Cold zone tunnel longitudinal temperature experimental device involving train piston wind factor

A technology for tunnels and experimental devices in cold regions, applied to measuring devices, railway vehicle testing, instruments, etc., can solve problems such as many assumptions, difficulty in meeting engineering needs, icing, etc., to ensure driving safety, reduce construction costs, and improve The effect of economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

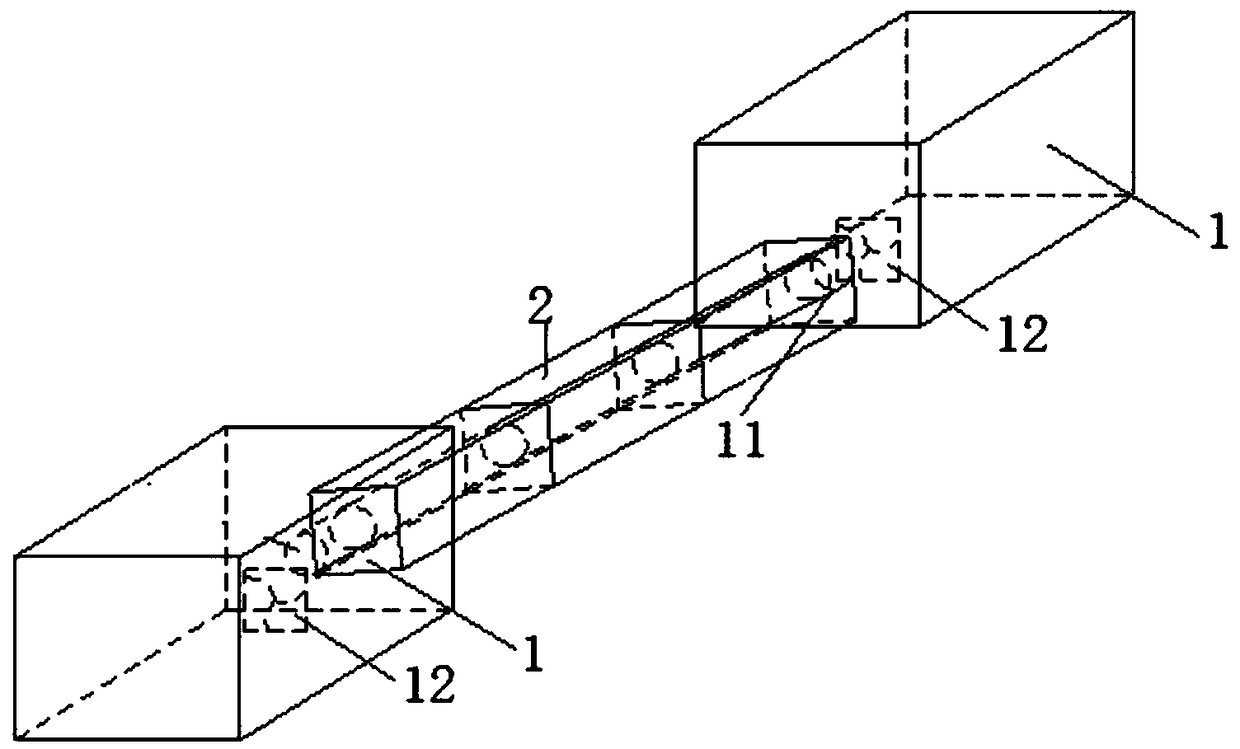

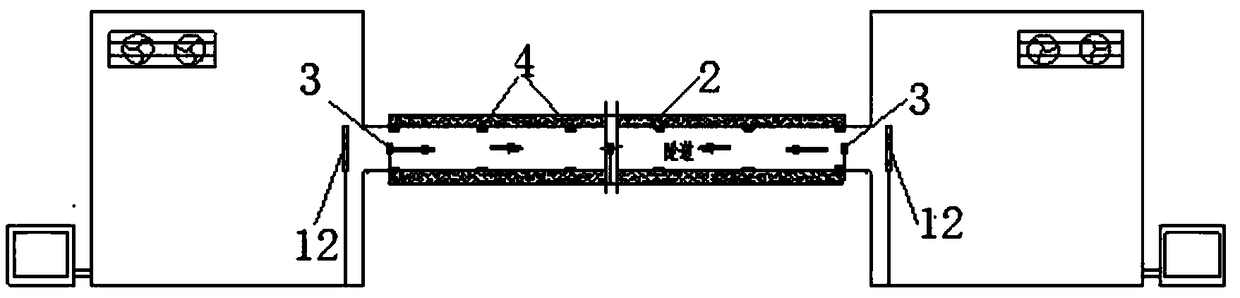

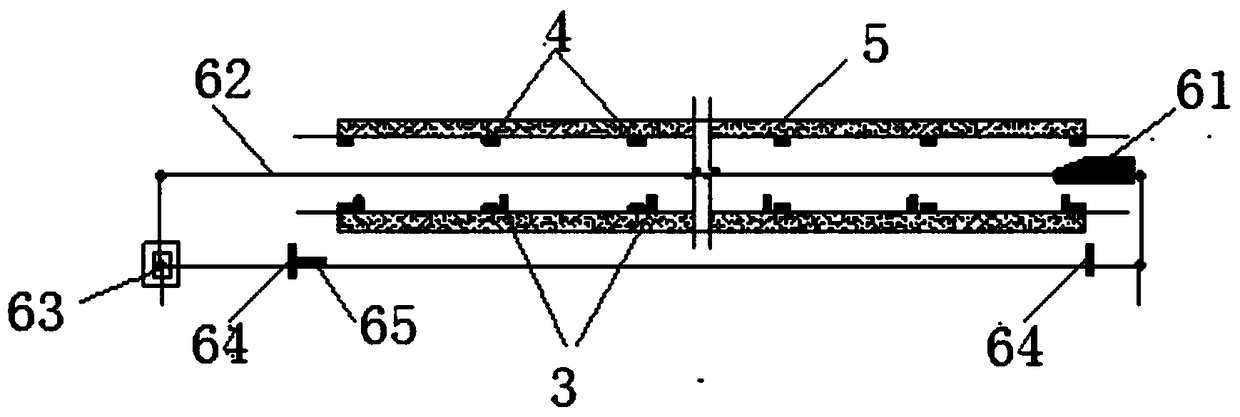

[0027] like Figure 1-6 As shown, the tunnel longitudinal temperature experiment device in the cold area involving the train piston wind factor includes a constant temperature warehouse 1, which is composed of a refrigeration system and a warehouse. There are 2 rooms in total, one main and one auxiliary. Warehouse 1 is mobile and can move freely. The temperature in the warehouse can be precisely controlled through the refrigeration system. There is a circular hole on one side of the warehouse (it can also be a tunnel-shaped hole for the experiment to be more realistic). The size of the circular hole 11 is consistent with the inner diameter of the tunnel model. The four corners of the lower part of the auxiliary constant temperature warehouse 1 are equipped with pulleys, which can move freely, thereby providing a more convenient cold source for experiments.

[0028] The wind speed control device is installed in the warehouse with an axial flow fan 12 at a distance of 1110-20cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com