Using method for semi-automatic frame combined welding tool

A welding tooling, semi-automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate spatial positioning of frame welding tooling, reducing welding labor intensity, and difficulty in frame ejection. Achieve the effect of reducing welding labor intensity, simple structure and small deformation of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

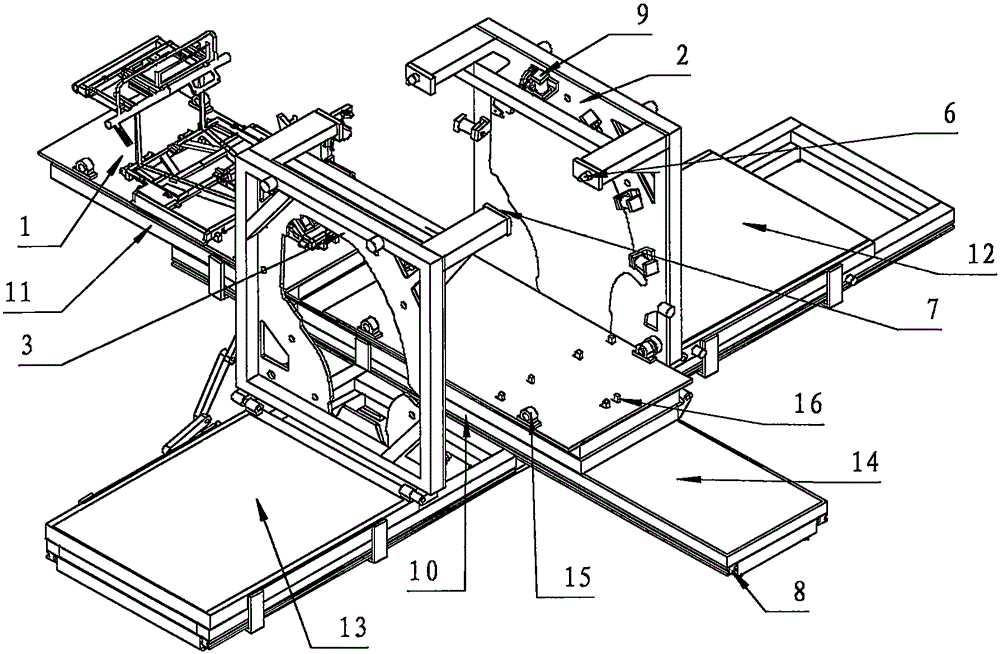

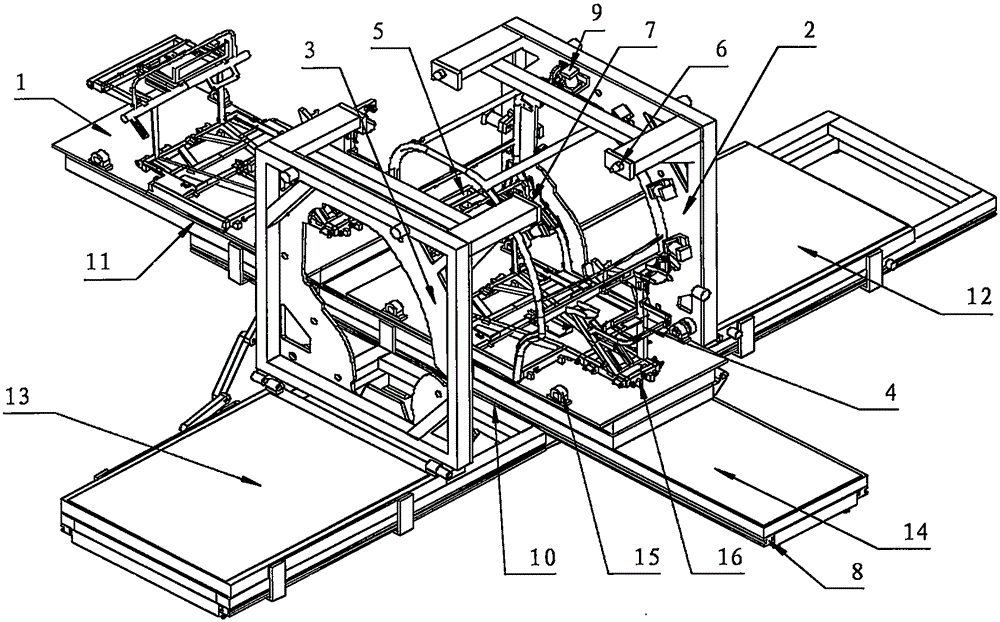

[0023] Wire gauge 8 is set under the combined welding tool of the frame, and three sections of stations are respectively set for wire gauge 8: at least one mobile station is reserved above the three sections of wire gauge 8, and at least one mobile chassis tooling is set above wire gauge 8 Component platform 1; chassis assembly welding station 11 is set in front of central assembly welding station 10, and assembly replacement station 14 is arranged behind central assembly welding station 10; horizontal guide rails are symmetrically arranged on both sides of center assembly welding station 10 section wire gauge 8; The assembly welding station 10 is arranged in a symmetrical line with the left door frame assembly welding station 12 and the right door frame assembly welding station 13;

[0024] The left door frame assembly welding station 12 on the left side of wire gauge 8 is provided above one end of the left door frame tooling assembly positioning frame 2, and the flipping devi...

Embodiment 2

[0028] After the chassis tooling component platform 1 moves to the central assembly welding station 10, start the air pump, and place the left door frame in the bayonet of the door frame opening reserved for the left door frame tooling component positioning frame 2 to clamp the cylinder 9, open the air valve, and clamp the cylinder 9 to pass through The rod clamps the left door frame and the right door frame tooling component positioning frame 3 to reserve the door frame mouth and clamps the right door frame in the bayonet of the clamping cylinder 9, and opens the air valve, and the clamping cylinder 9 clamps the left door frame through the rod; The door frame tooling assembly positioning frame 2 and the right door frame tooling assembly positioning frame 3 are correspondingly turned over, and the left door frame and the right door frame are driven to turn over and correspond respectively.

Embodiment 3

[0030] Then, the hydraulic devices on the left side and the right side start respectively, and promote the left door frame tooling assembly positioning frame 2 and the right door frame tooling assembly positioning frame 3 to move to the central assembly welding station 10; promote the left door frame and the right door frame to the front suspension tooling assembly 4 and The beam of the rear suspension tool assembly 5 is positioned and clamped, and when the positioning pin 6 of the positioning frame is clamped with the positioning pin seat 7, the assembly welding is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com