Intelligent continuous casting tundish induction heating control method with self-learning function

An induction heating and self-learning technology, applied in the direction of induction heating control, induction heating, manufacturing tools, etc., can solve the problems of large randomness, multiple temperature measuring heads, and increased cost, and achieve novel ideas, powerful logic functions, and realization The effect of constant temperature casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

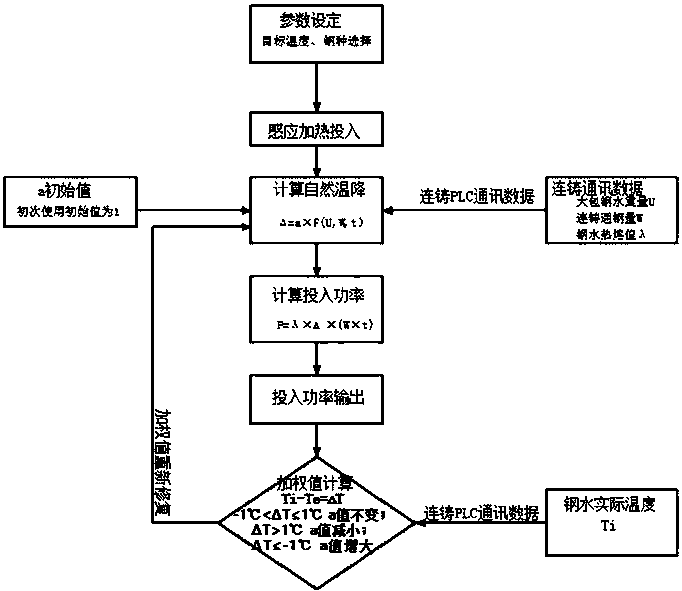

[0027] Embodiment 1: as figure 1 As shown, the model steps are parameter setting, induction heating input, calculation of natural temperature drop, input power calculation, input power output, weighted value calculation, initial value of a, continuous casting communication data, and actual temperature Ti of molten steel.

[0028] Working process of the present invention is as follows:

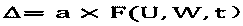

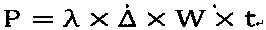

[0029] Parameter setting can set the target casting temperature and steel type selection. The target temperature is the optimal temperature of molten steel required for continuous casting of steel. Steel type selection can store multiple induction heating models of the same steel type to make the weighting value more accurate. The closer to the best state; calculate the natural temperature drop of molten steel in the tundish according to the weight of ladle molten steel and the amount of continuous casting steel; The melting value first calculates the natural temperature drop of the initial st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com