Patents

Literature

34results about How to "Small heating range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold crucible induction smelting method using ultrahigh smelting temperature

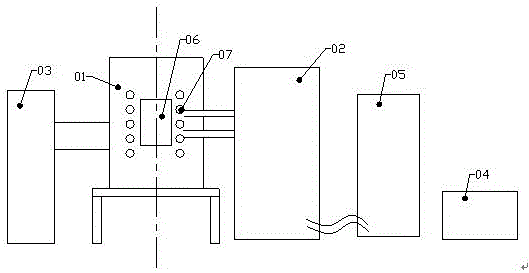

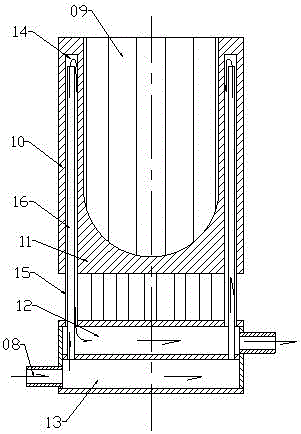

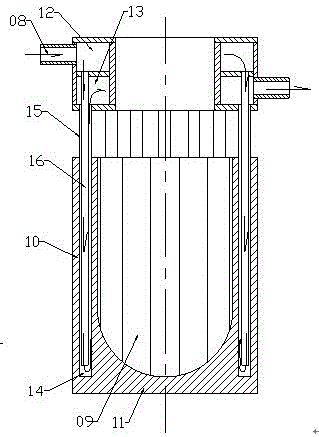

The invention relates to a cold crucible induction smelting method with ultra-high smelting temperature. Auxiliary energy device; (3) Set a branch cooling waterway at the bottom of the water-cooled copper crucible. The branch cooling waterway is to make a radial branch hole extending to the center of the bottom at the bottom of the crucible, and make the outer end of the radial branch hole and the crucible The cooling holes in the petals are connected to the main hole; (4) The water-cooled copper crucible is made into a shape with a hole in the bottom, and it is blocked by a separate water-cooled red copper crucible with a water supply jacket and a return water jacket at the bottom The bottom hole of the crucible and the upper part of the crucible plug are in the shape of petals. Its advantages are: the melting temperature of the induction cold crucible technology is increased to higher than 2000°C, even higher than 3000°C, and the application field of the induction cold crucible technology is extended to almost all refractory metals and high melting point precious metals.

Owner:李蔚晶

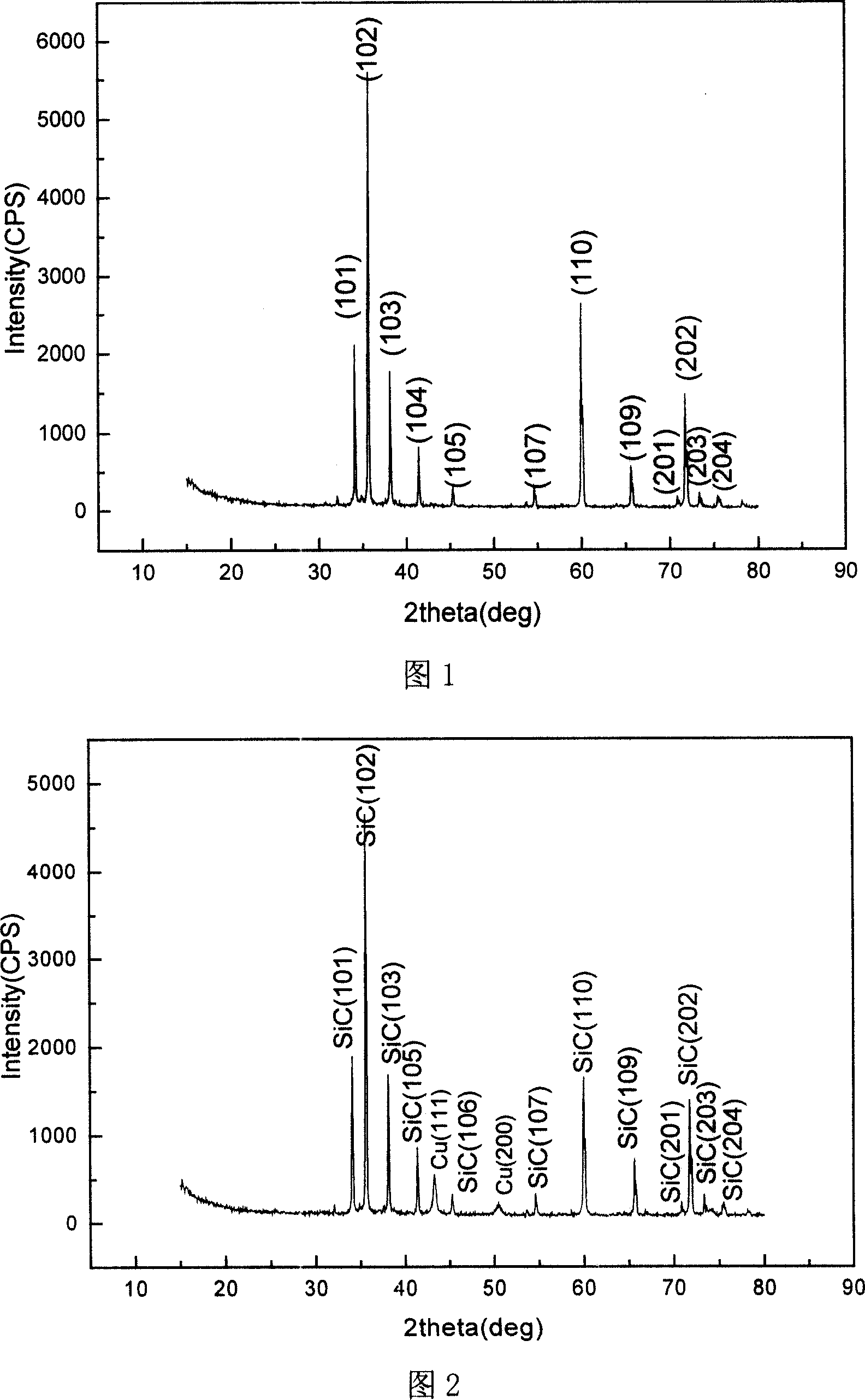

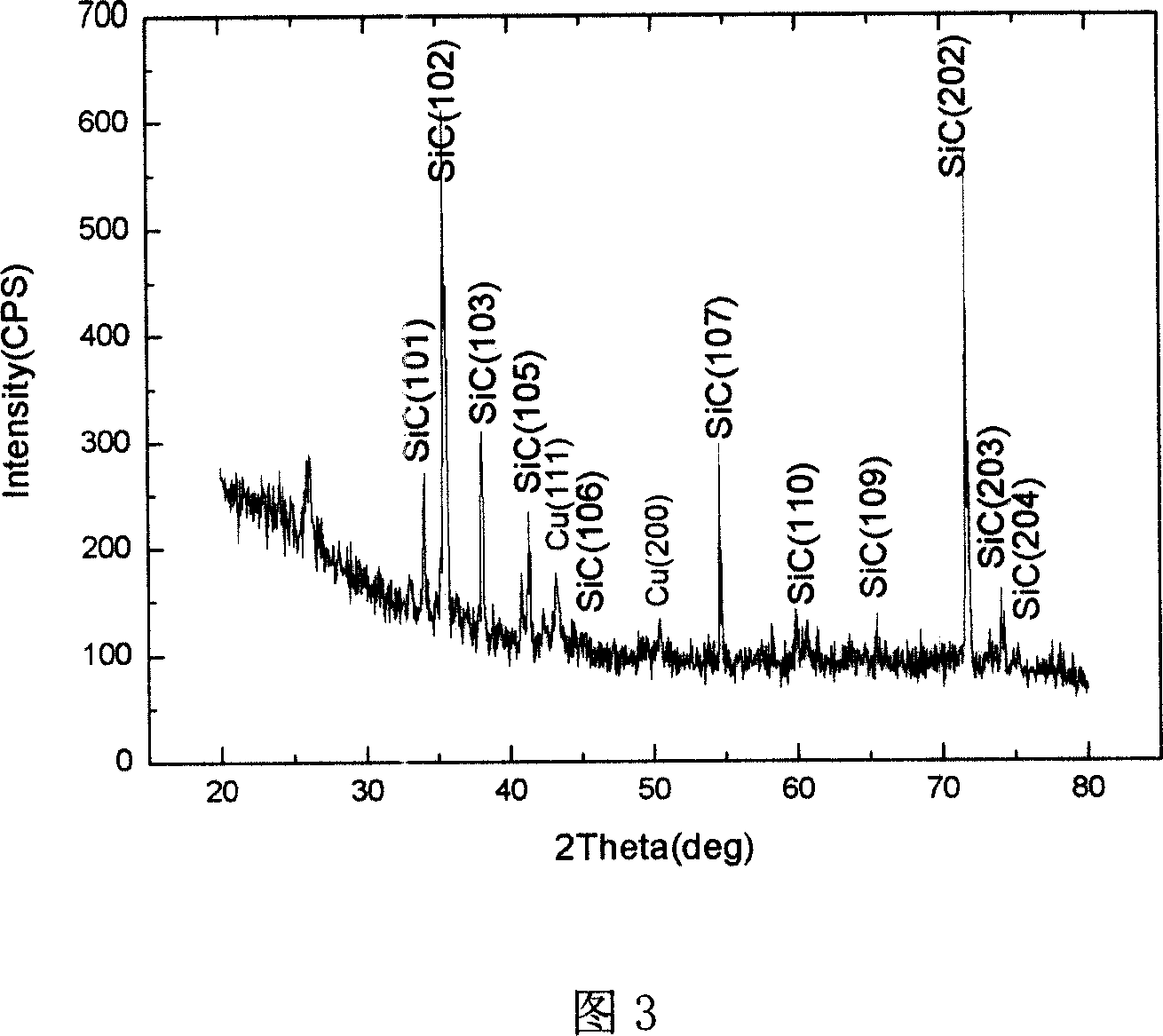

Method for magnetron sputtering coppering film on SiC micro-particle surface

InactiveCN101135045AUniform and continuous depositionImprove compactnessVacuum evaporation coatingSputtering coatingAtmospheric pressureCopper

The magnetically controlled sputtering process for coating copper film on the surface of SiC grain features that metal copper film is deposited on the surface of SiC grain in 0.1-500 micron size as the substrate inside magnetically controlled sputtering equipment with copper target of 99.999 % purity by means of regulating the vibrating power of ultrasonic wave and the oscillation frequency of sample holder to disperse SiC grains homogeneously and controlling the operation pressure inside the vacuum chamber, sputtering power, temperature, sputtering period and other technological conditions. The technological process is simple, low in cost and without waste pollution, and the prepared film is homogeneous and continuous.

Owner:CHINA NAT ACAD NANOTECH & ENG +2

Method for producing ammonium polyphosphate by using stepwise reaction and polymerization

The invention discloses a method for producing ammonium polyphosphate by using a stepwise reaction and polymerization, relates to a method for producing ammonium polyphosphateproducts with different polymerization degrees in the same set of device, in particular to a production method of ammonium polyphosphate with high purity, high polymerization degree and the average polymerization degree larger than 1000. The method comprises the following steps in sequence: a. adding a polycondensation agent into polyphosphoric acid as a raw material in the weight ratio of 1:1 and mixing evenly; b. adding the material obtained by the step a into a continuous synthetic reactor for reacting; and c. further polymerizing products obtained in the step b for 30-300 minutes at the pressure of 0.00MPa-0.6MPa and the temperature of 120DEG C-500DEG C to obtain the high-purity ammonium polyphosphate products with the polymerization degree of 10-1,800. The invention has the advantages of convenient production and control, high yield, low energy consumption and benefit for large-scale continuous industrial production.

Owner:YUNNAN CHEM RES INST

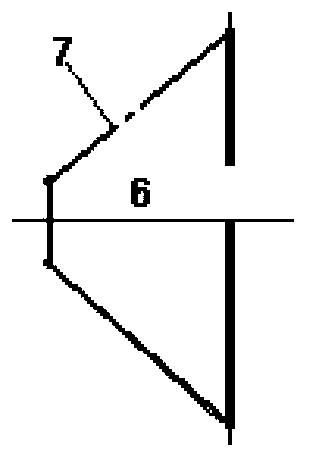

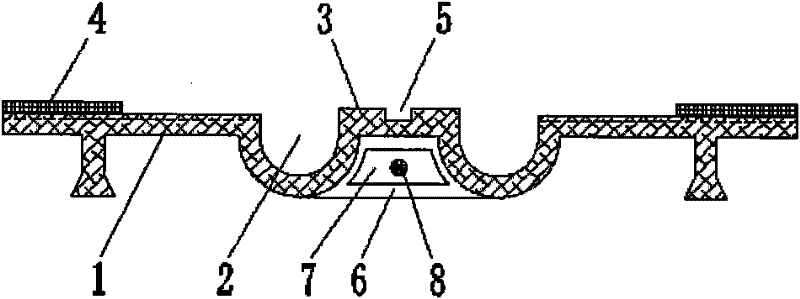

Brazing method for cable shielding layer and shell

InactiveCN102350552ARealize one-time moldingUniform and stable shapeSoldering apparatusEngineeringConductor Coil

The invention discloses a brazing method for a cable shielding layer and a shell, wherein wire branching holes are formed in two ends of the shell; a cable passes through the wire branching holes; and the brazing method comprises the following steps of: winding, namely winding brazing wires on parts, opposite to the wire branching holes, of the cable shielding layer; fixing, namely fixing the cable, the shell and the brazing wires by a clamp; heating, namely, putting a brazing part into an induction coil and heating the brazing part by induction heating equipment; and cooling, namely stopping heating until the brazing part is cooled. By the brazing method, one-time molding of joints at two ends of the shell can be realized, the shape of the shell is uniform and stable, the brazing quality is easy to guarantee, and efficient and automatic production requirements can be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

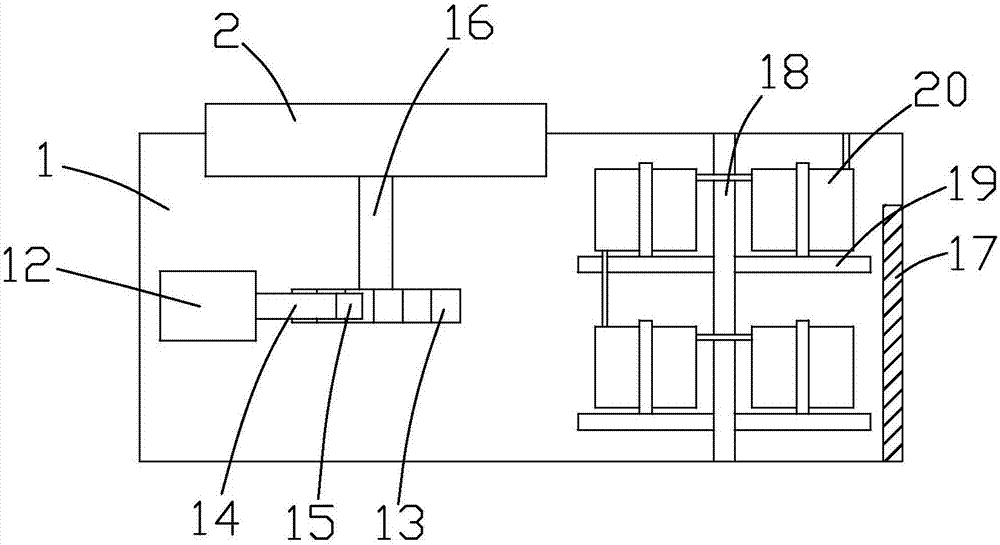

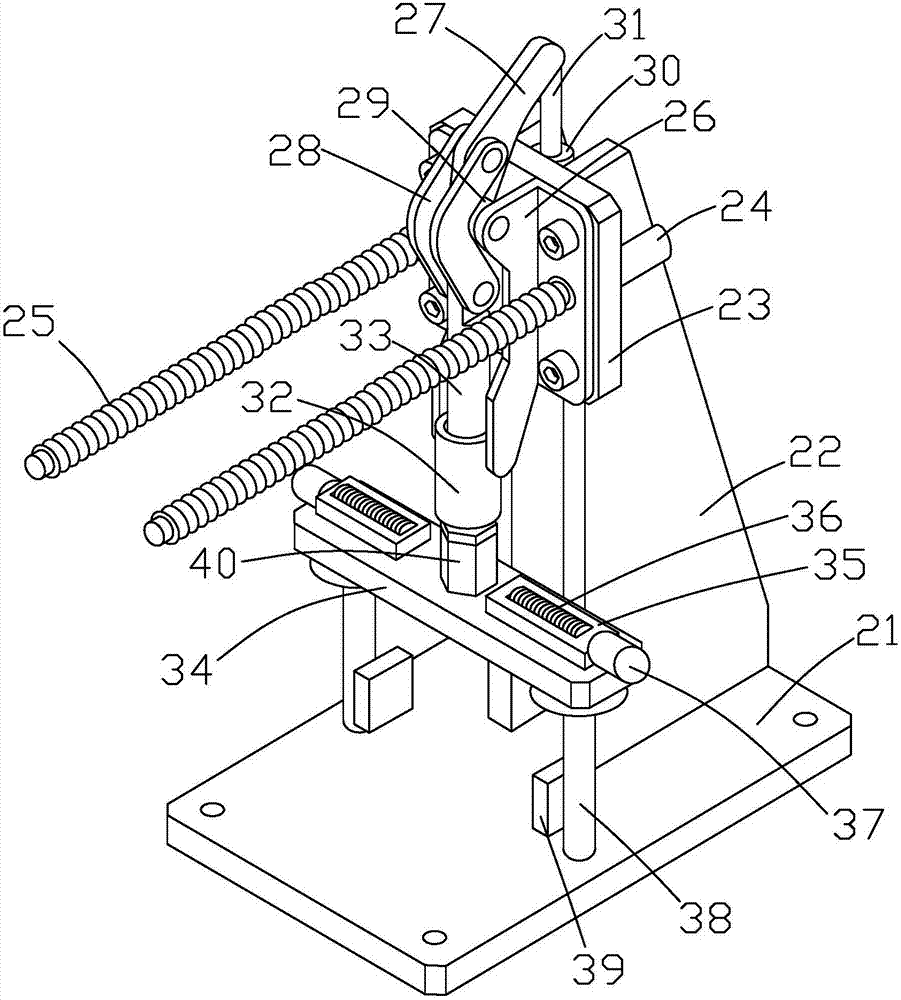

Rotary-disc flame welding machine and welding method thereof

ActiveCN107159994AAdjustable positionImprove welding precisionHeating appliancesSolder feeding devicesEngineeringElectric control

