Double-layer full-pitch winding coreless linear permanent magnet synchronous motor

A permanent magnet synchronous motor and full-pitch winding technology, which is applied to the shape/style/structure of synchronous machine components, windings, and winding conductors, can solve problems such as poor insulation characteristics and poor heat dissipation performance, and improve the strength of the primary structure And, improve the winding factor and thrust density, reduce the effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

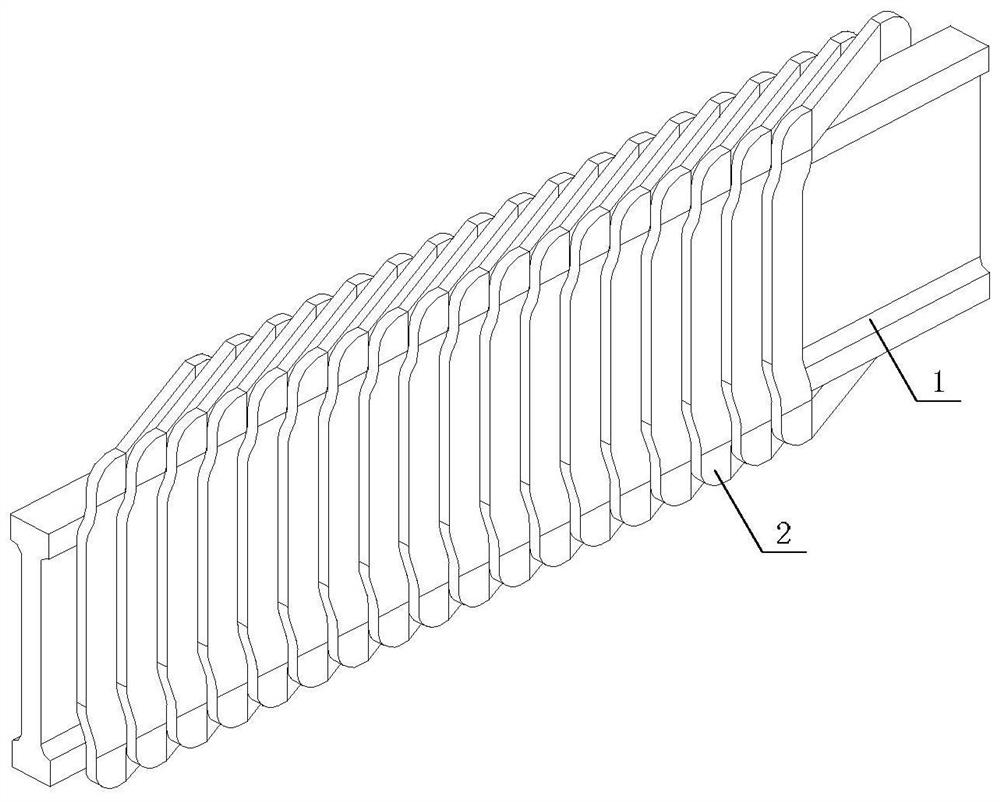

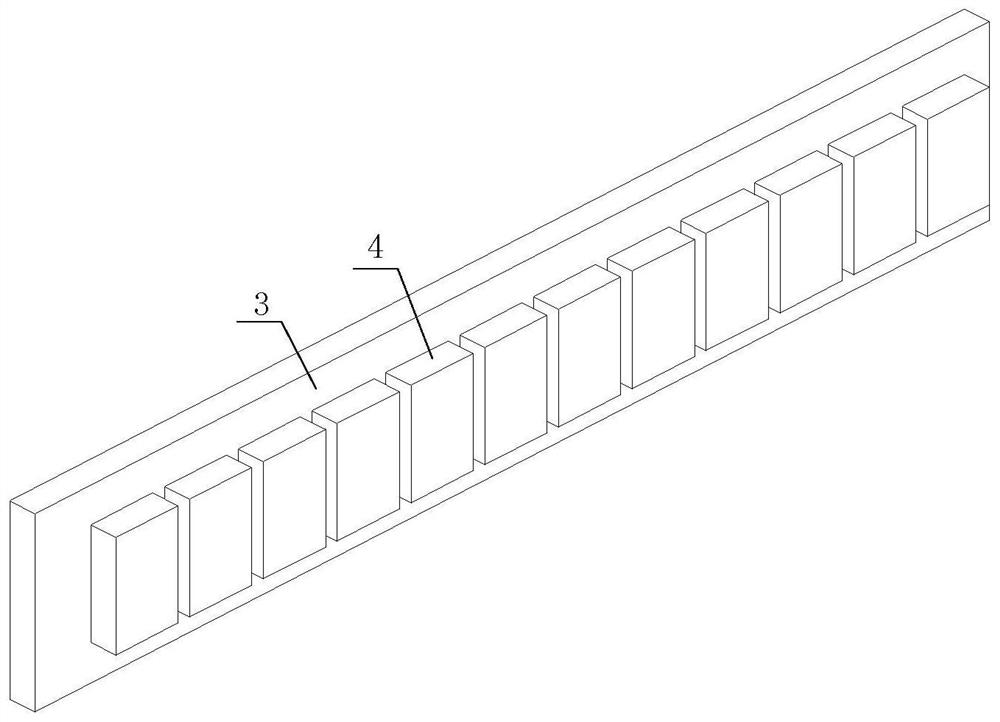

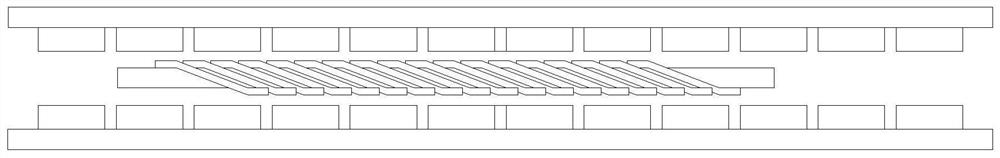

[0029] Specific embodiment one: reference Figure 1 to Figure 5 To describe this embodiment in detail, the double-layer whole-pitch winding ironless linear permanent magnet synchronous motor described in this embodiment includes one primary, two secondary and base 7. The two secondary are located on both sides of the primary, and an air gap is formed between the primary and the secondary. The two secondary bottoms are connected by the base 7. The secondary includes: a plate 3 and 12 permanent magnets 4, the 12 permanent magnets 4 are alternately arranged along the motor movement direction N and S poles and fixed on the air gap side of the yoke plate 3, so that the secondary 12 magnetic poles. The magnetizing directions of the permanent magnets 4 facing each other in the two secondary stages are the same.

[0030] The primary includes: a substrate 1, 18 coils 2 and an output board 5. The coil 2 is rectangular, and all four corners are provided with arc-shaped chamfers. The 18 ...

specific Embodiment approach 2

