Metal plate developed intersecting line marking-gauge

A scribing gauge and intersecting line technology, applied in the field of sheet metal unfolding intersecting line scribing gauges, can solve the problems of low scribing accuracy, repetitive labor, cumbersome and other problems, save template materials, and achieve high scribing accuracy. , Improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

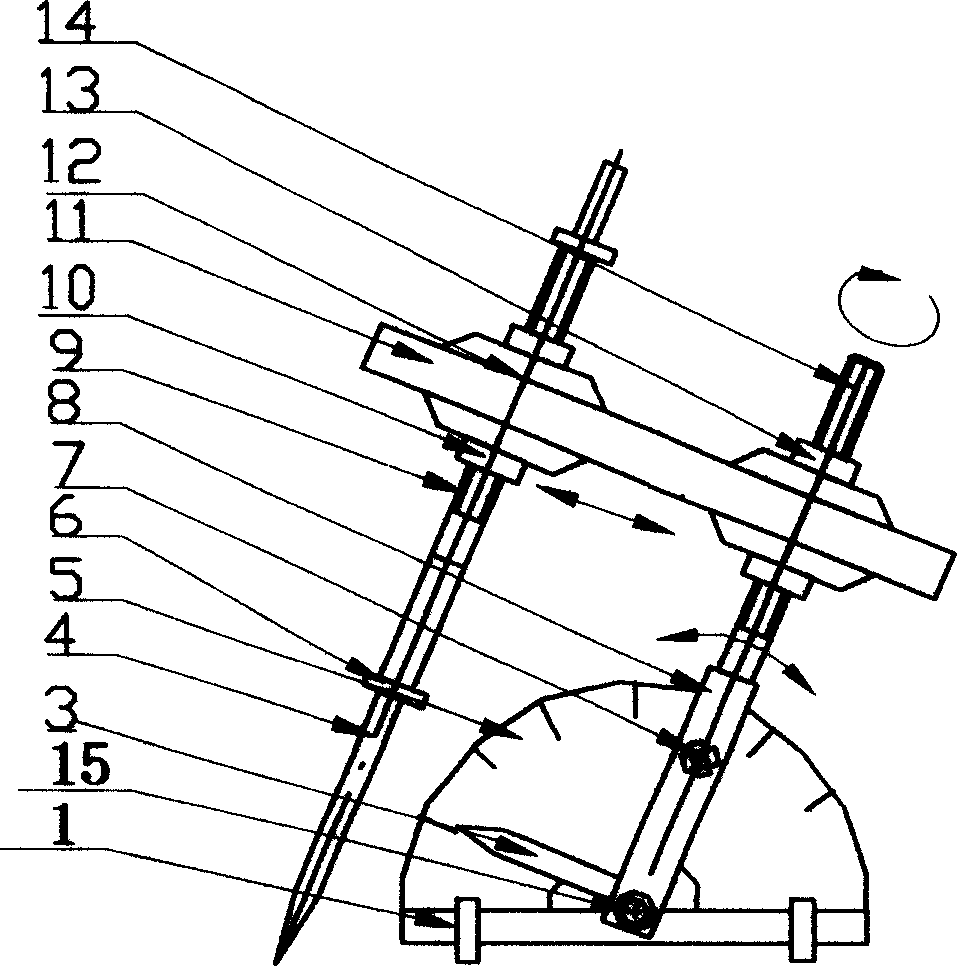

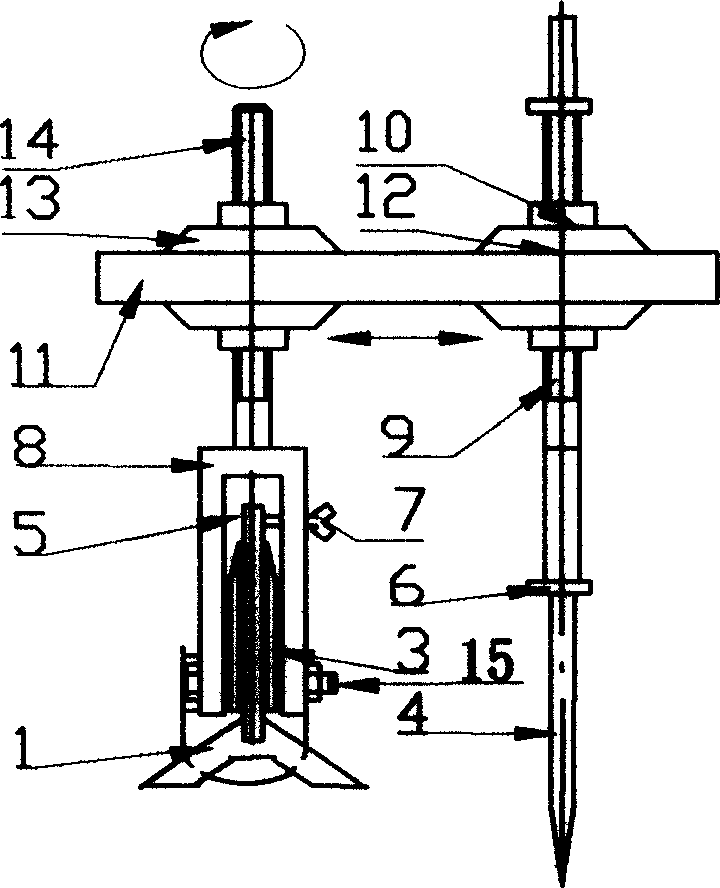

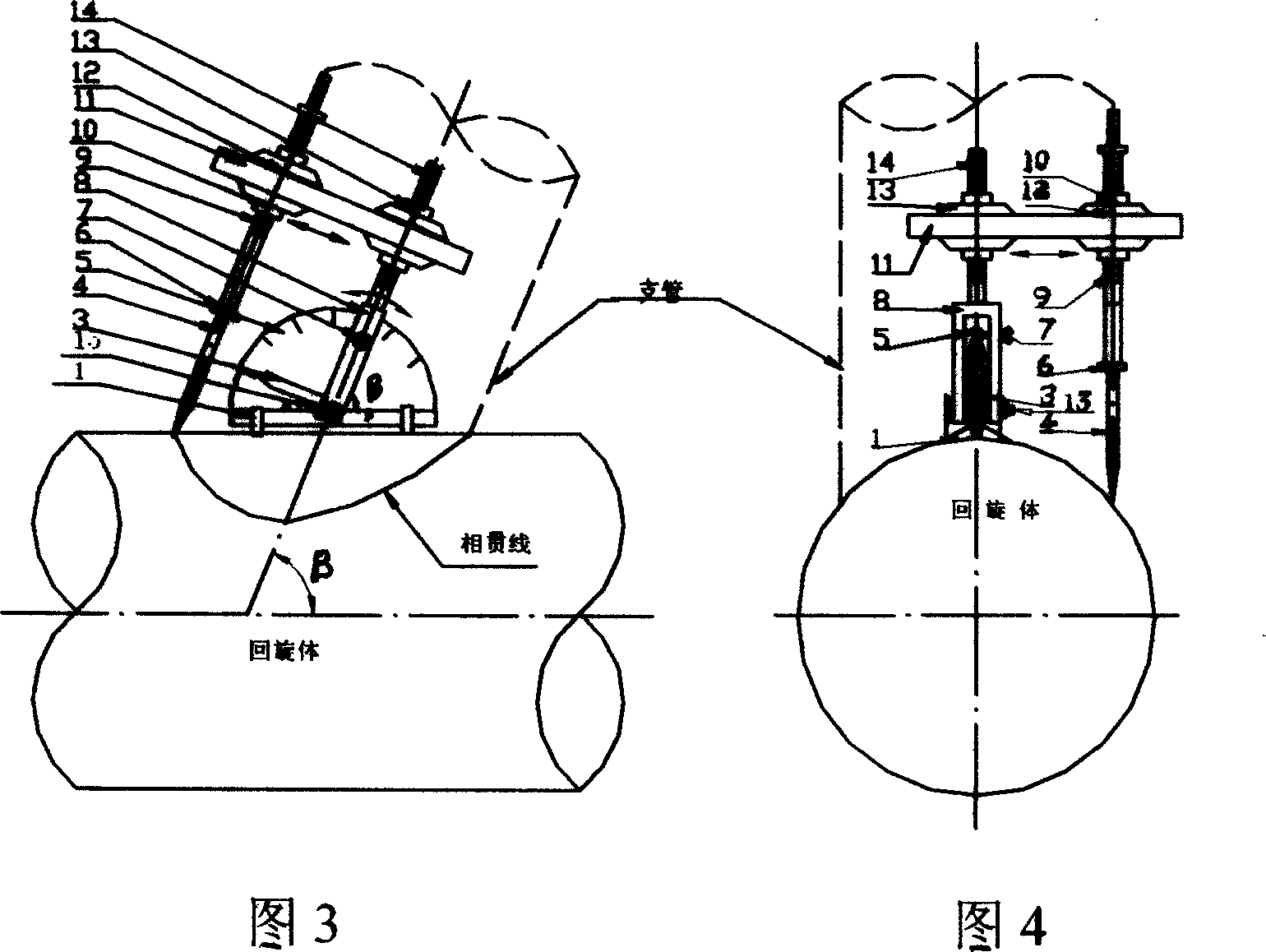

[0012] The present invention consists of a pointer 3, a marking needle 4, a dial 5, a centering sleeve 6, a positioning bolt 7, a fork rod 8, a sleeve 9, a positioning nut 10, an adjustable swivel frame 11, a sizing pointer 12, and an adjusting nut 13 , Adjustable screw rod 14 and connecting bolt 15 are formed. The dial 5 is a semi-circular angle dial, which can be made of an insulating glue board, such as an insulating glue board with a thickness of 9mm. The two ends of the dial 5 are respectively installed on a dial bracket 1, so that the dial can sit on the surface of the gyratory body with any diameter smoothly, and keep the dial surface and the axis of the gyratory body in the same plane. There is a central hole in the center of the disc angle, and the connecting bolt 15 connects the lower ends of the two fork rods of the fork rod 8, the pointer 3 and the dial 5 through the central hole on the dial 5, and the pointer 3 and the fork rod 8 are connected to each other. Vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com