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

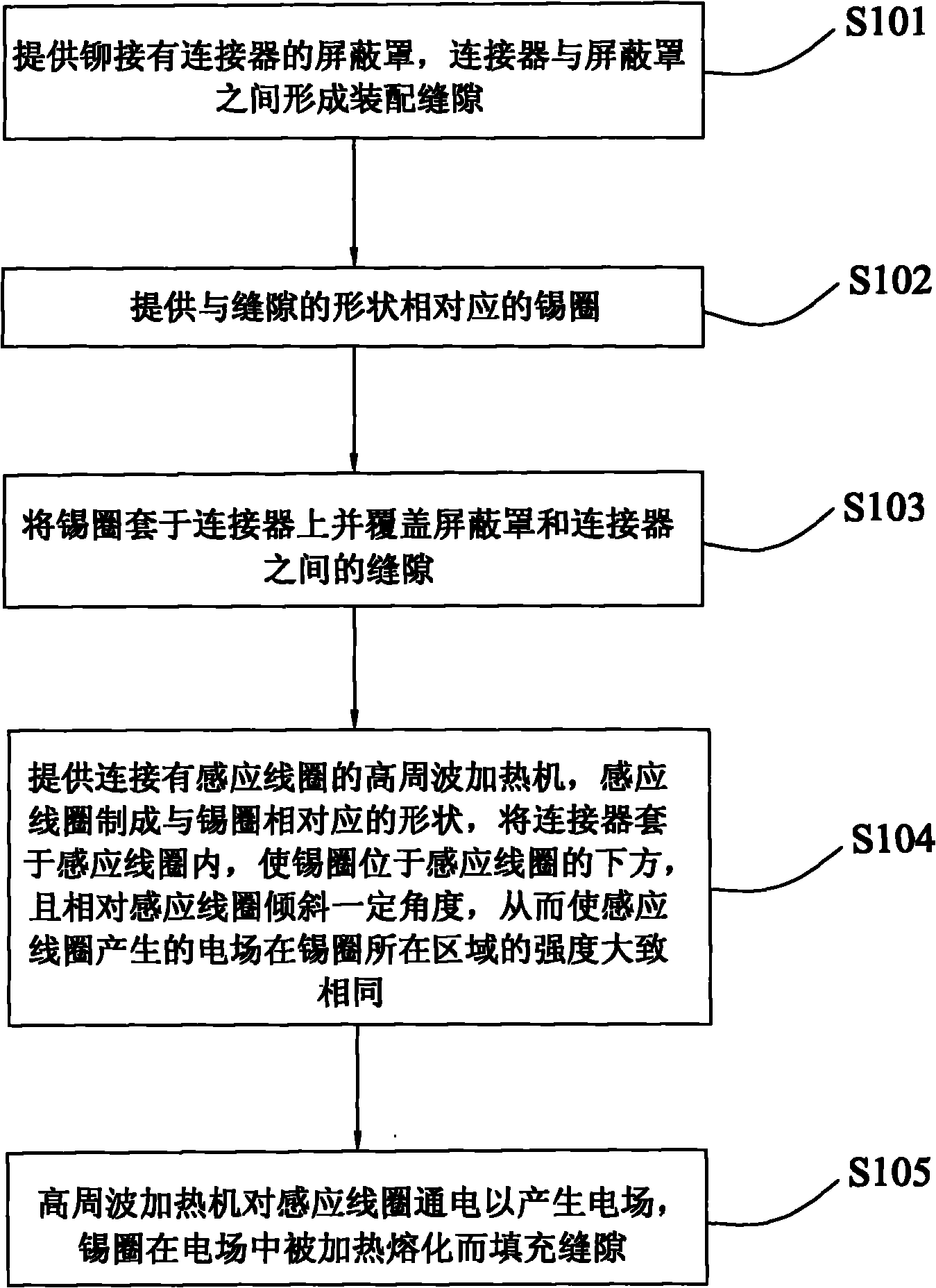

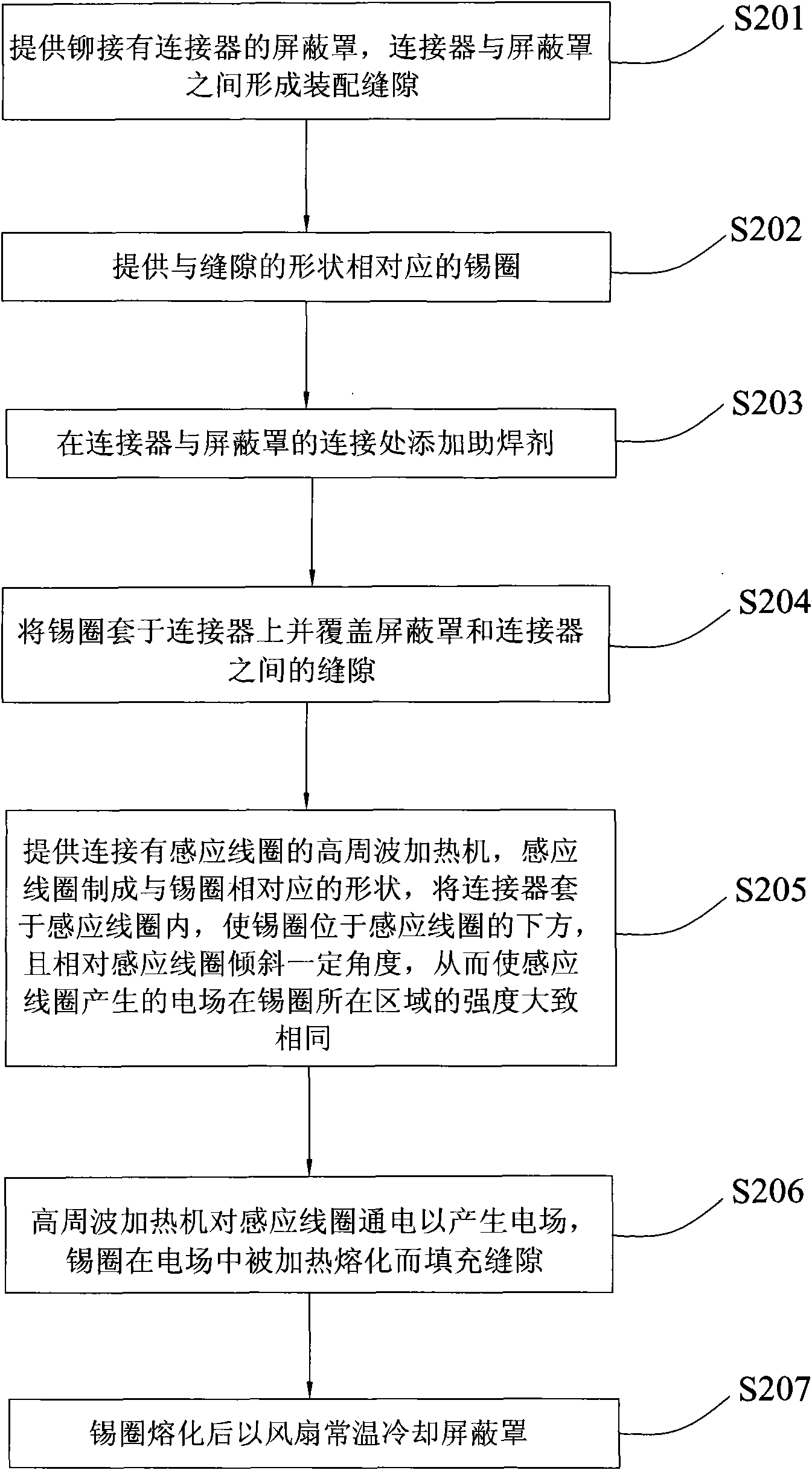

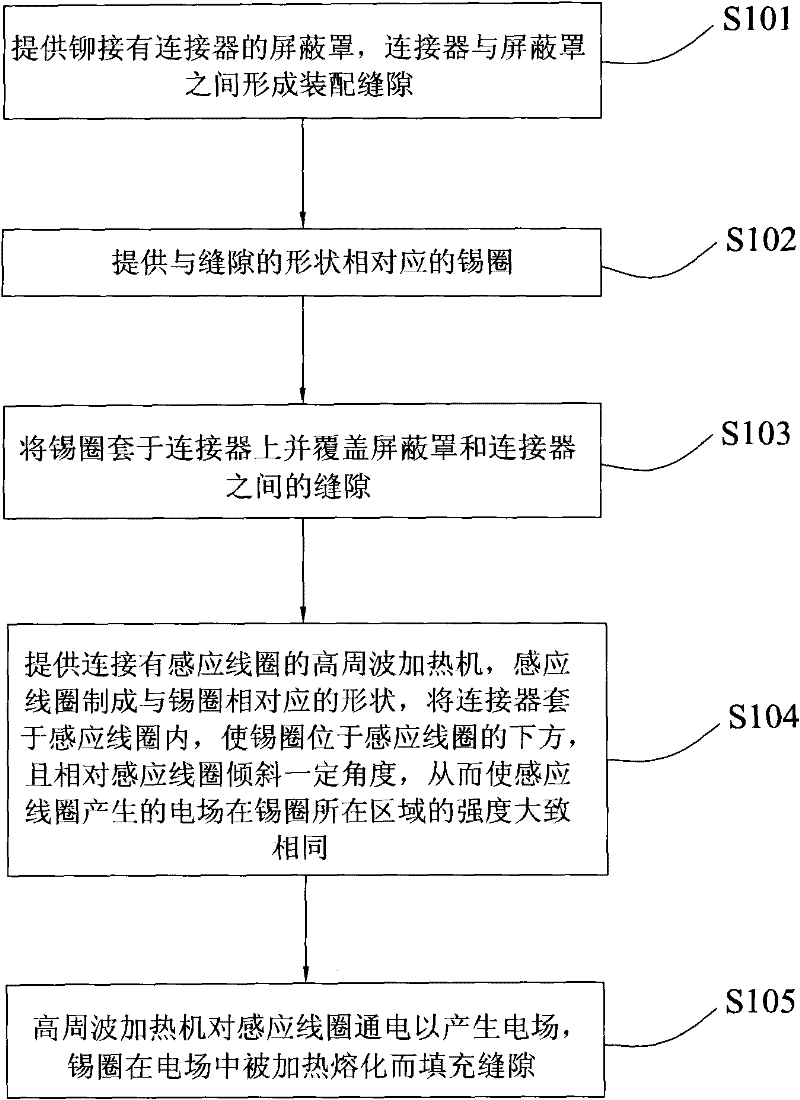

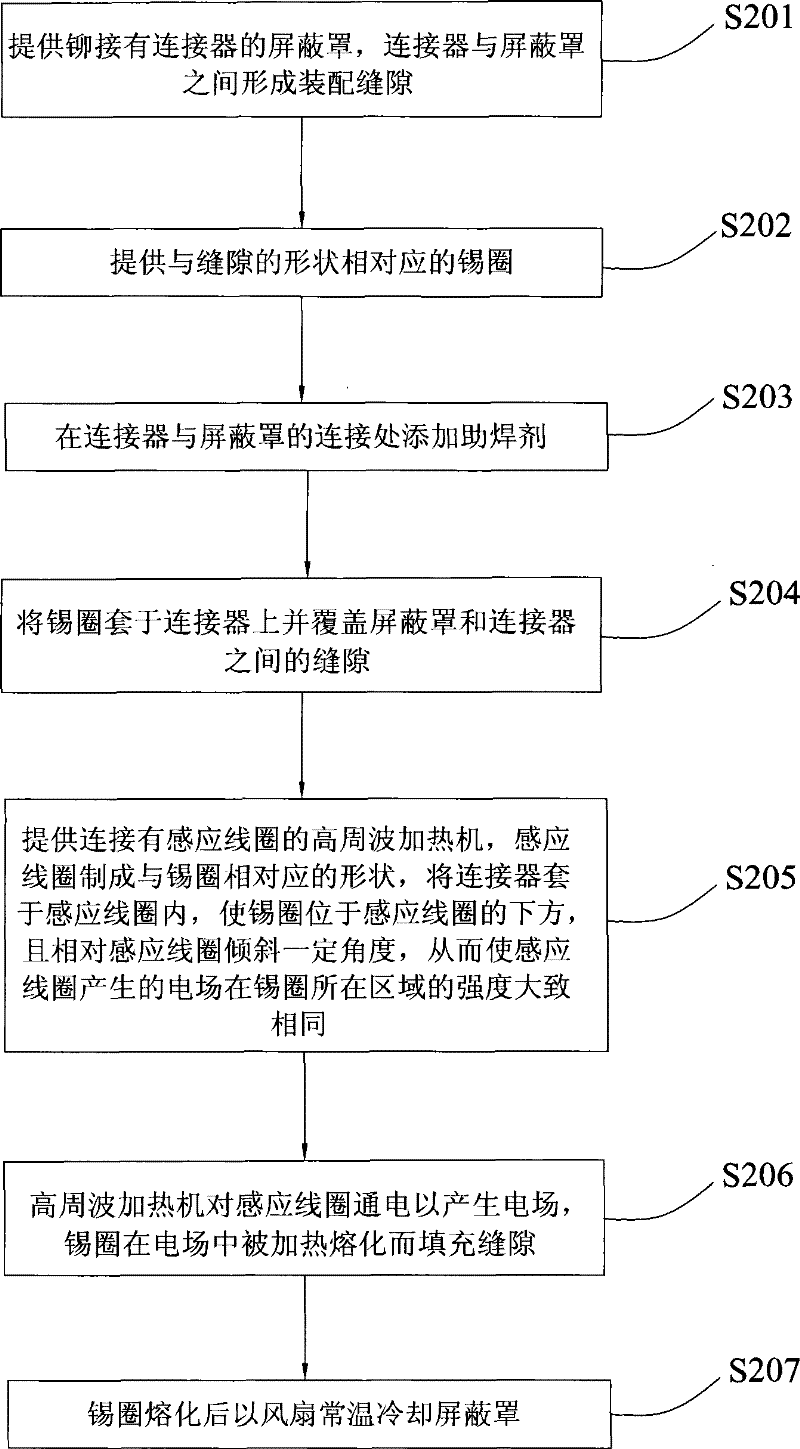

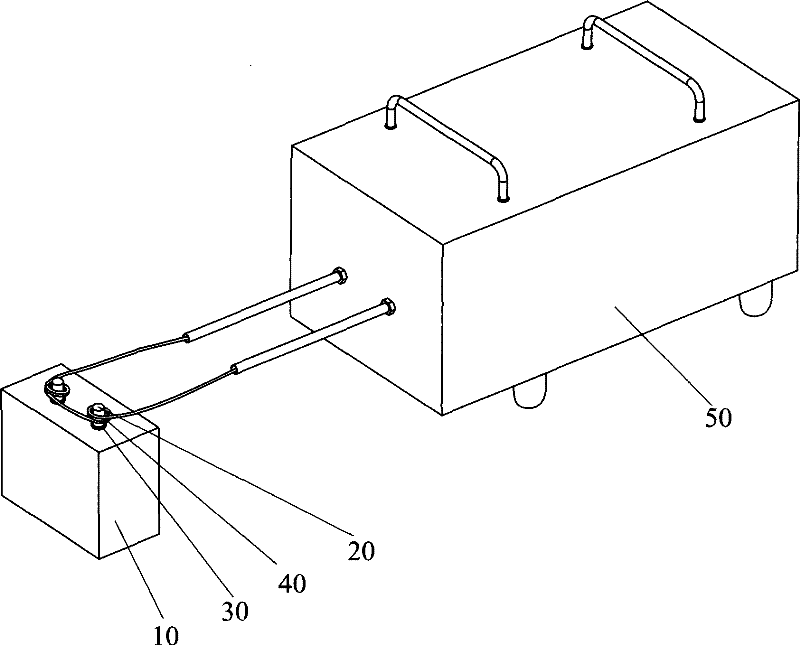

Method for sealing shielding can

InactiveCN101837495AAvoid magnetizationGuaranteed smoothSoldering apparatusEngineeringRadio frequency

The invention discloses a method for sealing a shielding can, comprising the following steps: providing a shielding can riveted with a connector, wherein an assembling gap is formed between the shielding can and the connector; providing an stannum ring with the shape corresponding to that of the gap; sheathing the stannum ring on the connector to cover the gap between the shielding can and the connector; providing a radio frequency heater connected with an inductance coil; preparing the inductance coil into a shape corresponding to that of the stannum ring; and sheathing the connector in the inductance coil, positioning the stannum ring below the inductance coil, and leading the stannum ring to lean a certain angle relative to the inductance coil, thus the strength of magnetic fields generated by the inductance coil at a region at which the stannum ring is positioned to be almost same. The radio frequency heater electrifies the inductance coil to generate a magnetic field; and the inductance coil is heated and molten in the magnetic field to fill the gap. The method for sealing the shielding can of the invention has good sealing effect and higher qualification rate and production efficiency.

