High-temperature superconducting induction motor stator

An induction motor and high-temperature superconducting technology, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of large pulsating torque, low superconducting winding coefficient, and difficulty in superconducting coil arrangement and fixing. The effect of running instability, avoiding eddy current loss problems, optimizing the difficult effect of the superconducting coil fixing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail in conjunction with the accompanying drawings.

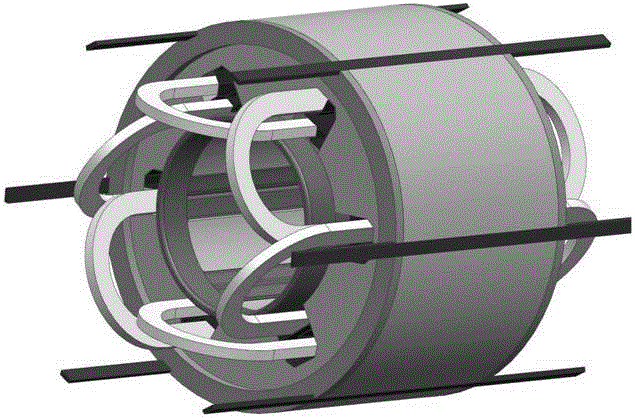

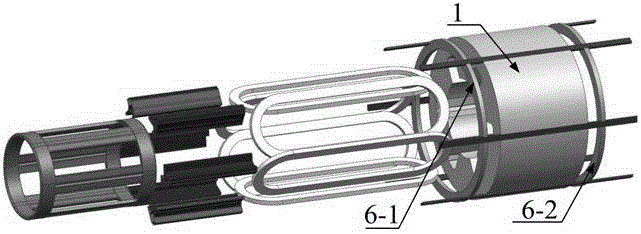

[0035] A high temperature superconducting induction motor stator, referring to figure 1 , figure 2 , the high temperature superconducting induction motor stator includes: a stator core 1 and pressure rings on both sides thereof, a racetrack-shaped superconducting stator coil, and a frame, and the racetrack-shaped superconducting stator coil is fixed in the slot of the stator core.

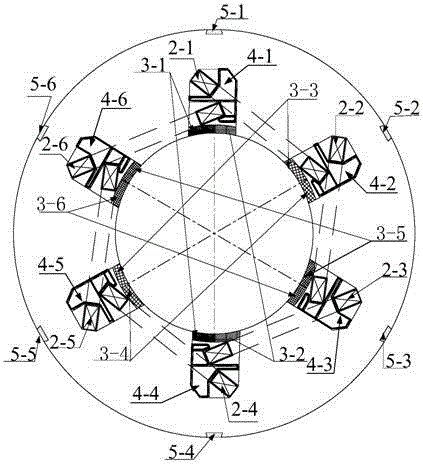

[0036] The stator core 1 has first, second, third, fourth, fifth, sixth opening rectangular slots 1-1, 1-2, 1-3, 1-4, 1-5, 1- 6, and the bottom of the groove is chamfered. The racetrack superconducting stator coils include first, second, third, fourth, fifth and sixth racetrack superconducting stator coils 2-1, 2-2, 2-3, 2-4, 2 -5, 2-6.

[0037] Lay the B12 surface on one side of the straight line part of the first racetrack-shaped superconducting stator coil 2-1 with the C11 surface of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com