coils are short-distance coils with span of 2 slots and 4 coils are long-distance coils with span of 3 slots; Each phase winding branch is composed of four short-range coils with span of 2 slots and two long-range coils with span of 3 slots, which are connected in series according to the principle of maximum composite fundamental electromotive force. All the coil edges belonging to the same phase winding are located in the stator slot at the same position as all the coil edges in the stator slot of a 36-slot 14-pole three-phase permanent magnet synchronous motor with 3-slot long-distance coil double-layer winding, Only the order of connection between all the coil sides belonging to the same phase winding is changed, and the fundamental winding coefficient is 0.9236. Compared with the two-layer distributed winding with two-slot short-distance coil, the coefficient of fundamental winding is 0.8985, the copper is saved, and the comprehensive performance index of motor is high.

Owner:TIANJIN UNIV

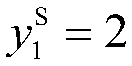

High-winding-factor permanent magnet brushless motor and design and fault-tolerant control method

ActiveCN106357073AReduce volumeReduce weightAC motor controlElectric motor controlBrushless motorsElectric machine

The invention discloses a high-winding-factor permanent magnet brushless motor and a design and fault-tolerant control method. The high-winding-factor permanent magnet brushless motor comprises a stator, an armature winding, a rotor and a permanent magnet, wherein an armature groove is formed in the stator, and the armature winding is placed in the armature groove; double-layer winding is adopted. An air gap is arranged between the stator and the rotor, and a permanent magnet is attached to the surface of the rotor, and is magnetized by using a Halbach array structure. The motor is an eight-phase motor, and phases are evenly distributed at a phase belt angle of 45 degrees; after the phases are distributed, four phase line terminals and a common neutral point are led out. The single-phase open-circuit fault-tolerant algorithm of the motor of the invention solves the problem that the fault-tolerant algorithm can be implemented only by utilizing the phase which and the fault phase has a difference of 180 degrees when the ordinary four-phase motor is in a single-phase open-circuit fault state, and the capacity of an inverter and the insulation rating of the motor winding can be reduced by the fault-tolerant control strategy of the motor. Finally, the motor of the invention and the control algorithm have good fault-tolerant effects, and the average torque after fault tolerance is basically consistent with that in the normal operation.

Owner:JIANGSU UNIV

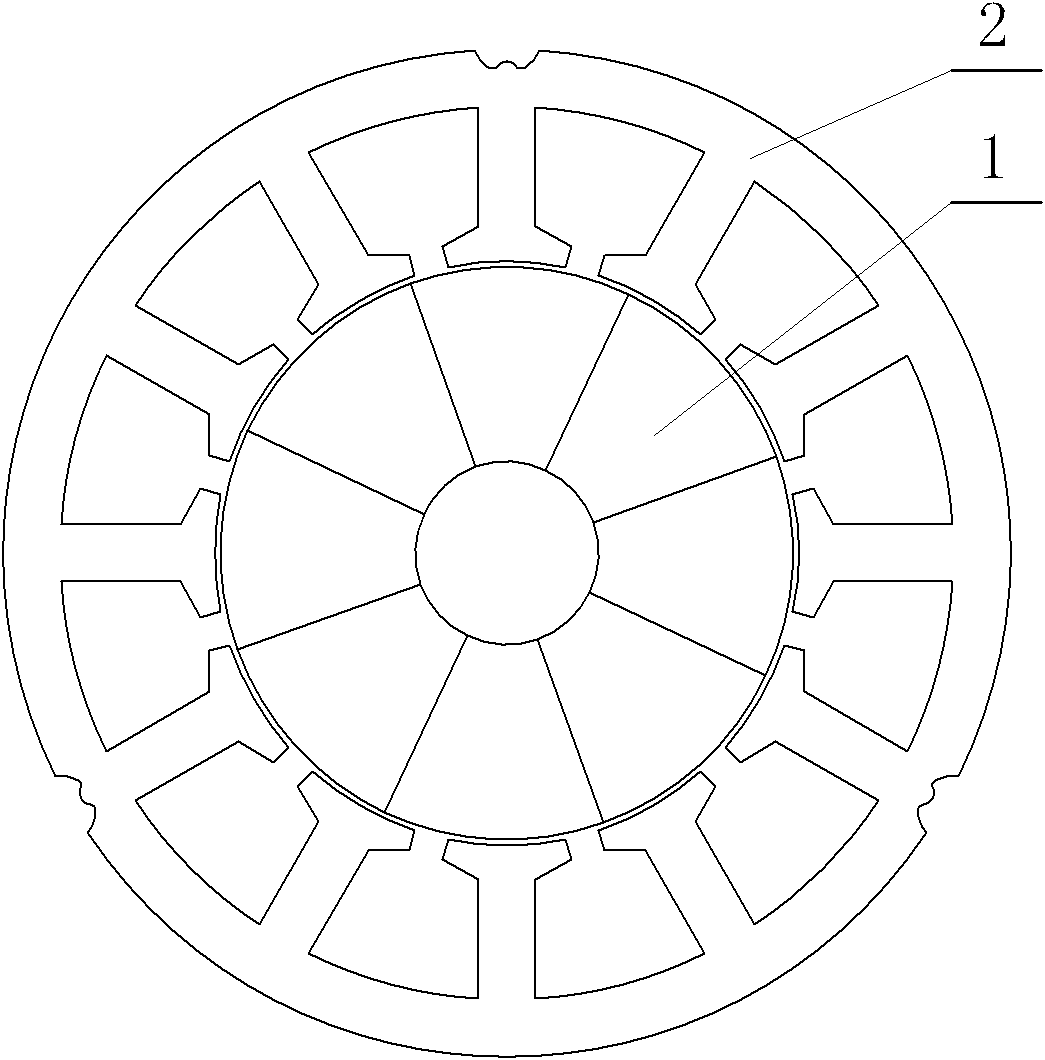

Permanent magnet synchronous motor with magnetism concentration effect

PendingCN109286295ASimple structureReduce transportationMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorTorque density

The invention relates to a permanent magnet synchronous motor with a magnetism concentration effect, which comprises a stator and a rotor, wherein the stator includes a spliced stator core and a stator winding, the spliced stator core is an annular body composed of a plurality of sub-cores uniformly distributed around the rotor, two adjacent sub-cores are provided with a stator gap therebetween, each sub-core is provided with two wire slots at the side opposite to the rotor, the part between the two wire slots of the same sub-core form a winding tooth, the top of the winding tooth and the topof the non-winding tooth are the same in width, and the tooth width of the non-winding tooth is equal to the sum of the tooth width of the winding tooth and the width of the stator gap. The permanentmagnet synchronous motor adopts the spliced stator core, thereby not only simplifying the motor structure, reducing the transportation, installation and maintenance difficulty, but also being capableof avoiding a short circuit between phases and improving the fault-tolerant ability of the motor. The spliced stator core also improves the winding factor and generates a magnetism concentration effect, thereby improving the torque density and operation efficiency of the motor.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

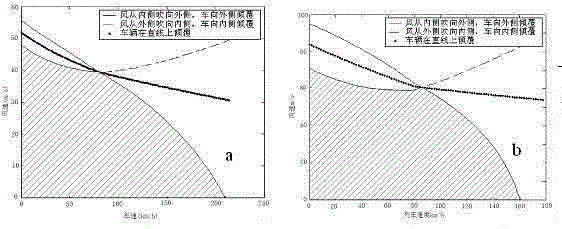

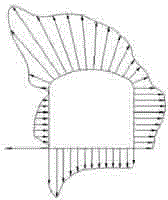

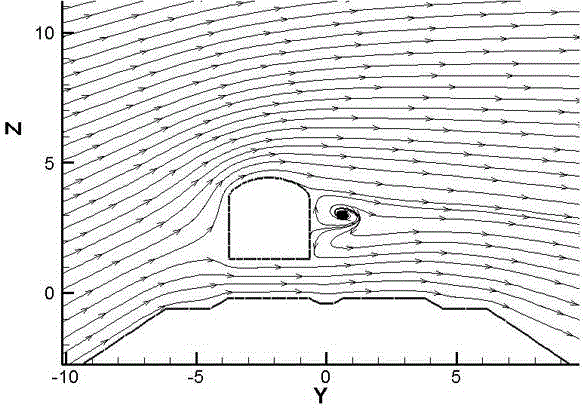

Method and system for determining train running safety threshold value under coupling of wind, vehicle, road, network, wall and terrain

ActiveCN103983462AEasy to excludeGood drivingAerodynamic testingRailway vehicle testingTerrainCoupling

The invention discloses a method and system for determining the train running safety threshold value under coupling of wind, vehicle, road, network, wall and terrain, and therefore the problem that due to the fact that at present, a train overturning coefficient serves as the only criterion for judging wind area driving safety, various influence factors in the actual environment can not be comprehensively considered. The method includes the steps of firstly, determining a first relational expression between the wind speed and a vehicle speed under the state that the road condition, the vehicle type and load, the wind speed and direction and the vehicle speed are coupled, a second relational expression between the critical wind speed and a vehicle speed under the train liter weight ratio critical state, and a third relational expression between the critical wind speed and a vehicle speed under the state that a bow network loses efficacy due to wind-induced network deviation; secondly, obtaining and comparing three vehicle speeds according to the current wind speed during train running and according to the three relational expressions, wherein the minimum vehicle speed is the train running safety threshold value under the environment where a current wind factor, a current vehicle factor, a current road factor, a current network factor, a current wall factor, a current terrain factor and the like are coupled. In this way, the train running safety threshold value determined through the method is closer to the actual environment of train running, and higher reference value is provided for selection of the train running speed.

