Numerical control electromagnetic brake winding tension device for distribution transformer

A distribution transformer and electromagnetic braking technology, which is applied in the manufacture of inductance/transformer/magnet, circuit, coil, etc., can solve the problems of unstable air pressure source, energy consumption, loose wire, etc., and achieve the purpose of overcoming insufficient tension force Stable, easy to operate, and stable braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to describe in detail the technical content and structural features of the digitally controlled electromagnetic braking winding tensioning device for distribution transformers of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

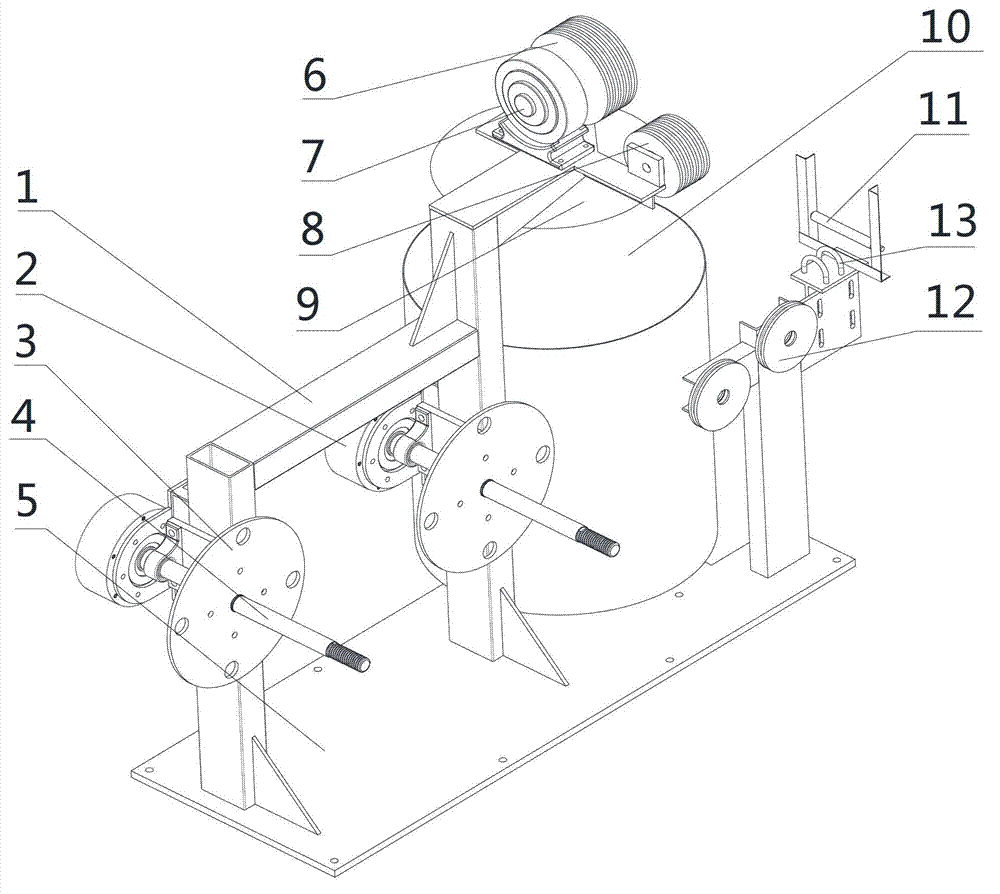

[0009] Such as figure 1 As shown, the numerically controlled electromagnetic brake winding tensioning device for distribution transformers of the present invention is composed of a controller, enamelled round wire tensioning mechanism, paper-wrapped flat wire tensioning mechanism, enameled wire guiding mechanism, enameled wire buffering mechanism and outgoing wire guiding anti-twisting mechanism. Scratch-resistant body composition. The enameled round wire tensioning mechanism, the paper-wrapped flat wire tensioning mechanism, the enameled wire guiding mechanism, the enameled wire buffering mechanism and the outlet guiding anti-twist and anti-scratch mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com