[0032] Specific embodiment two: reference Image 6 with 7 Detailed description of this embodiment, this embodiment is a further description of the double-layer full-pitch winding coreless linear permanent magnet synchronous motor described in the first embodiment. In this embodiment, the primary is a liquid cooling structure. Specifically:

[0033] The upper end of the base plate 1 is provided with a "U"-shaped cooling pipe 8 arranged along the three sides of the top end of the base plate 1. The cooling pipe 8 is located between the top end of the base plate 1 and the inner ring surface of the top end of the coil 2.

[0034] The double-layer full-pitch winding coreless linear permanent magnet synchronous motor in this embodiment adopts direct liquid cooling at the coil end, which improves the cooling capacity and output capacity of the motor.

specific Embodiment approach 3

[0035] Specific embodiment three: reference Figure 8 with 9 Detailed description of this embodiment, this embodiment is a further description of the double-layer full-pitch winding coreless linear permanent magnet synchronous motor described in the first embodiment. In this embodiment, the primary is a liquid cooling structure. Specifically:

[0036] Four cooling liquid flow channels 9 are opened along the length of the substrate 1, and the four cooling liquid flow channels 9 are located on the upper and lower parts of the substrate 1 in pairs.

[0037] The double-layer full-pitch winding coreless linear permanent magnet synchronous motor in this embodiment adopts direct liquid cooling at the coil end, which improves the cooling capacity and output capacity of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com