Owner:CENT SOUTH UNIV

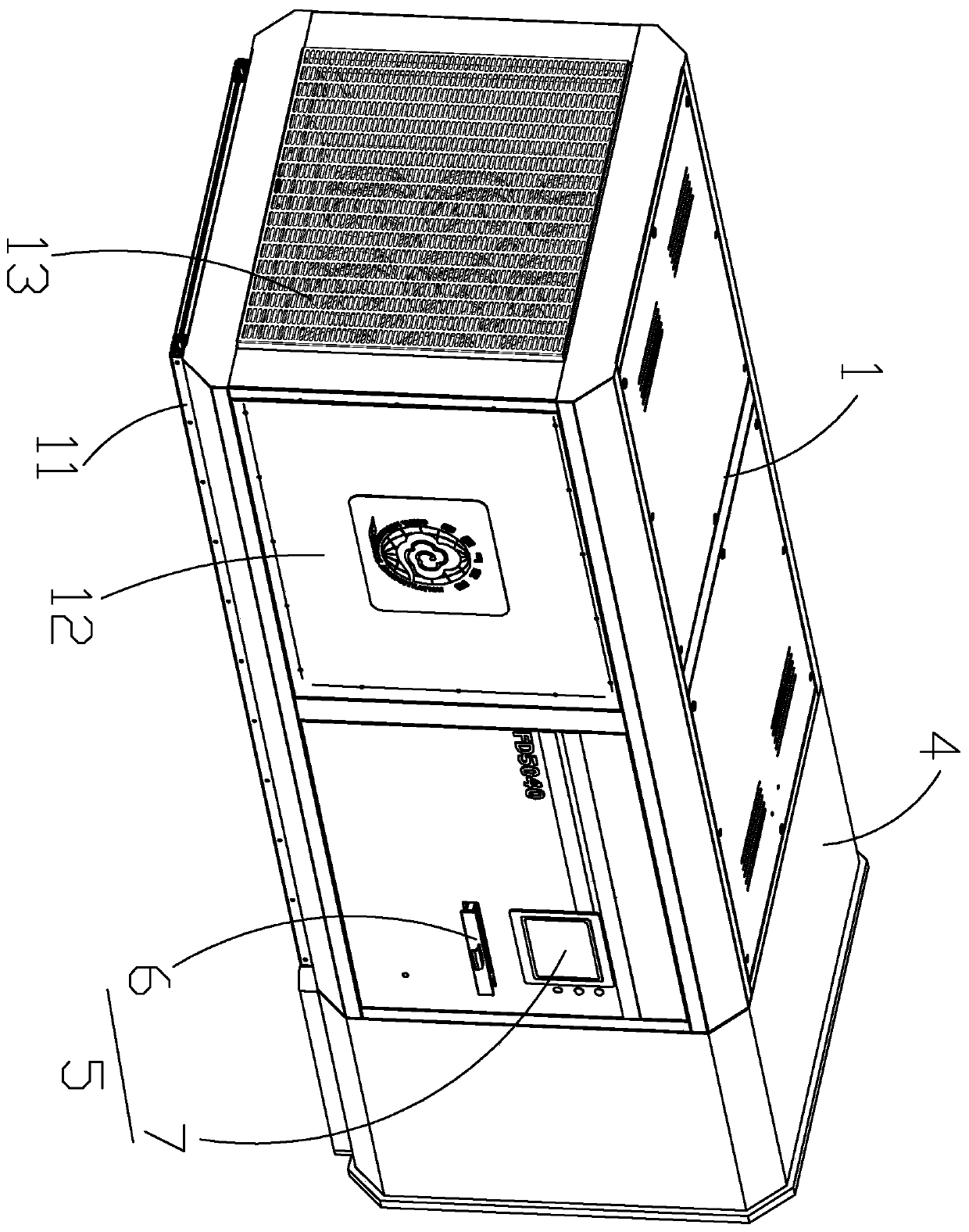

Multifunctional integrated wind factor verification device

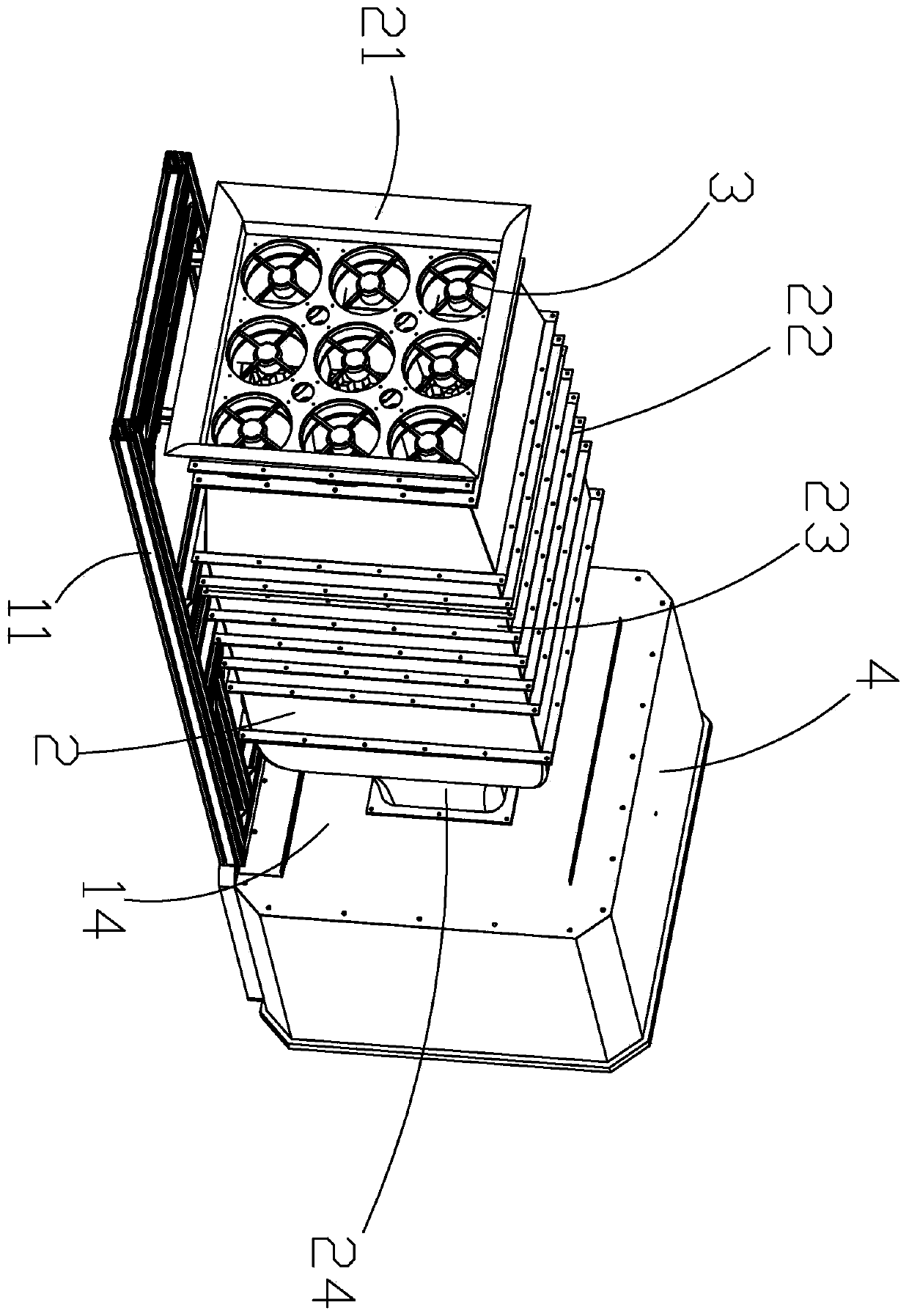

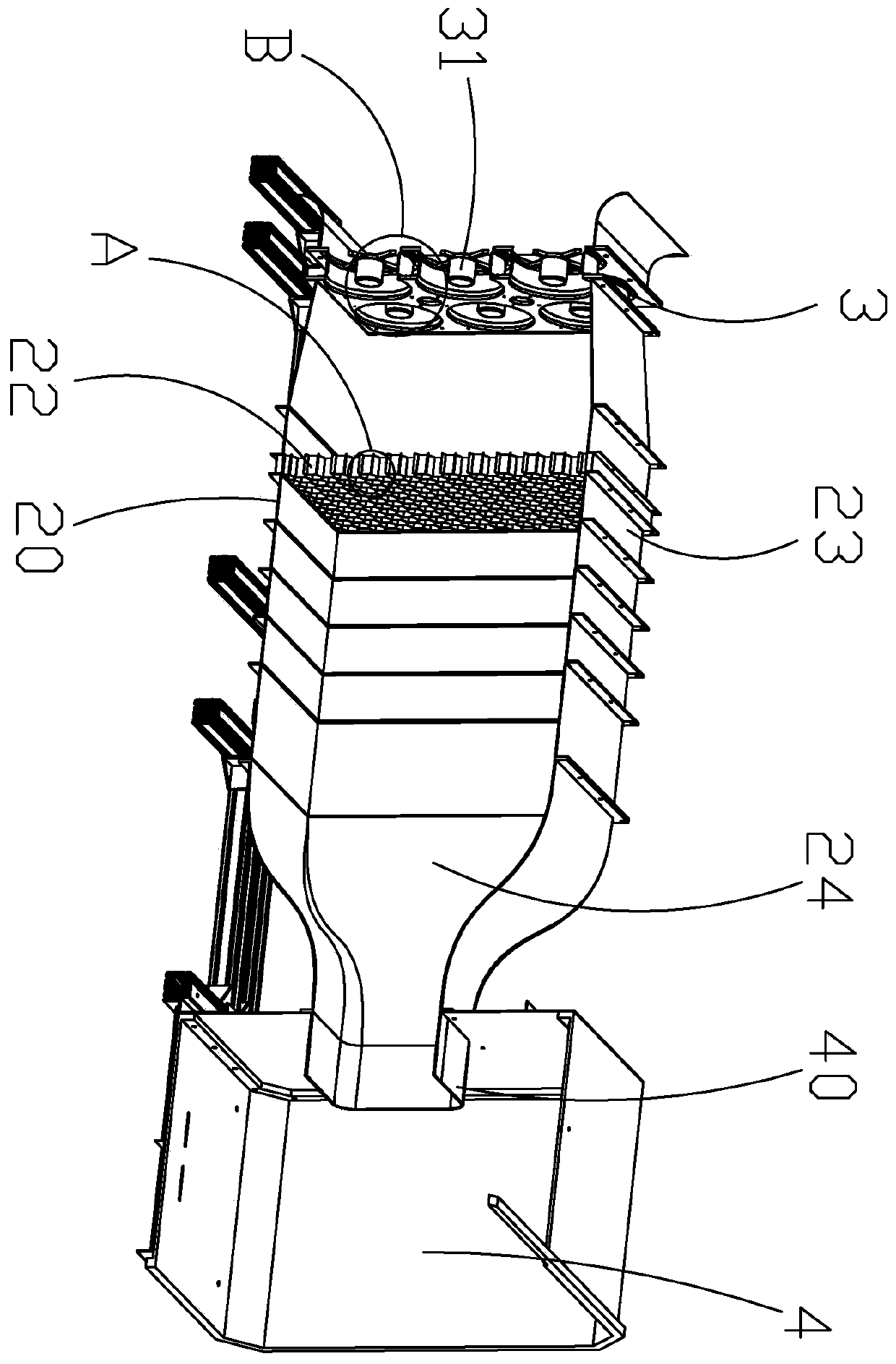

PendingCN110412315AControl speedSmall footprintTesting/calibration of speed/acceleration/shock measurement devicesFrequency changerManufacturing cost reduction

The invention discloses a multifunctional integrated wind factor verification device. The device comprises an outer frame, a down-blowing wind tunnel and a control system, wherein the down-blowing wind tunnel and the control system are mounted in the outer frame; the outer frame is provided with a bracket and an outer wall plate mounted on the bracket, one end of the outer frame is provided with an air inlet, and the other end of the outer frame is provided with a transparent standing chamber. By blowing a power section into the down-blowing wind tunnel, compared with an air suction mode, thedevice has the advantages that reduction of the occupied area of wind tunnel equipment is facilitated and has no special requirement for the field, and the manufacturing cost is reduced. A frequency converter of the control system is connected with the power section to better control the power section, and therefore the stable airflow flowing demands are met.