Owner:DONGGUAN HONGLONG METAL PRODS

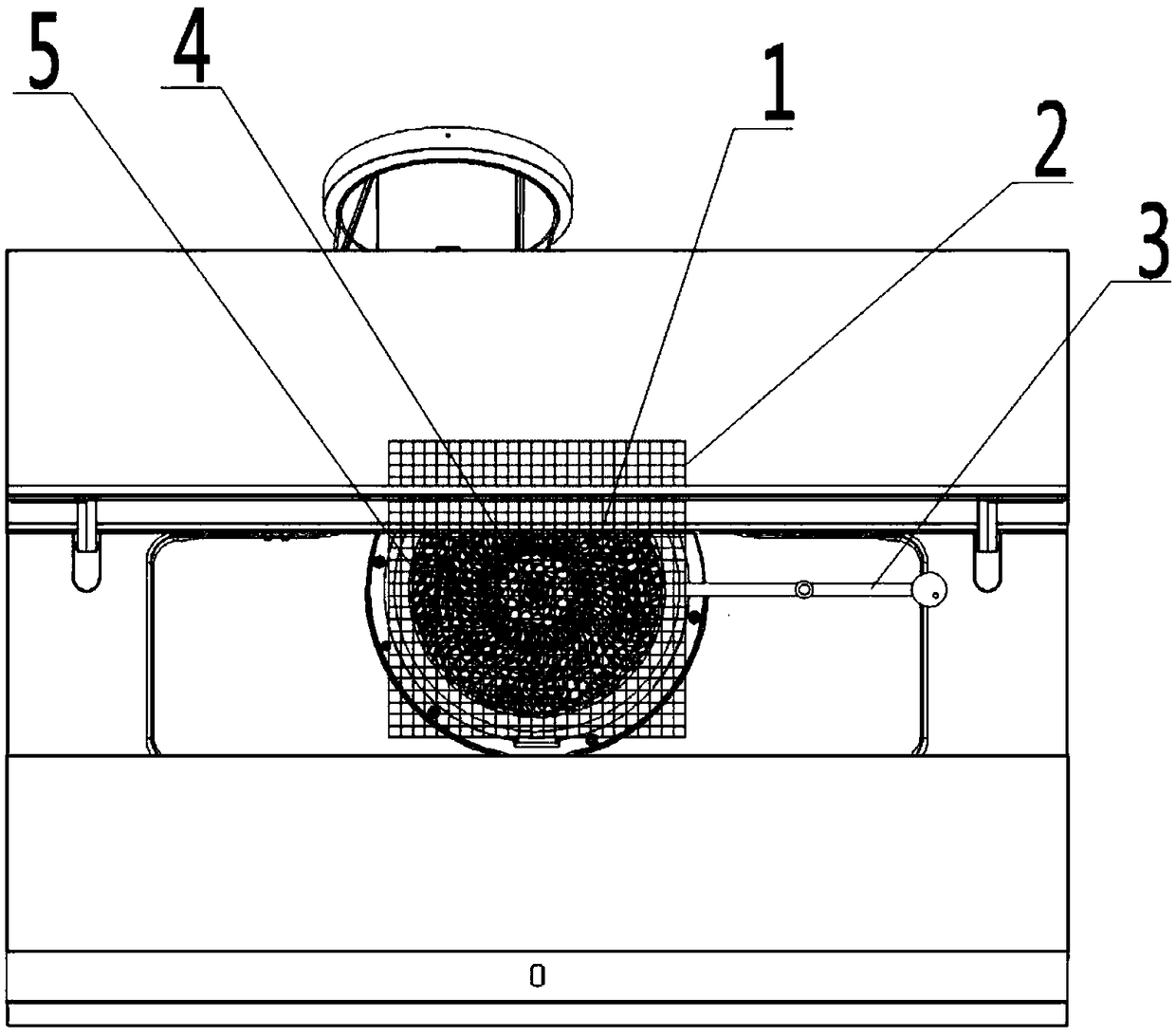

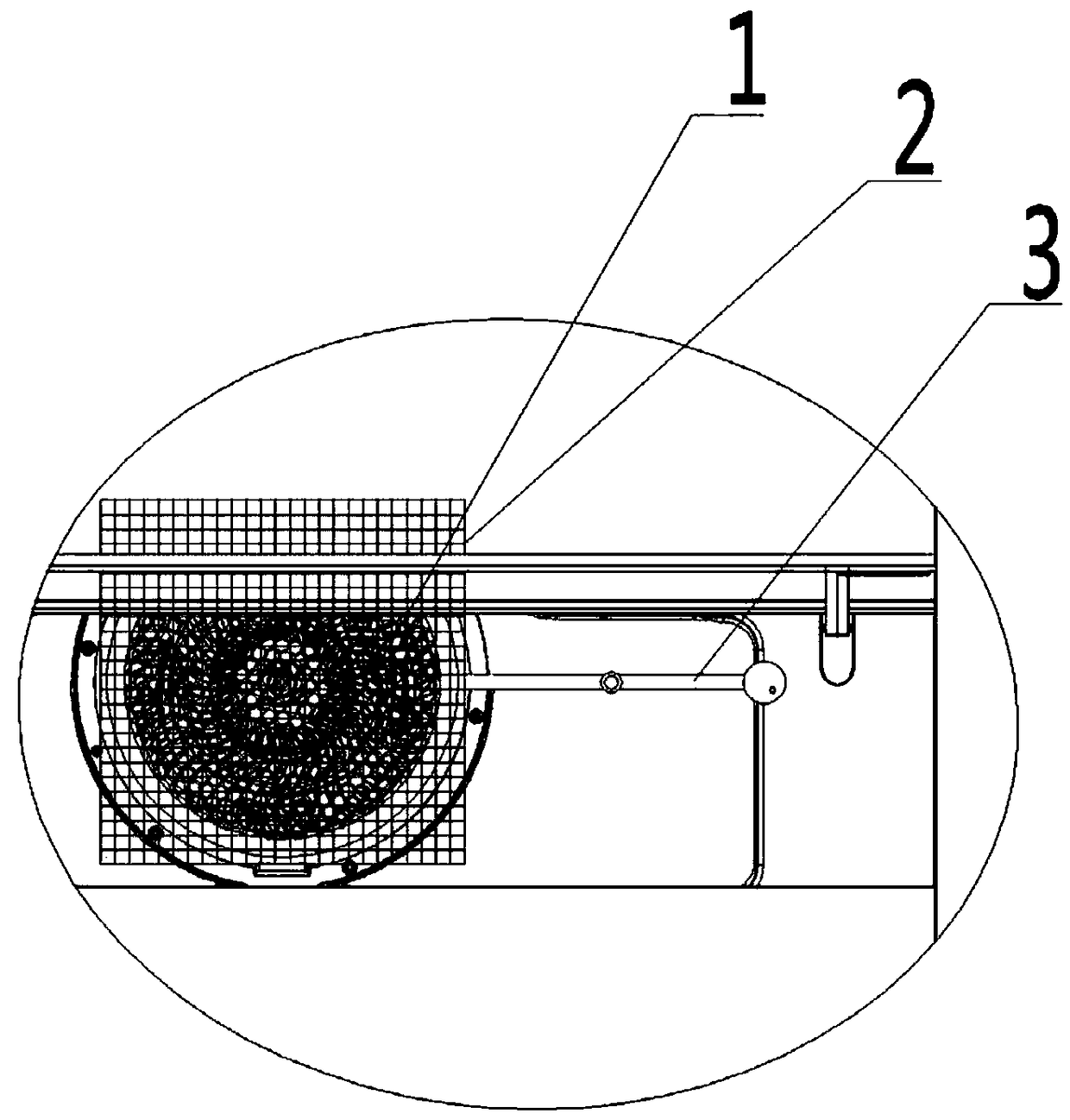

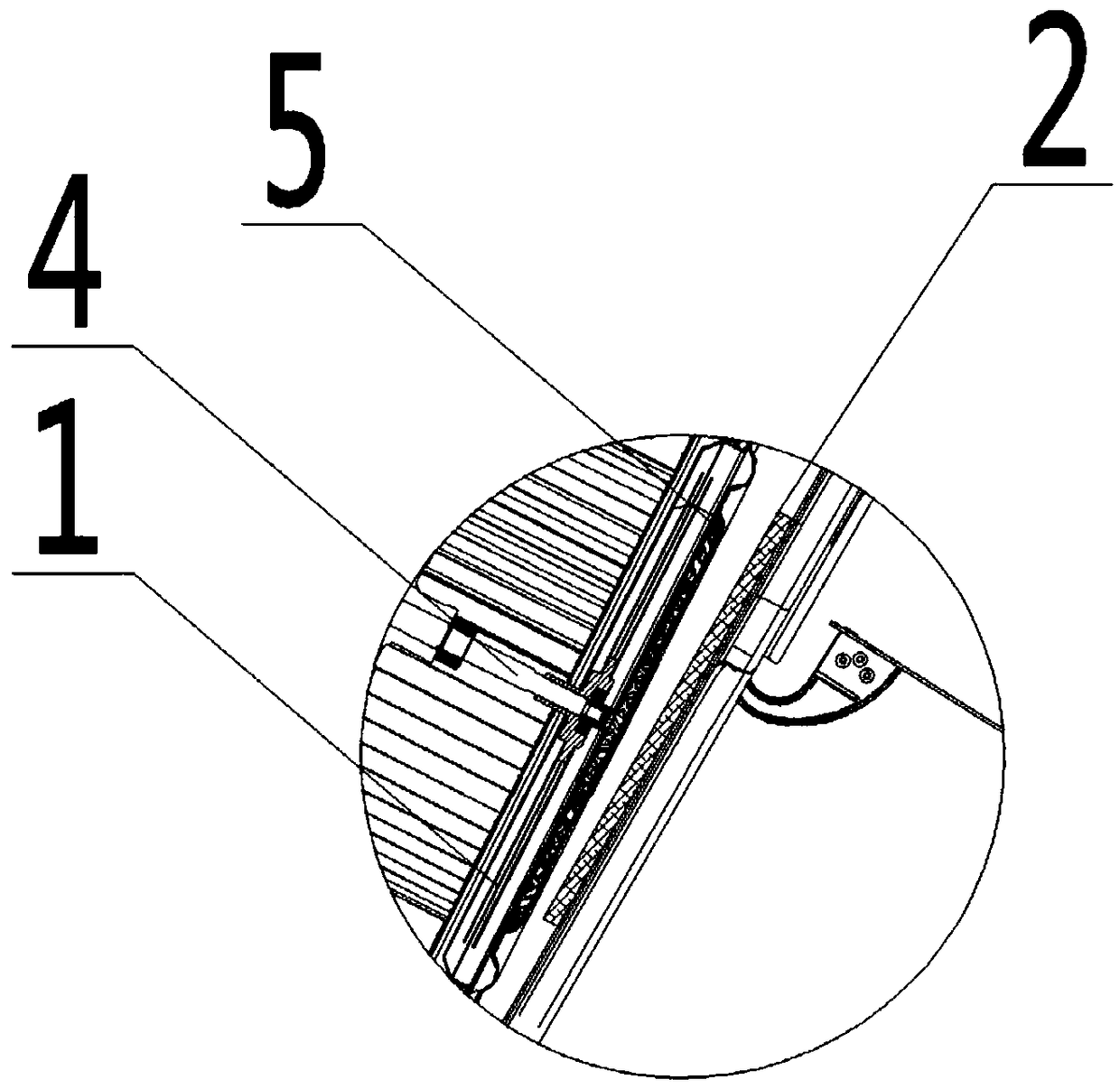

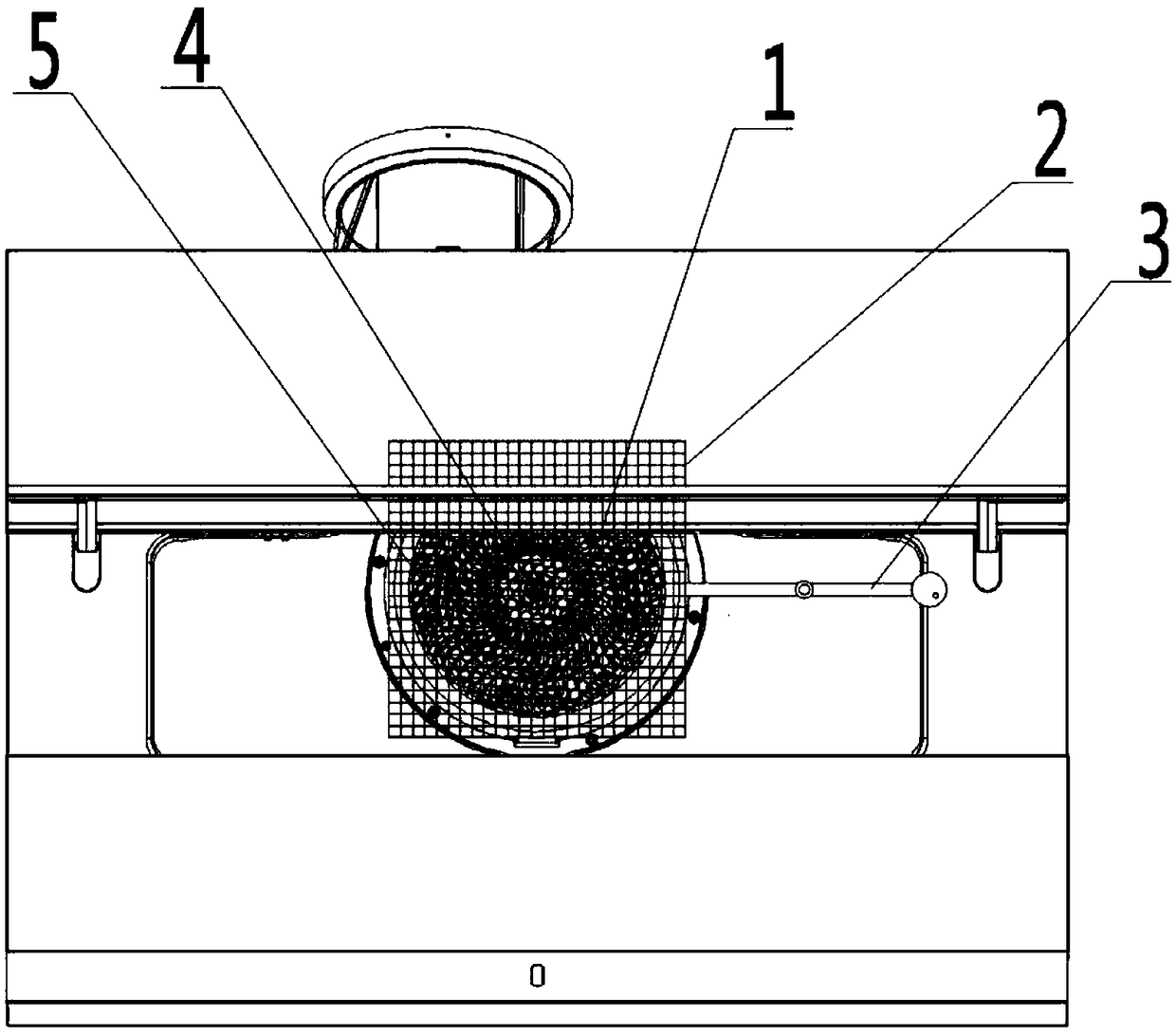

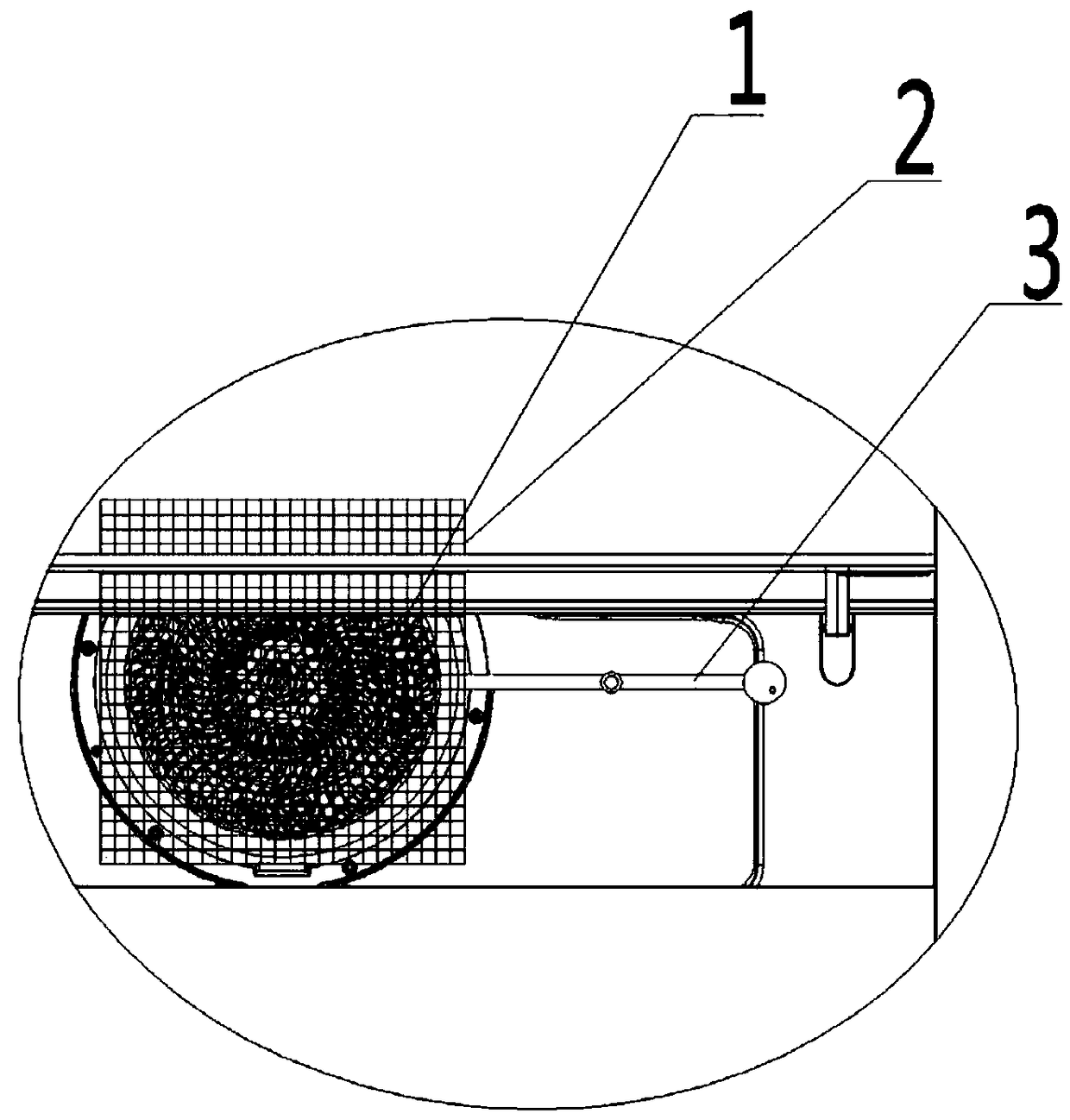

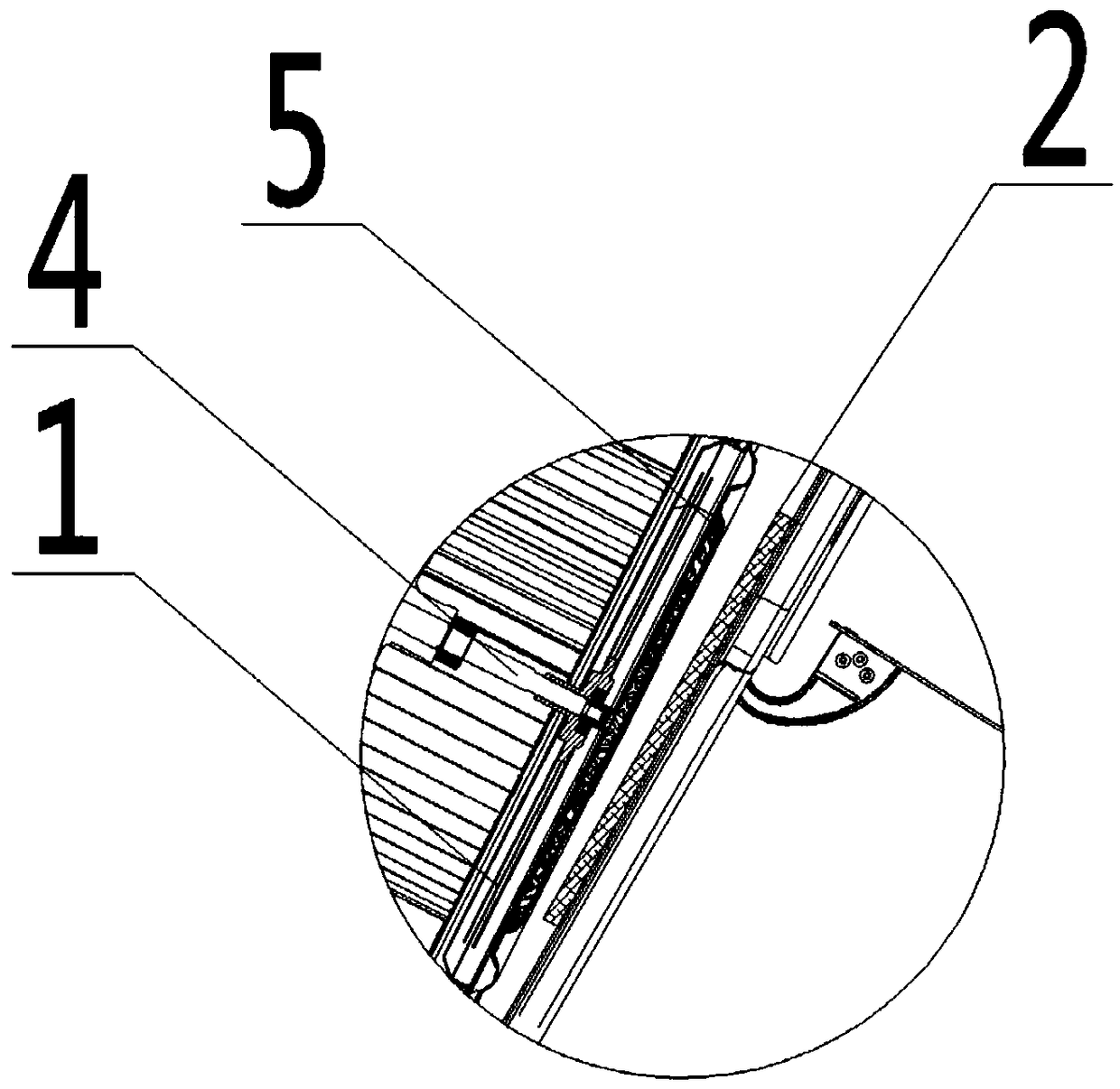

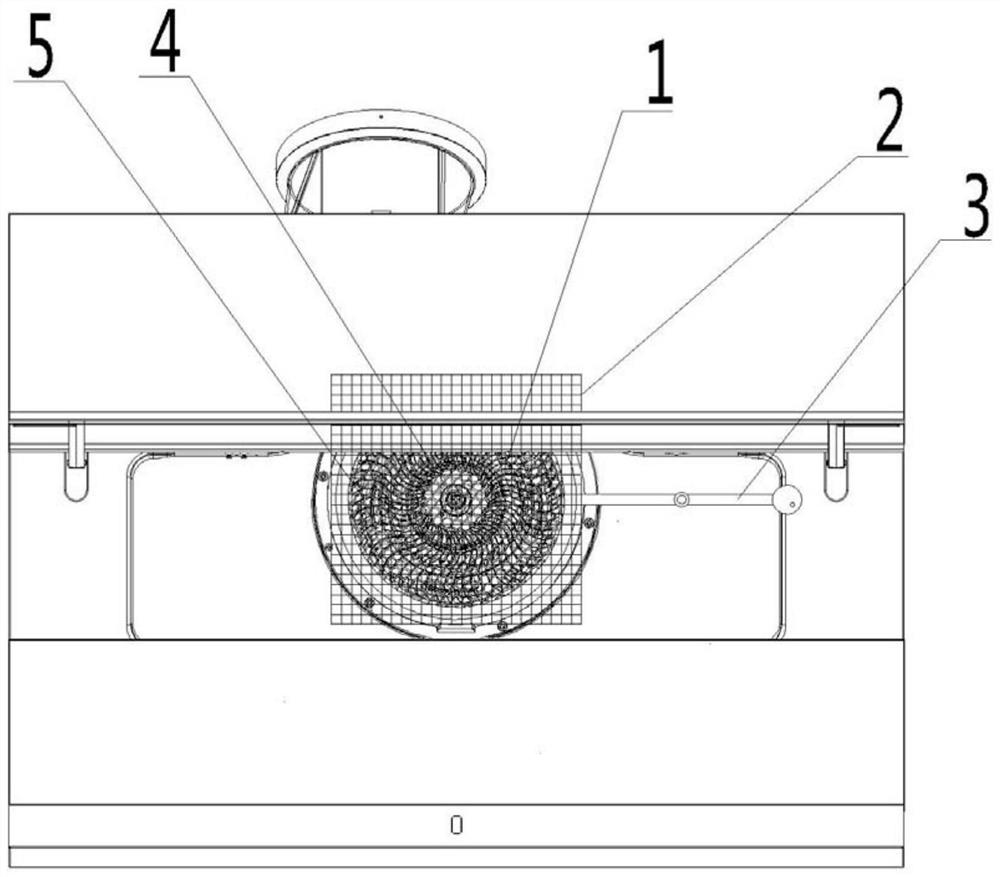

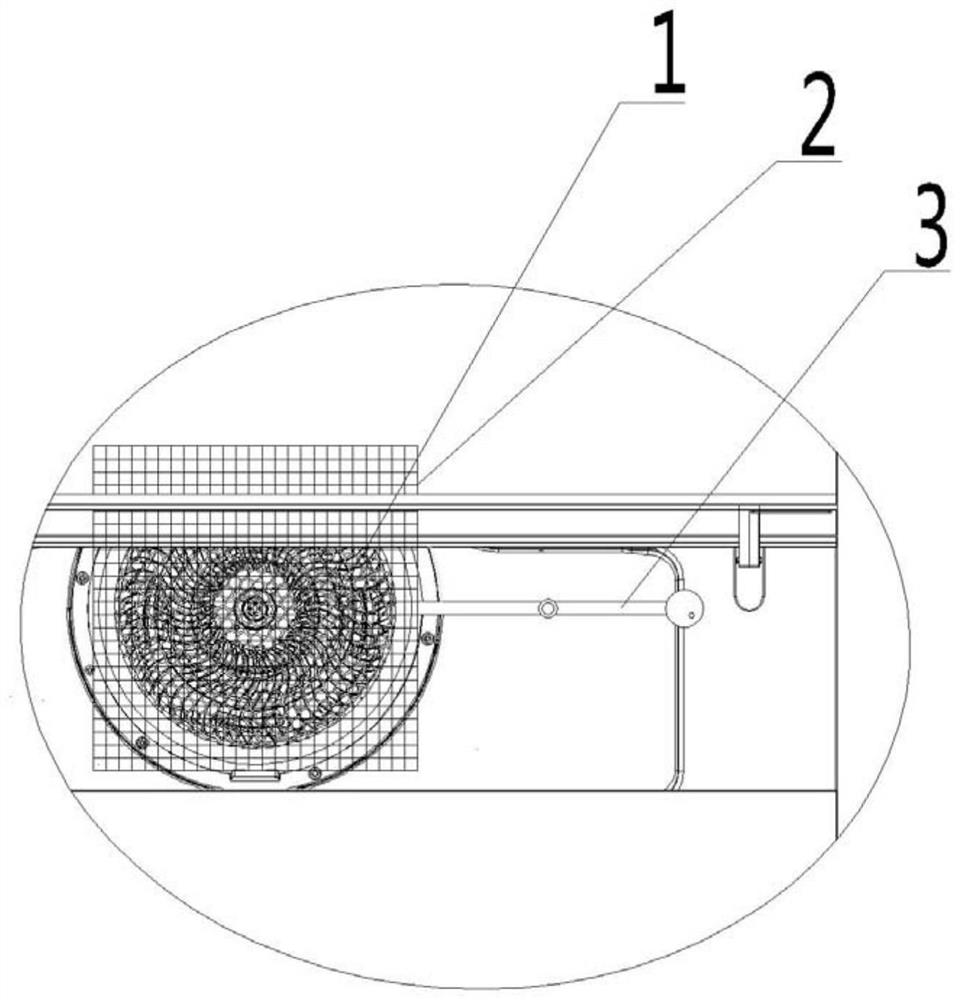

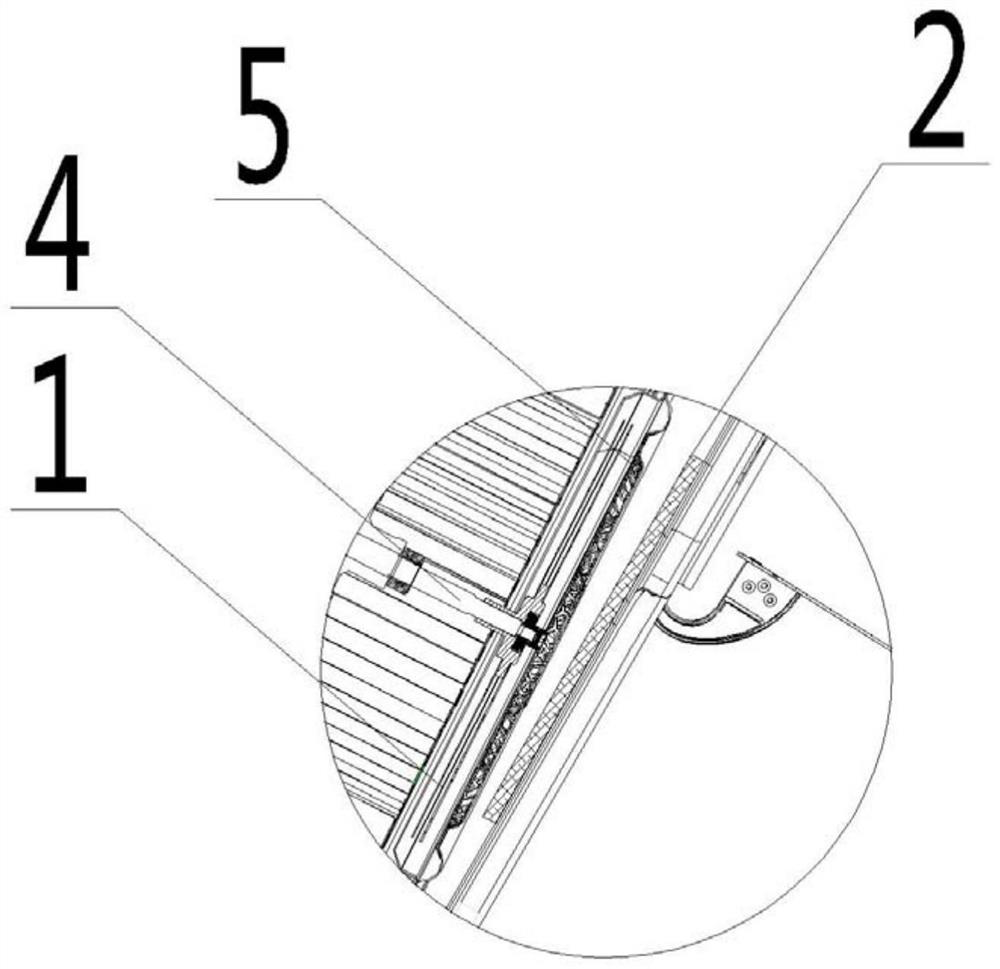

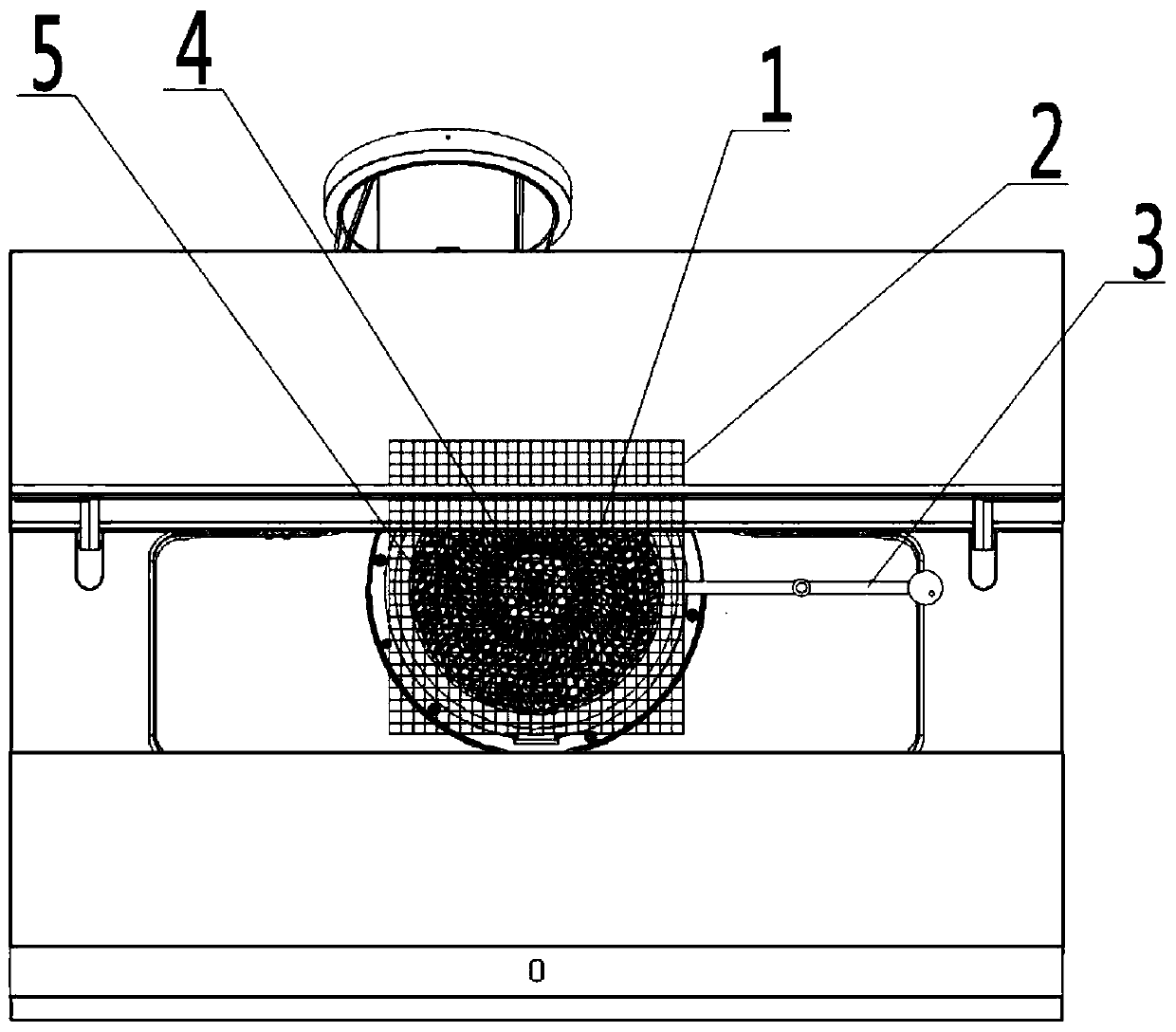

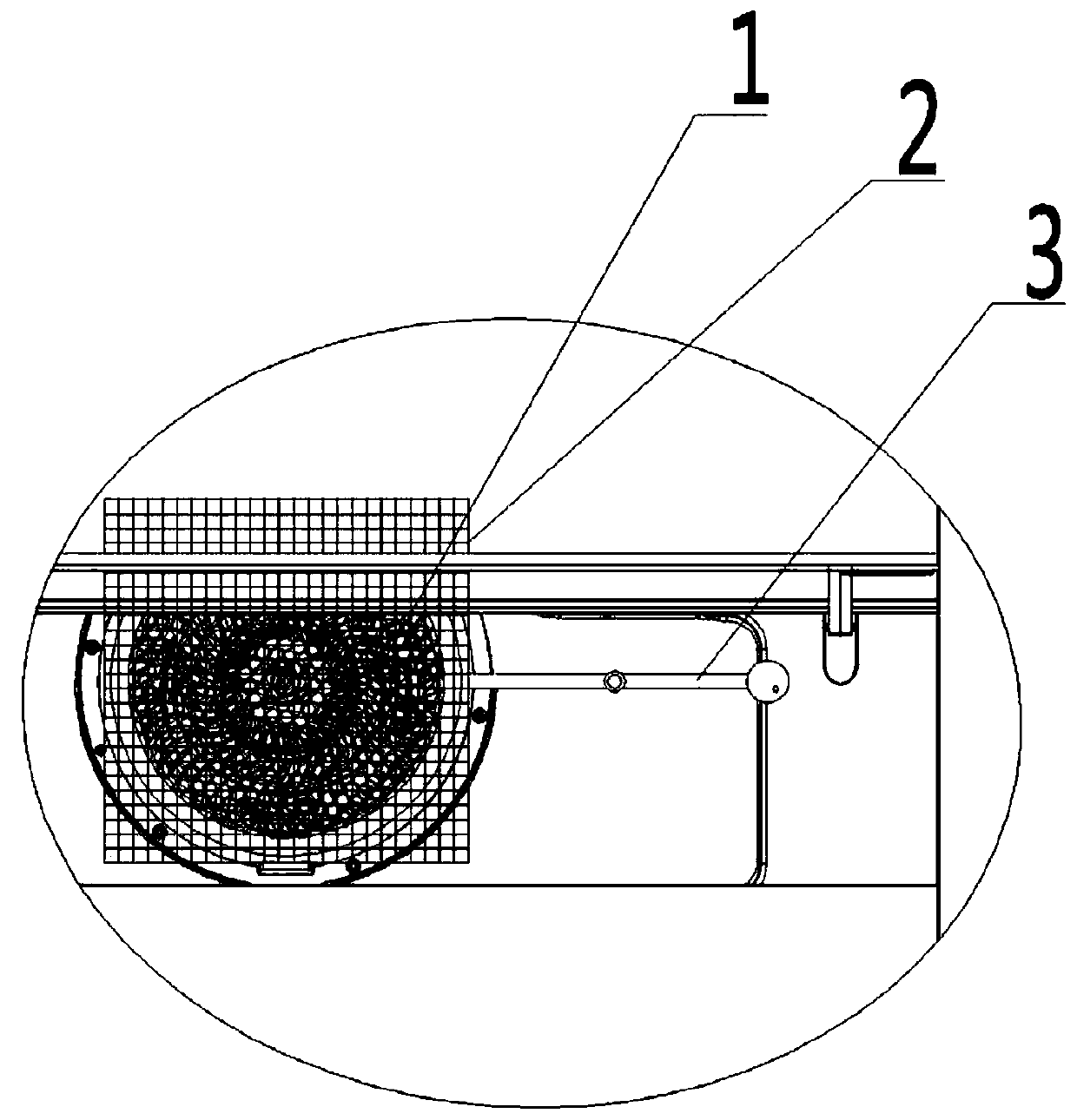

Self-cleaning structure and method of range hood and range hood

ActiveCN109268888APromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusEngineeringAir heating

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a hot air heating devicewhich is arranged on the range hood, and cleans the inner oil screen by heating the inner oil screen, wherein the hot air heating device comprises a fan and an air outlet which is connected with the fan, and is used for heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particlesin the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better, and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Plasma display panel (PDP) terminal hot-pressing head structure

InactiveCN102176400AThere is no parallelism problemThere will be no problems with excessive pressureCold cathode manufactureTemperature controlOperability

The invention discloses a plasma display panel (PDP) terminal hot-pressing head structure, which relates to the PDP terminal hot-pressing head structure realizing hot-pressing pressure and temperature control by distributing a plurality of pressing heads. The PDP terminal hot-pressing head structure provided by the invention aims to overcome the shortcomings of the prior art, and can effectively solve the problem of pressing head pressure and heating distribution and improve pressing head regulation processibility and pressing head maintenance operability. To fulfill the aims, the technical scheme adopted by the invention is that: the PDP terminal hot-pressing head structure comprises a base and the pressing heads; a bottom plate is detachably connected to the base by a connecting device;the PDP terminal hot-pressing head structure further comprises the plurality of pressing heads; the rear ends of each pressing head are connected with a pressure device; and the pressure devices control the actions of the pressing heads, can output constant pressure according to a set value, and are fixed on the bottom plate. The PDP terminal hot-pressing head structure is applied to tape carrierpackage (TCP) hot-pressing.

