A rotary cutting and beveling machine

A bevel cutting, rotary technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve problems such as difficult and no open flame requirements, unable to meet market demand, and prone to open flames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

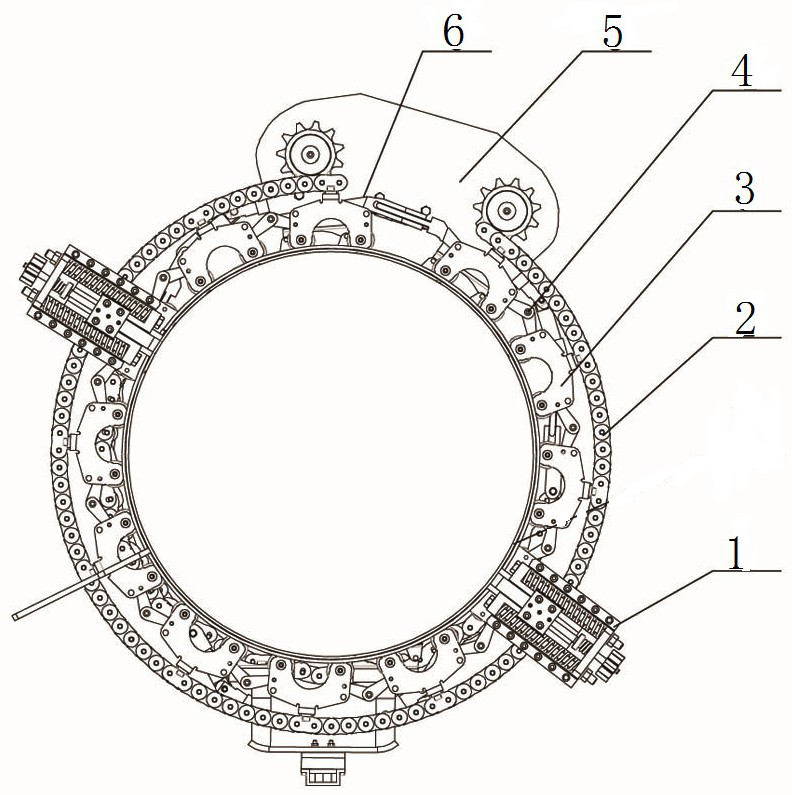

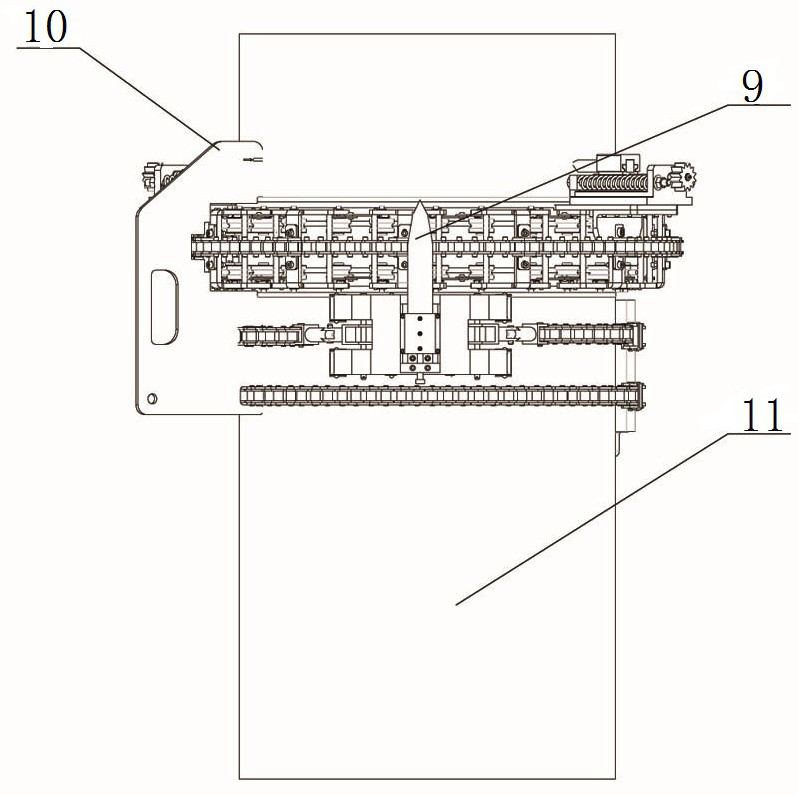

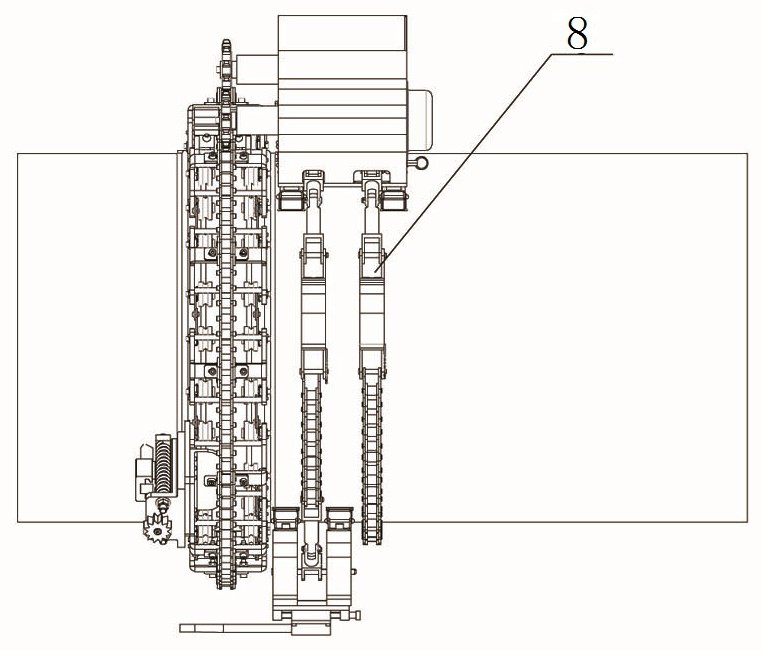

[0059] A rotary cutting and beveling machine, comprising an automatic feed profiling tool holder 1, a telescopic transmission device, a telescopic guide rail 47 and a lever mechanism 9, the telescopic transmission device is installed on the telescopic guide rail 47; The telescopic transmission device includes a sprocket box 5 and a track trolley chain. The track trolley chain is composed of several track trolleys 3 hinged head to tail through connecting hinges 4. The track trolley 3 at the head end of the track trolley chain and the track trolley 3 at the tail end pass through the chain tensioning mechanism 6 connection, the track trolley chain and the chain tensioning mechanism 6 form a ring-shaped support structure; the outer side of the track trolley chain is provided with a transmission chain 2, and the top of each track trolley 3 is connected with the transmission chain 2 through a thread pair, and the transmission chain 2 The first and last two ends of the chain are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com