Owner:CMA METEOROLOGICAL OBSERVATION CENT

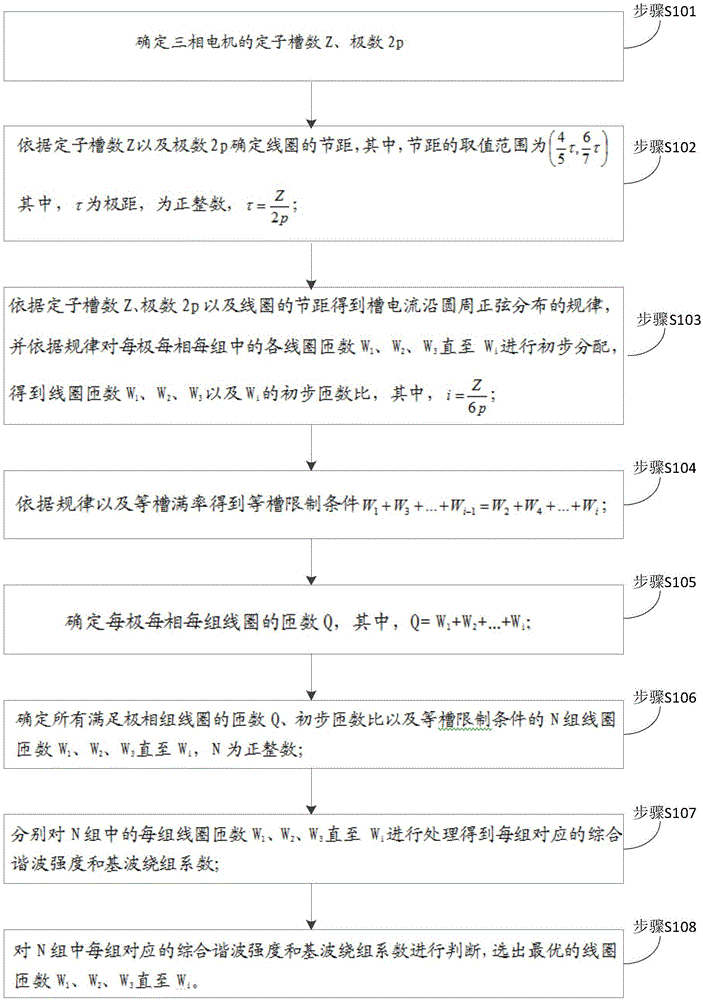

Method for confirming equivalent-groove fullness rate three-phase double-layer stacking sine winding

InactiveCN106300752AHigh fundamental winding factorIncrease profitMagnetic circuit stationary partsWindings conductor shape/form/constructionHarmonicThree-phase

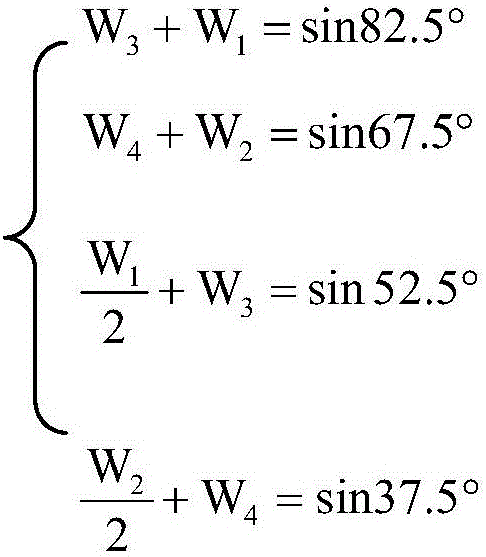

The invention discloses a method for confirming an equivalent-groove fullness rate three-phase double-layer stacking sine winding. The method comprises the following steps: confirming a stator groove number Z and a pole number 2p of a three-phase motor; according to the stator groove number Z and the pole number 2p, confirming the pitch of a coil; according to the stator groove number Z, the pole number 2p and the pitch of the coil, acquiring a primary turns ratio; according to rules and an equivalent-groove fullness rate, acquiring equivalent-groove limiting conditions; confirming turns numbers Q of each pole, each phase and each group of coils; confirming all turns numbers W1, W2, W3 to Wi of N groups of coils which meet the turns numbers Q of coils of pole phase groups, the primary turns ratio and the equivalent-groove limiting conditions; respectively processing the turns numbers W1, W2, W3 to Wi of N groups of the coils so as to obtain comprehensive harmonic wave intensity and base wave winding coefficients corresponding to each group; judging the comprehensive harmonic wave intensity and the base wave winding coefficients corresponding to each one of N groups, and selecting optimal coil turns numbers W1, W2, W3 to Wi. The method is high in base wave winding coefficient, the winding utilization rate is increased, and most harmonic waves can be weakened.

Owner:GUANGDONG UNIV OF TECH

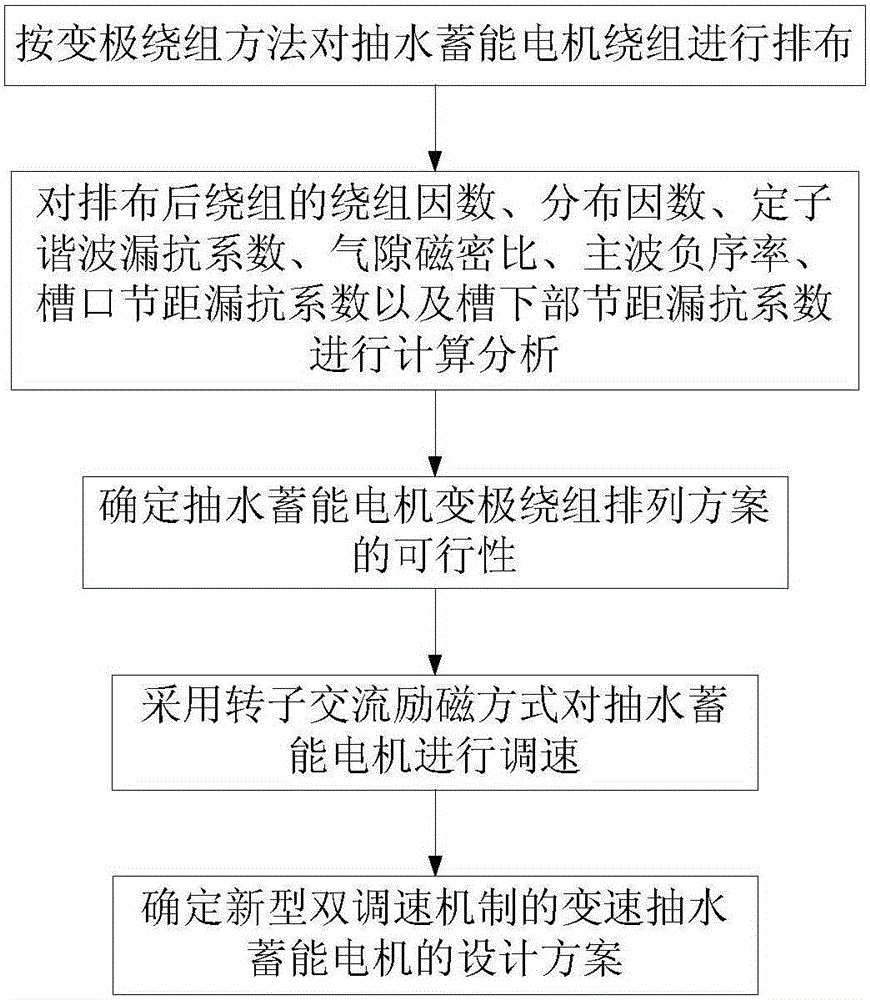

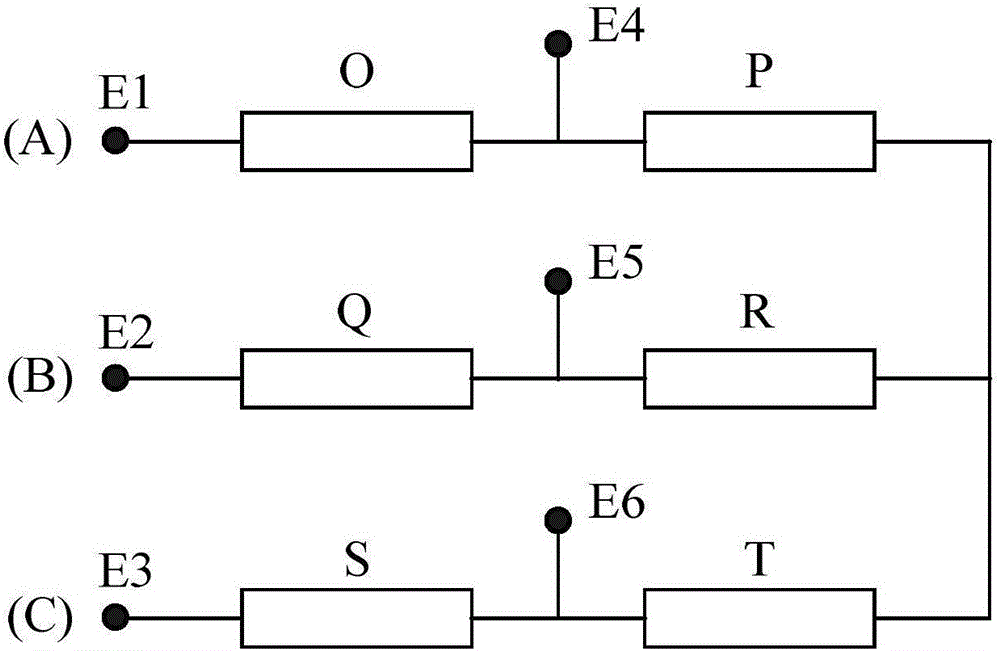

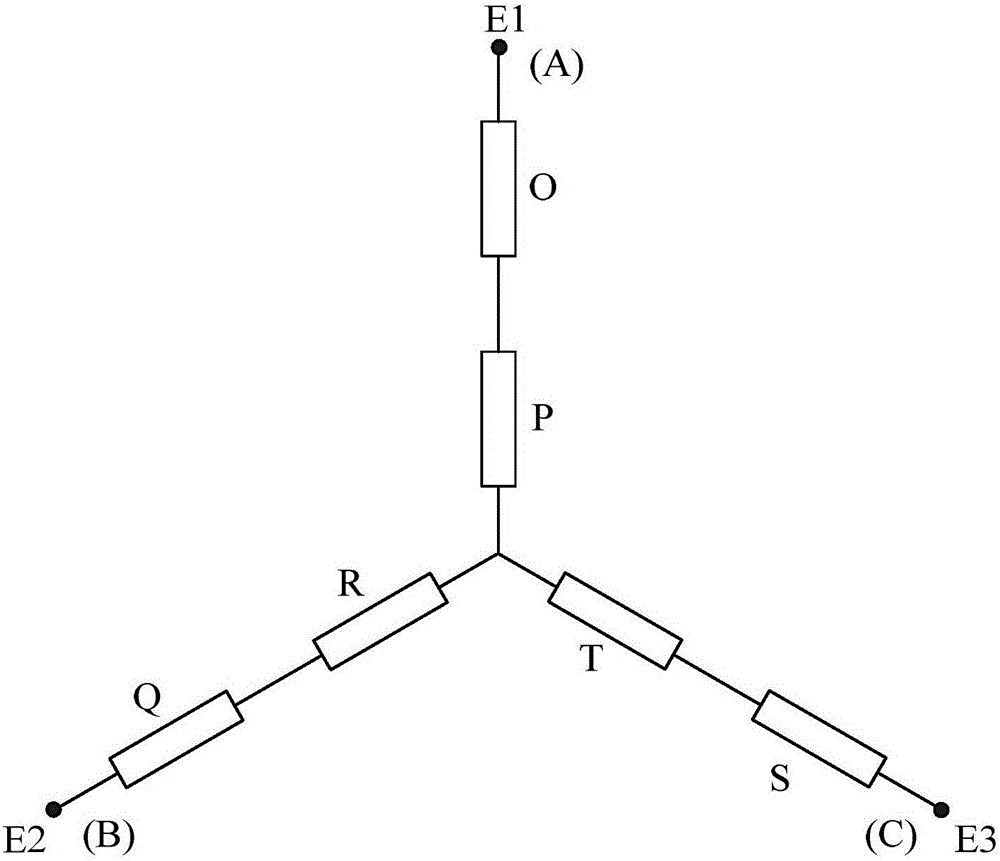

Method for designing variable speed pumped storage motor with double speed regulation mechanisms

ActiveCN105975716AImprove operational efficiencyGuaranteed uptimeGeometric CADSpecial data processing applicationsDensity ratioWater turbine

The invention provides a method for designing a variable speed pumped storage motor with double speed regulation mechanisms. The method is technically characterized by comprising the following steps that 1, pumped storage motor windings are arranged according to a change pole winding method; 2, the winding factor, distributing factor, stator harmonic leakage reactance coefficient, gap flux density ratio, dominant wave dominant wave rate, notch pitch leakage reactance coefficient and groove lower pitch leakage reactance coefficient of the arranged windings are calculated and analyzed to determine the feasibility of a pumped storage motor change pole winding arrangement scheme; 3, a rotor alternating current excitation mode is adopted for regulating the speed of the pumped storage motor; 4, the design scheme of the novel variable speed pumped storage motor controlled with double speed regulation mechanisms is determined. The change range of rotor speed of the pumped storage motor can be widened more effectively, and then the optimal operating performance of a water pump-water turbine is fully achieved.

