Selection method of bearing preload tooling and adjusting shim for dual clutch automatic transmission

A technology of automatic transmission and double clutch, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve the problems of gearbox life damage, large design preload requirements, and lack of operability. To achieve the effect of extending bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below through specific examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as a technical solution of the present invention. Program limitations.

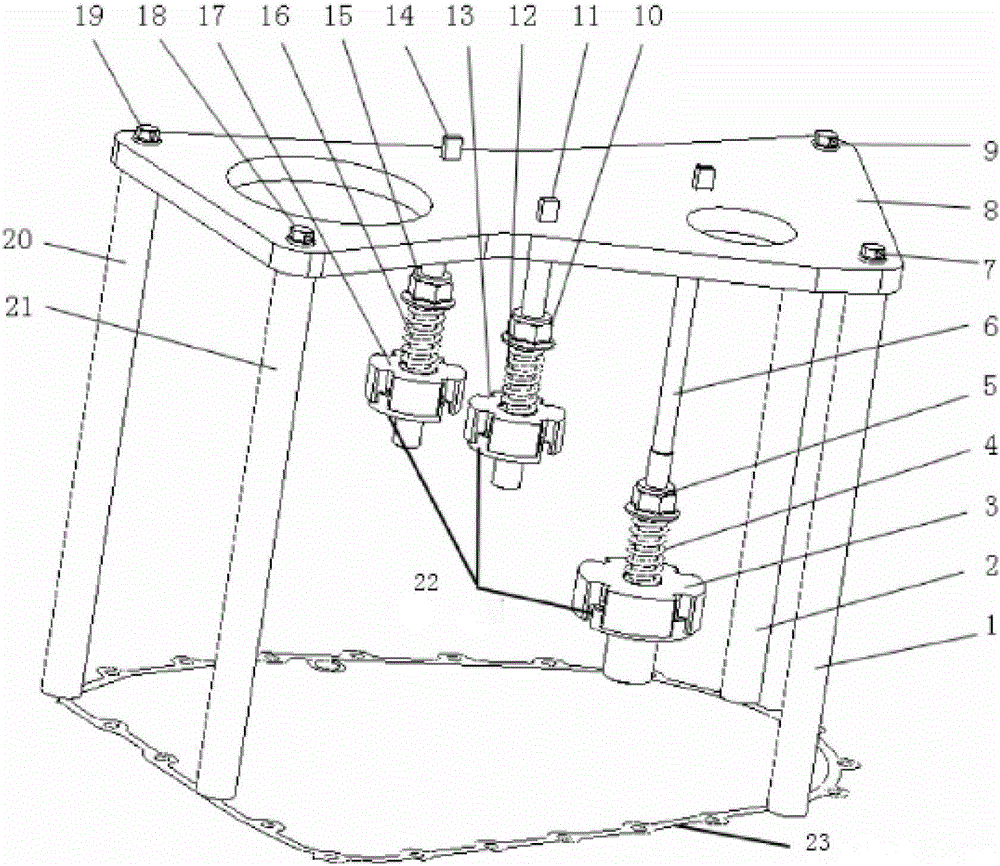

[0027] Such as figure 1 and figure 2 As shown, the dual-clutch automatic transmission bearing preload tooling includes four support rods (1, 2, 20, 21) mainly used to support the entire tooling connected to the housing.

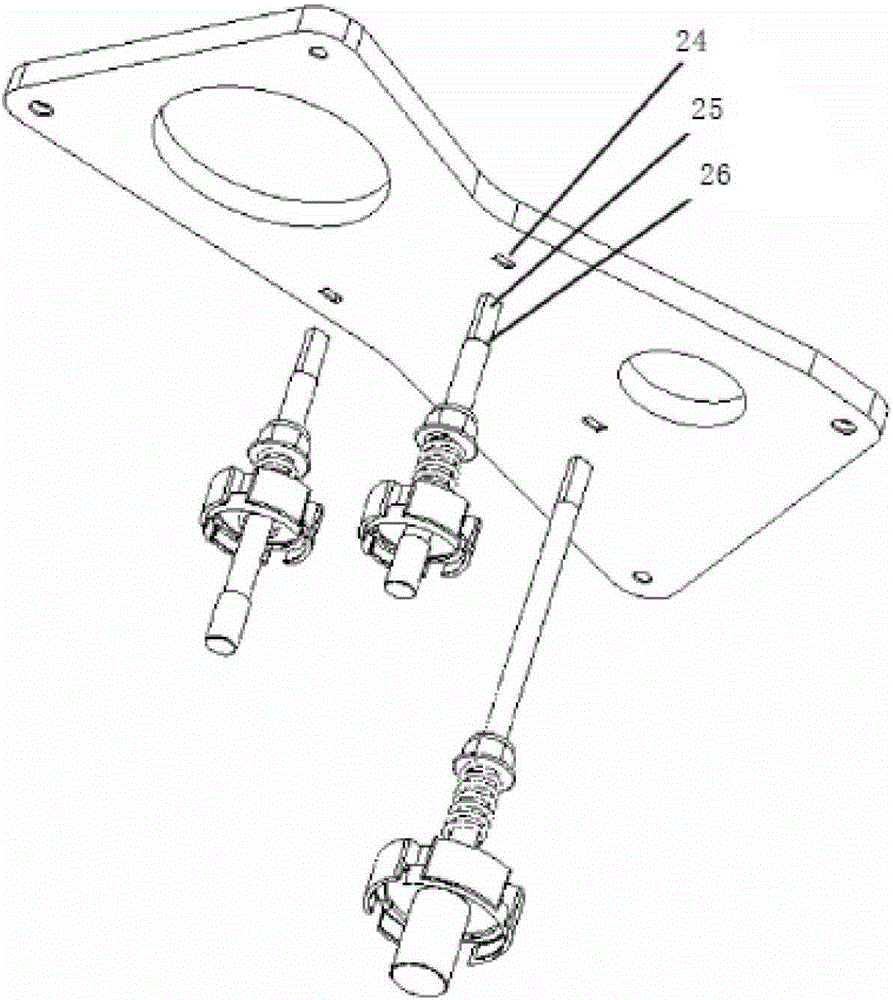

[0028] The limit partition 8 is connected with the support rods (1, 2, 20, 21) through connecting bolts (7, 9, 18, 19); the limit partition 8 is provided with three through holes 24, and the differential cone bearing sleeve The barrel assembly, the output shaft I taper bearing sleeve assembly and the output shaft II taper bearing sleeve assembly are connected with the limiting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com