Method for magnetron sputtering coppering film on SiC micro-particle surface

A magnetron sputtering plating and micro-particle technology, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of poor film uniformity, weak adhesion, poor compactness, etc., and achieve adhesion Strong, dense and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

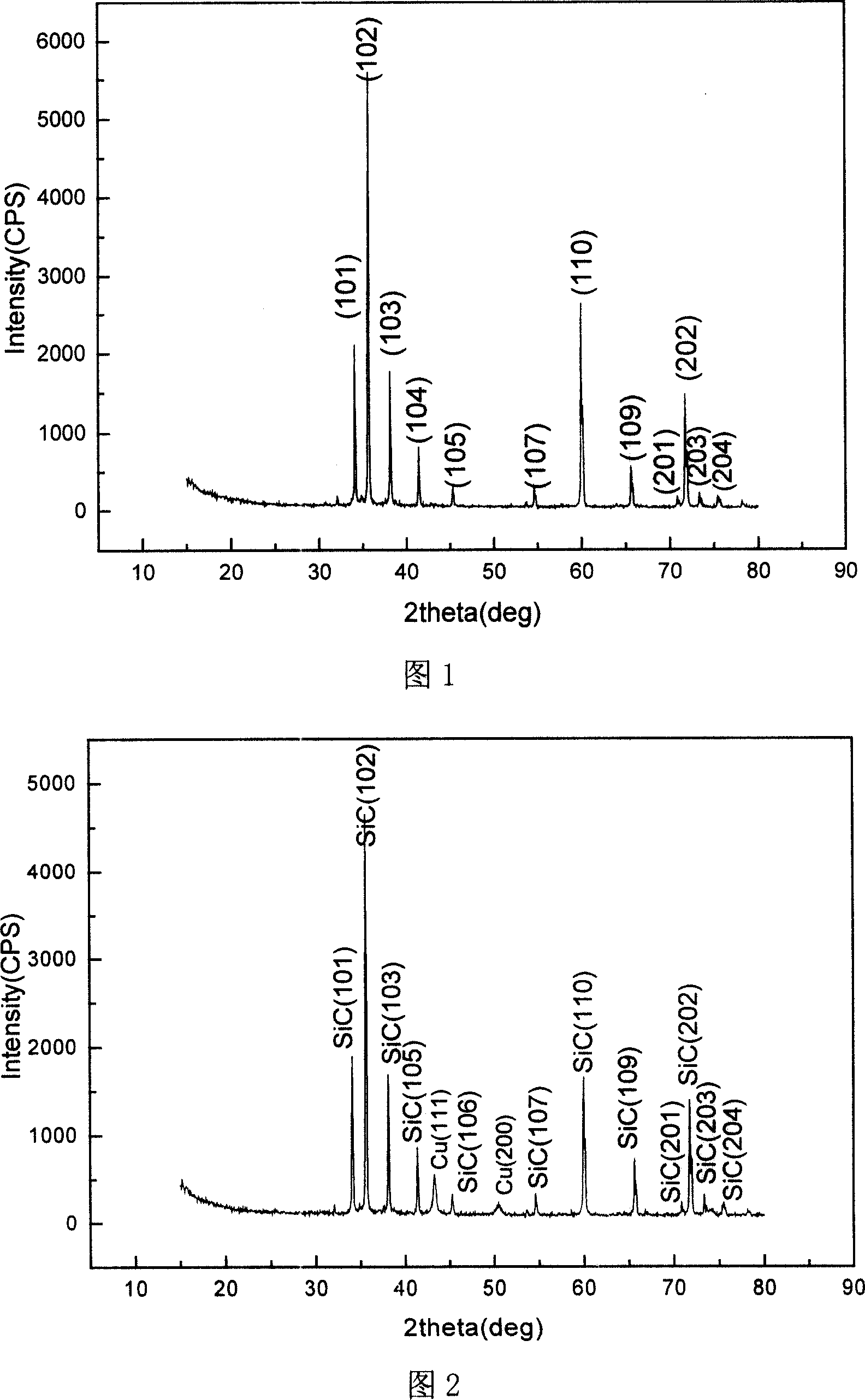

[0027] Embodiment 1: a kind of method (seeing Fig. 1 and 2) of magnetron sputtering copper plating film on SiC microparticle surface, it is characterized in that it comprises the following steps:

[0028] (1) Prepare microparticle magnetron sputtering coating equipment;

[0029] (2) Open the vacuum chamber and install the sample dish loaded with 4g SiC particles on the sample stage;

[0030] (3) Close the vacuum chamber, turn on the mechanical pump to evacuate to 3.30Pa;

[0031] (4) Turn on the molecular pump to evacuate to 3.0×10 -3 Pa;

[0032] (5) Open the flowmeter and fill the vacuum chamber with argon to 0.7Pa;

[0033] (6) Turn on the ultrasonic wave and the sample holder swing device, the ultrasonic vibration power is 12w, and the swing frequency of the sample stage is 10 times / min;

[0034] (7) Turn on the sample heater, and the heating temperature is 100°C;

[0035] (8) Turn on the target power supply, adjust the power to 280w, and start sputtering coating;

...