Owner:HARBIN UNIV OF SCI & TECH

Single-phase capacitor-operated motor

InactiveCN101557148AIncrease productivityThe amount of copper used is obviousWindingsMagnetic circuit rotating partsCapacitanceCopper

The invention provides a single-phase capacitor-operated motor, comprising a motor shaft, a rotor, a stator, a front end cover and a rear end cover; wherein, the rotor is sheathed on the motor shaft and the stator is sheathed at the outer side of the rotor; mutually snap-fit front end cover and rear end cover are arranged at the outer side of the stator; the two ends of the motor shaft are installed on the front end cover and rear end cover via bearings; a stator core of the stator is provided with double-row grooves including a deep-row groove and a shallow-row groove; stator winding is concentrated winding comprising first winding and second winding; coils of the first winding and the second winding are respectively wound in the deep-row groove and the shallow-row groove of the stator core; the adjacent coils of the first winding, which are wound in the deep-row groove, are wound forward and reverse; the adjacent coils of the second winding, which are wound in the shallow-row groove, are wound forward and reverse; the first winding is in parallel connection with the second winding after series connection with capacitance or the second winding is in parallel connection with the first winding after series connection with capacitance. The single-phase capacitor-operated motor can save wires by about 20%; motors with thin iron core and large winding span witness more obvious saving of copper content for windings; in addition, the winding shortens the axial length of the motor; manufacturing of the stator winding achieves machine winding, simplifies the processing flows and improves the production efficiency of the stator; besides, the concentrated stator winding adopted by the invention has high coefficient and good motor property and is suitable for motors with different poles and power.