Owner:SICHUAN COC DISPLAY DEVICES

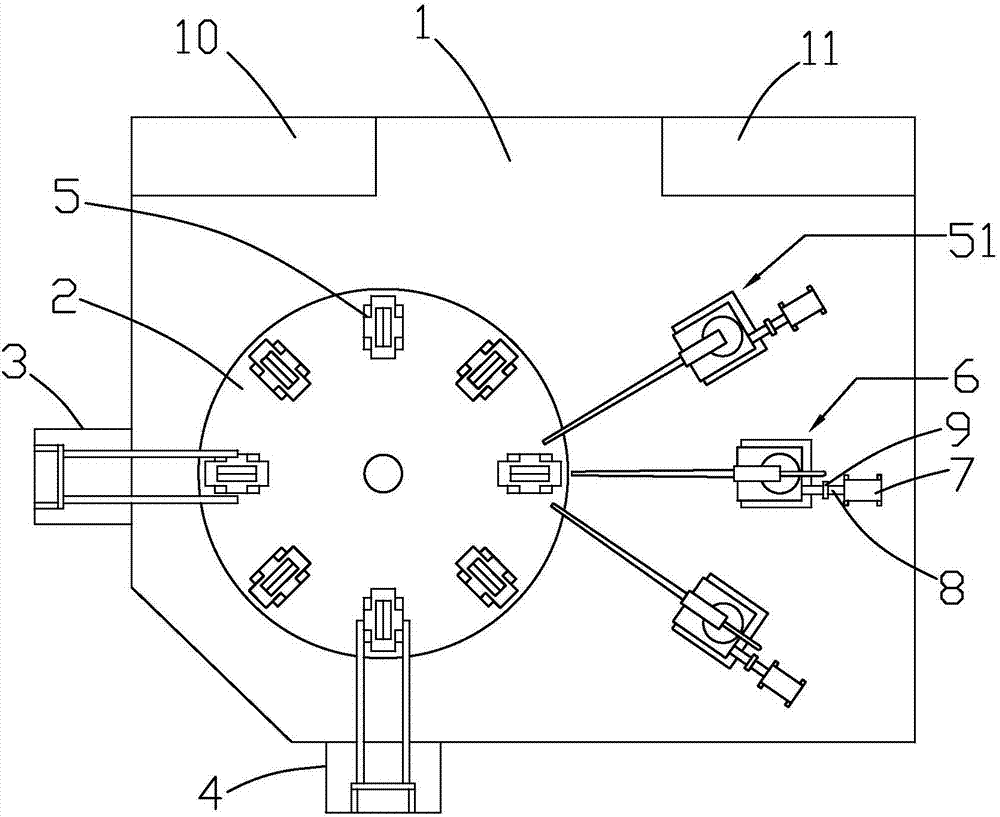

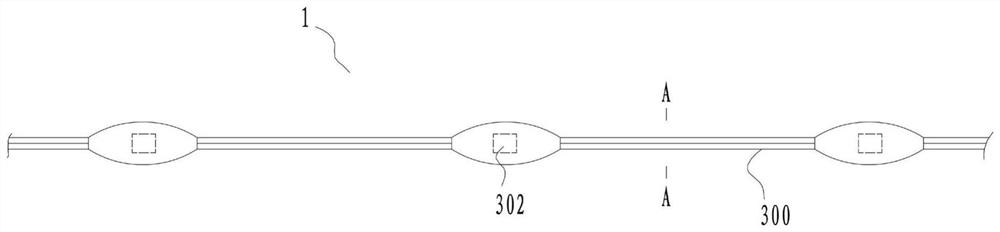

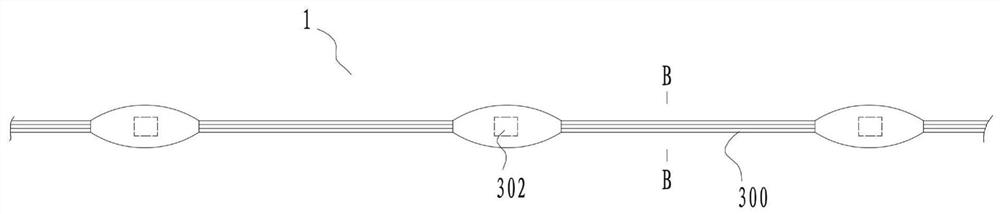

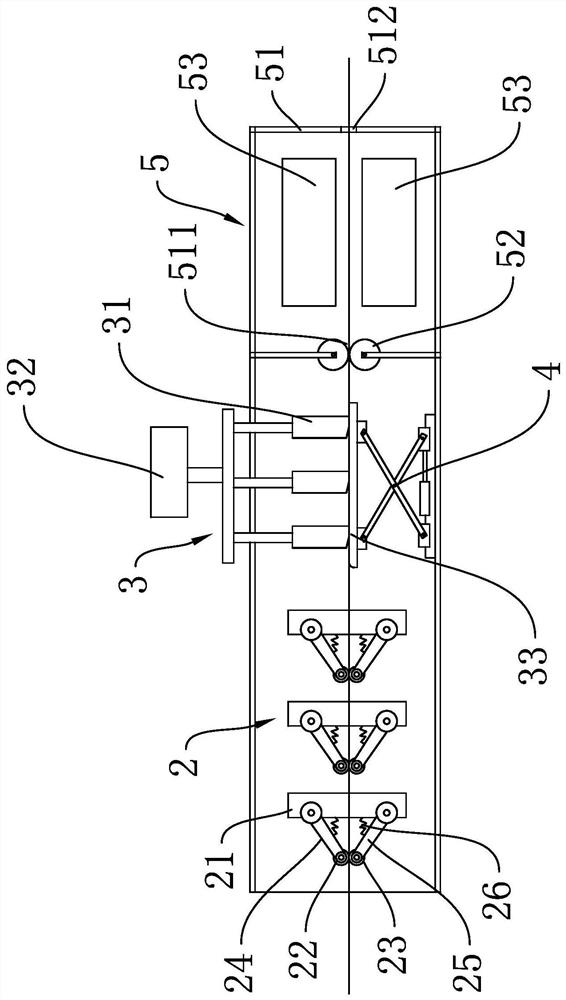

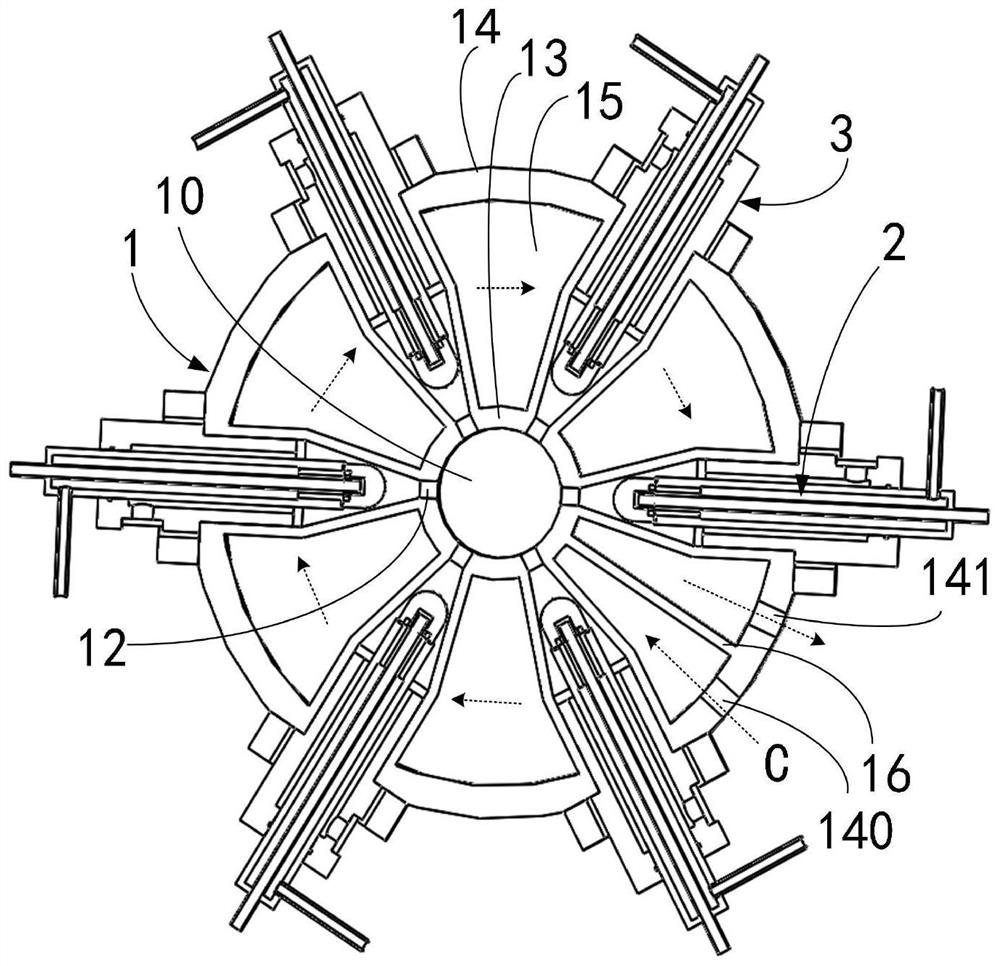

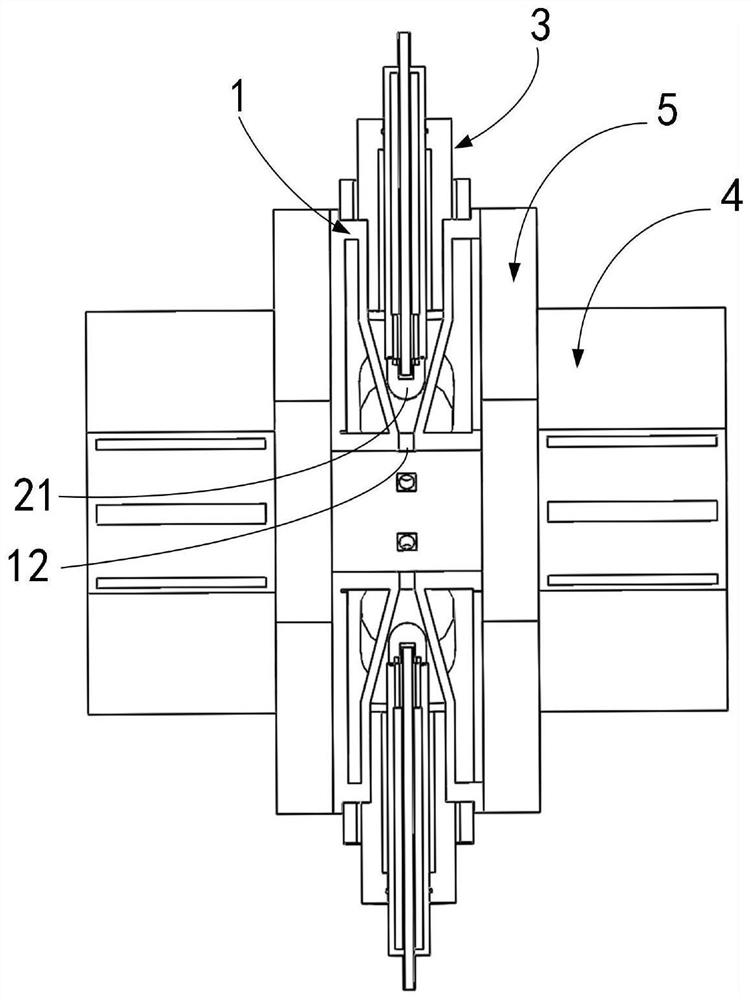

Full-automatic disc-type rubber-insulated wire lamp string production device and production method thereof

PendingCN113513713ARealize fully automatic productionReduce labor costsElectric circuit arrangementsFilament handlingCopper wireEngineering

The invention belongs to the field of decorative lamp production and manufacturing, and particularly relates to a full-automatic disc-type rubber-insulated wire lamp string production device and a production method thereof.The full-automatic disc-type rubber-insulated wire lamp string production device comprises a disc clamping and conveying mechanism, a wire guiding mechanism, a cutting mechanism, a peeling mechanism, a chip welding module and a glue injection mechanism, wherein the wire guiding mechanism, the cutting mechanism, the peeling mechanism, the chip welding module and the glue injection mechanism are sequentially arranged around the disc clamping and conveying mechanism; the disc clamping and conveying mechanism is used for clamping a rubber-insulated wire and intermittently conveying the rubber-insulated wire along a circumferential line; the wire guiding mechanism is used for guiding the rubber-insulated wire to enter the disc clamping and conveying mechanism; the cutting mechanism is used for cutting the rubber-insulated wire; the peeling mechanism is used for pressing the cut rubber-insulated wire downwards to expose a copper wire in the rubber-insulated wire; the chip welding module is used for welding a chip on a copper wire; and the glue injection mechanism is used for injecting glue to the copper wire, so that the chip is packaged. According to the production device and the production method, full-automatic production of the rubber-insulated wire lamp string can be achieved, high efficiency and convenience are achieved, and the labor cost is saved.

