Digitalized welding machine with parameter self-learning function

A self-learning, functional technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve the effect of reduced development cycle and development cost, reduced number of tests, and good weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the implementation method and scope of protection of the present invention are not limited thereto.

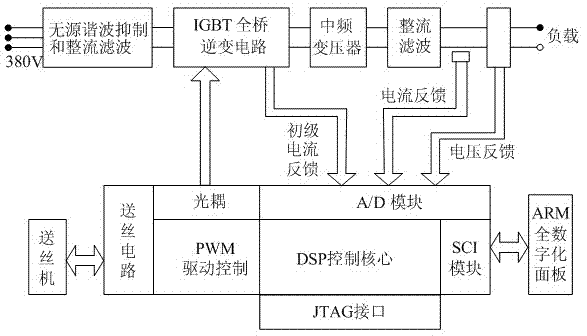

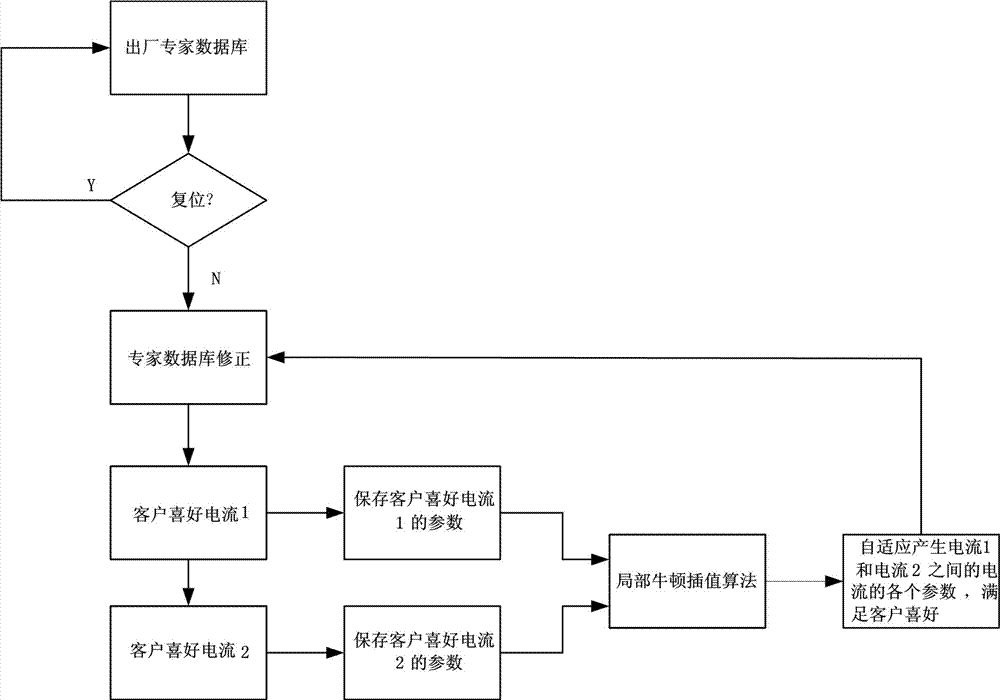

[0017] Digital welding machine with parameter self-learning function, including passive harmonic suppression and rectification and filtering circuit, IGBT full-bridge inverter circuit, intermediate frequency transformer, rectification and filtering circuit, wire feeding circuit, optical coupler, PWM drive control module, AD module, DSP control core module, SCI module, JTAG interface and ARM all-digital panel; The input end of described passive harmonic suppression and rectification circuit is connected to 380V AC power supply, and the output end of described passive harmonic suppression and rectification circuit is connected to The power input end of the IGBT full-bridge inverter circuit, the power output end of the IGBT full-bridge inverter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com