Owner:MIDEA GRP CO LTD

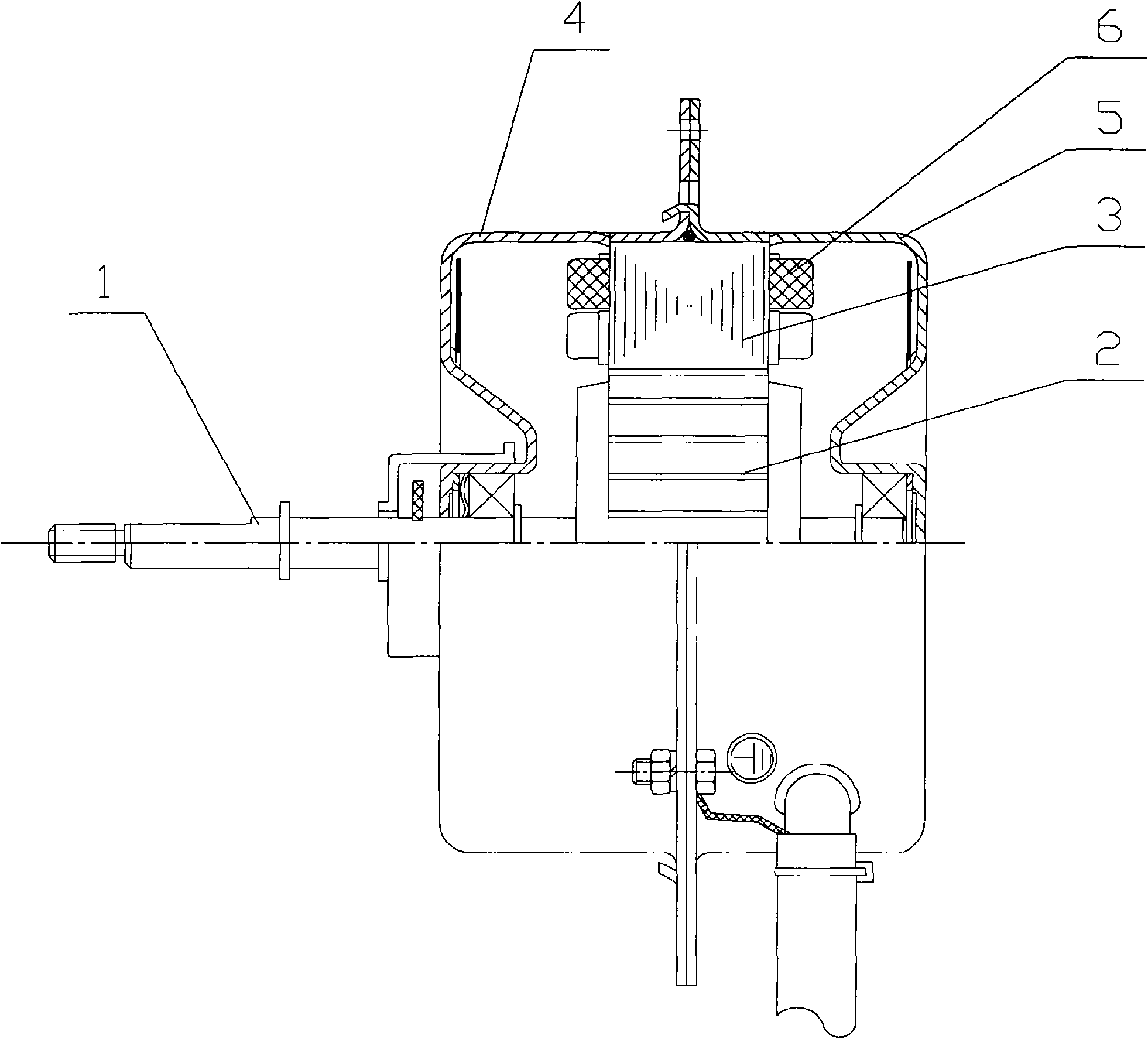

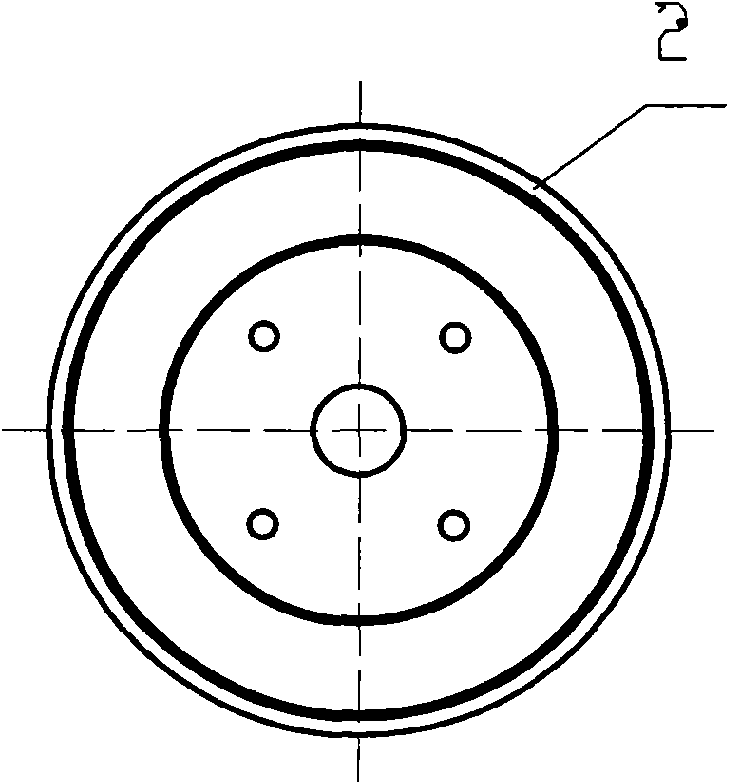

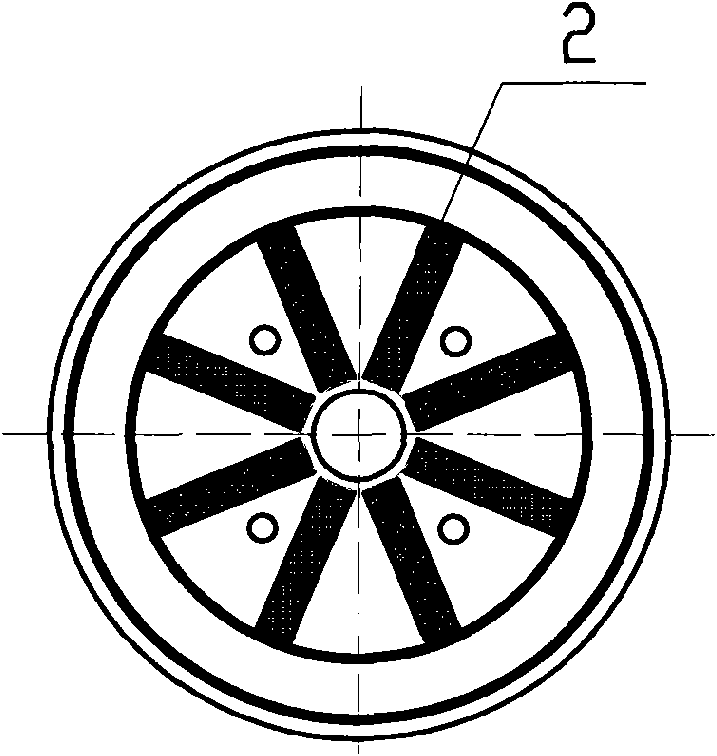

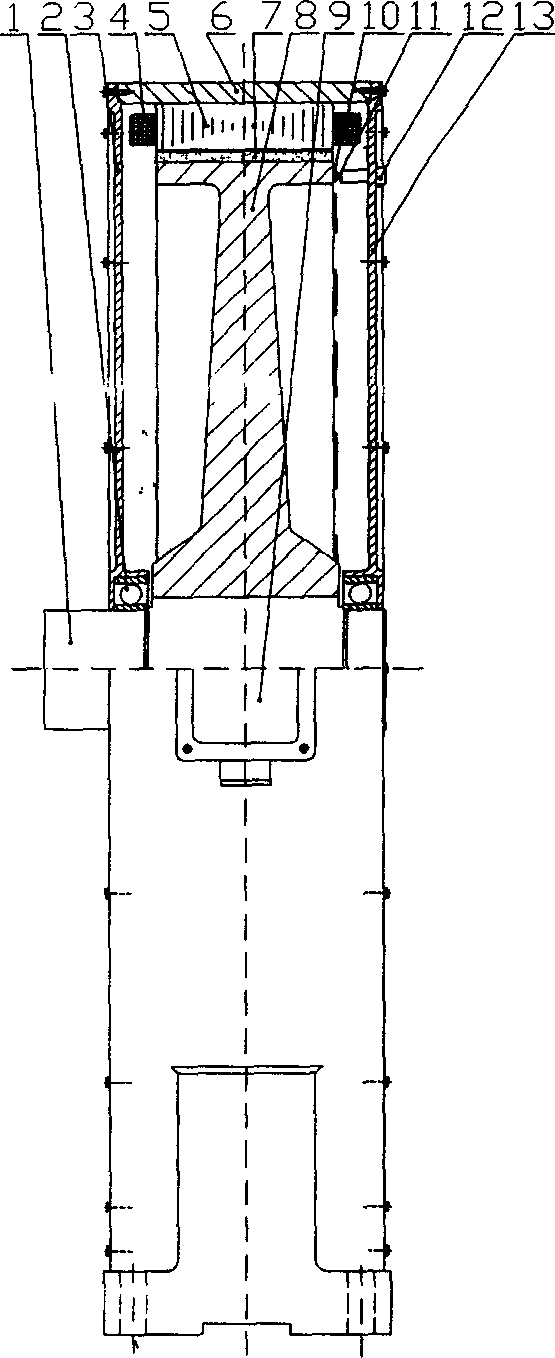

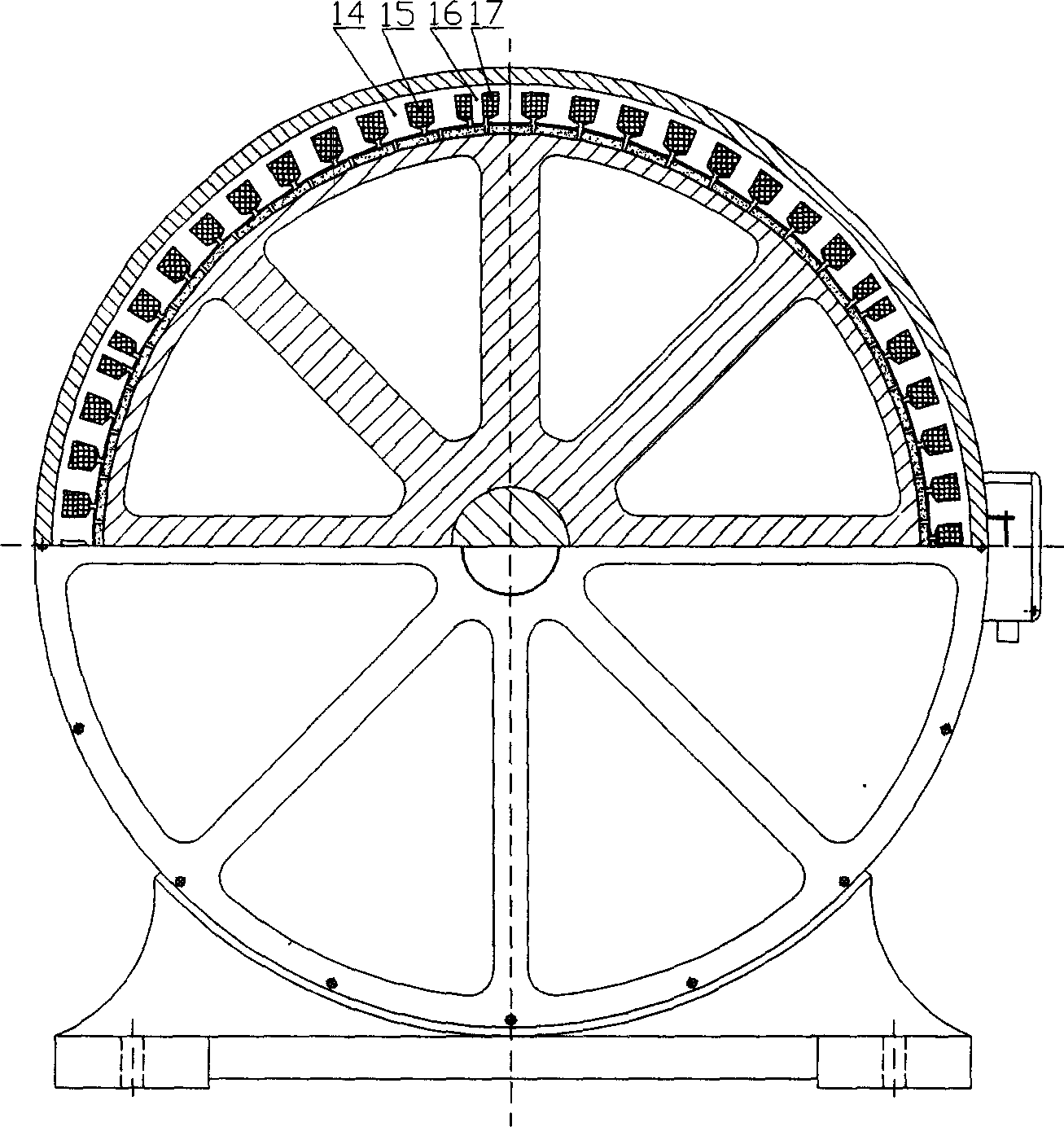

Modular stator structural low-speed DC brushless motor

InactiveCN1889340AImprove efficiencySimple winding processMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsLow speed

This invention discloses a low speed DC brushless motor of a module stator structure, which divides the internal circle of a stator core into k1 fan zone sets uniformly, in which, three phases of A, B and C in each set share it to three zones in same area, k2 big teeth are set on the core of each zone uniformly, the tooth distance of the adjacent teeth is a pole one, a small groove is set on the core between two adjacent zones and a small tooth is set between two small grooves, full-pitched centralized coils are winded around each bug tooth, many pole numbers can be set to the invented motor, the ends of the stator winding are short and not laminated to each other, the factor of which is 1 and the winding process is simply.

Owner:TIANJIN UNIV

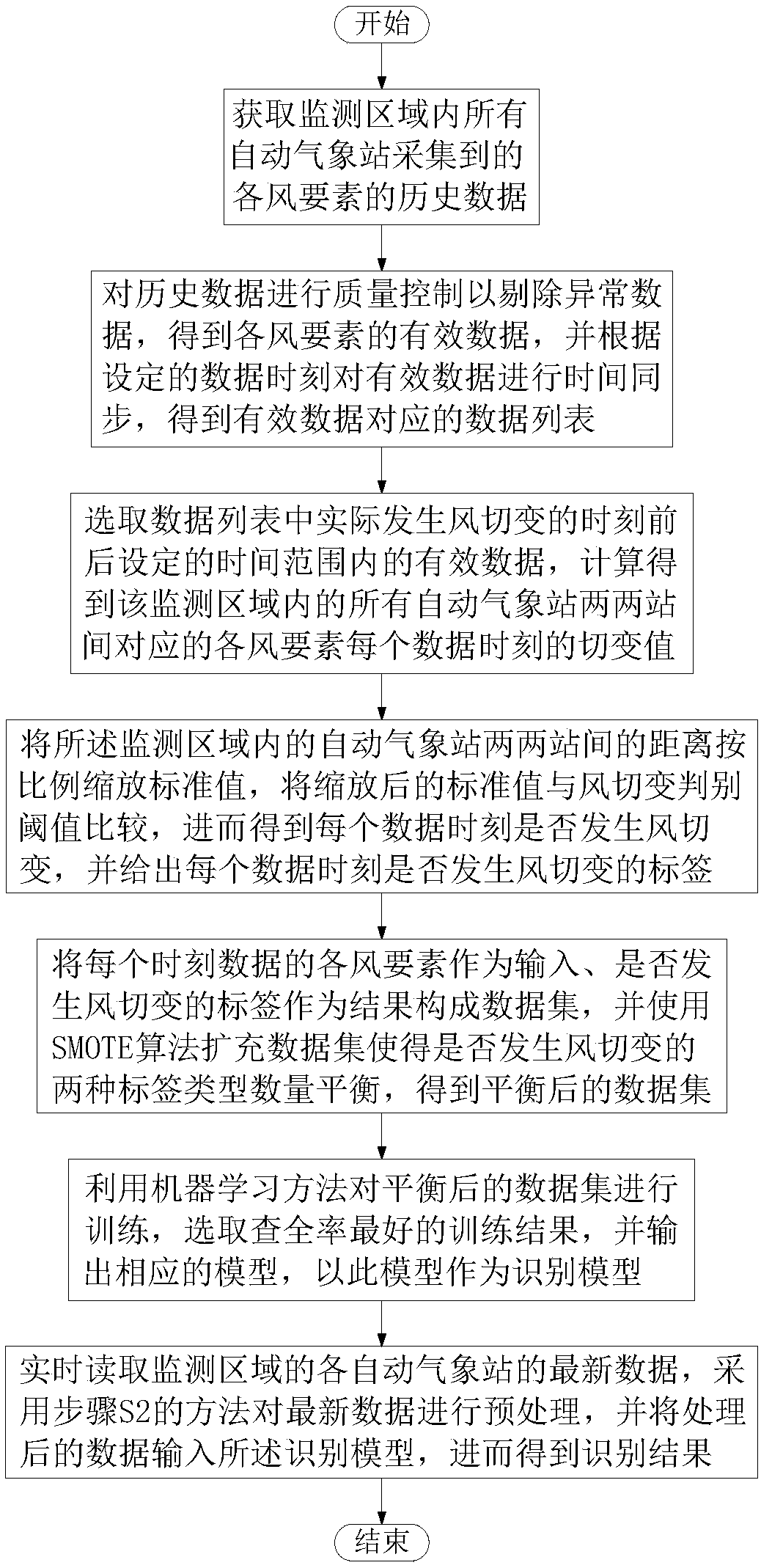

Low-altitude wind shear identification method based on an automatic meteorological station

ActiveCN109583593AHigh precisionData processing applicationsIndication/recording movementData setDiscrimination threshold

The invention relates to a low-altitude wind shear identification method based on an automatic meteorological station. The method comprises the following steps: obtaining historical data of each windelement in a monitoring area; Performing quality control and time synchronization on the historical data to obtain a data list; Selecting effective data actually subjected to wind shear, and calculating a shear value of each wind factor; Scaling a standard value according to the distance between every two automatic meteorological stations, and comparing the standard values with a wind shear discrimination threshold to obtain a label of whether wind shear occurs or not; Taking each wind factor as an input, taking a label with wind shear as a result to form a data set, and using an SMOTE algorithm to balance the number of the two label types; A machine learning method is used for training, and an identification model is output; And reading the latest data of each automatic meteorological station, and inputting the latest data into the identification model to obtain an identification result. The method has the advantages of being high in recognition precision and good in local adaptability, the horizontal wind shear near the ground of the runway can be effectively recognized, and the guarantee efficiency of meteorological services is improved.

Owner:ANHUI SUN CREATE ELECTRONICS

Flat wire conductor stator winding with two branches and motor

PendingCN111917211ATo achieve the purpose of equal resistanceSolve the imbalanceWindings conductor shape/form/constructionWinding factorElectrical conductor

The invention provides a two-branch flat wire conductor stator winding and a motor. The two-branch flat wire conductor stator winding comprises a stator body, stator slots, a flat wire conductor and an end part conductor, wherein z stator slots are arranged on the stator body; 2n layers of flat wire conductors are arranged in the stator slots; 2n layers of flat wire conductors in different statorslots are connected with each other through end part conductors to form a winding; every n layers of flat wire conductors are connected through end conductors to form a branch circuit. According to the flat wire conductor stator winding with the two branches provided by the invention, the problem of unbalanced branches in a motor in an existing flat wire winding mode is solved through the structure of the stator body, the stator slots, the flat wire conductors and the end part conductors; two branches formed in a flat wire winding mode are equal in resistance, high in winding coefficient, lowin winding harmonic content, sufficient in material utilization, small in end portion and wide in market application value.

Owner:厦门势拓御能科技有限公司

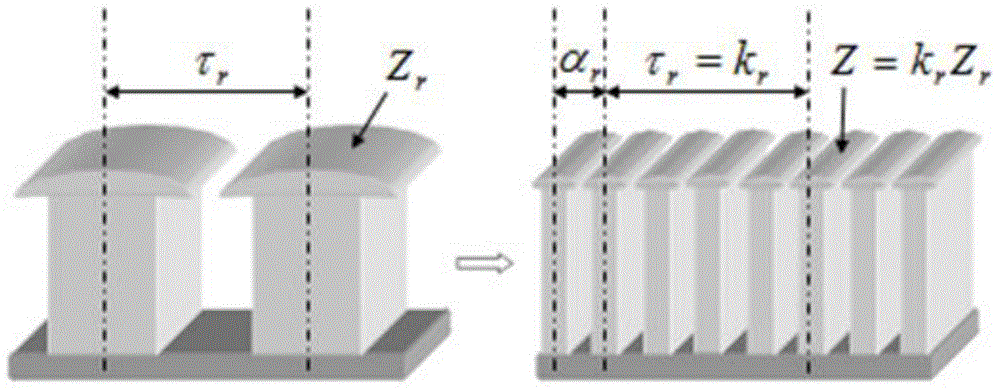

Small-size rotary transformer for optimizing tooth socket fit and winding

InactiveCN103762065AHigh fundamental winding factorLow harmonic winding factorMagnetic circuit rotating partsTransformersMiniaturizationEngineering

The invention discloses a small-size rotary transformer for optimizing tooth socket fit and a winding. The small-size rotary transformer for optimizing the tooth socket fit and the winding mainly comprises a stator and a rotor. The stator is composed of 13 slot cores which are distributed uniformly and sinusoidally distributed two-phase orthogonal stator windings; the rotor is composed of rotor cores which are distributed uniformly and equal-pitch and equal-turns windings. The small-size rotary transformer with optimized tooth socket fit and winding has advantages that the fundamental wave winding coefficient is high while the harmonic winding coefficient is low, the winding is reasonable in form and is convenient to wind, the rotor winding with the power of N to 2 (1, 2, 4, 8) pole pairs is formed easily, the rotor winding with 3, 5 or 7 pole pairs is convenient to form, the pitch of the rotor winding is maintained, the number of turns of each group of elements is maintained, and the miniaturization, universalization and serialization are realized conveniently.

