Three-phase single-layer winding of intermediate frequency permanent magnet motor

A single-layer winding, permanent magnet motor technology, applied in the shape/style/structure of winding conductors, synchronous machine parts and other directions, can solve the motor performance such as efficiency, noise, vibration, adverse effects of waveform, double-layer insulation material accounted for. The problem of large slot area and small winding slot full rate can achieve the effect of good magnetic potential sinusoid, high slot full rate, and good sinusoid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

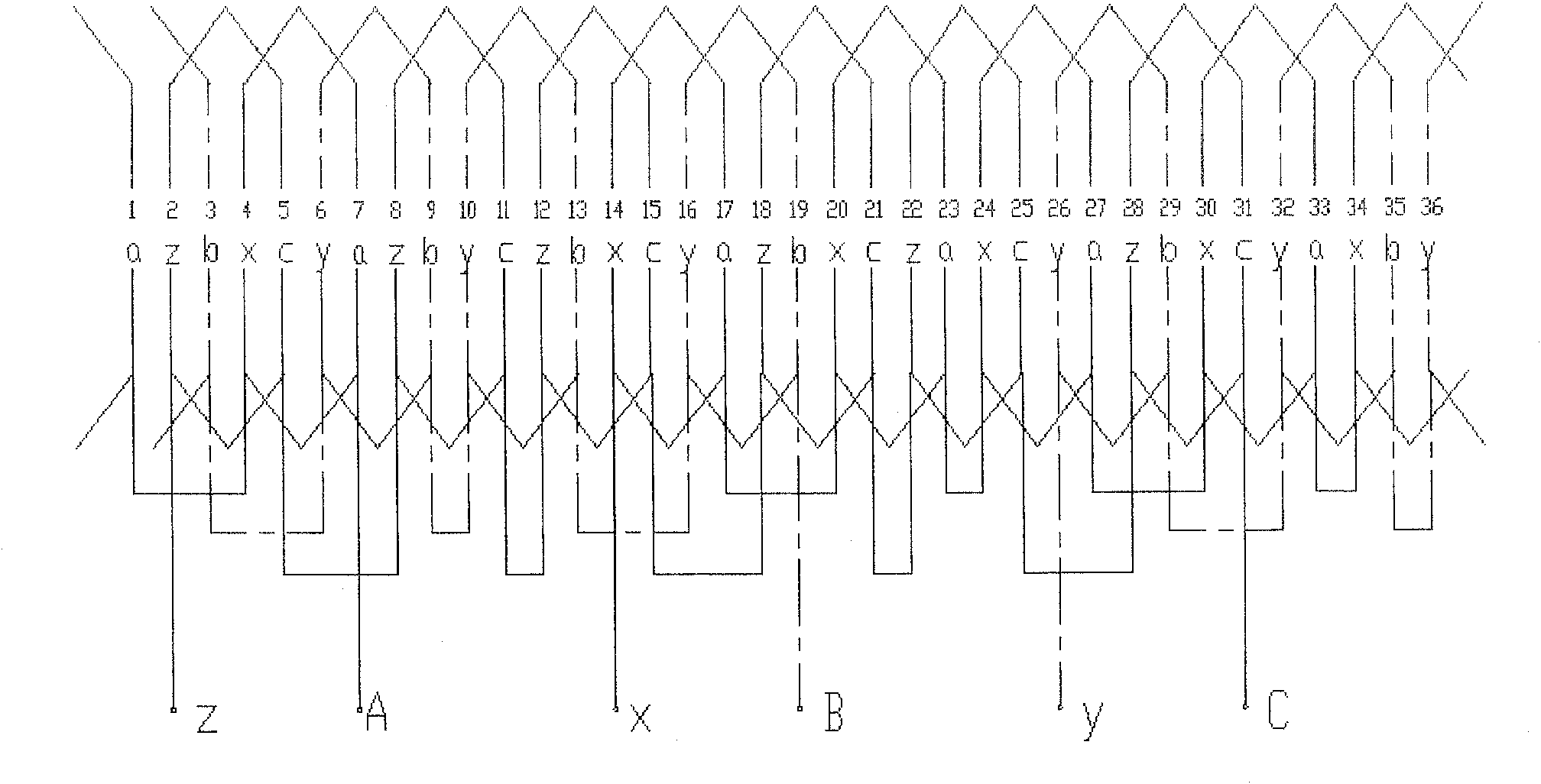

[0008] Embodiment 1: as figure 1 As shown, a Z=36 2P=14 m=3 y=1-4 intermediate frequency permanent magnet motor three-phase single-layer winding layout diagram The three-phase windings AX, BY, CZ are symmetrically arranged, and the pitch is Y=1-4 , Phase A is composed of 6 coils of AX winding in series with all openings, and is placed in the twelve slots of slots 14, 17; 20, 23; 24, 27; 30, 33; 34, 1; 4, 7. The B phase is formed by connecting all openings of the 6 coils of the BY winding in series, and the bottom is in the twelve slots of slots 26, 29; 13, 35; 36, 3; 6, 9; 10, 13; 16, 19. In the same way, the C phase is formed by connecting all 6 coils of the CZ winding in series, and they are placed in the twelve slots of slots 2, 5; 8, 11; 12, 15; 18, 21; 22, 25; 28, 31. The three-phase symmetrical single-layer winding formed in this way has six lead-out joints A, X, B, Y, C, and Z, which can be connected in Y or △ according to needs, and provide different voltages.

