18N-10N structure low-noise fractional slot concentrated winding permanent magnet motor

A 18N-10N, concentrated winding technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electric components, etc., can solve the problem of reducing the torque output capacity of the motor, increasing the amount of permanent magnets, The total torque is not improved, etc., to achieve the effect of improving torque output capacity, reducing vibration and noise, and increasing reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

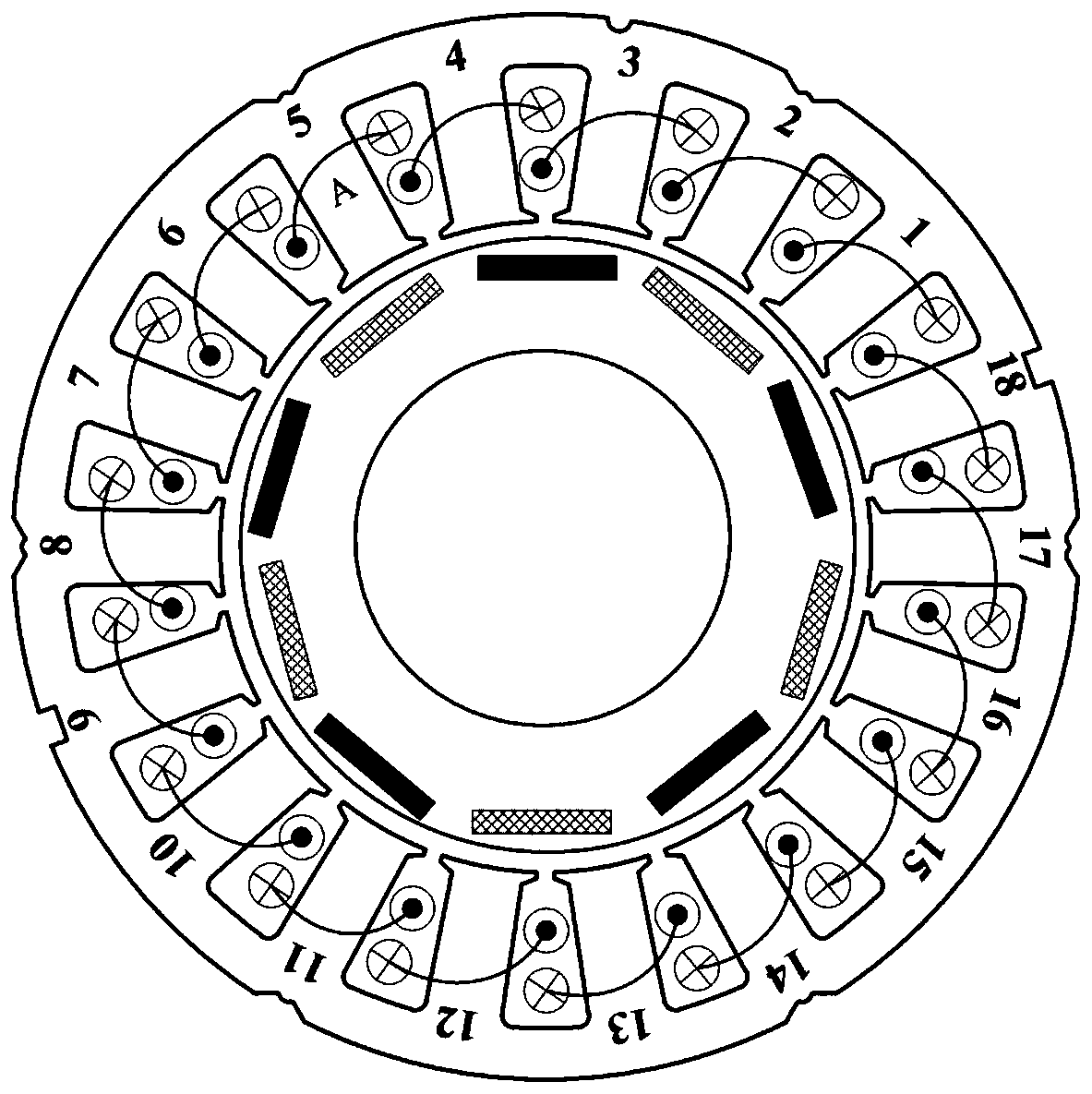

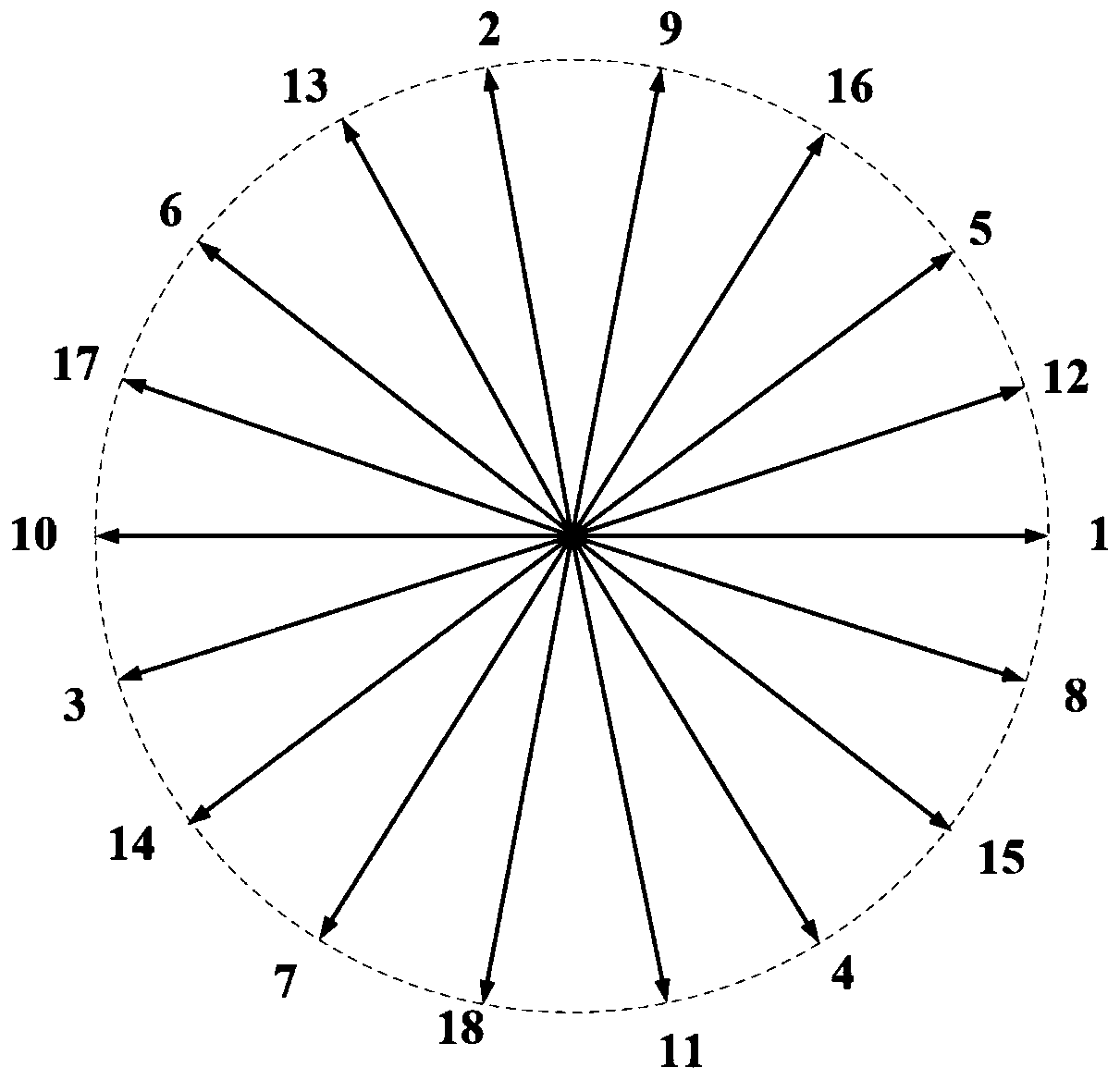

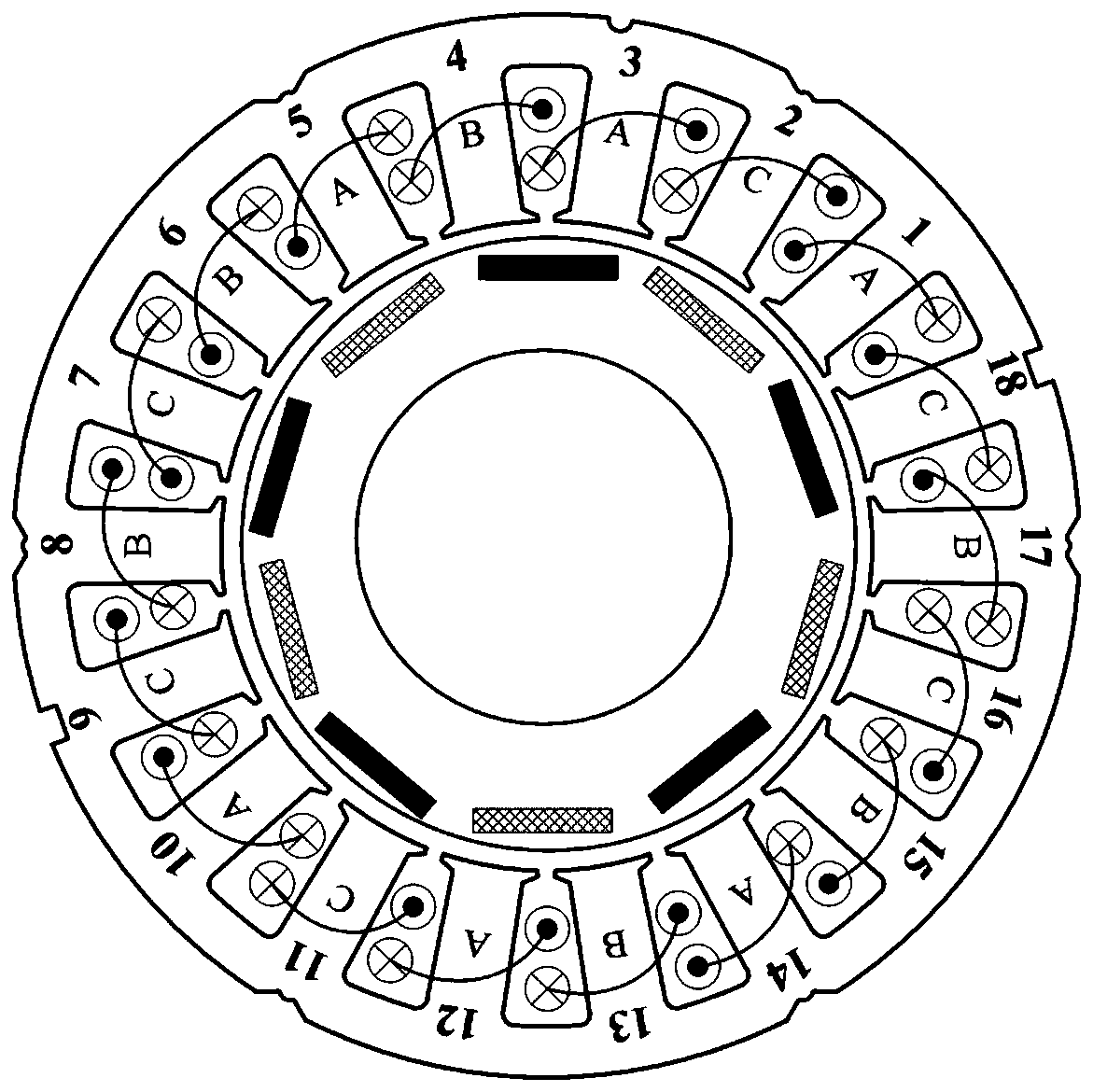

[0030] A 18N-10N structure low noise fractional slot concentrated winding permanent magnet motor, including a stator and a rotor, the stator includes a stator core and an armature winding, the rotor includes a rotor core and a permanent magnet, 18N stator teeth are evenly distributed on the stator, and the rotor is 10N pole, where N is an integer greater than or equal to 1. The rotor is a permanent magnet built-in structure, such as a straight, V-shaped magnetic steel groove structure, etc. The motor topology adopts radial magnetic field or axial magnetic field topology, the motor is an external rotor motor or a double rotor structure, and the winding can also be a dual three-phase system.

[0031] figure 1 The definition of the winding direction of the inlaid winding on each tooth of the concentrated winding permanent magnet motor with 18 slots and 10 pole fractiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com