Owner:SHANGHAI WIN DOUBLE ELECTRIC

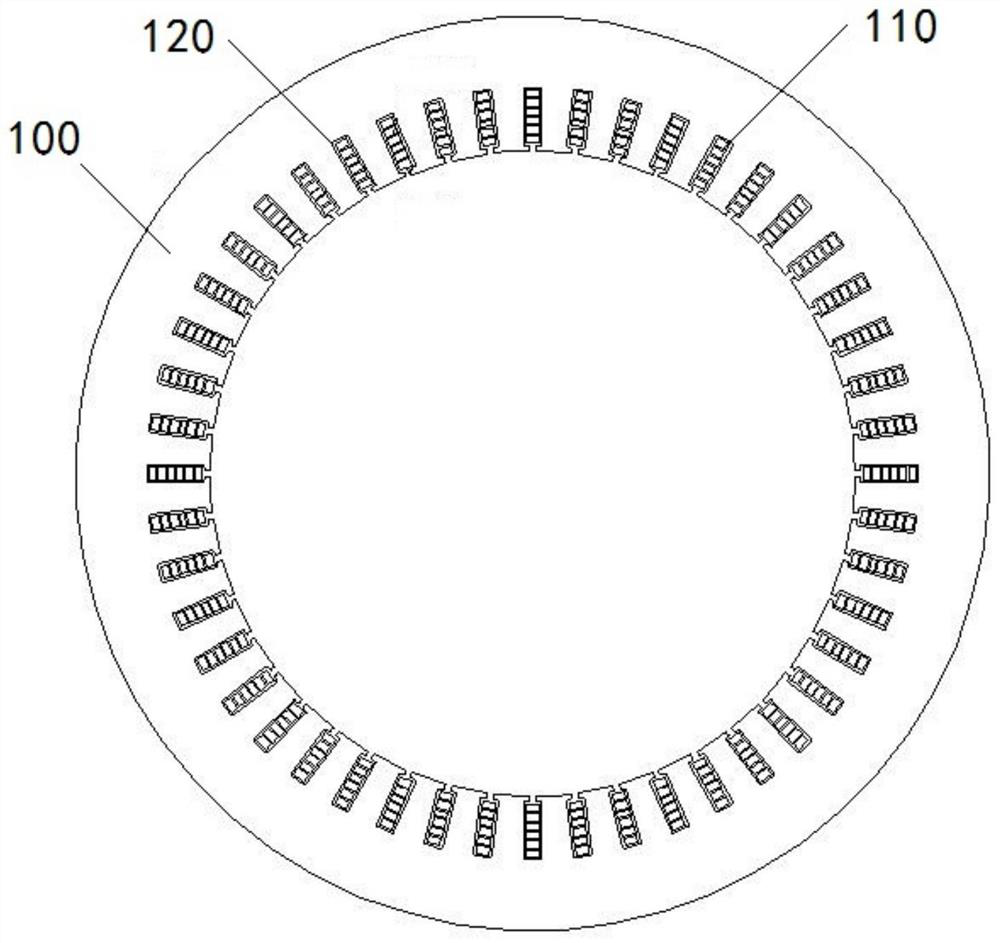

Novel inner rotor permanent magnet motor

ActiveCN102185447AGuaranteed uptimeImprove craftsmanshipMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsSlot insulationElectric machine