Owner:临海市宾力灯饰有限公司

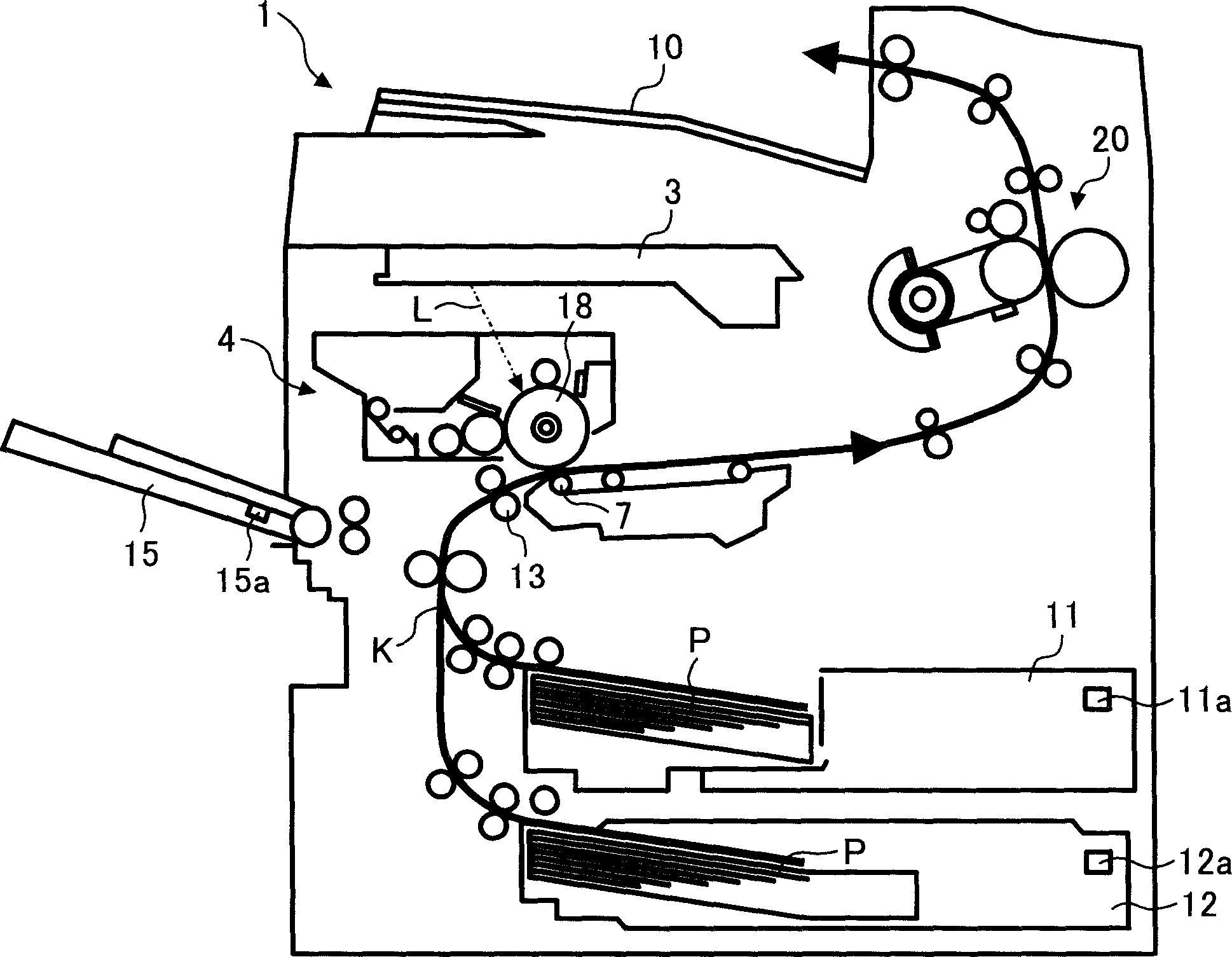

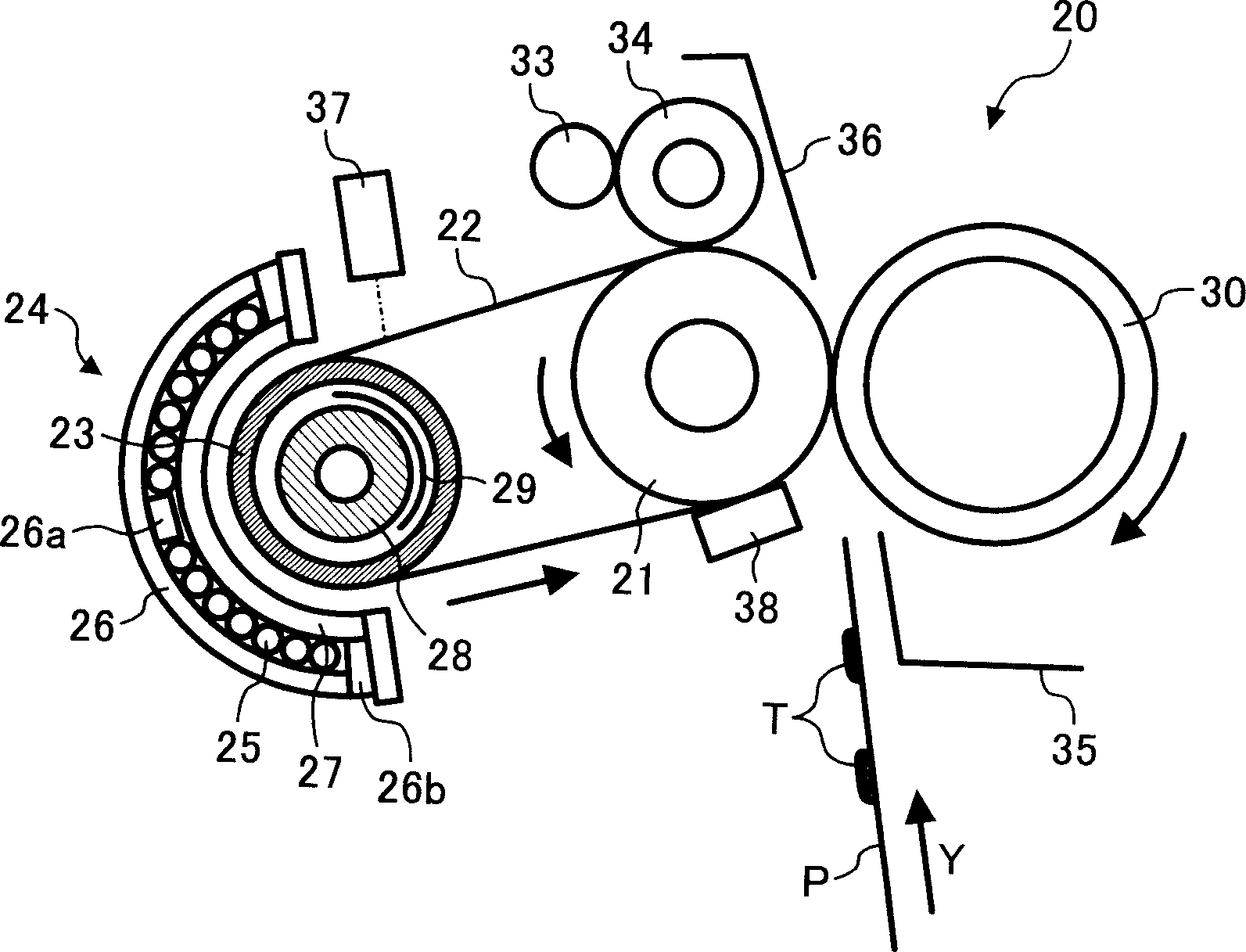

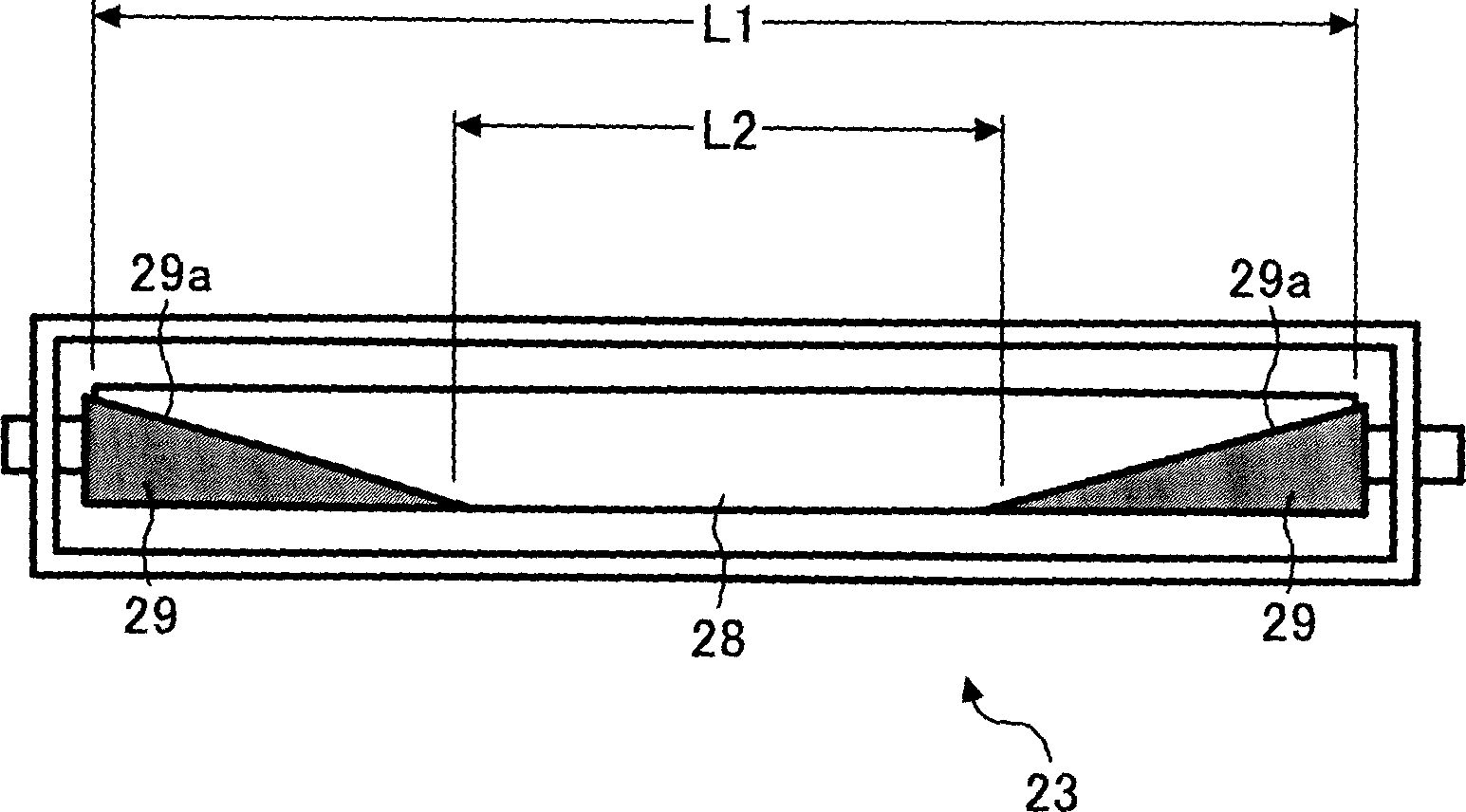

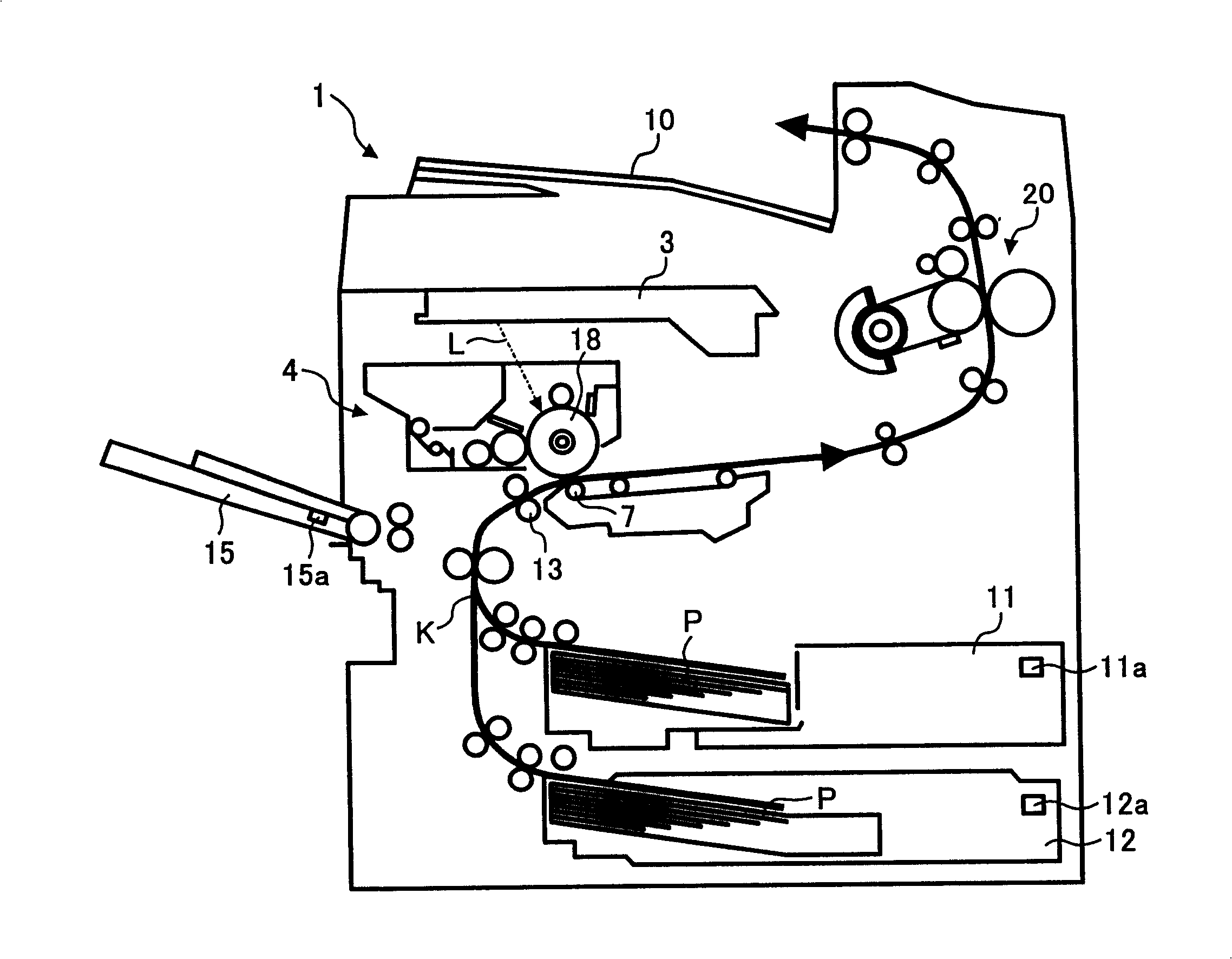

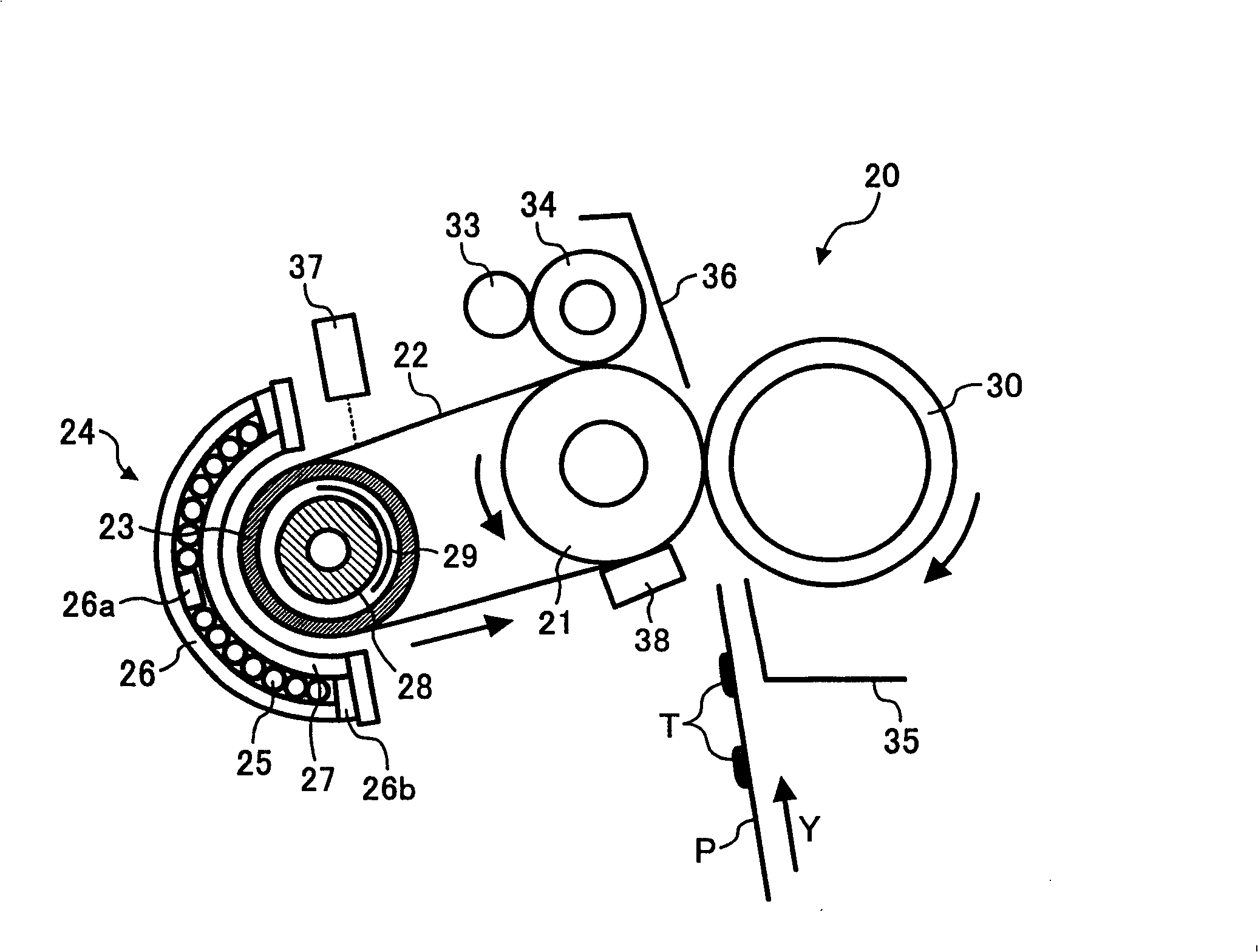

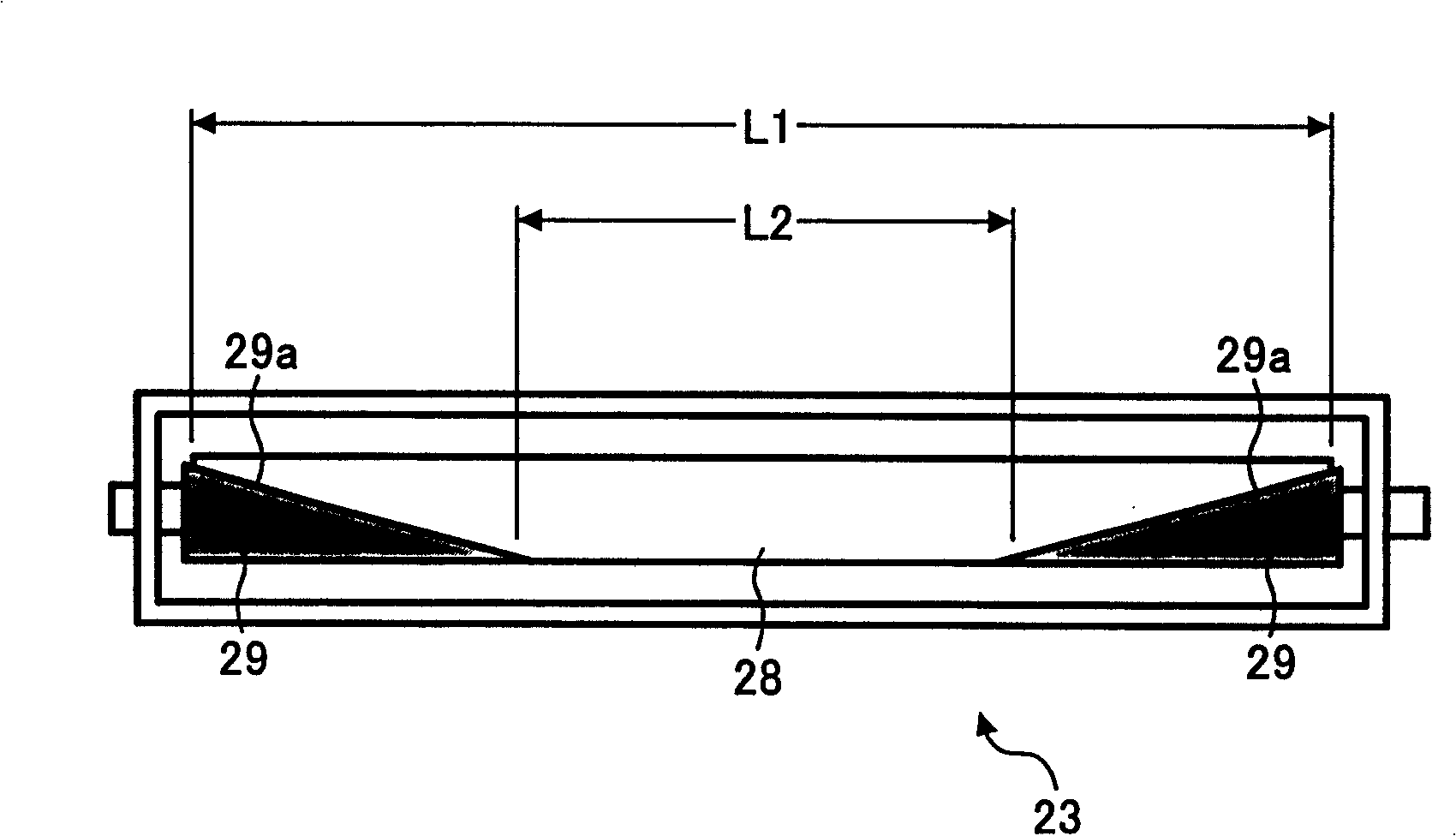

Image fixing apparatus image forming apparatus using the same

ActiveCN1725122AInhibit temperature riseReduce variable errorElectrographic process apparatusMagnetic fluxElectromagnetic induction

The present invention relates to a fixing device, in particular to a fixing device that adopts a heating method of electromagnetic induction and an image forming device. The fixing device 20, which is used for fixing an toner image T on a recording medium P, is provided with a magnetic flux generation means 24 that is used for generating the magnetic flux, heating components 22 and 23 that are heated by induction of the magnetic flux, a magnetic flux adjusting component 29 in the width direction, the set adjustment range of which lowers the magnetic flux that affects the heating components 22 and 23; the adjusting component 29 can be driven to adjust a changeable means of changeable adjustment range. During the period of continuous fixation of the toner image T by a plurality of recording media P, the changeable means controls and drives the adjusting component 29. The present invention also provides a fixing device and an image forming device, which can reliably inhibit the temperature of the heating components or the two ends in the width direction of the fixing component, even on the occasions of continuous fixation of a plurality of recording media.

Owner:RICOH KK

Repairing process of chromium-molybdenum steel tube bundle and tube plate

The invention discloses a repairing process of a chromium-molybdenum steel tube bundle and a tube plate, and belongs to the field of repairing of chromium-molybdenum steel. The process comprises a tube bundle repairing process and a tube plate repairing process. A leaking point is determined firstly, then the tube bundle and / or the tube plate are repaired according to the steps of preheating of adjacent tube openings, welding and post-welding treatment of the adjacent tube openings. The adjacent tube openings are pre-heated and subjected heat post-welding treatment through an oxygen-acetylene inner flame, a nickel base welding wire serves as welding materials, the heating and temperature control conditions on the repairing site can easily meet the requirements of the repairing process, an obtained welding joint is high in quality and not prone to new cracks, the tube openings replace crack-stopping holes in the tube plate repairing process, cracks are not prone to spread, and the welding cost and labor intensity are effectively reduced.

Owner:PETROCHINA CO LTD

Self-cleaning structure and method of range hood and range hood

ActiveCN109268889APromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusEngineeringHeating efficiency

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a heating device which isarranged on the range hood, and cleans the inner oil screen by heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particles in the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better,and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

