Method for modifying double layer winded performing winding into Y-Delta mixed performed winding

A technology for hybrid forming and forming windings, which is applied in the shape/style/structure of winding conductors, electric components, and the manufacture of motor generators, etc. It can solve the problems of low level of high-voltage motors and difficulty in improving the efficiency of high-voltage motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

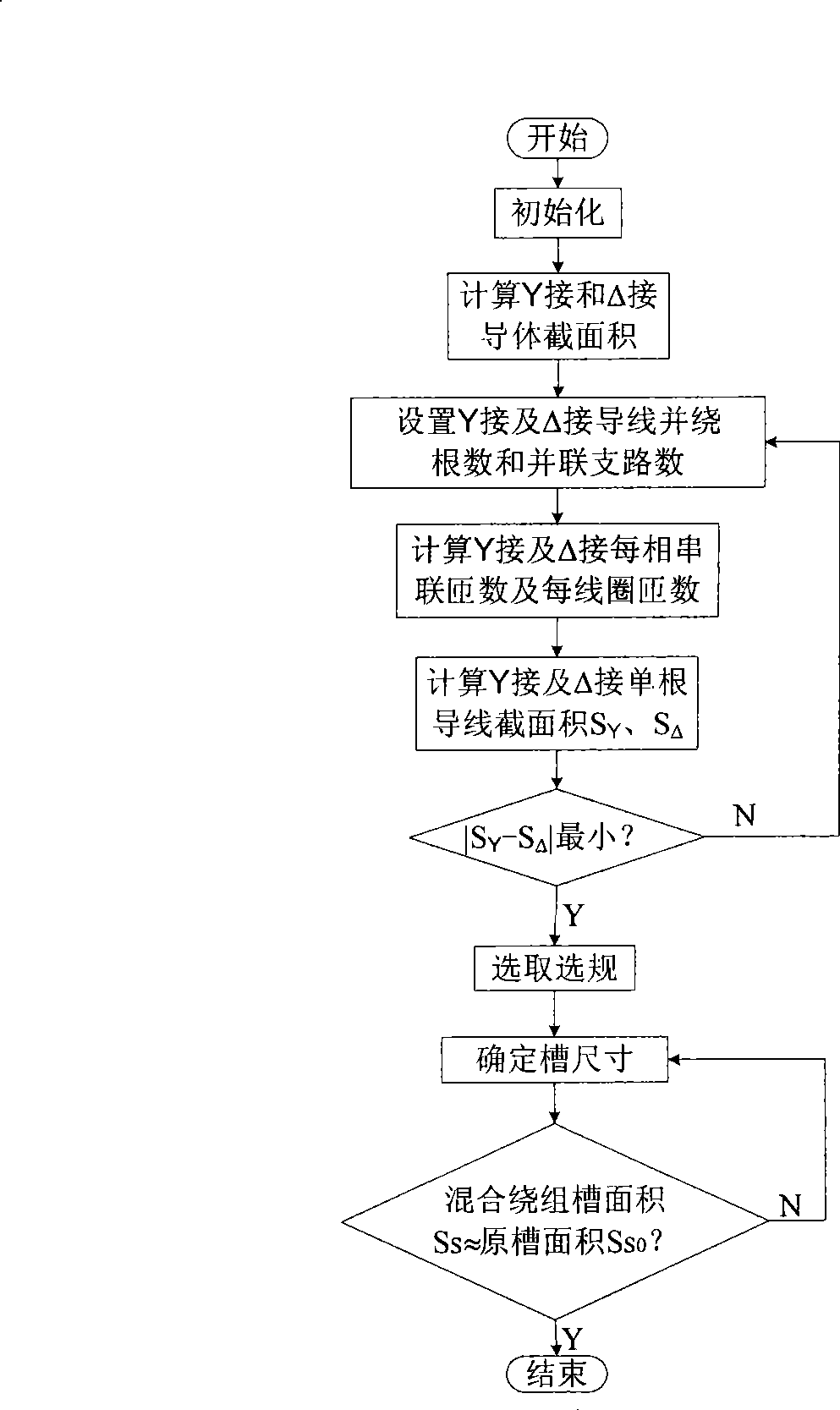

[0032] The key of the present invention is the determination of the wire gauge, the number of coil turns and the number of parallel branches in the Y connection and the Δ connection part. The method flow is as follows: figure 1 shown. The specific implementation is as follows:

[0033] 1. Know the data of the original three-phase winding, including the following parameters:

[0034] Number of parallel branches a 1 , the number of parallel wires n, the number of slots per pole per phase q, the number of series turns per phase N φo , the point angle α between two adjacent slots, the fundamental wave winding coefficient k dp1 , wire width b and thickness a, wire cross-sectional area A c , pitch y, number of stator slots Q 1 and the number of pole pairs p of the motor;

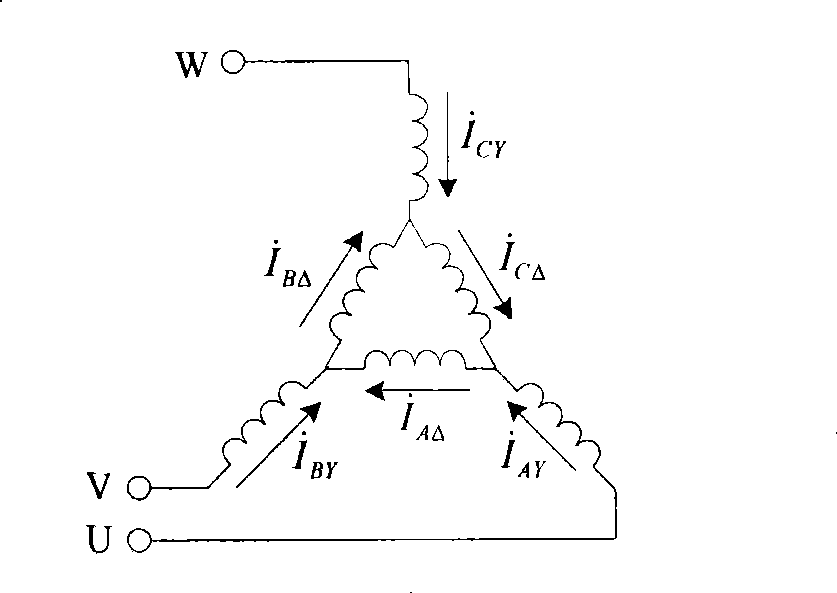

[0035] 2. Let the current of the original ordinary three-phase winding wire be I 1 , the current density is J, and the conductor cross-sectional area is A c ,but image 3 Medium Y part phase current I AY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com