Owner:FANS TECH ELECTRIC CO LTD

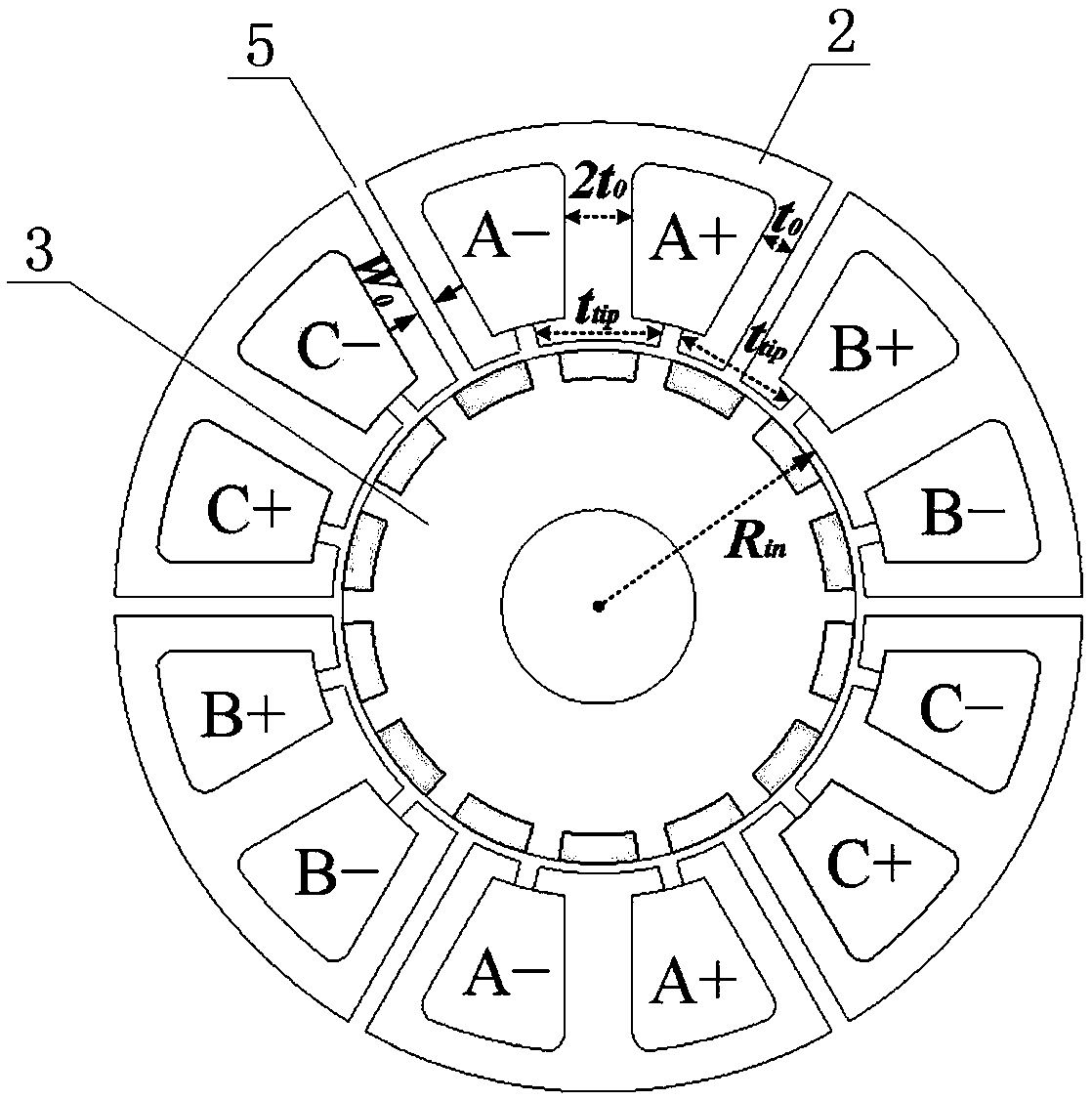

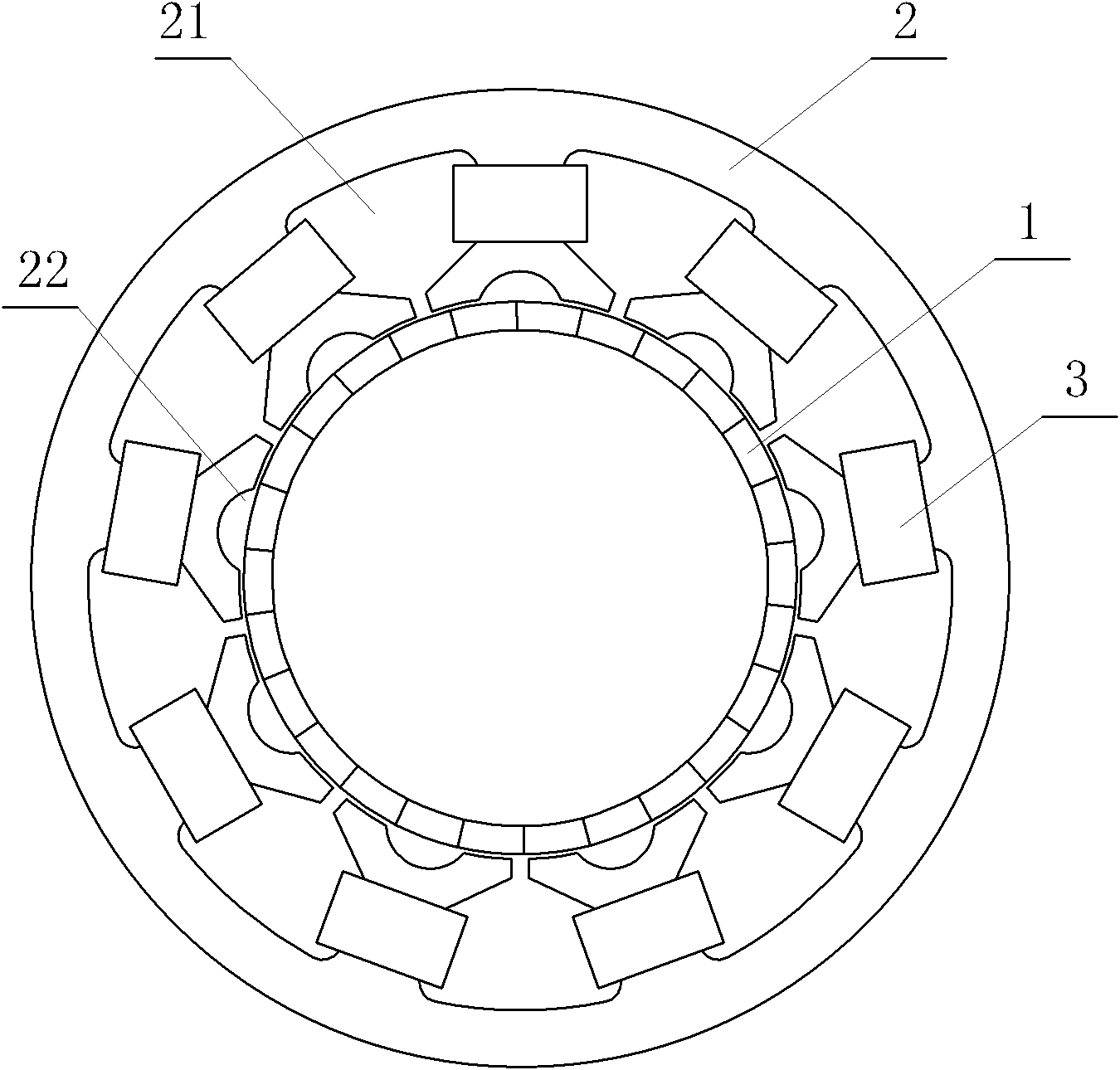

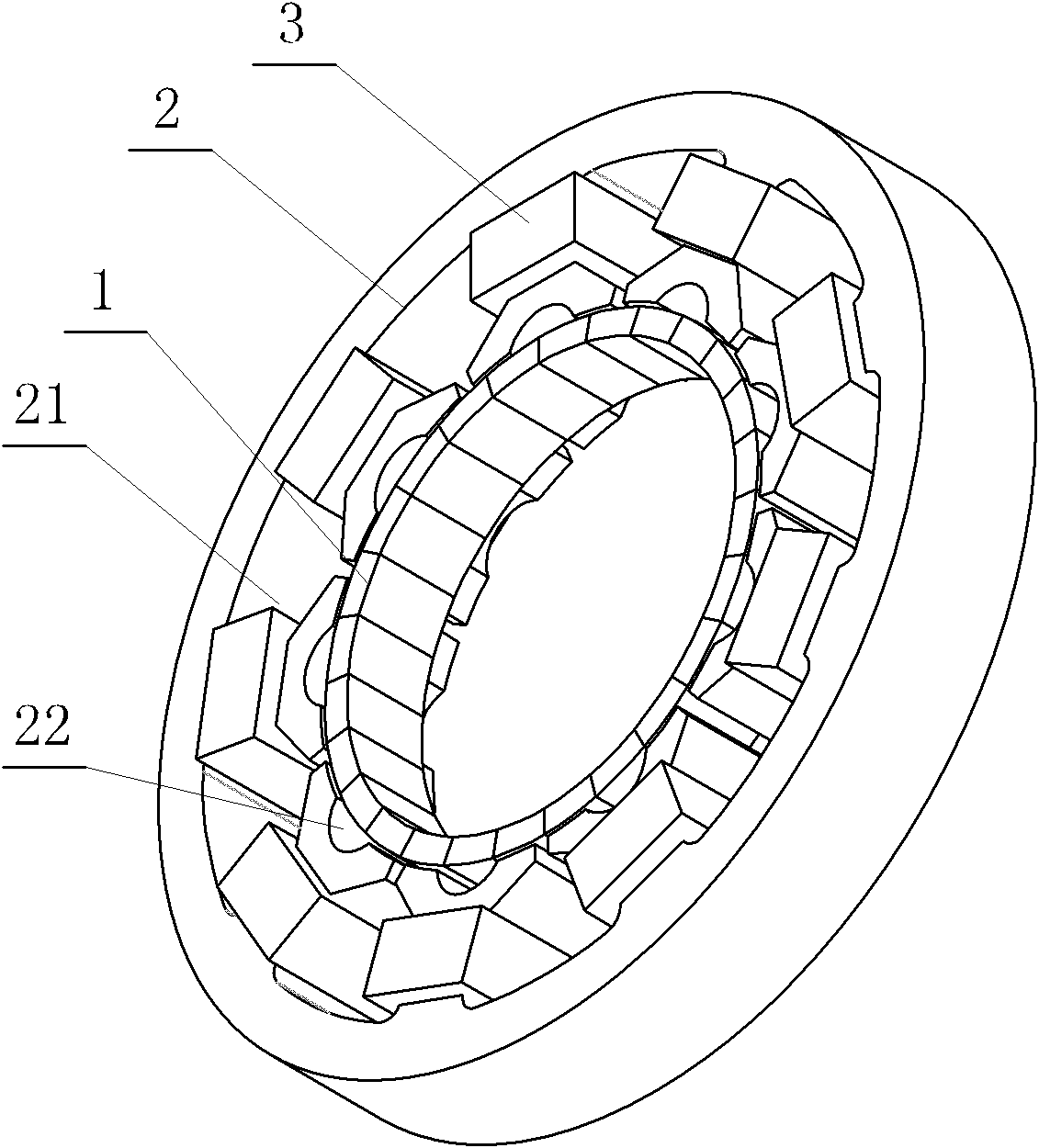

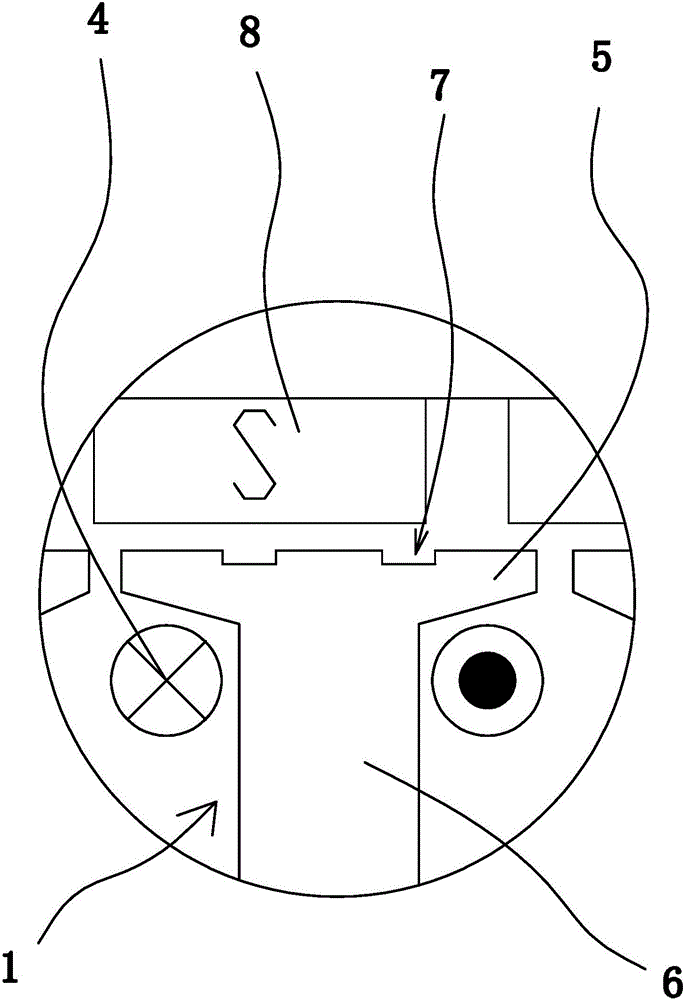

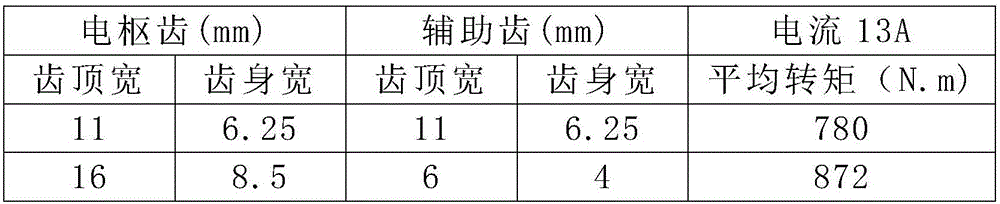

Rotor-stator structure of permanent magnet brushless DC motor

InactiveCN105978182AImprove the winding factorReduce magnetic saturationMagnetic circuit stationary partsElectric machineTorque density

The invention provides a rotor stator structure of a permanent magnet brushless DC motor, which belongs to the technical field of motors. It solves the problems of low torque density and control precision of the existing permanent magnet brushless DC motor. The stator structure of the permanent magnet brushless DC motor includes stator teeth, stator slots and stator windings. The stator teeth include a number of armature teeth and auxiliary teeth. The width of the top and teeth, a number of armature teeth and a number of auxiliary teeth are spaced apart from each other in turn, a stator slot is formed between adjacent armature teeth and auxiliary teeth, the stator winding is embedded in the stator slot and each armature tooth Both are wound with a stator winding. The motor adopts the unequal tooth width design of the armature teeth and auxiliary teeth, which improves the winding coefficient of the motor. At the same time, by rationally designing the tooth width of the armature teeth and auxiliary teeth, the distribution of the magnetic density of the teeth is optimized to avoid saturation of the teeth and improve The output torque of the motor is improved, and the control accuracy of the motor is improved.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

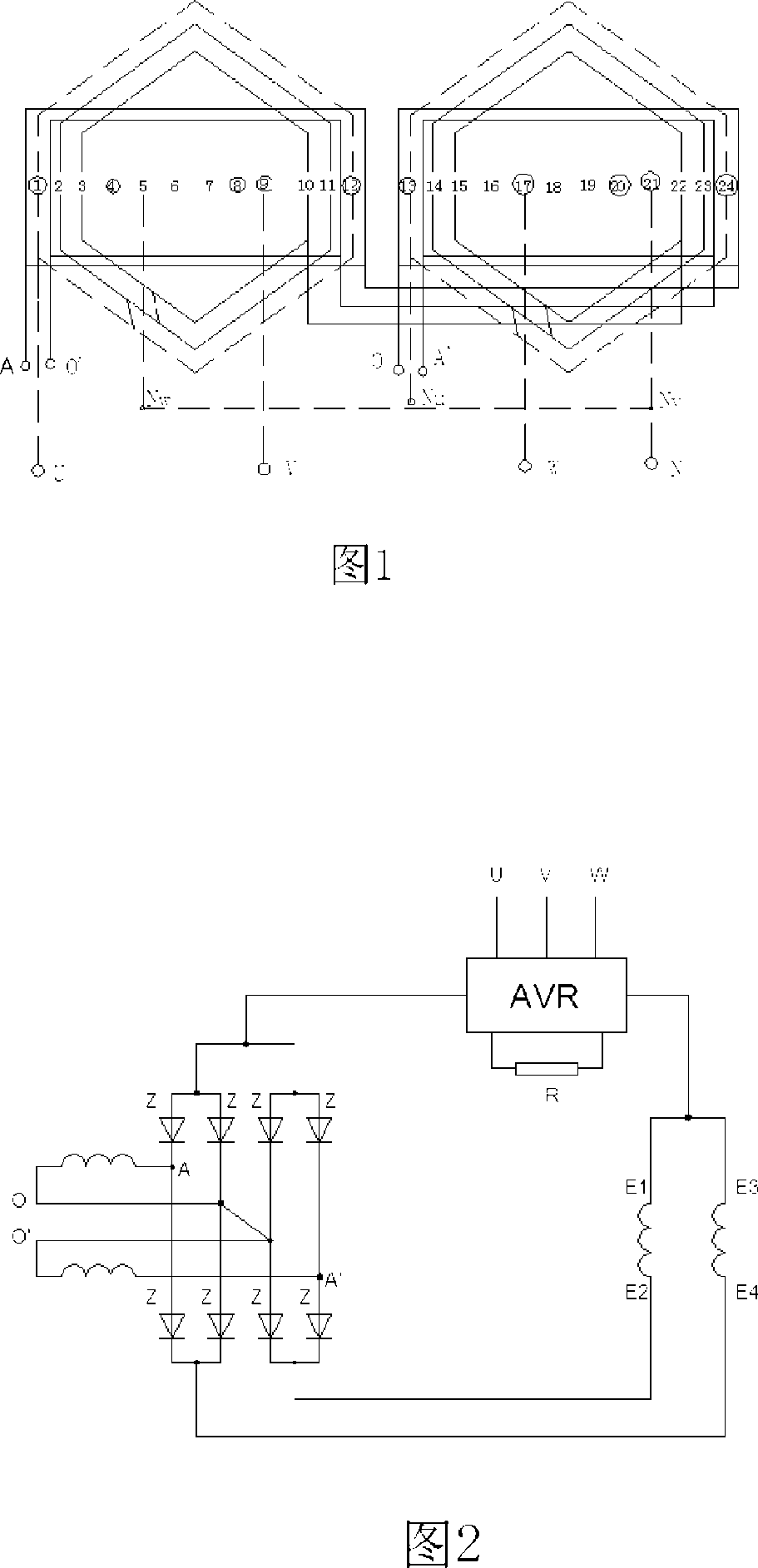

Self-excitation generator multiphase excitation device

ActiveCN101083418ANo interferenceImprove performanceSynchronous generatorsWindings conductor shape/form/constructionWinding factorVoltage

The invention is a self-excited generator's multiphase exciter, characterized in that: primary winding of the generator is designed into concentric single-double layer winding of low-harmonic magnetometive force, base wave winding coefficient is high, and the 5th and 7th harmonics are largely weakened or eliminated, therefore the power generating efficiency is high and the voltage has good sine property. And it overcomes the interference phenomenon caused by obtaining excitation source from generator end or base wave auxiliary winding, and it is a self-exciter without interference to output power.