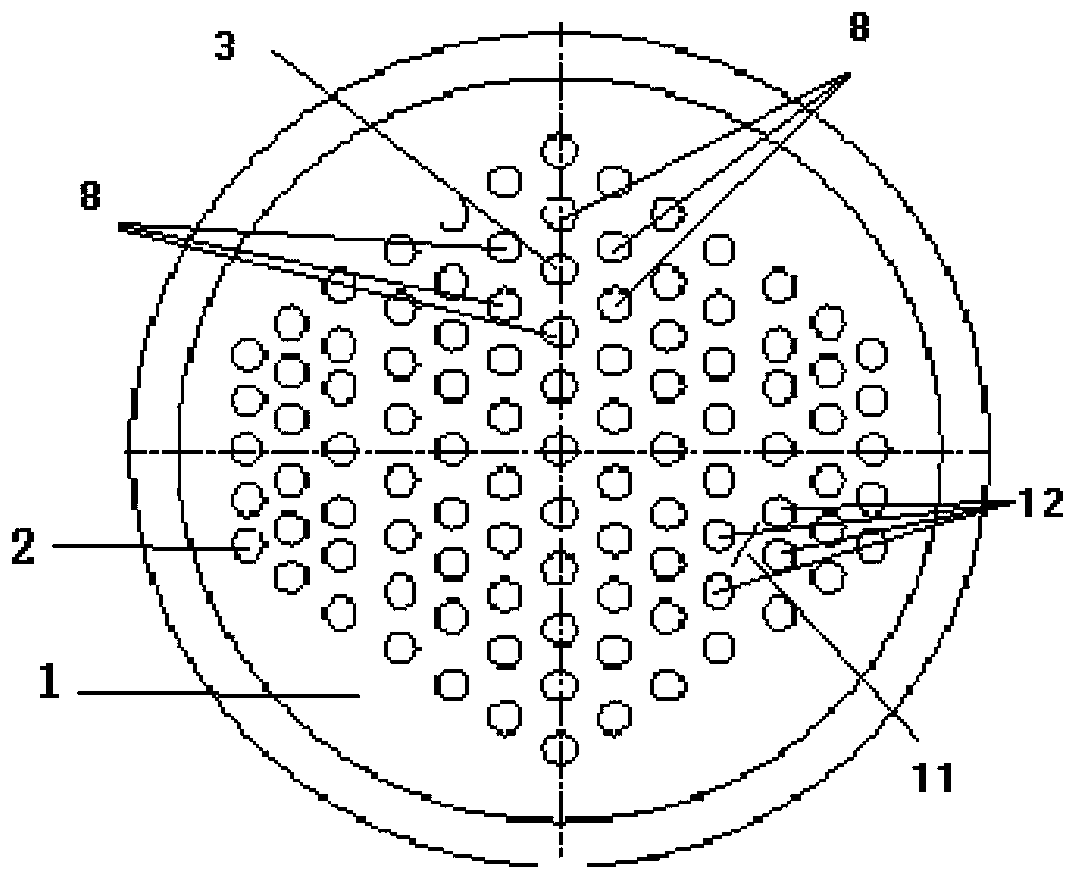

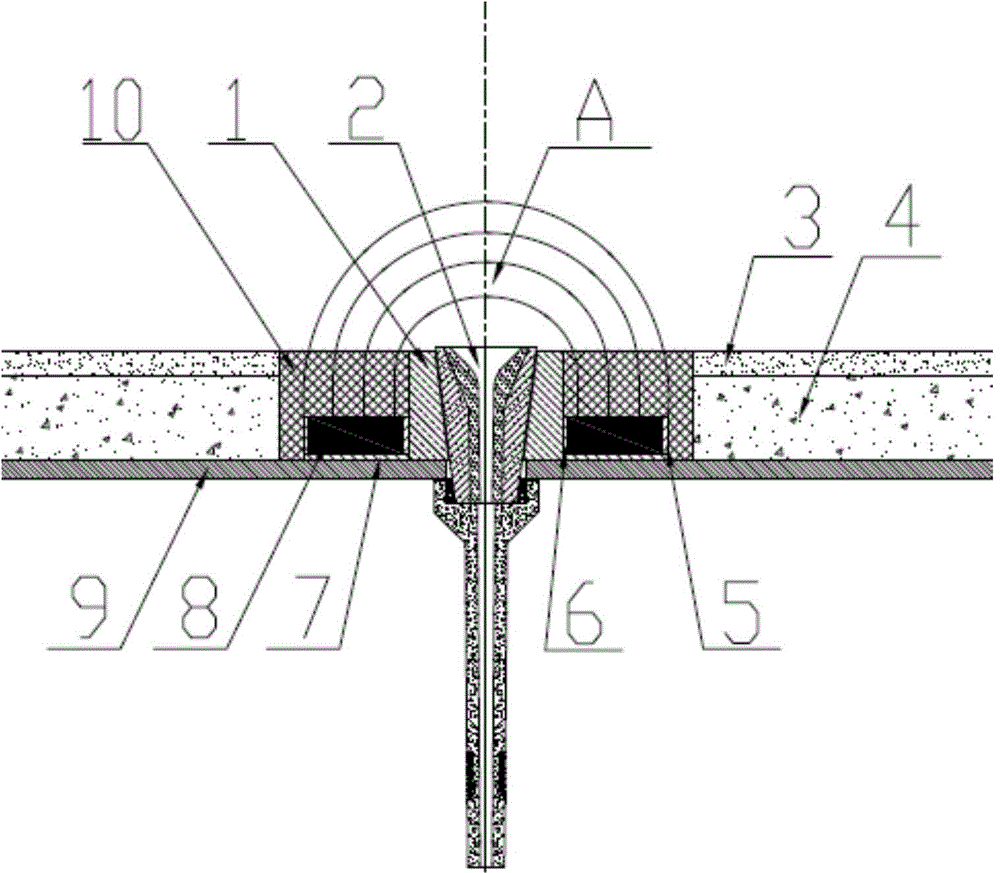

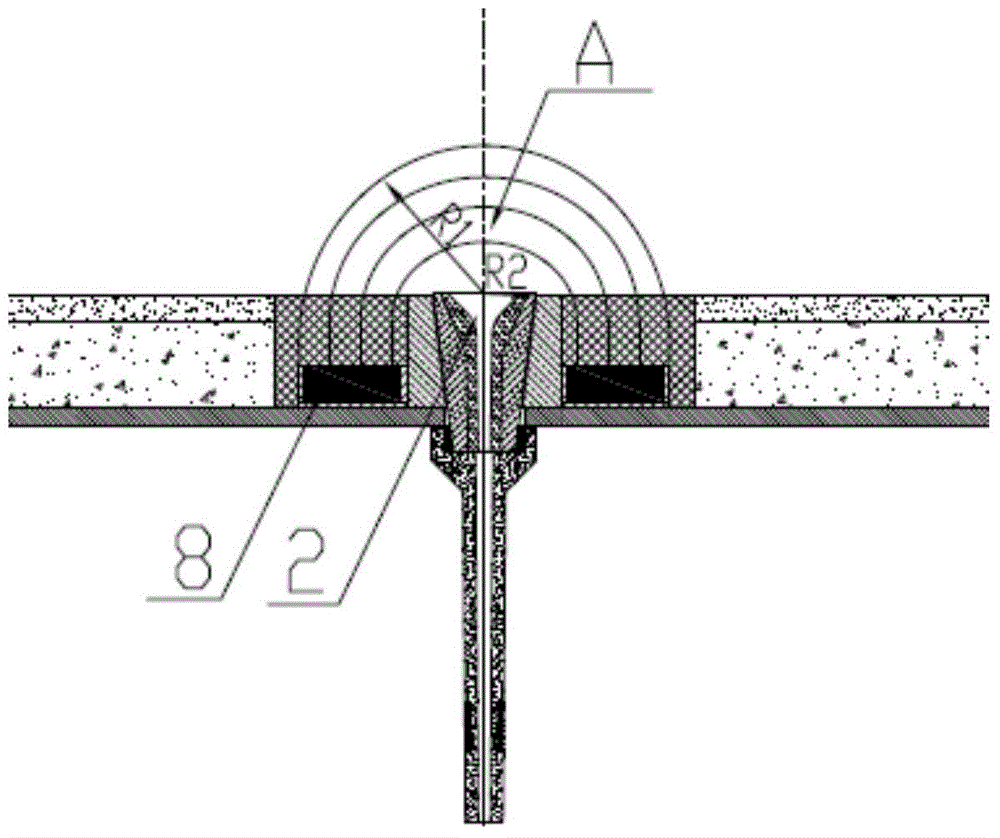

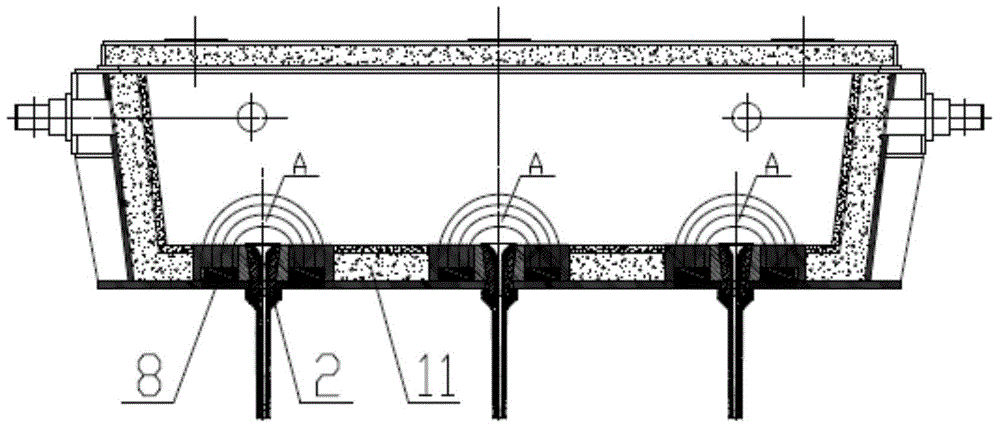

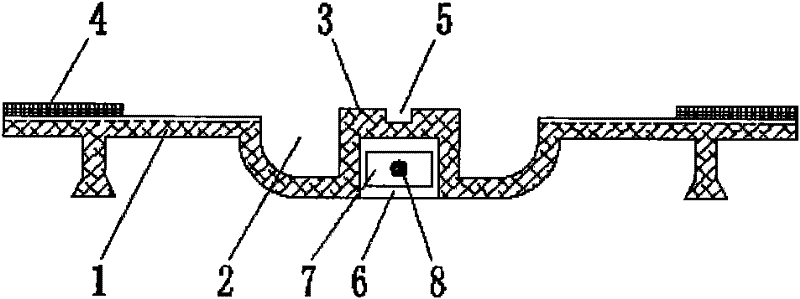

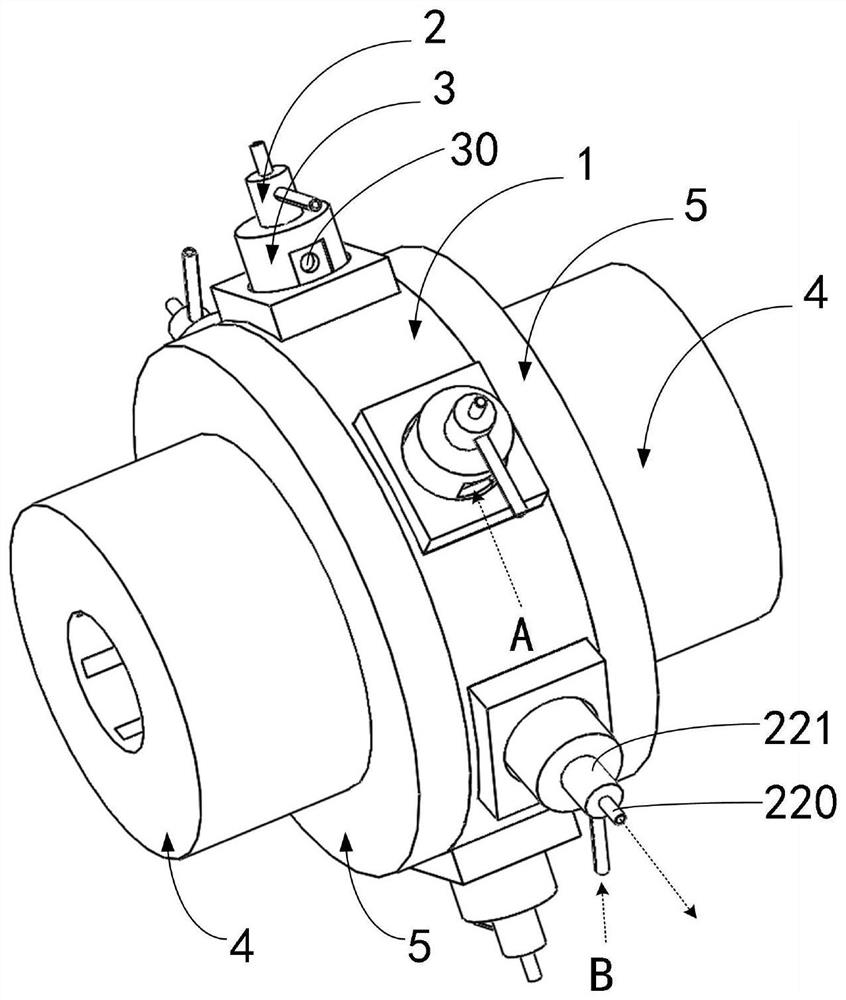

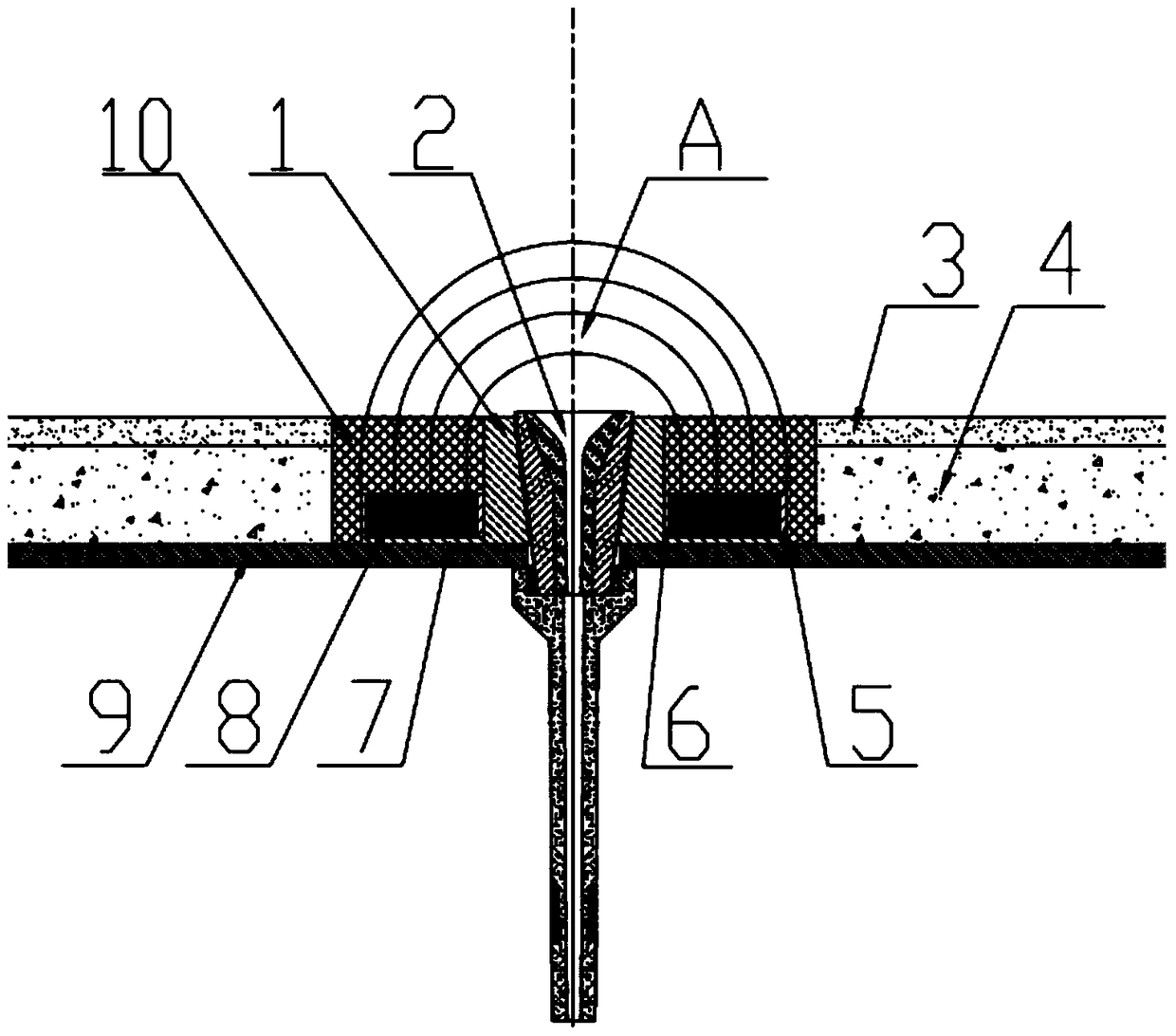

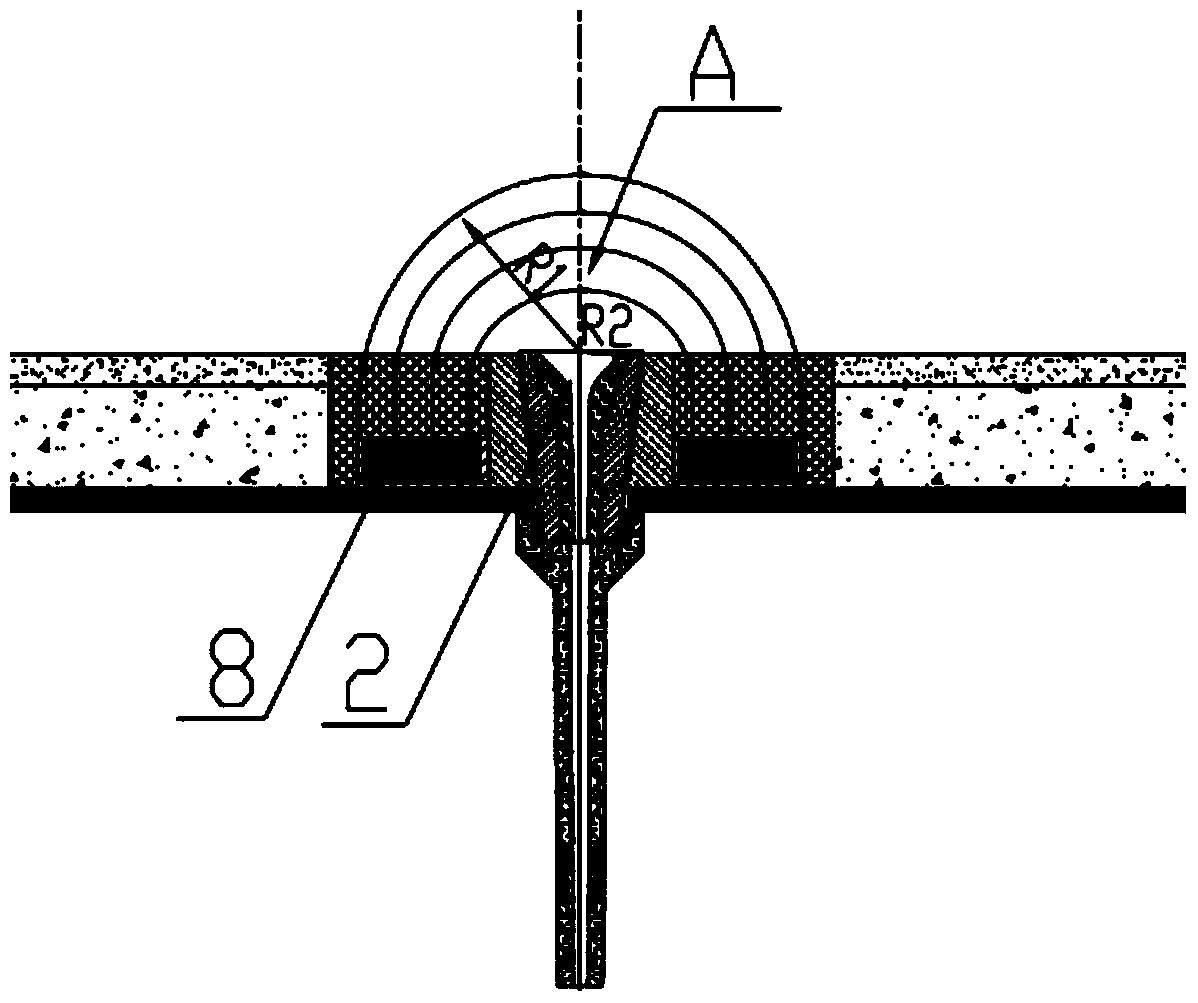

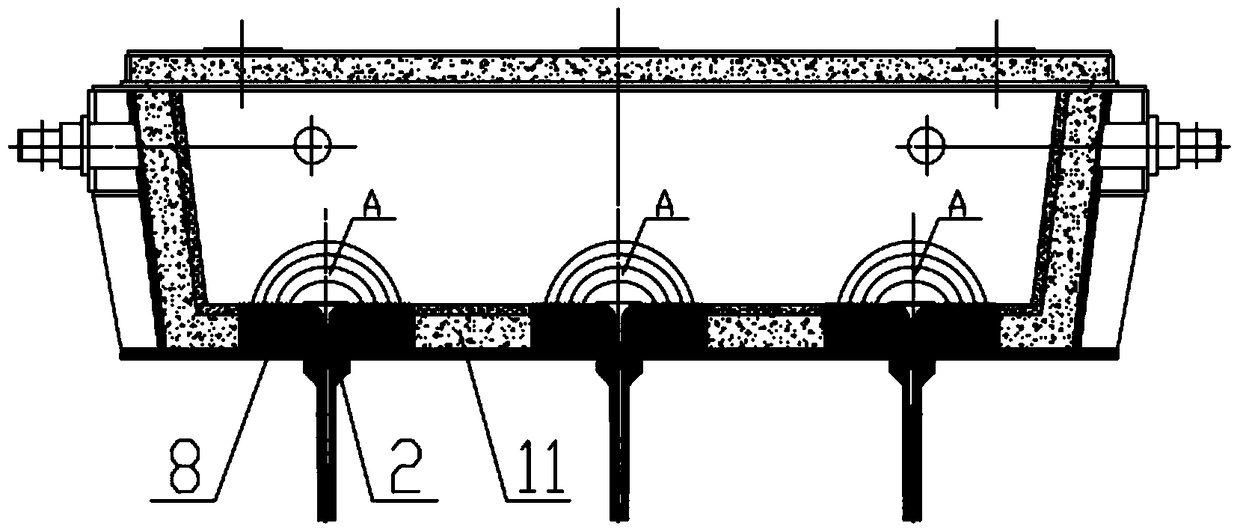

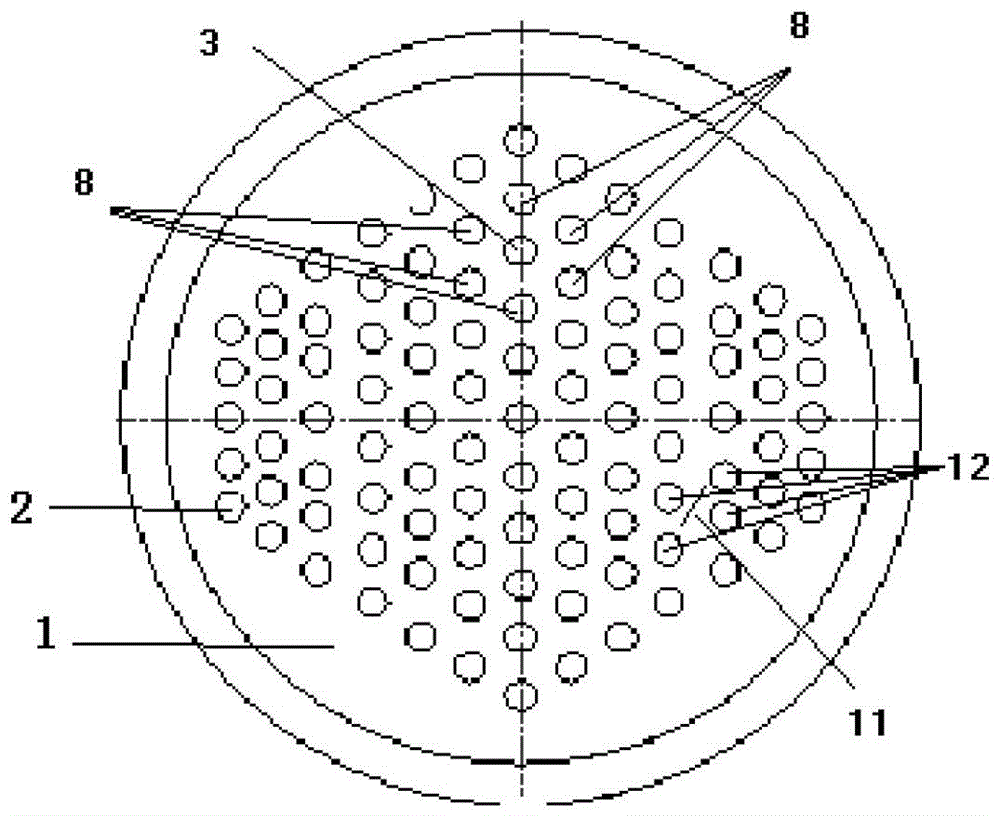

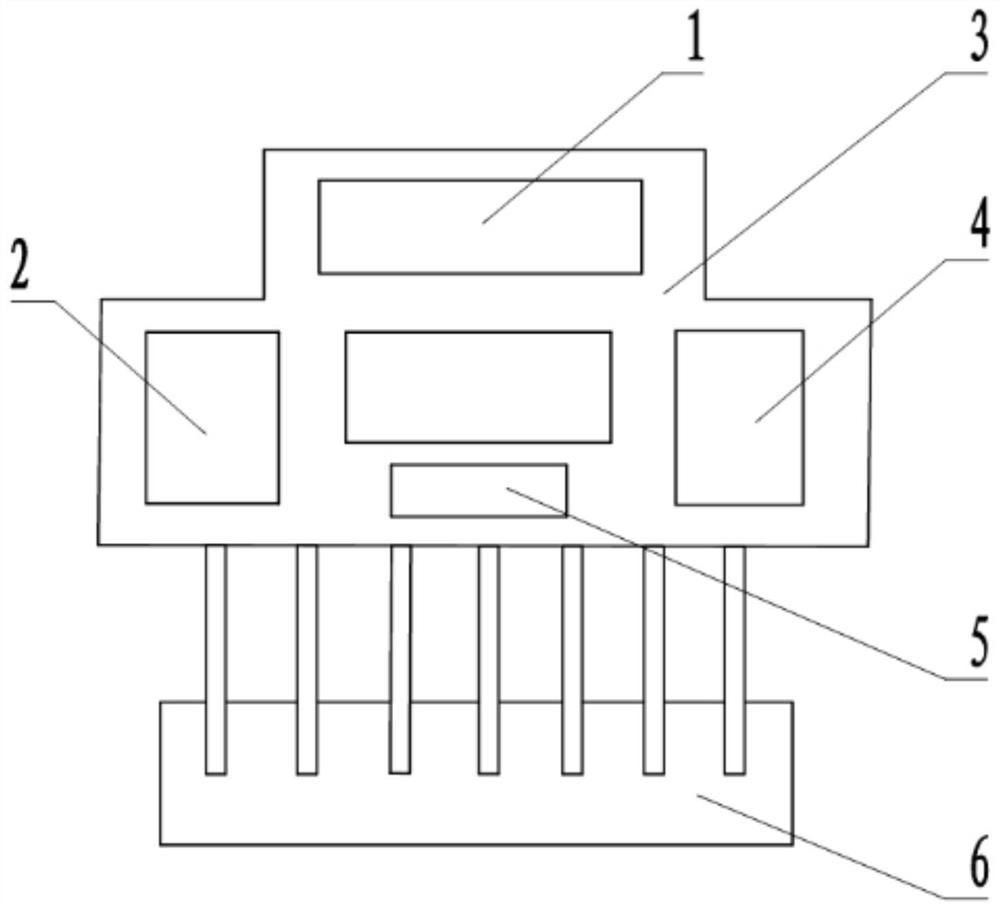

Tundish electromagnetic fixed point target area heating structure

ActiveCN104827018ARealize constant temperature castingIncrease equiaxed crystal ratioMelt-holding vesselsBrickElectromagnetic heating

The invention discloses a tundish electromagnetic fixed point target area heating structure, and solves the problems of short water port life, unreasonable molten steel heating area, high operation cost and easy generation of such accidents as breaking out and steel overflowing in terms of traditional tundish electromagnetic heating. The tundish electromagnetic fixed point target area heating structure comprises a tundish bottom consisting of a working layer, a permanent layer and a tundish baseplate, and a water port formed in the tundish bottom, wherein annular moving base bricks positioned above the tundish baseplate are arranged at the periphery of the water port; an annular electromagnetic inductive heating device is embedded in the lower section of the moving base bricks; and inner shielding rings are annularly arranged in the electromagnetic inductive heating device. The tundish electromagnetic fixed point target area heating structure is simpler in structure, excellent in controllability and uniform in molten steel heating, convenient to install and maintain, effectively realizes the constant-temperature casting of low superheating degree, is high in safety and reliability, and effectively prevents the damage of the water port.