Embodiment 2

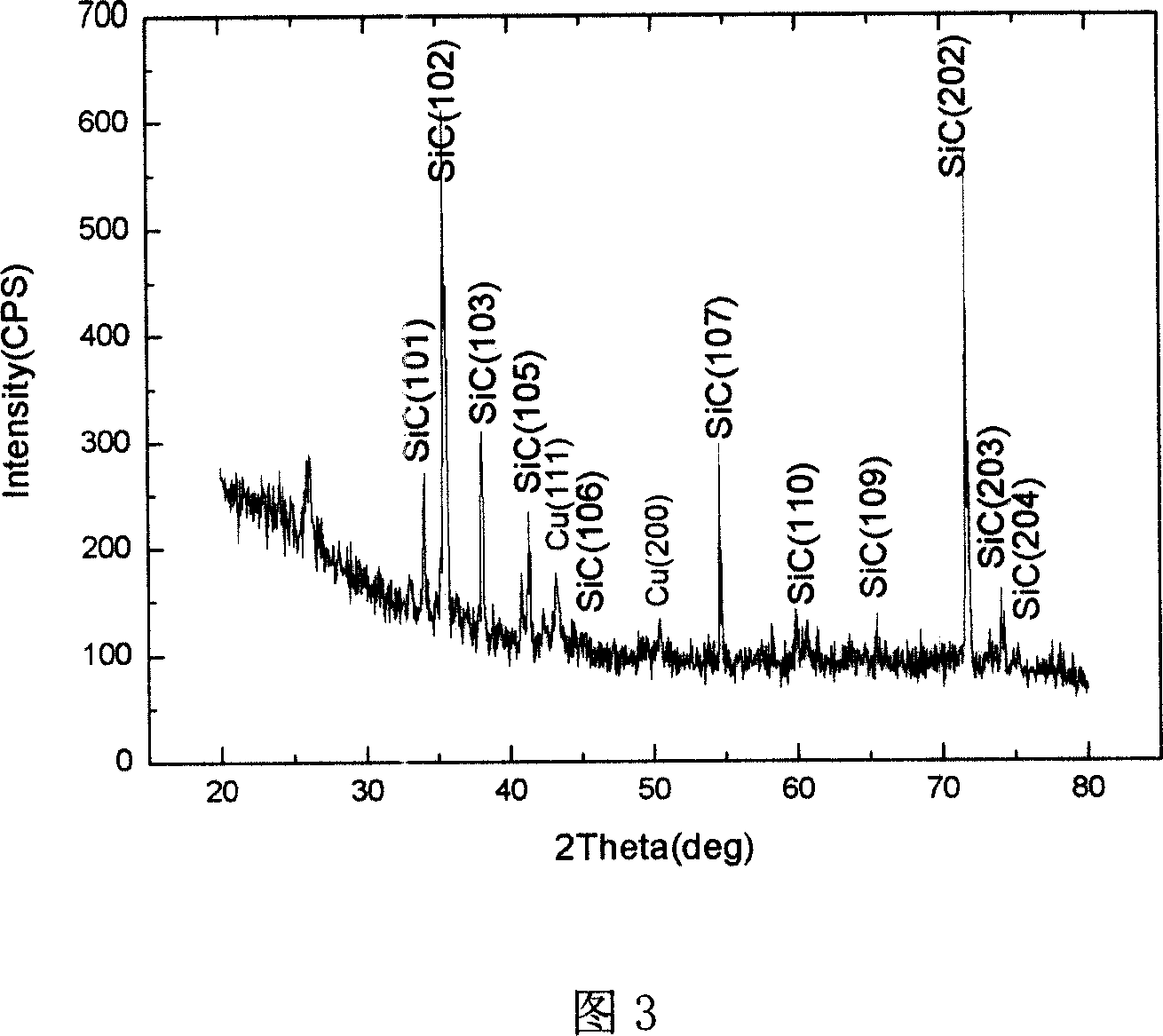

[0039] Embodiment 2: a kind of method (seeing Fig. 1 and 3) of magnetron sputtering copper plating film on SiC microparticle surface, it is characterized in that it comprises the following steps:

[0040] (1) Prepare microparticle magnetron sputtering coating equipment;

[0041] (2) Open the vacuum chamber and install the sample dish loaded with 4g SiC particles on the sample stage;

[0042] (3) Close the vacuum chamber, turn on the mechanical pump to evacuate to 2.5Pa;

[0043] (4) Turn on the molecular pump to evacuate to 2.0×10 -3 Pa;

[0044] (5) Open the flowmeter and fill the vacuum chamber with argon to 0.4Pa;

[0045] (6) Turn on the ultrasonic wave and the sample holder swing device, the ultrasonic vibration power is 20w, and the swing frequency of the sample stage is 8 times / min;

[0046] (7) Turn on the sample heater, and the heating temperature is 200°C;

[0047] (8) Turn on the magnetron sputtering target power supply, adjust the power to 350w, and start sput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com