Heating structure of electromagnetic fixed-point target area of tundish tank

A heating structure, electromagnetic induction heating technology, applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of electrode consumption on molten steel, difficult to maintain plasma arc, large internal cracks, etc. Inclusion floating, inclusion reduction, easy local temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0030] The experiment of the electromagnetic fixed-point target area heating structure of the tundish in the actual continuous casting production:

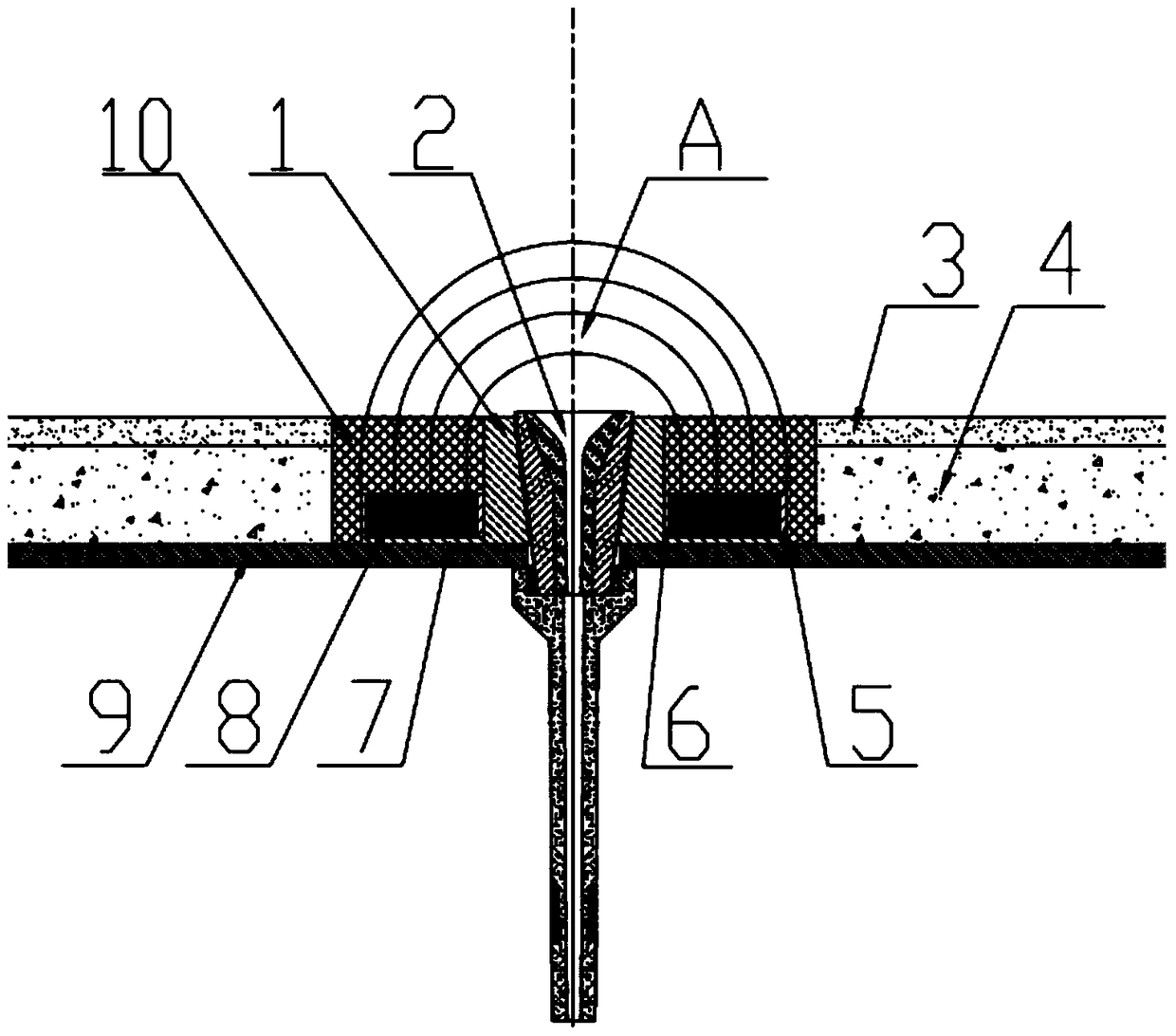

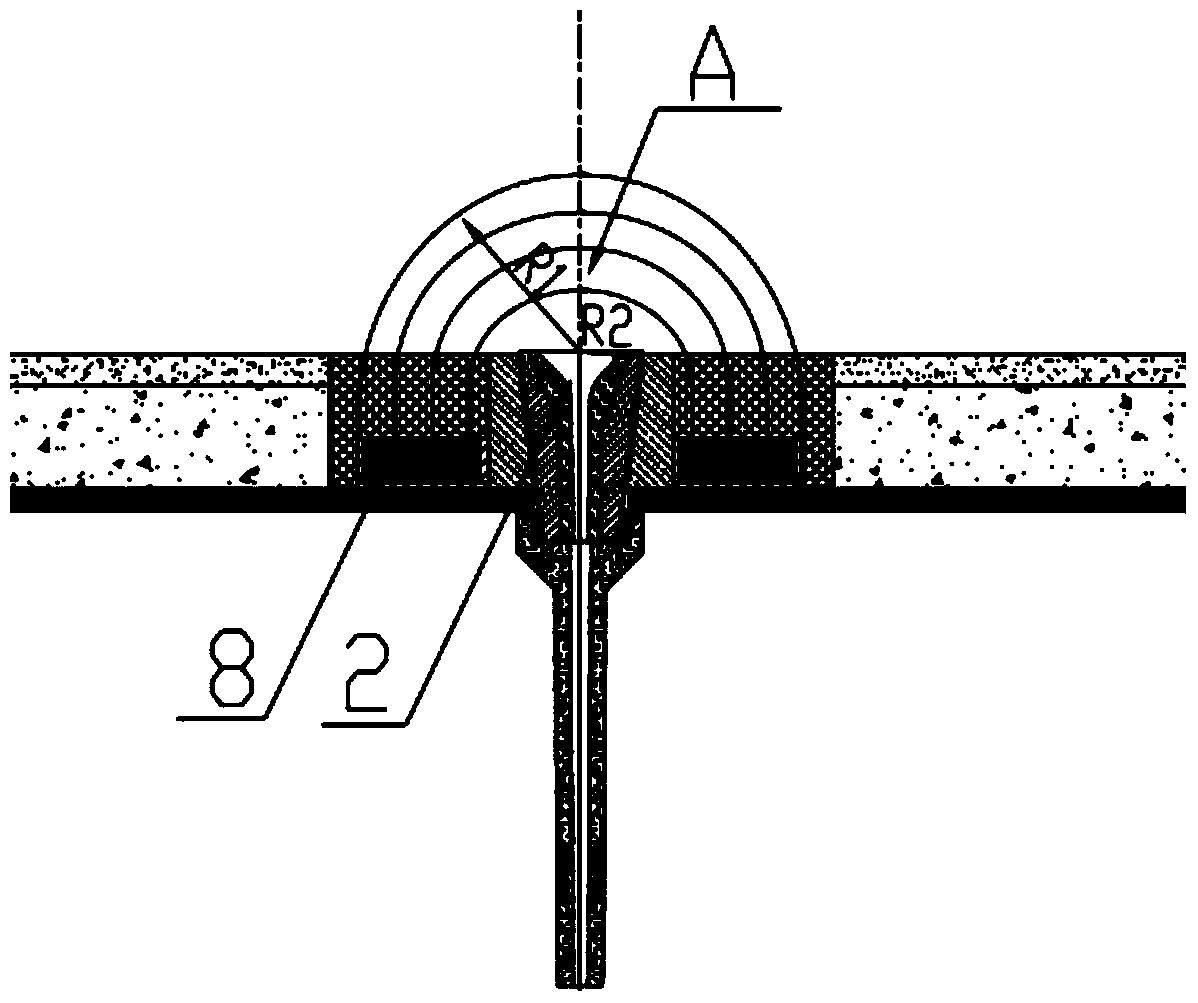