Owner:WUHAN XISAI METALLURGICAL ENG CO LTD

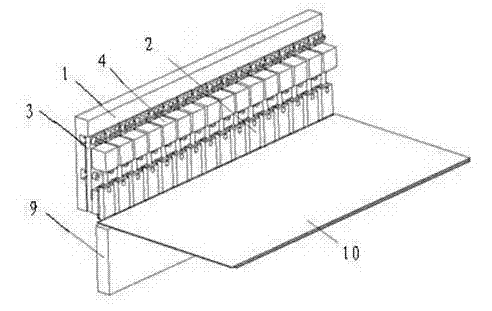

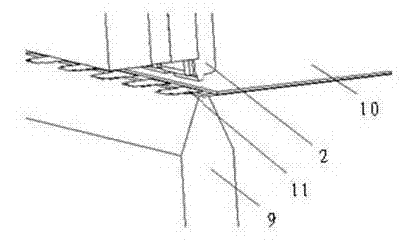

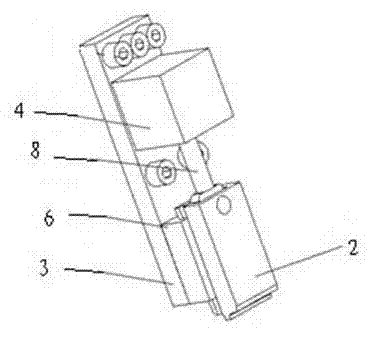

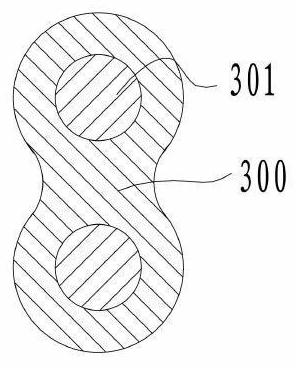

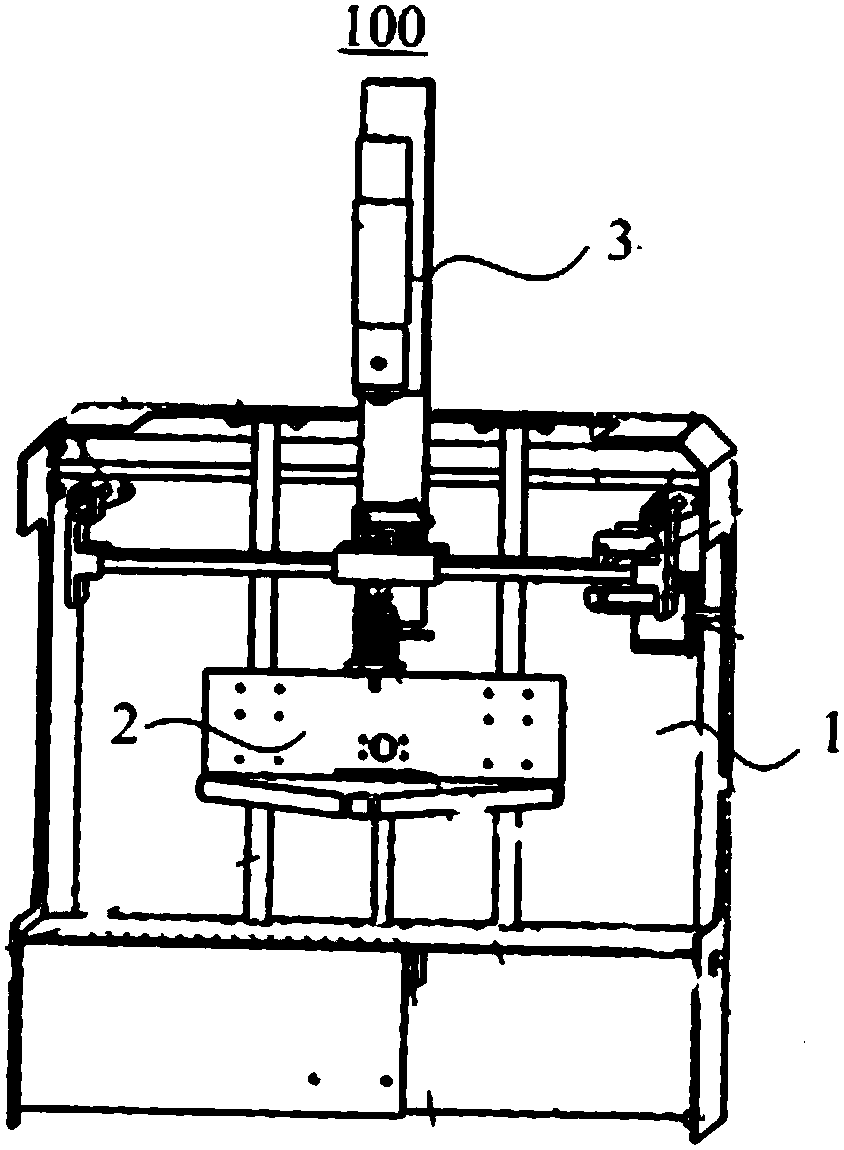

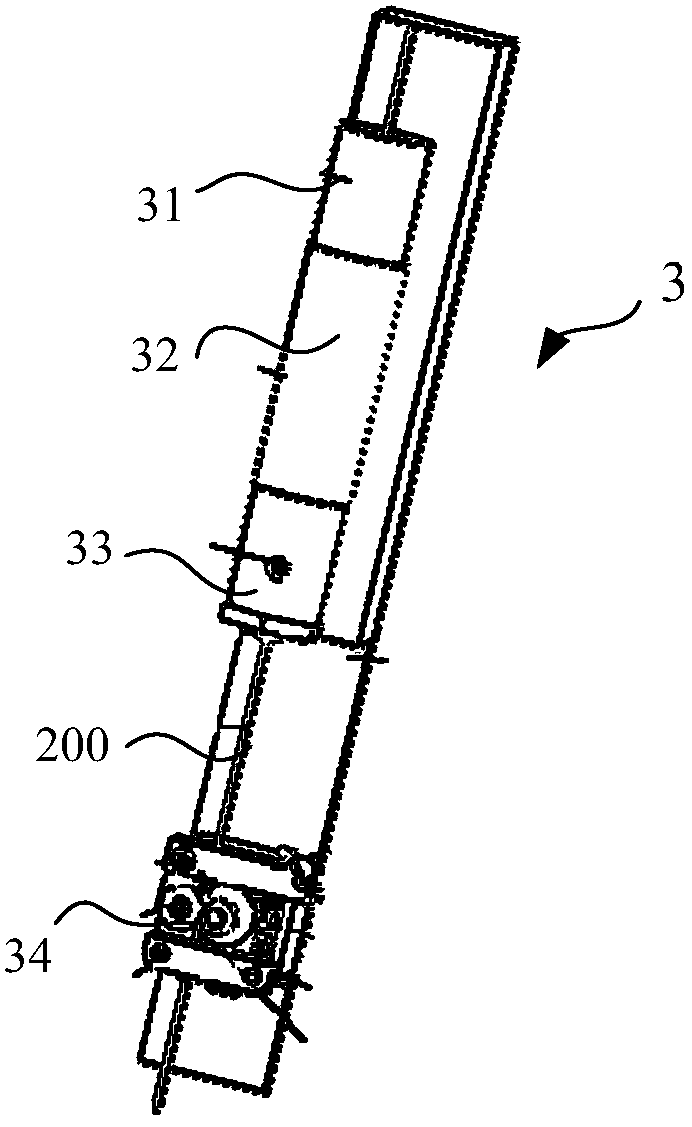

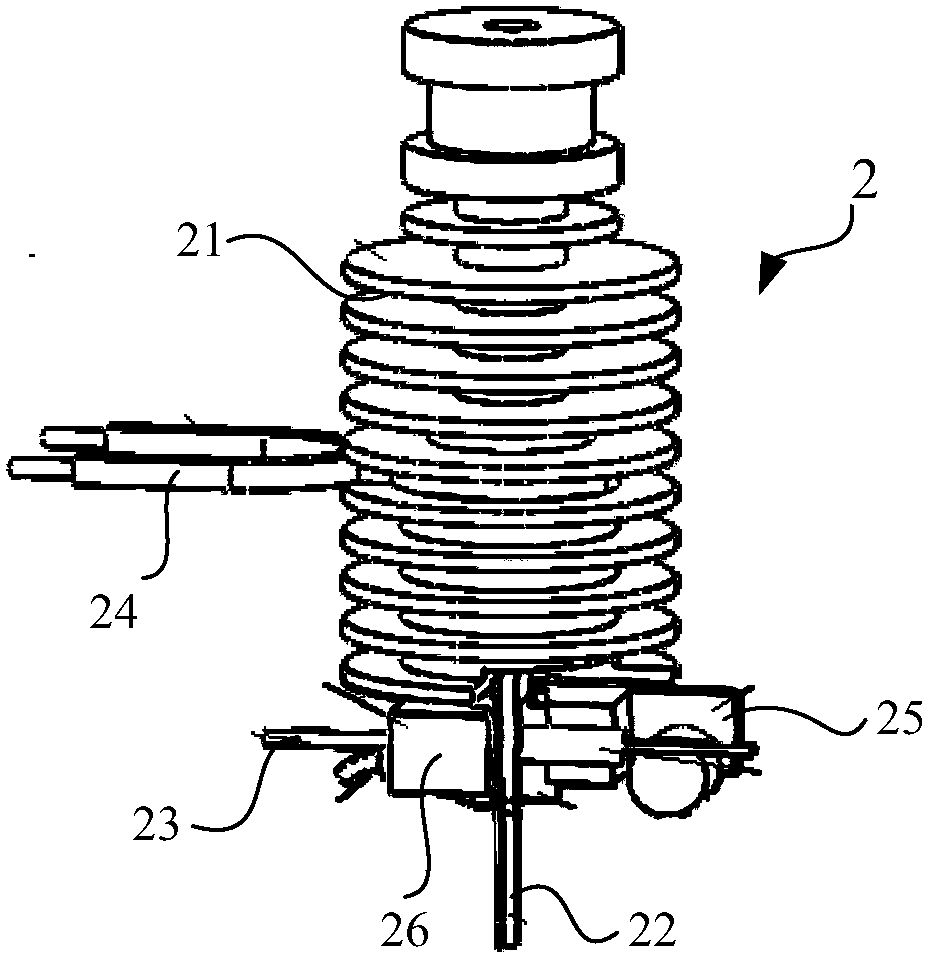

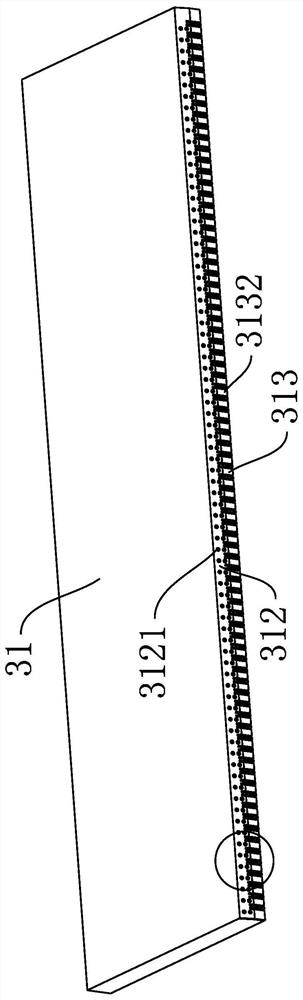

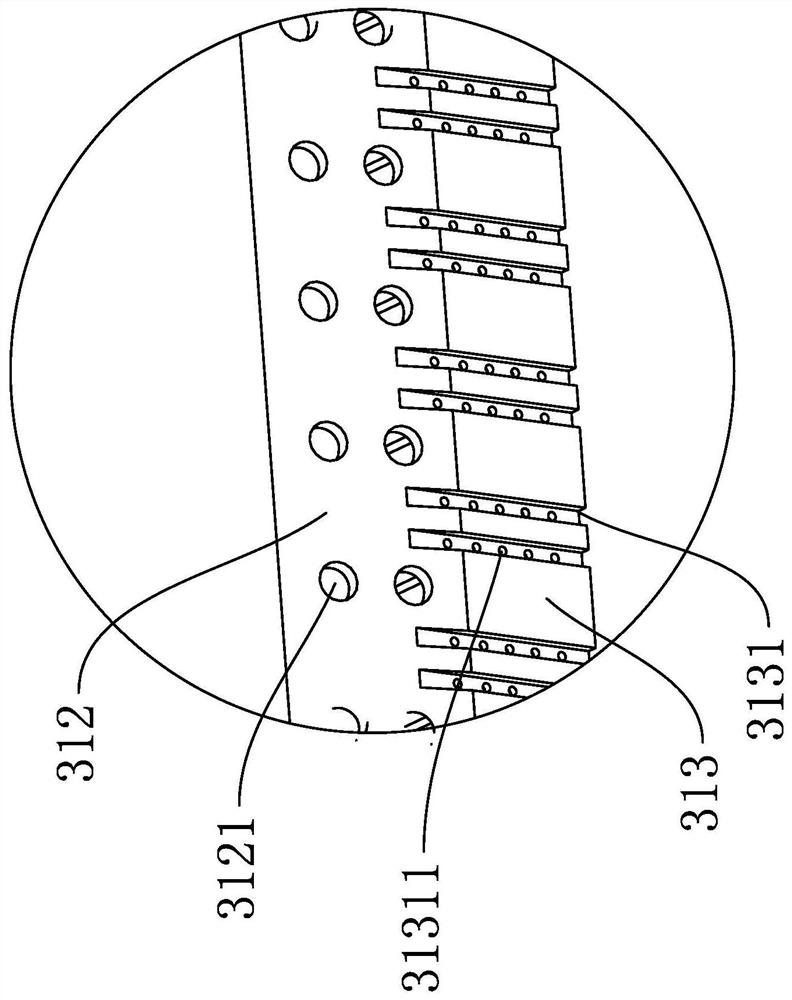

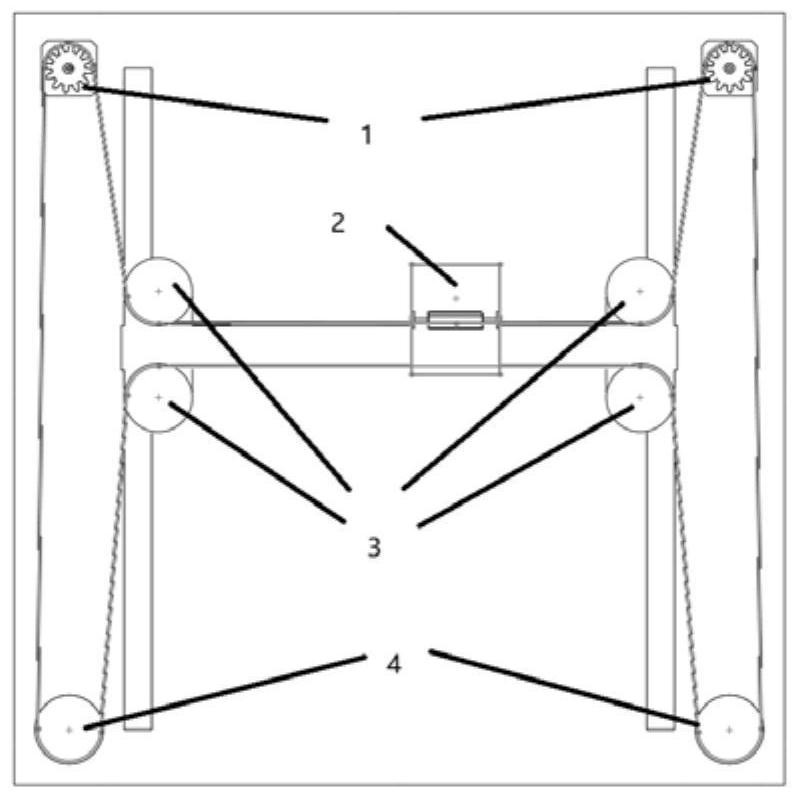

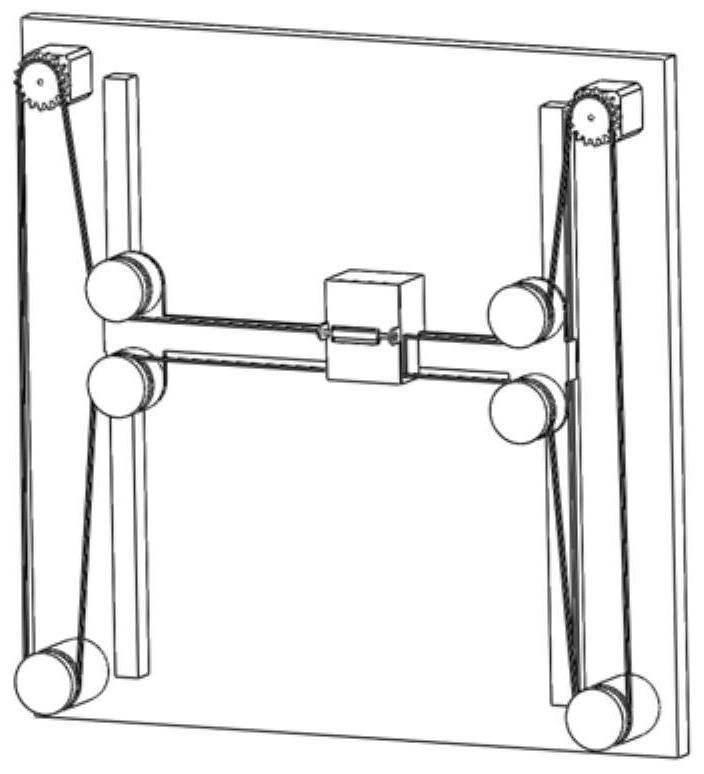

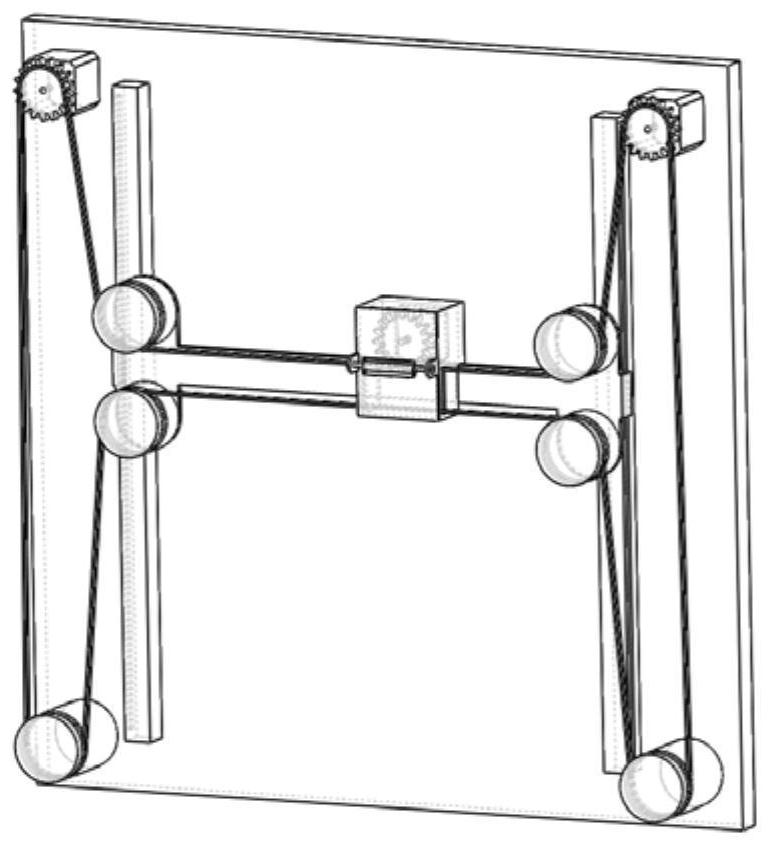

A 3D printer capable of printing continuous fibers, a printer nozzle and a printer feed structure

ActiveCN106087113BControl the direction of transportReduce frictionAdditive manufacturing apparatusArtificial filament chemical after-treatmentFiberFixed frame

The invention discloses a 3D printer capable of printing continuous fibers, a printer spray head and a printer feeding structure. The 3D printer comprises a fixing frame, a feeding portion, a material extruding portion, a guide assembly, a spray head portion, a spray nozzle and at least one heating portion, wherein the feeding portion comprises a first heat transfer part, a heating part is installed on the first heat transfer part, the material extruding portion is connected with the first heat transfer part, the guide assembly is opposite to the material extruding portion, the spray head portion is fixedly connected with the feeding portion and fixedly arranged on the fixing frame, comprises a second heat transfer part and is arranged between the second heat transfer part and the material extruding portion, the spray nozzle connected with the second heat transfer part, and the heating portion is arranged on the second heat transfer part so as to conduct point-to-point heating on the second heat transfer part. The technical problem that a 3D printing material is limited in the prior art is solved or partially solved, and the technical effect of printing the continuous fibers through 3D printing is achieved.

Owner:深圳华纤创新科技有限公司

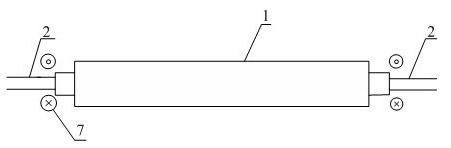

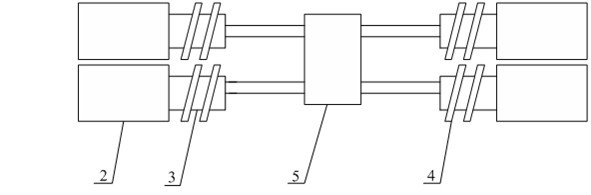

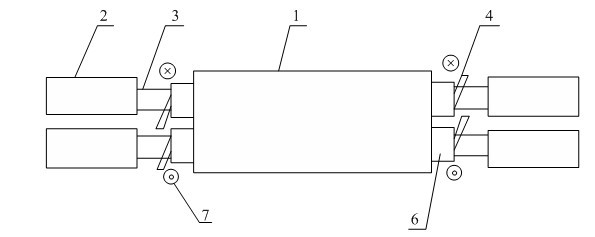

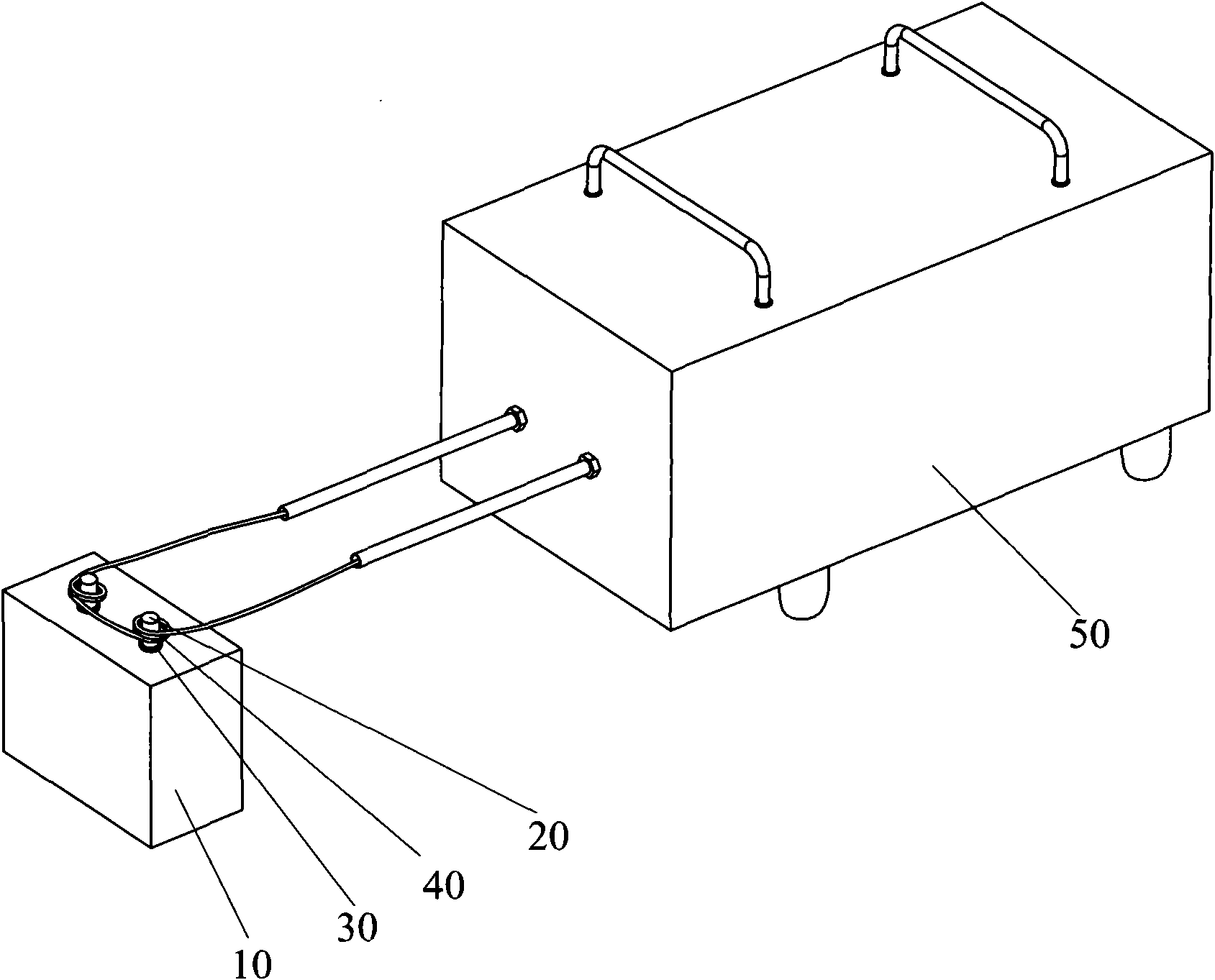

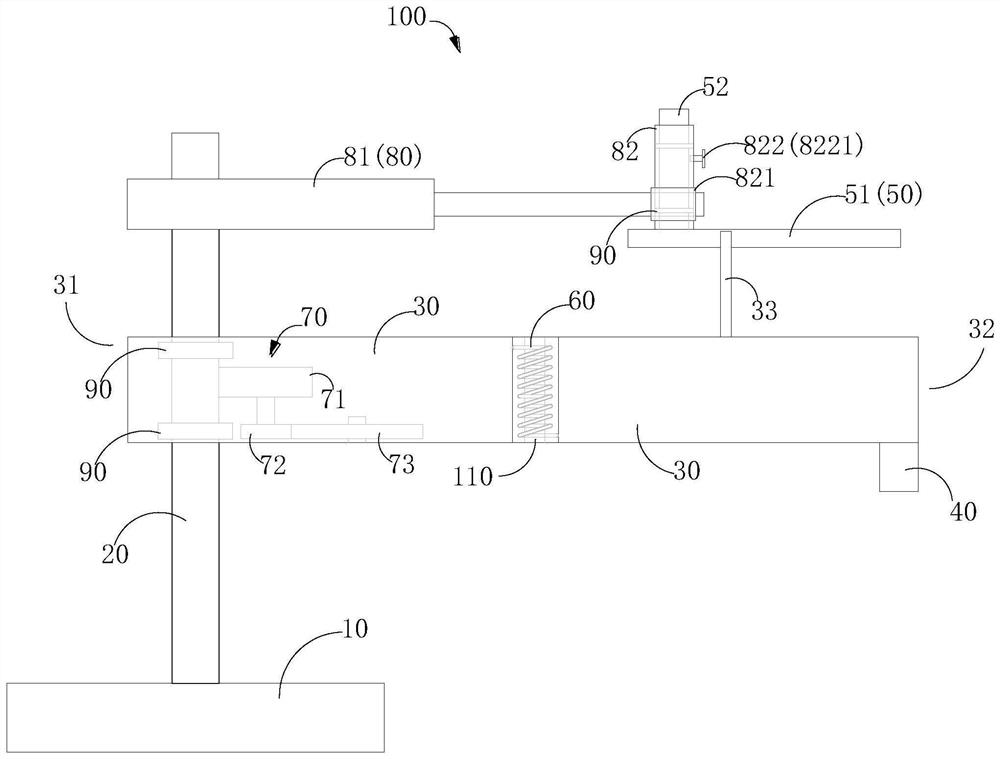

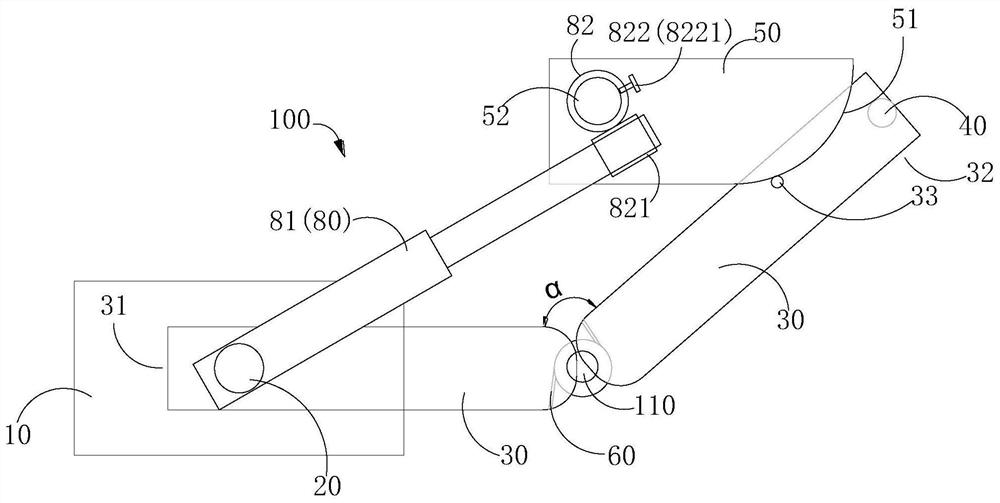

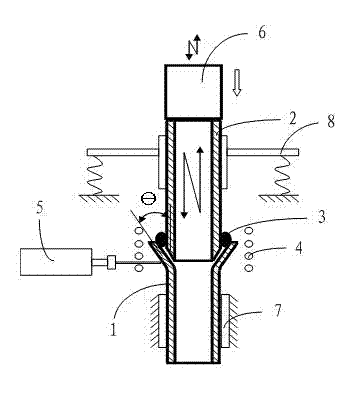

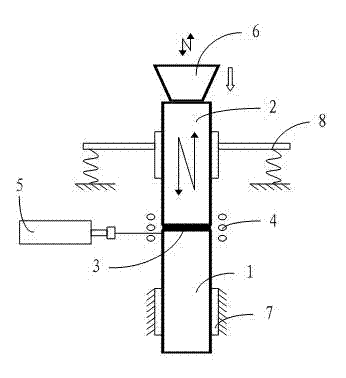

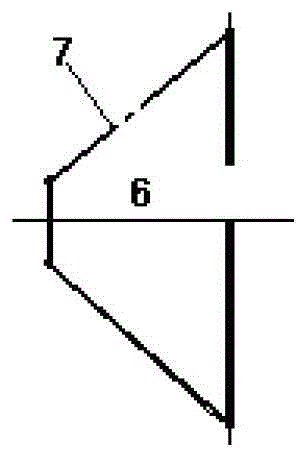

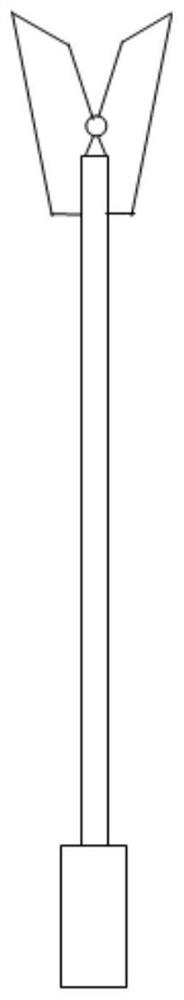

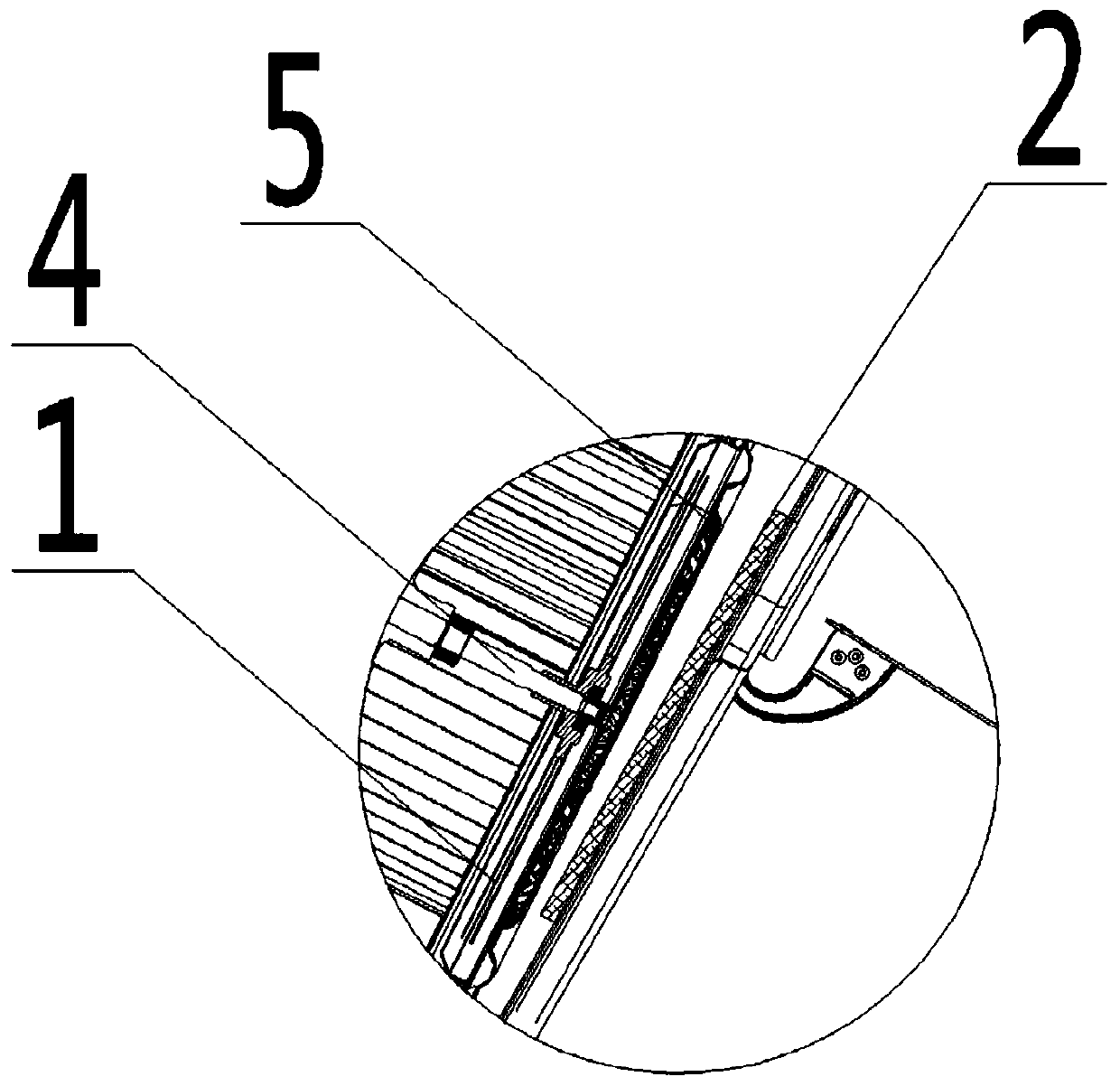

Heating device for making bending fire curve

PendingCN112091082AAccurate displacementSmall heating rangeShaping toolsCantileverMechanical engineering

The invention discloses a heating device for making a bending fire curve. The heating device comprises a base (10), a rotating shaft (20), at least two cantilever rods (30) and a guide plate (50); therotating shaft (20) is fixedly connected to the base (10); the at least two cantilever rods (30) are hinged in sequence and comprise a first connecting end (31) and a second connecting end (32), thefirst connecting end (31) and the second connecting end (32) are arranged end to end, the first connecting end (31) is connected with the rotating shaft (20) in a pivoted mode, and the second connecting end (32) is provided with a fire curve heating head (40); and one end of the guide plate (50) is connected with the rotating shaft (20), the other end of the guide plate (50) is opposite to the second connecting end (32), the guide plate (50) is provided with a guide end face (51), and the second connecting end (32) is suitable for moving along the guide end face (51). The heating device is small in heating range, low in heat energy loss, accurate in fire curve displacement during bending, simple in structure, high in reliability and convenient to operate, and the production efficiency is greatly improved.

Owner:JIANGSU HUADIAN STEEL TOWER MFG

Drying device for producing flexible fabric

PendingCN113503698AReduce settingsSmall heating rangeDrying solid materials without heatDrying gas arrangementsProcess engineeringMechanical engineering

The invention provides a drying device for producing flexible fabric, and belongs to the technical field of machinery. A drying device for producing a flexible fabric comprises a water squeezing assembly used for squeezing out water on the upper surface and the lower surface of a lamp box fabric and draining the water out of two sides of the water squeezing assembly; a water absorption assembly which is used for carrying out water absorption treatment on the upper surface of the lamp box fabric; and a drying assembly which is used for drying the water on the upper surface and the lower surface of the lamp box fabric, wherein the water squeezing assembly, the water absorption assembly and the drying assembly are sequentially arranged. The device has the advantage of being good in water removal effect.

Owner:浙江明士达股份有限公司

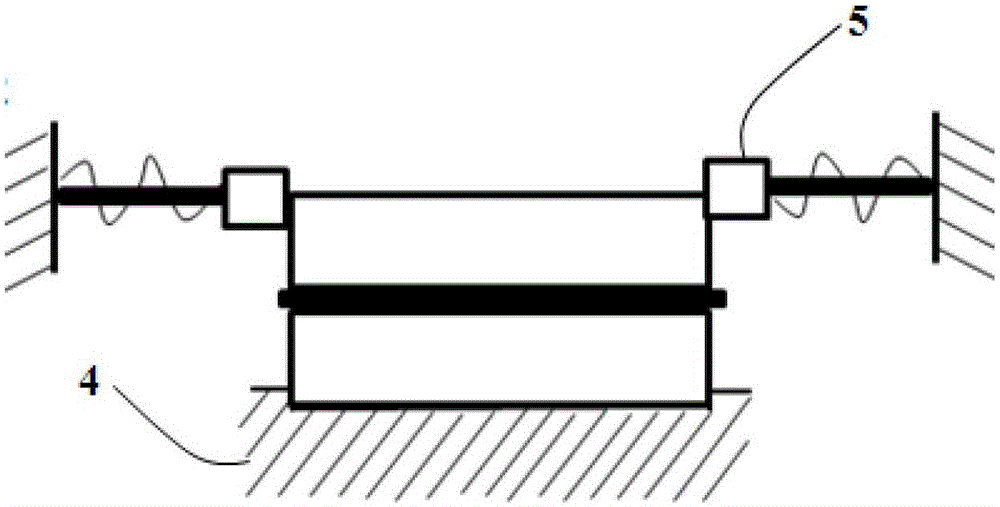

Dissimilar metal material brazing method

ActiveCN102151930BImprove the mixing effectReduce spreadWelding/cutting media/materialsSoldering mediaMetallic materialsUltrasonic vibration

The invention discloses a dissimilar metal material brazing method. The dissimilar metal material includes a first base metal and a second base metal different from each other. The method comprises the following steps: clamping the first base metal on a telescopic fixture and clamping the second base metal on a fixed fixture in such a manner that the welding surfaces of the first base metal and the second base metal face to each other, and placing a solder between the welding surfaces; applying a pre-pressure on the first base metal relative to the welding surface; locally rapidly heating thewelding parts of the first base metal and the second base metal to a preset temperature and keeping the temperature; increasing the pre-pressure to a welding pressure; applying ultrasonic vibration to the first base metal relative to the welding surfaces by an ultrasonic compression bar; and continuously keeping the temperature and the pressure after the ultrasonic vibration completes, stopping heating, and further keeping the pressure until the welding parts are cooled. The method can improve the strength of a brazed joint of dissimilar metal materials by reducing the formation of laminar brittle intermetallic compounds and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Image fixing apparatus image forming apparatus using the same

InactiveCN100454173CAvoid temperature riseSmall heating rangeElectrographic process apparatusImage formationMagnetic flux

Owner:RICOH KK

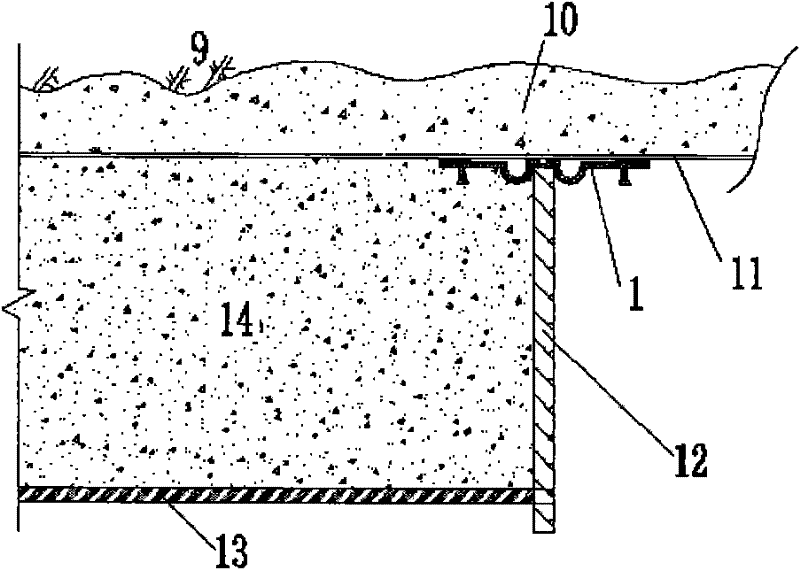

A dual-source heating and drainage antifreeze method for tunnel construction joints in cold regions

ActiveCN101566073BPrevent frostbitePrevent freeze blockageMining devicesHot-air central heatingDouble tubeEngineering

The invention discloses a dual-source heating and drainage antifreeze method for construction joints of tunnels in cold regions. Two energy sources, hot gas and electric energy, are used to supply small-scale heating and drainage to drainage channels at construction joints. The hot gas and electric energy are used alone or in combination. Based on the drainable waterstop, this method uses two energy sources, hot air and electric energy, to heat and thaw tunnel construction joints in a small area, by section and by time, by setting dual-source heat supply pipes, so as to prevent drainage at the construction joints. The channel is frozen and blocked to achieve effective drainage, thereby avoiding freezing damage in tunnel construction joints in cold regions.

