A telescopic transmission

A transmission, telescopic technology, applied in transmissions, transmission parts, belts/chains/gears, etc., to achieve a wide range of uses, ensure convenience, and prevent foreign objects from entering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

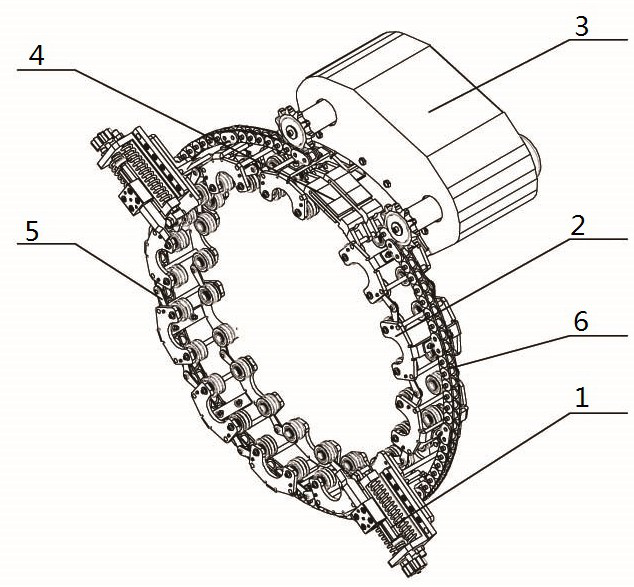

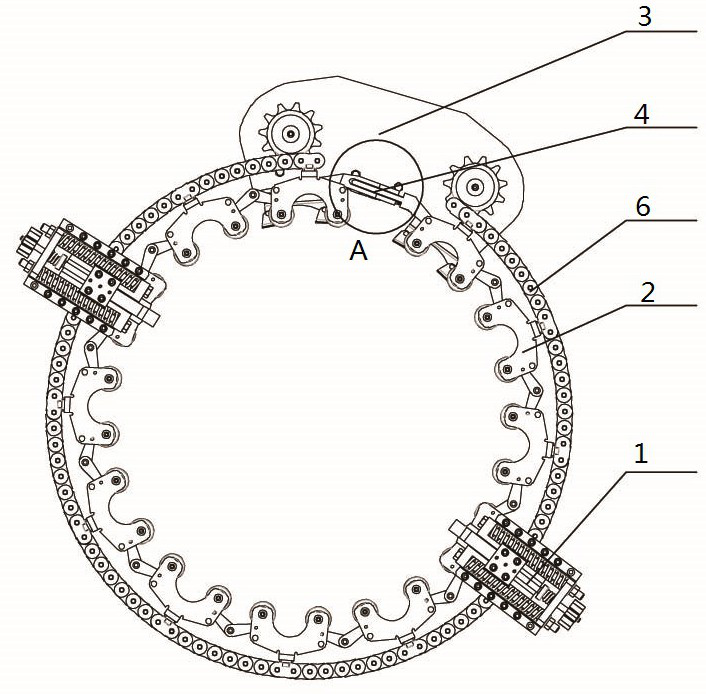

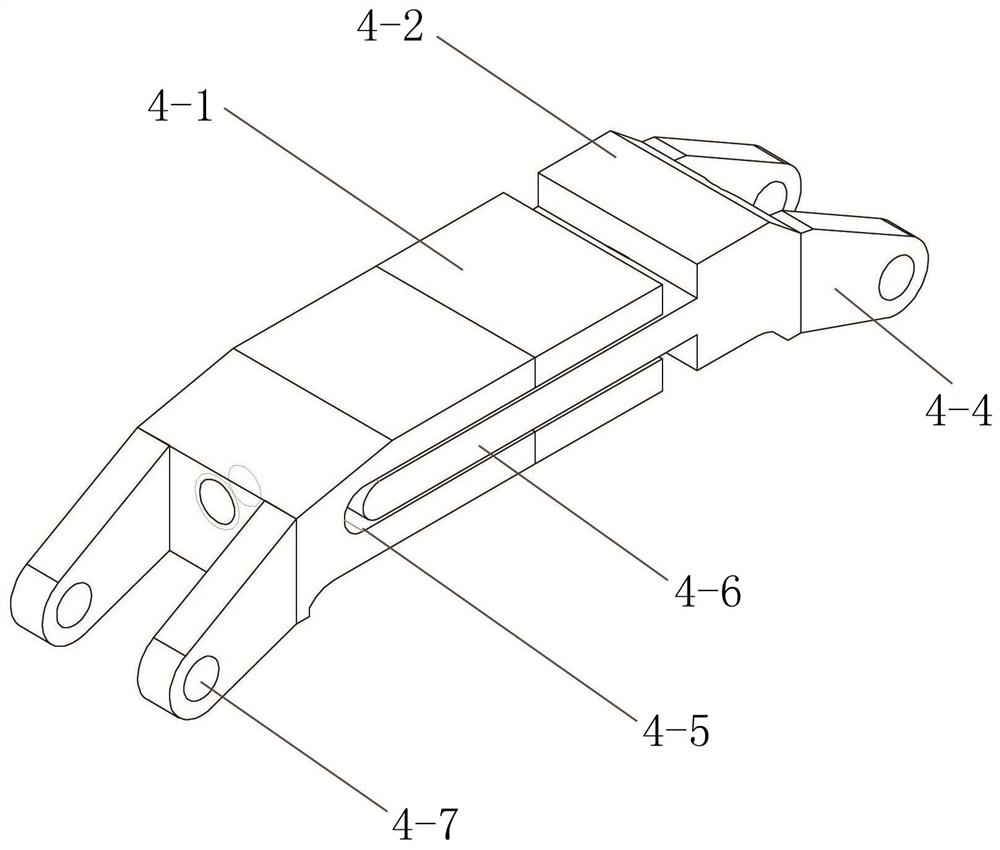

[0030] Such as Figure 1-12 As shown, a telescopic transmission device includes a sprocket box 3 and a track trolley chain. The track trolley chain is composed of a plurality of track trolleys 2 hinged at the end, and two adjacent track trolleys 2 are connected by a movable hinge 5. The hinge 5 can be adjusted arbitrarily in the range of 360°, which is convenient for the dolly to be fixed on various workpieces of different shapes. The track trolley at the head end of the track trolley chain is connected to the track trolley at the tail end through the tensioning mechanism 4, and the track trolley chain and the tensioning mechanism 4 form a ring-shaped support structure; the outer side of the track trolley chain is provided with a transmission chain 6, and each track trolley 2 The tops of the tops are all connected with the transmission chain 6 by thread pairs, and the head and tail ends of the transmission chain 6 are respectively arranged on the track trolley 2 at the head en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com