Annular axial pressing device and annular axial pressing method for transformer coil

A technology of transformer coil and compression device, which is applied in coil manufacturing and other directions to achieve uniform compression, improve product quality, and ensure the effect of line segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

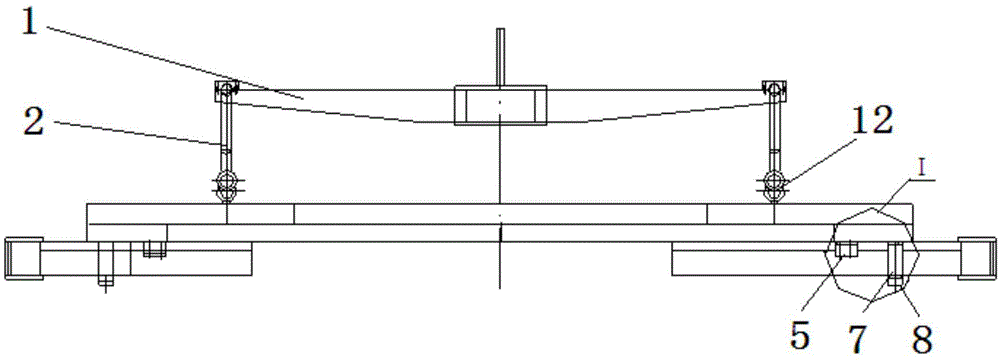

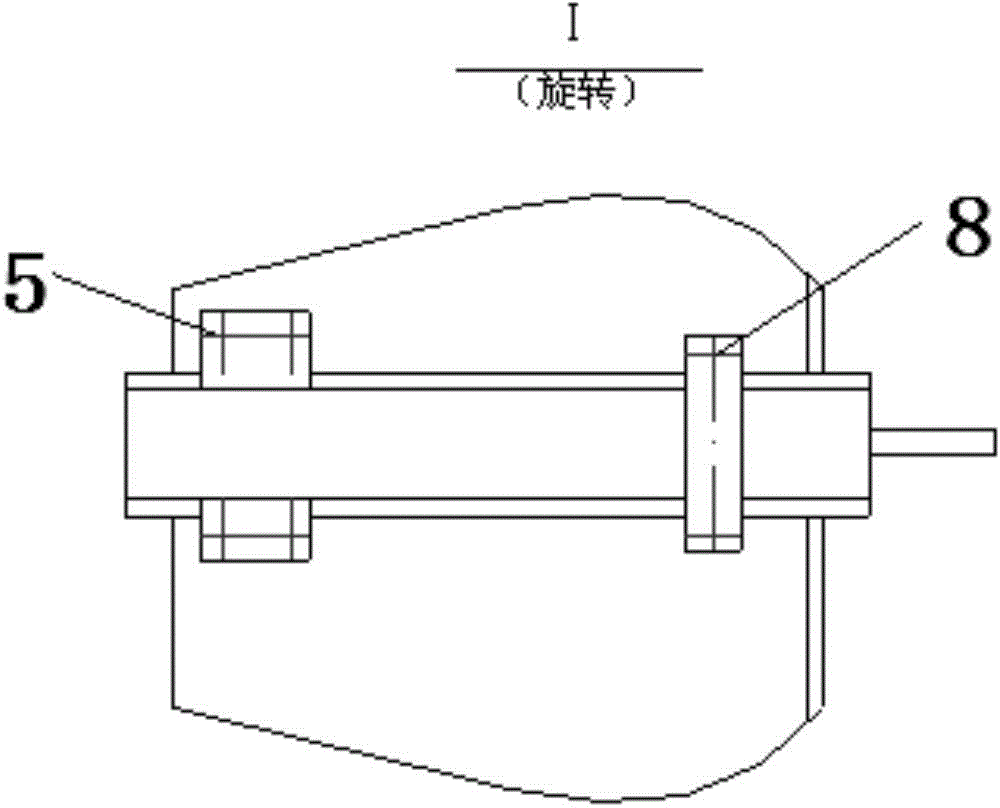

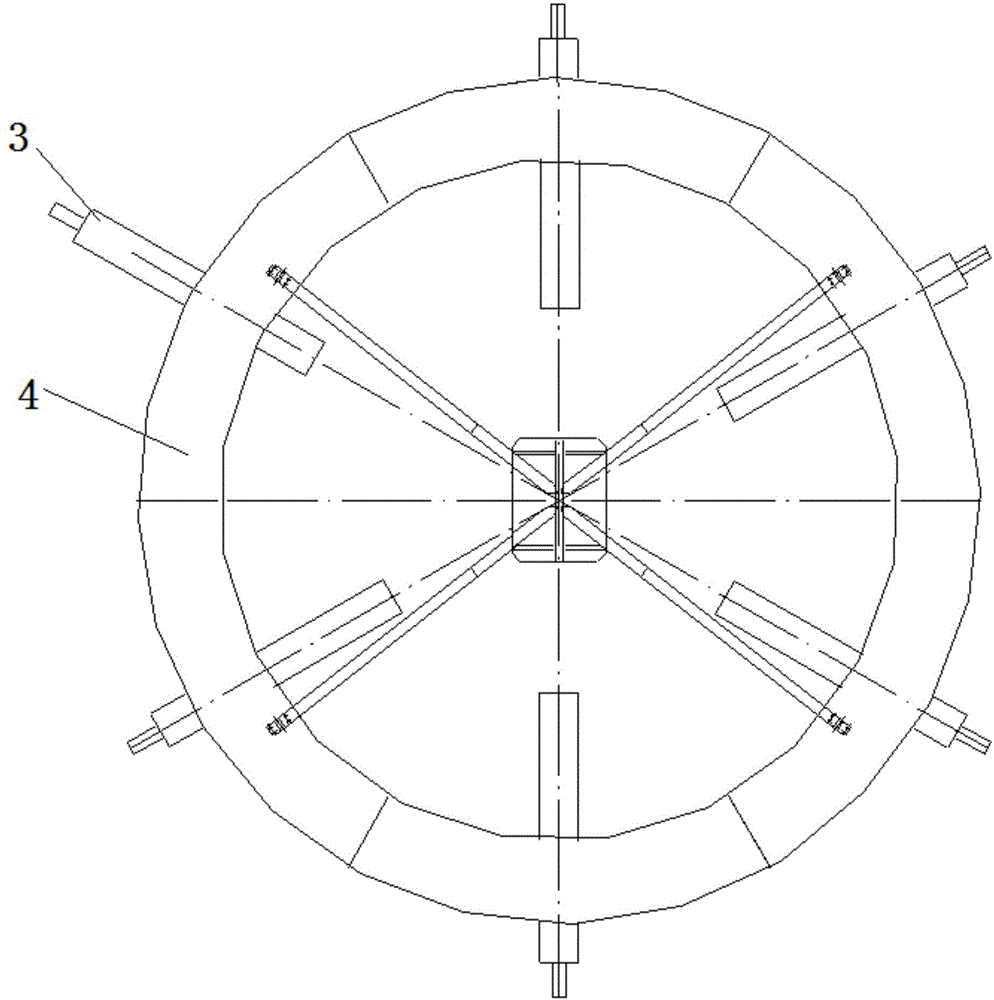

[0030] Such as Figure 1A ~ 1C As shown, a transformer coil annular axial compression device of the present invention is characterized in that it has a pressure plate 4 and an upper hanging plate 1, the two are connected by a chain 2, and the lower part of the pressure plate 4 is provided with multiple Adjust the pressure beam 3 of the position. The part of the lower part of the pressure plate 4 corresponding to the pressure beam 3 is provided with a pull-out structure. The pull-out structure includes a slide rail 5 and ferrules. The slide rail and ferrule are fixedly installed on the bottom surface of the pressure plate 4 along the radial direction of the pressure plate 4. 3 sides are slidably connected to the slide rail 5, and the pressure beam 3 is inserted into the ferrule.

[0031] Such as Figure 1C As shown, the ferrule includes two connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com