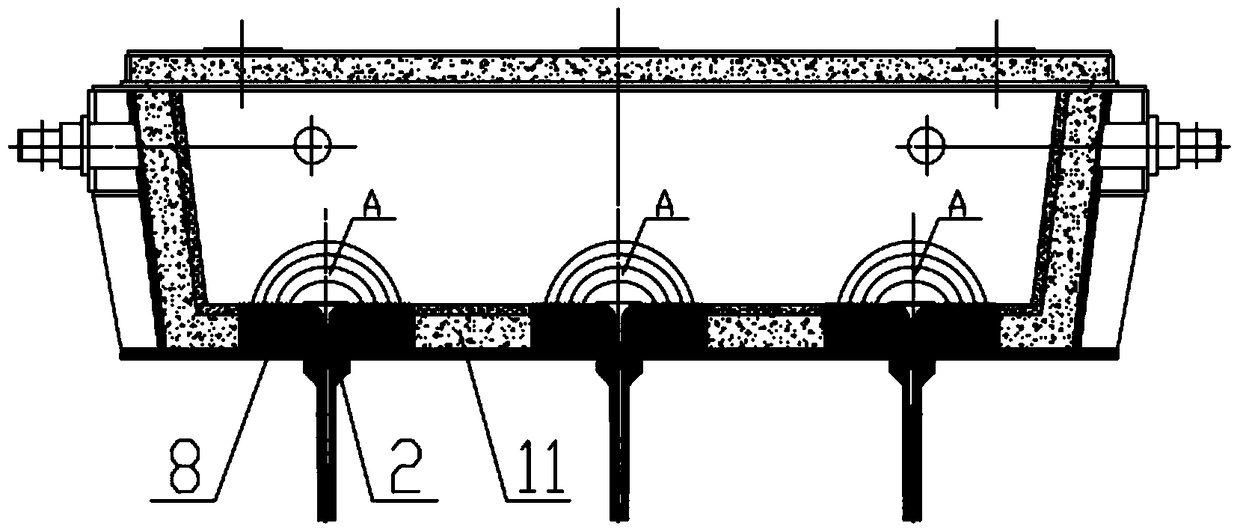

[0031] 1. The installation structure is as follows figure 1 , 2 , 3, 4 shown;

[0032] 2. Intermediate tank capacity 20t;

[0033] 3. Number of streams: 3 streams;

[0034]4. Power of single-flow electromagnetic induction heating device: 200KW, 50HZ, multi-level adjustable.

[0035] After 30 hours of continuous production, the measured temperature fluctuation range of molten steel is -1.8°C to +1.7°C; the nozzle can work continuously for 30 hours without replacement; the cast slab obtained is of good quality and has no large inclusions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com