Embodiment 2

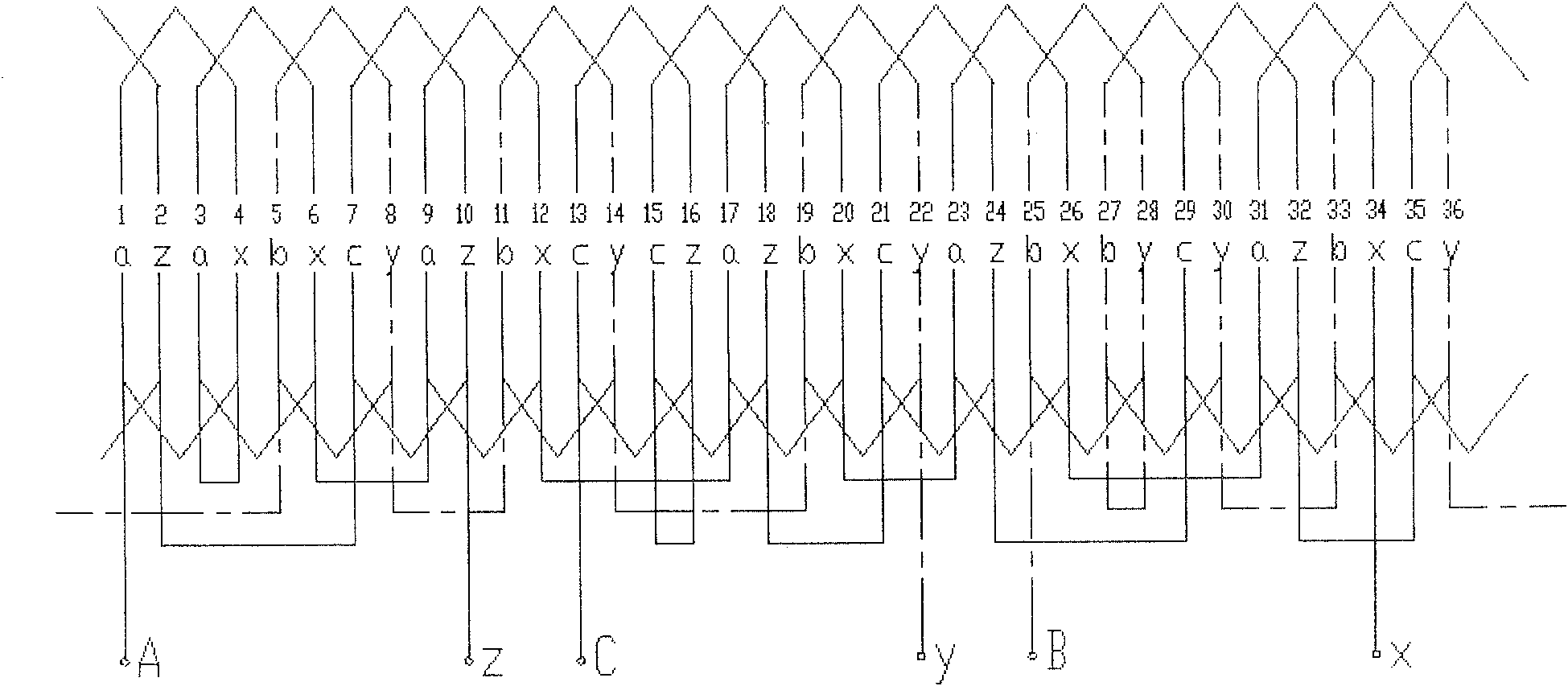

[0009] Embodiment 2: as figure 2 Shown is a Z=36 ZP=10 m=3 y=1-4 intermediate frequency permanent magnet motor three-phase single-layer winding layout diagram, three-phase winding AX, BY, CZ symmetrical layout, pitch Y=1-4 , Phase A is composed of 6 coils of AX winding in series with all openings, and is placed in the twelve slots of slots 1, 4; 3, 6; 9, 12; 17, 20; 23, 26; 31, 34. The B phase is composed of all openings of the 6 coils of the BY winding connected in series. Down in the grooves 25, 28; 27, 30; 33, 36; 5, 8; 11, 14; 19, 22 twelve grooves. Similarly, phase C is composed of 6 coils of CZ winding connected in series with all openings, which are placed in slots 13, 16; 15, 18; 21, 24; 19, 32; 35, 2; 7, 10 in twelve slots. The three-phase symmetrical single-layer winding formed in this way has six lead-out joints A, X, B, Y, C, and Z, which can be connected in Y or △ as required. Different voltages are available. The three-phase symmetrical single-layer short-pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com