Owner:TELLHOW SCI TECH CO LTD

Double-layer full-pitch winding coreless linear permanent magnet synchronous motor

ActiveCN111934461AIncrease leakage reactanceReduce thrust fluctuationSynchronous machine detailsMagnetic circuit rotating partsEpoxyElectric machine

The invention discloses a double-layer full-pitch winding coreless linear permanent magnet synchronous motor, and relates to the field of motors. The invention aims to solve the problems that the existing bilateral secondary coreless structure linear permanent magnet synchronous motor adopts an integer slot single-layer winding, two effective edges of a coil are in the same plane, the end parts ofthe coil are overlapped, and the insulation characteristic is poor, and the problem that the heat dissipation performance is poor because the winding is completely packaged in epoxy resin with a lowheat conductivity coefficient. By adopting the double-layer full-pitch winding, the winding factor and the thrust density are improved, the thrust fluctuation of the motor and the eddy-current loss ofthe secondary permanent magnet are reduced, the non-overlapping of the end parts of the coils is realized, and the insulating property of the winding is improved. The end part of the coil is directlycooled by liquid, so that the cooling capacity and output capacity of the motor are improved. The winding substrate is made of a high-strength material, so that the primary structural strength of themotor and the armature coil arrangement precision are improved. By reasonably designing the size of the secondary iron core near the end part of the winding, the leakage reactance of the winding is increased, the current harmonic is reduced, and the secondary permanent magnet eddy-current loss is reduced.

Owner:HARBIN INST OF TECH

Frequency converting control system

InactiveCN102969860BImprove efficiencyImprove the winding factorAC motor controlWindings conductor shape/form/constructionTransformerConductor Coil

The invention discloses a multi-phase brushless double-fed motor and a frequency converting control system. The frequency converting control system comprises the multiphase brushless double-fed motor and a multi-phase driving circuit, wherein a set of power winding and N sets of control windings are arranged in a stator of a multi-phase brushless double-fed motor, and every set of control winding in the N sets of control windings controls the windings to be distributed with a phase of 60 / N electricity degree. The multi-phase driving circuit comprises N power converters respectively connected with the N sets of control windings, N filters respectively connected with N power converters and a phase-shifting transformer. The phase-shifting transformer comprises N auxiliary square windings and N original square windings, wherein the N auxiliary winding square windings are respectively connected with the N filters, and the original square windings are connected with a three-phase power grid. The control windings of the multi-phase brushless double-fed motor is demounted into a plurality of sets from one set, the phase belt width is changed into 30 degrees or less from the conventional 60 degrees, therefore, winding coefficients of fundamental waves of the control windings are improved, harmonic wave magnetic potential is reduced, and efficiency of a motor is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

High-temperature superconducting induction motor stator

ActiveCN106059126AGuaranteed running statusGuaranteed work efficiencyMagnetic circuit stationary partsWindings conductor shape/form/constructionSuperconducting electric machinePower factor

The invention relates to a high-temperature superconducting induction motor stator. First to sixth parts of the stator structure are respectively placed in first to sixth opened rectangular grooves; first two sixth copper coils are respectively embedded at the notches of the first to sixth opened rectangular grooves; the parts, extending out of the end part of a stator core (1), of the first to sixth copper coils circumferentially and respectively bend along the inner diameter of the stator core (1) so as to prevent end coils from intersection, and cannot contact first to sixth superconducting coils. According to the stator, the problem that relatively large pulsating torque is generated as the arrangement and fixation of the superconducting coils in a stator slot are difficult and the superconducting winding coefficients are too low overcome, superconducting coil fixing frames are prevented from generating eddy-current loss, the superconducting cooling cost is reduced, the volume and weight of a superconducting motor are greatly decreased, and the power factor and efficiency of the motor are improved.

Owner:BEIJING JIAOTONG UNIV

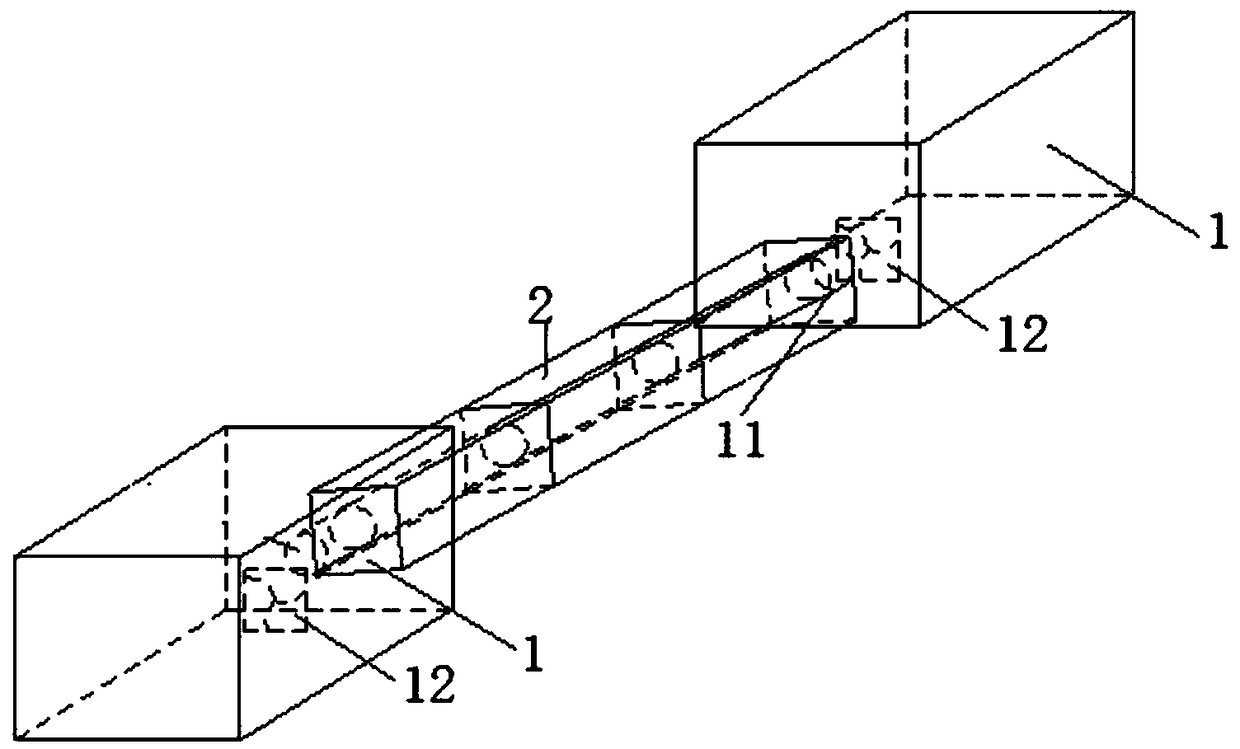

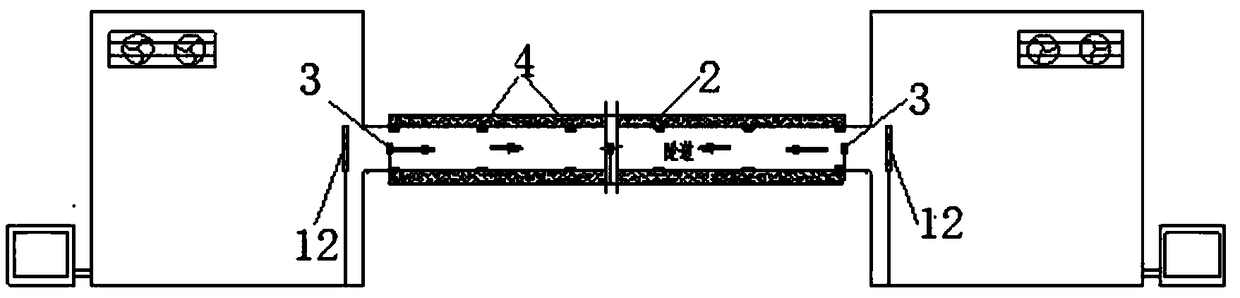

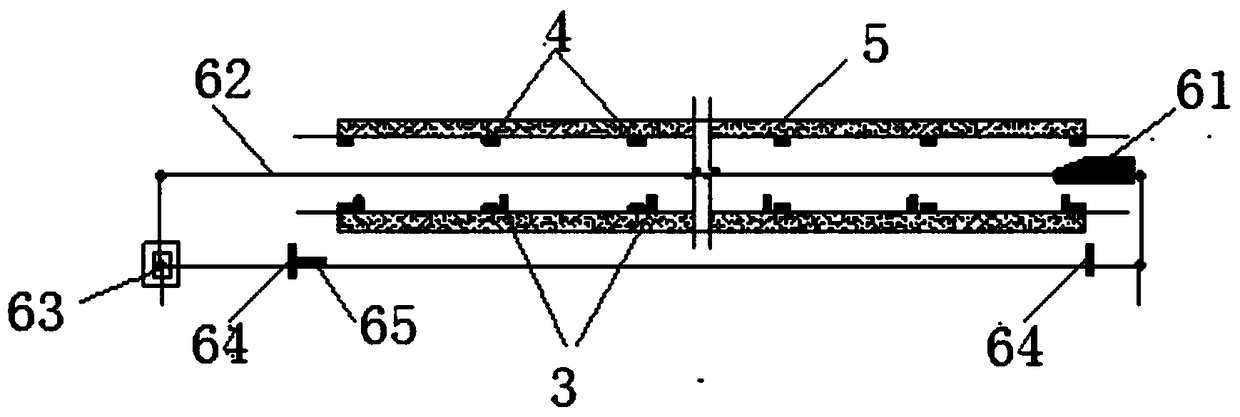

Cold zone tunnel longitudinal temperature experimental device involving train piston wind factor

PendingCN109443809APrevent frostbiteReduce construction costsMaterial thermal analysisRailway vehicle testingInsulation layerData acquisition

The invention discloses a cold zone tunnel longitudinal temperature experimental device involving a train piston wind factor. The device comprises a constant temperature warehouse, a wind speed control device, a tunnel model, a train model device, a thermostatic bath, wind speed sensors, temperature sensors, and a data acquisition system; the constant temperature warehouse is used for providing acold source; the wind speed control device is used for providing wind energy; tunnel model units are spliced to form the tunnel model; the thermostatic bath is composed of thermostatic bath units which are independently arranged; the thermostatic bath unit wraps the outer surface of the corresponding tunnel model unit; and the wind speed sensors and the temperature sensors are disposed in the tunnel model and are electrically connected with the data acquisition system. With the experimental device for testing the longitudinal temperature distribution law of tunnels in a cold zone under a one-way or two-way ventilation condition provided by the invention adopted, the distribution law of the longitudinal temperature of long tunnels under the conditions of different tunnel lengths, differenttunnel portal temperatures, different tunnel portal wind speeds, different surrounding rock initial temperatures and the like can be simulated; and accurate parameters can be provided for the laying length of the insulation layers of the long tunnels in the cold zone.

Owner:中铁西南科学研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com