Alternating current brushless double-fed motor and design method for tooth harmonic coil-wound rotor distributed winding therefor

A technology of a doubly-fed machine and a design method, which is applied to the shape/style/structure of winding conductors, electric components, asynchronous induction motors, etc., can solve the problems of unequal number of coil turns, complex structure, irregular overlapping of ends, etc. Achieve the effects of low harmonic content, high conductor utilization, and neat structure and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

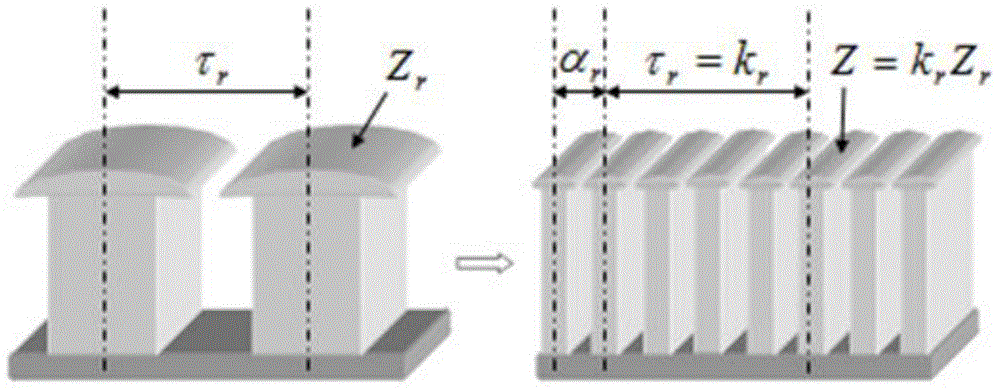

[0066] Example 1 design p 1 = 1 and p 2 = 3 tooth harmonic wound rotor winding scheme

[0067] here p r =p 1 +p 2 = 4, take k r =τ r =20, then Z=k r Z r =80, assuming n r = 11 and y r =16r , at this time The results of harmonic analysis of winding magnetomotive force are shown in Table 2. As can be seen from Table 2, p 1 = 1 The winding coefficient is 0.5698, p 2 =3 The winding factor is 0.7080.

[0068] table 280 slot p 1 / p 2 = 1 / 3 distributed tooth harmonic winding magnetomotive force harmonic analysis

[0069]

[0070]

[0071] because y r =16r , so the concentric winding method can be used, and the pitch of each large and small coil of each phase winding is according to the formula y=y r +n r -(2n-1) calculation, n=1 corresponds to the coil with the largest pitch y=26, n=n r Corresponding to the coil with the minimum pitch y=6, the specific coil expansion layout is as follows Figure 4 shown. from Figure 4 It can be seen that the adjacent ph...

example 2

[0072] Example 2 design p 1 = 2 and p 2 = 4 tooth harmonic wound rotor winding scheme

[0073] here p r =p 1 +p 2 = m r = 6, take k r =14, then Z=k r Z r =84, in order to make the harmonic content in the rotor magnetomotive force small and have a high conductor utilization rate, the scheme of combining two sets of windings in series is adopted. One set of windings takes n r =8 and y r =12, another set of windings takes n r = 5 and y r =9, then The results of harmonic analysis of winding magnetomotive force are shown in Table 3. As can be seen from Table 3, p 1 = 2 The winding coefficient is 0.6878, p 2 =4 The winding coefficient is 0.8106, while the relative amplitude of the main high-order tooth harmonics is <4%.

[0074] Table 384 slot p 1 / p 2 = 2 / 4 distributed tooth harmonic winding magnetomotive force harmonic analysis

[0075]

[0076]

[0077] The winding coil still adopts the concentric winding method, according to the calculation formula y=y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com