Owner:CENT SOUTH UNIV

Smoke machine self-cleaning structure, method and smoke machine

ActiveCN109268888BPromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusOil and greaseElectric machine

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a hot air heating devicewhich is arranged on the range hood, and cleans the inner oil screen by heating the inner oil screen, wherein the hot air heating device comprises a fan and an air outlet which is connected with the fan, and is used for heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particlesin the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better, and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Plasma heating furnace for melting shrinkage of optical fiber preform

ActiveCN113896412AQuality is not affectedSmall heating rangeGlass making apparatusGlass productionPlasma jetGraphite

The invention relates to a plasma heating furnace for melting shrinkage of an optical fiber preform. The plasma heating furnace comprises a furnace body and a plurality of cathodes, the furnace body forms an anode, the furnace body is provided with a fusion shrinkage channel through which the optical fiber preform passes, a plurality of mounting cavities are formed in the furnace body, and the mounting cavities are communicated with the fusion shrinkage channel through plasma jet orifices; and the cathodes are arranged on the mounting cavities, working gas channels are formed between the cathodes and the mounting cavities, cathode heads of the cathodes face the plasma jet orifices, and insulating rings are arranged between the cathodes and the inner walls of the corresponding mounting cavities. The plasma heating furnace is provided with a melting shrinkage channel for the optical fiber preform to pass through, and working gas is introduced into the working gas channels to generate plasmas. A graphite piece is omitted in the furnace body, so that the situation that dust is generated through oxidation does not exist, no dust is attached to the optical fiber preform, and the quality of the optical fiber preform cannot be affected. The heating interval of the plasma flame generated by the plasma heating furnace is small, and compared with the related technical scheme, the energy is more concentrated and more energy-saving, and the efficiency is higher.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

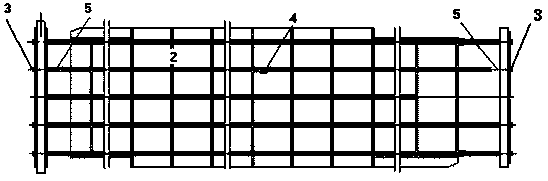

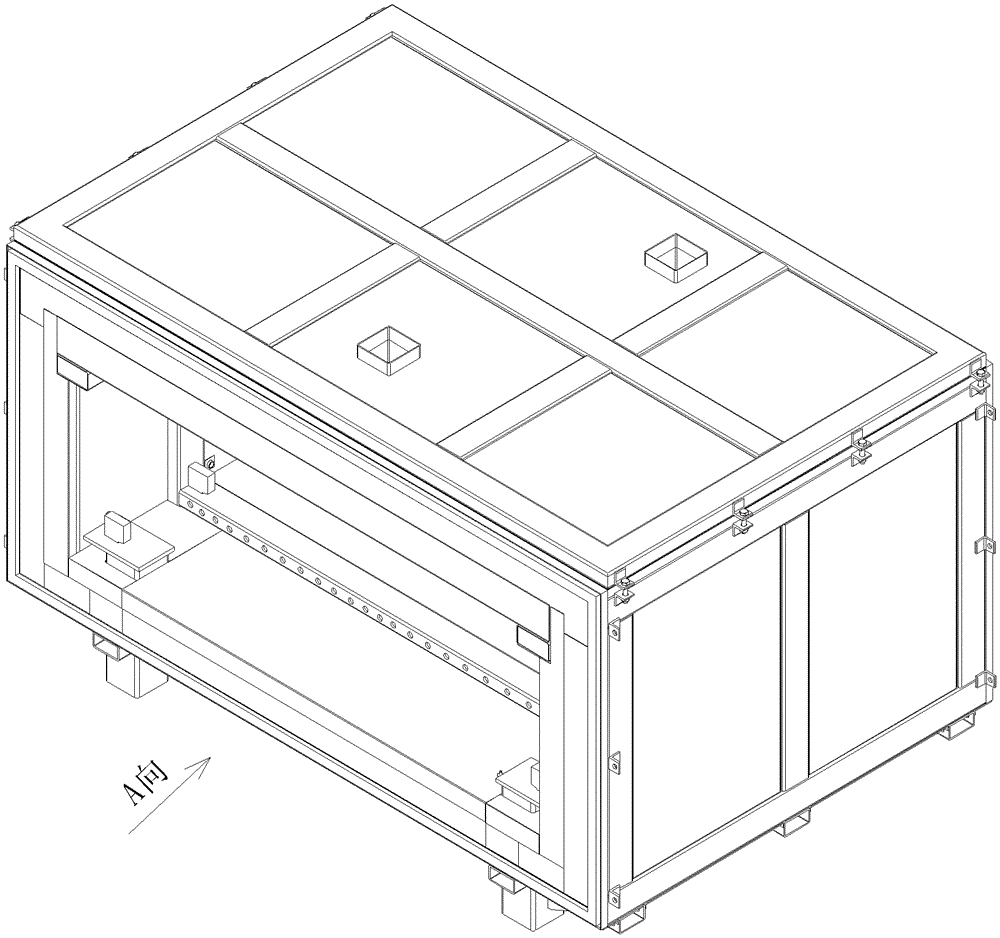

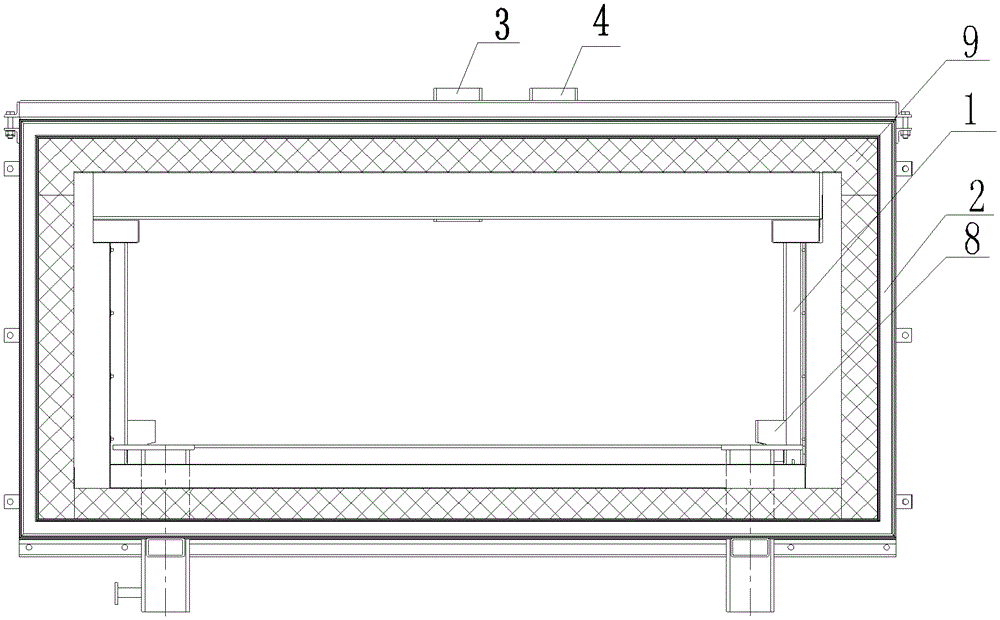

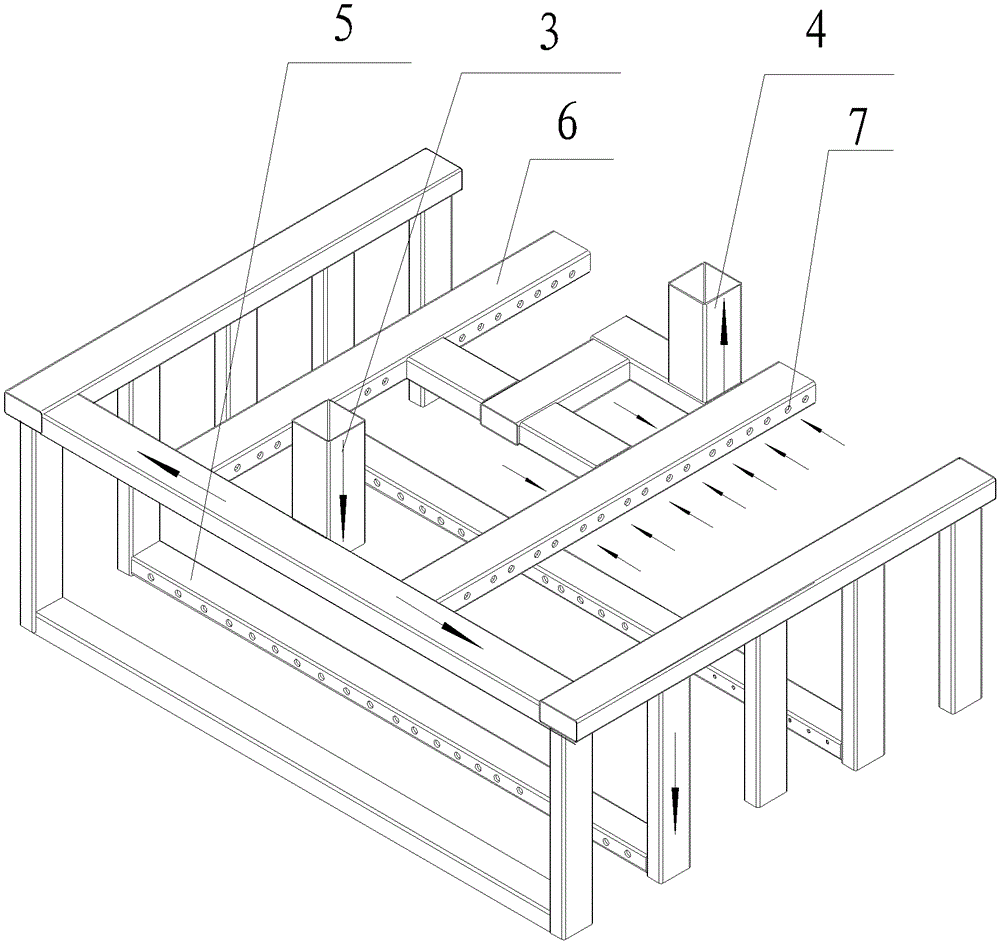

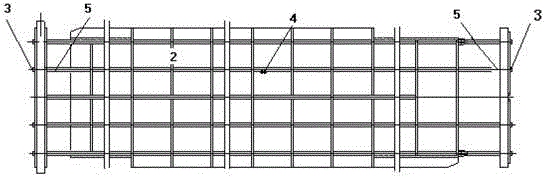

Furnace body of a continuous annealing furnace

ActiveCN103131839BEvenly heatedImprove utilization efficiencyFurnace typesHeat treatment furnacesContinuous annealingTuyere

The invention discloses a furnace body of a continuous annealing furnace. The furnace body is composed of connecting a plurality of independent furnace bodies, wherein two neighboring independent furnaces are separated through a furnace door. Each independent furnace body comprises a furnace body skeleton and a sealing cover arranged outside the skeleton, wherein the sealing cover is square-type, two ends of the furnace body are provided with the furnace body connected with the sealing cover, the sealing cover of each independent furnace body is provided with an air inlet pipe and an air outlet pipe, the air inlet pipe and the air outlet pipe are respectively connected with an air outlet of a warm air machine and an air inlet of the warm air machine, the air inlet pipe and the air outlet pipe are respectively communicated with an air outlet pipe inside the furnace and an air backflow pipe inside the furnace, are at least one supporting pillar, are not communicated, and are hollow pipes with a plurality of air holes arranged on the surfaces of the hollow pipes, and a guide rail pressing block is arranged at the bottom of the skeleton of the furnace body. The furnace body of the continuous annealing furnace can effectively use heat source and improve heating efficiency.

Owner:SNTO TECH GRP

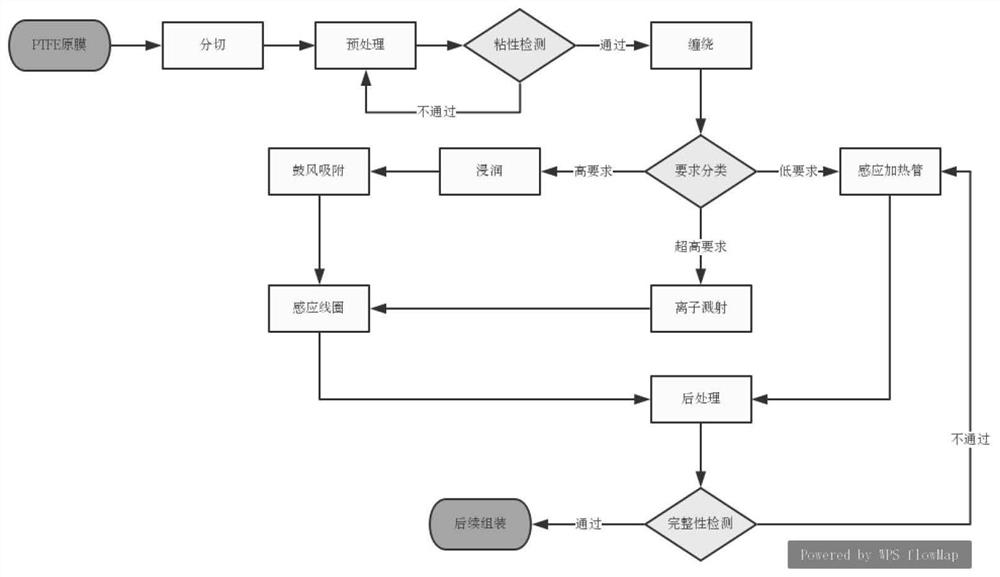

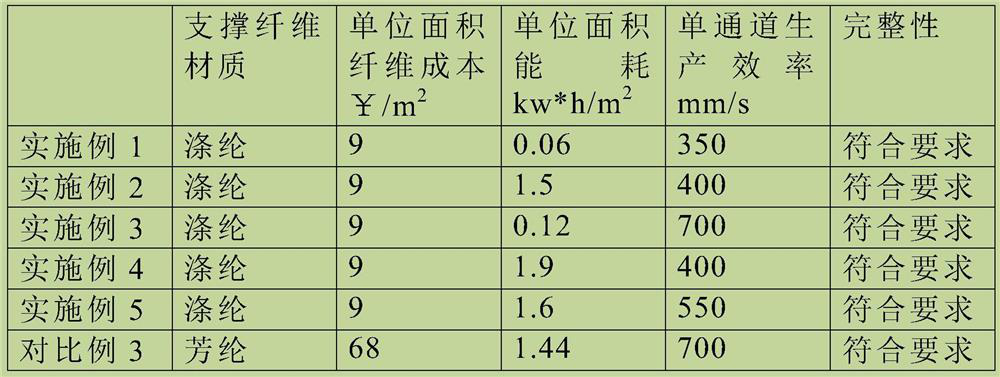

A kind of processing method of ptfe hollow fiber membrane

ActiveCN111111469BLow costGuaranteed flexibilitySemi-permeable membranesPolymer scienceThermal treatment

The invention relates to a processing method of a PTFE hollow fiber membrane, belonging to the technical field of hollow fiber membrane processing. The processing method of the PTFE hollow fiber membrane of the present invention includes the following steps: pretreating the PTFE original membrane; wrapping the pretreated PTFE original membrane on a braided tube to form a wound long fiber membrane filament; The wire is subjected to high-frequency induction heating treatment; the heated membrane wire is subjected to post-treatment to obtain the finished product. Compared with the traditional blast heating method, the preparation method of the present invention can significantly reduce the energy consumption, and can adopt cheap materials that are not resistant to high temperature as the supporting material, thereby reducing the cost significantly.

Owner:NINGBO JINGYUAN MEMBRANE TECH

Heating structure of electromagnetic fixed-point target area of tundish tank

ActiveCN104827018BRealize constant temperature castingIncrease equiaxed crystal ratioMelt-holding vesselsBrickEngineering

The invention discloses an electromagnetic fixed-point target area heating structure for a tundish tank, which solves the problems of low nozzle life, unreasonable molten steel heating area, high operating cost, easy leakage, steel overflow and other accidents existing in the existing tundish electromagnetic heating . The technical solution includes the bottom of the tundish which is composed of the working layer, the permanent layer and the bottom plate of the tundish, and the nozzle arranged at the bottom of the tundish, the outer periphery of the nozzle is provided with an annular movable seat brick above the bottom plate of the tundish, and the movable seat An annular electromagnetic induction heating device is embedded in the lower section of the brick, and the inner ring of the electromagnetic induction heating device is provided with an inner screen ring. The invention has the advantages of extremely simple structure, good control performance, convenient installation and maintenance, uniform heating of molten steel, effectively realizing constant temperature casting with low superheat, high safety and reliability, and effectively avoiding nozzle damage.

Owner:WUHAN XISAI METALLURGICAL ENG CO LTD

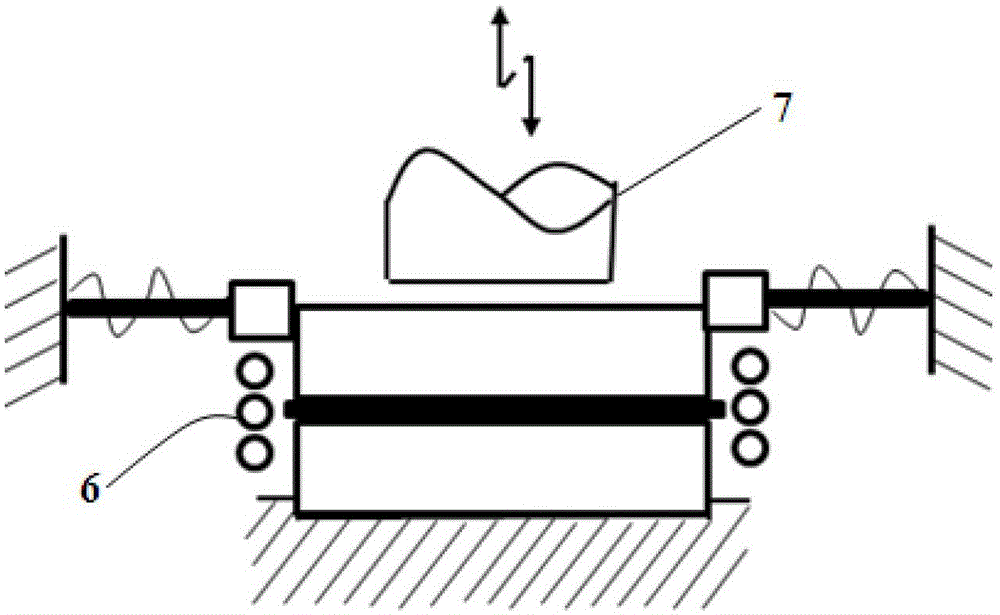

Auxiliary online heating device and method for fused deposition additive manufacturing system

ActiveCN114834039AEasy to moveHighly IntegratableManufacturing heating elementsIncreasing energy efficiencyThermodynamicsProcess engineering

The invention provides an auxiliary online heating device and method for a fused deposition additive manufacturing system, the device comprises a bottom plate, an x-direction moving device, a y-direction moving device and a heating source, the heating source is installed on the x-direction moving device, the x-direction moving device is connected with the y-direction moving device, and the y-direction moving device is installed on the bottom plate; when the y-direction moving device is static, the x-direction moving device is started to reciprocate on the y-direction moving device, so that the heating source reciprocates in the x direction; and when the x-direction moving device is static, the x-direction moving device drives the heating source to reciprocate in the y direction through the movement of the y-direction moving device. The auxiliary heating source can be integrated in the cavity shell of the fused deposition system, and the situation that the overall size of the additive manufacturing system is increased due to the fact that a heat source is additionally added is avoided.

Owner:DALIAN MARITIME UNIVERSITY

Method for sealing shielding can

InactiveCN101837495BAvoid magnetizationGuaranteed smoothSoldering apparatusRadio frequencyInductance

The invention discloses a method for sealing a shielding can, comprising the following steps: providing a shielding can riveted with a connector, wherein an assembling gap is formed between the shielding can and the connector; providing an stannum ring with the shape corresponding to that of the gap; sheathing the stannum ring on the connector to cover the gap between the shielding can and the connector; providing a radio frequency heater connected with an inductance coil; preparing the inductance coil into a shape corresponding to that of the stannum ring; and sheathing the connector in the inductance coil, positioning the stannum ring below the inductance coil, and leading the stannum ring to lean a certain angle relative to the inductance coil, thus the strength of magnetic fields generated by the inductance coil at a region at which the stannum ring is positioned to be almost same. The radio frequency heater electrifies the inductance coil to generate a magnetic field; and the inductance coil is heated and molten in the magnetic field to fill the gap. The method for sealing the shielding can of the invention has good sealing effect and higher qualification rate and production efficiency.

Owner:DONGGUAN HONGLONG METAL PRODS

A chromium-molybdenum steel pipe bundle and tube sheet maintenance process

The invention discloses a repairing process of a chromium-molybdenum steel tube bundle and a tube plate, and belongs to the field of repairing of chromium-molybdenum steel. The process comprises a tube bundle repairing process and a tube plate repairing process. A leaking point is determined firstly, then the tube bundle and / or the tube plate are repaired according to the steps of preheating of adjacent tube openings, welding and post-welding treatment of the adjacent tube openings. The adjacent tube openings are pre-heated and subjected heat post-welding treatment through an oxygen-acetylene inner flame, a nickel base welding wire serves as welding materials, the heating and temperature control conditions on the repairing site can easily meet the requirements of the repairing process, an obtained welding joint is high in quality and not prone to new cracks, the tube openings replace crack-stopping holes in the tube plate repairing process, cracks are not prone to spread, and the welding cost and labor intensity are effectively reduced.

Owner:PETROCHINA CO LTD

A connection method for rapid in-situ formation of homogeneous phase alumina ceramics in an atmospheric environment

ActiveCN103170723BOvercome limitationsReduce limitationsNon-electric welding apparatusAlloyCorrosion

The invention provides a connection method of rapid in-situ forming same quantity and phase aluminum oxide ceramics in an atmospheric environment, and belongs to the ceramics-ceramics or ceramics-metal connecting field. Rapid wetting of a joint can be achieved in the atmospheric environment, joint internal stress of a composite phase structure is greatly alleviated, and meanwhile the joint is strengthened and use temperature is improved. Compared with a connection method of other ceramics, the connection method of the rapid in-situ forming same quantity and phase aluminum oxide ceramics in the atmospheric environment can obtain excellent performances of high sealing performance (joint jointing rate is larger than or equal to 95%), high intensity (70-90 MPa) and wide service temperature range, and is especially suitable for rapid, efficient and high-strength connection of structures of aluminum oxide ceramics- aluminum oxide ceramics and aluminum oxide ceramics-metal(aluminum, copper, stainless steel, corresponding alloy and the like) which need long time vacuum pressure withstand, high service temperature, high intensity and high corrosion resistance performance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

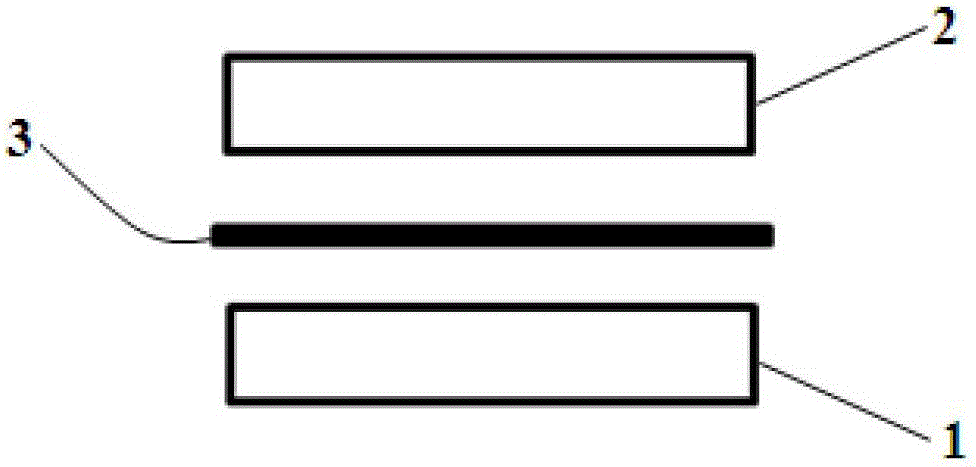

Carrier for heating test of electronic device

PendingCN113917259AHigh control precisionLow costMeasurement instrument housingEnvironmental/reliability testsTemperature controlProcess engineering

The invention relates to the technical field of device testing equipment, in particular to a carrier for heating test of an electronic device. The carrier comprises: a carrier body, which is used for loading a device to be tested; a heating device, which comprises a heating top plate and a heating bottom plate, wherein the heating top plate and the heating bottom plate are used for clamping and heating the carrier body and the device to be tested; a temperature sensor, which is used for collecting the temperature of the carrier body and sending the temperature to the controller; and a controller, which is used for controlling the heating power of the heating device according to the temperature collected by the temperature sensor. By adopting the above scheme, the time and the cost of testing the electronic device can be reduced, the control precision of the heating temperature is improved, and the speed of reflecting the temperature condition of the to-be-tested device is accelerated.

Owner:重庆平创半导体研究院有限责任公司

Smoke machine self-cleaning structure, method and smoke machine

ActiveCN109268889BPromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusOil and greaseElectric machine

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a heating device which isarranged on the range hood, and cleans the inner oil screen by heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particles in the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better,and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com