Fractional slot single and double-layer lap winding for servo permanent magnet synchronous motor

A permanent magnet synchronous and motor technology, applied in the shape/style/structure of winding conductors, etc., can solve the problems of large vibration noise, large subharmonics, and poor sinusoidal magnetic potential of the motor, and achieve sinusoidal magnetic potential. Good, small span, short end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

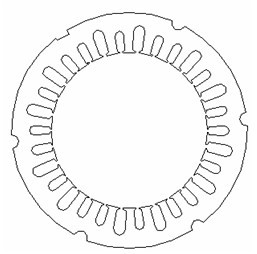

[0009] The embodiment is a servo permanent magnet synchronous motor with a power of 22Kw, a voltage of 330v, 3 phases, a Y connection, a rated current of 45A, a rated speed of 2000r / min, a stator slot of 30 slots, and the number of poles is 8 poles, each pole and each phase slot The number is 5 / 4, and the rotor is a permanent magnet tangential structure (the specific structure is omitted).

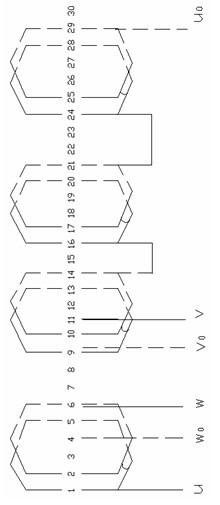

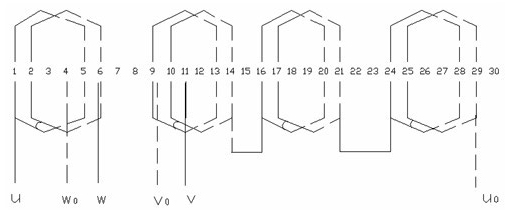

[0010] Such as figure 1 As shown, the number of stator slots is 30, the number of poles is 8 poles, and the number of slots per pole and phase is 5 / 4. It is a fractional slot and arranged symmetrically in 3 phases. The u-phase outlet slot is marked as uu. It consists of 8 coils 1-5, 2-6; 9-13, 10-14; 16-20, 17-21; 24-28, 25-29, all of which are open coils in series, of which 1-5, 10- 14, 16-20, 25-29 four coils with 4 turns per circle (n turns), 2-6, 9-13, 17-21, 24-28 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com