A dual-source heating and drainage antifreeze method for tunnel construction joints in cold regions

A technology for tunnels in cold areas, drainage and antifreeze, applied in drainage, heating methods, household heating, etc., can solve the problems of insulation layer failure, high cost of insulation layer, failure, etc., achieve short heating time, small heating range, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

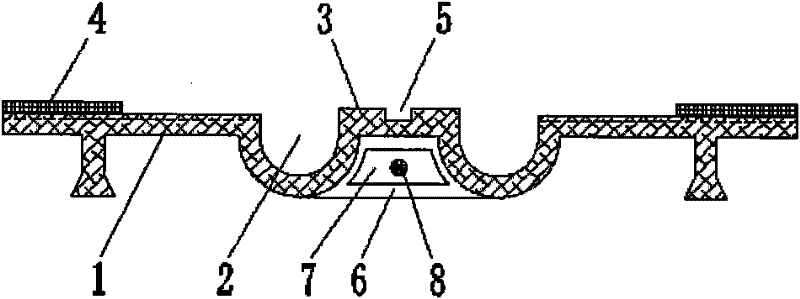

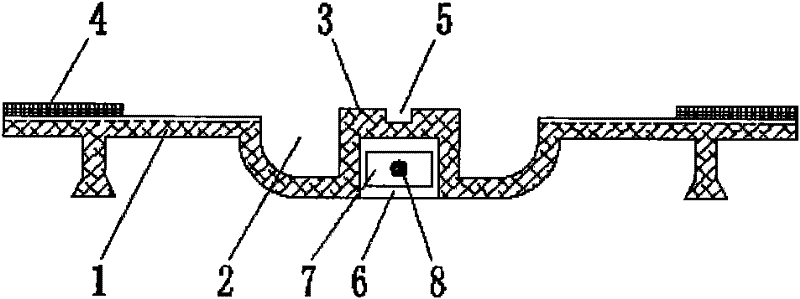

[0022] see figure 1 and figure 2 As shown, the main structure of the dual-source heating type back-mounted drainage waterstop is a strip-shaped substrate 1, a strip-shaped substrate 1, drainage channels 2, water-proof convex ribs 3, slurry-stop filter belt 4, and detection tank 5 Together they form a common back-mounted drainable waterstop. In the middle groove of the backwater surface of the two drainage channels 2, a dual-source heat supply pipe 6 is arranged. The dual-source heating pipe 6 can be trapezoidal, rectangular or circular, and can be made of polymer materials such as polyvinyl chloride and rubber. There is a cavity 7 in the dual-source heat supply pipe 6, which can be used for heating fluid to pass through, so as to heat the drainage channel 2 and prevent it from freezing and blocking; Drain channel 2 is heated.

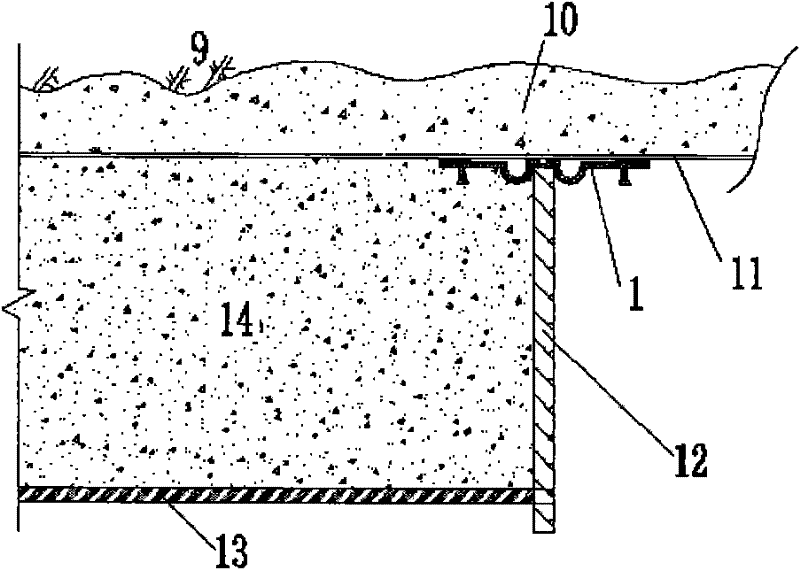

[0023] Figure 3 ~ Figure 5 It is the construction status diagram of the present invention. In tunnel and underground engineering, when pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com