Roll-to-roll device used for continuous growing of two-dimension materials on strip/wire material and control method of roll-to-roll device

A two-dimensional material, roll-to-roll technology, applied in metal material coating process, gaseous chemical plating, plating of superimposed layers, etc., can solve problems such as no research given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

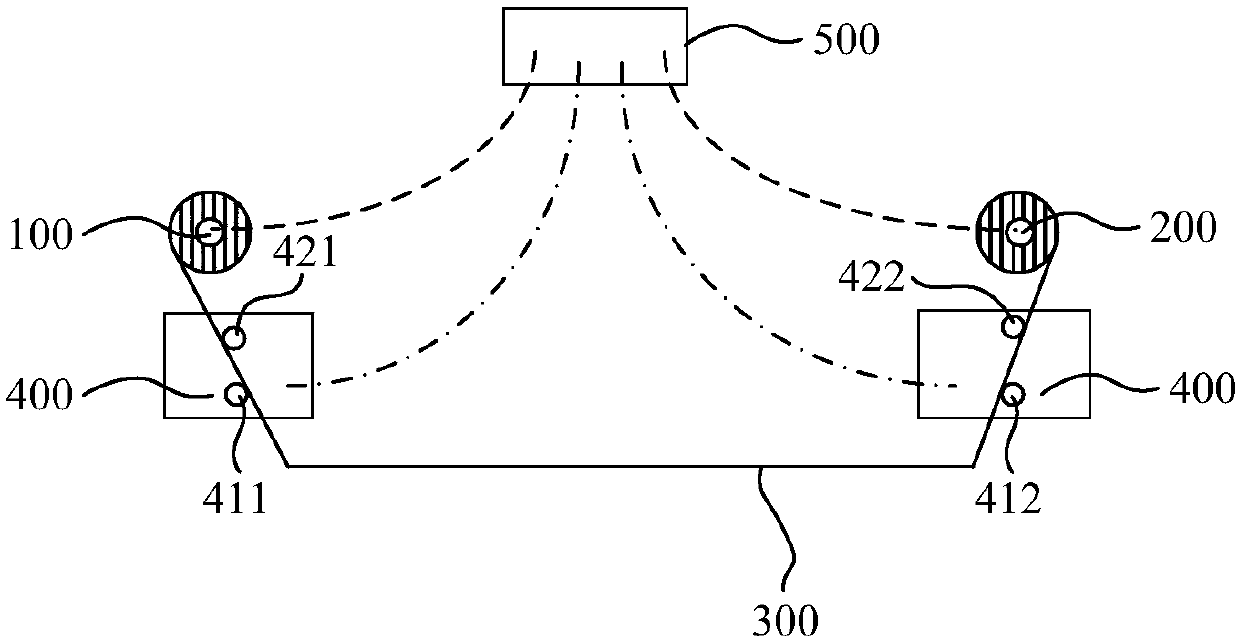

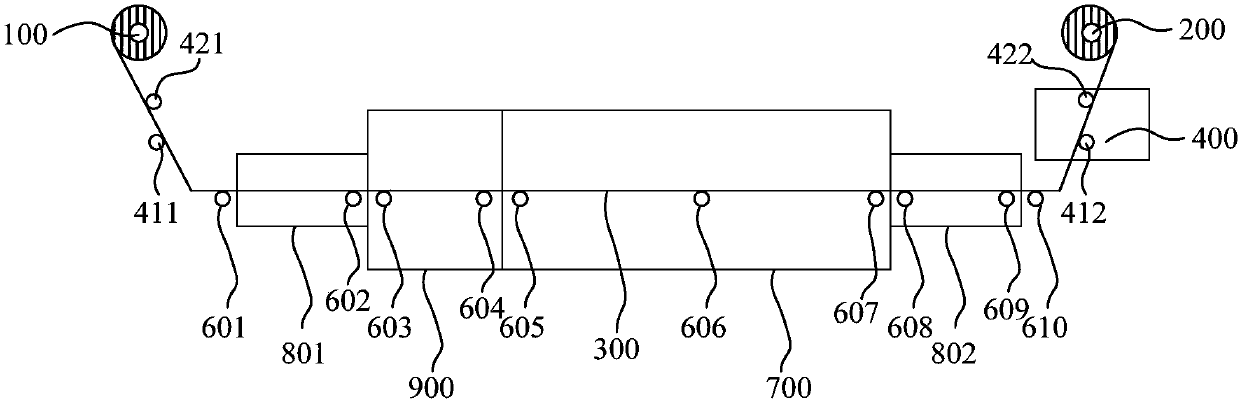

[0123] A device for continuous growth of two-dimensional materials on tape / wire, such as figure 2 As shown, a roll-to-roll device is included, and the rotation of the first winding roll 100 and the second winding roll 200 enables the tape / wire 300 to be transferred between the two winding rolls;

[0124] Starting from the first winding roll 100, a first cooling chamber 801, a magnetron sputtering unit 900, a two-dimensional material growth chamber 700, a second cooling chamber 802, and a second winding roll 200 are arranged in sequence; and the belt / The wire 300 sequentially passes through the first cooling chamber 801, the magnetron sputtering unit 900, the two-dimensional material growth chamber 700, the second cooling chamber 802, and finally winds up on the second winding roller 200;

[0125] Between the first winding roll 100 and the first cooling chamber 801, a first speed test roll 411 and a first tension test roll 421 are arranged, and the first speed test roll 411 a...

Embodiment 2

[0148] The difference from Example 1 is that the copper strip is 20 μm thick, 0.1 m wide, and 1000 m long. Step (2) is to start the two-dimensional material growth chamber 700, and wait until the internal vacuum degree of the two-dimensional material growth chamber 700 reaches 1×10 -3 Torr, feed CH at a flow rate of 100 sccm 4 Carbon source, 100sccm flow rate into H 2 , be warming up to 1000 ℃ of temperature; Step (3) is that 15N and moving speed are 30cm / min for inputting setting tension to control unit 500, start the first winding roller 100 and the second winding roller 200, make copper strip from the first A winding roll 100 is transferred to a second winding roll 200, while chemical vapor deposition of graphene on the copper strip is performed.

[0149] Performance Testing:

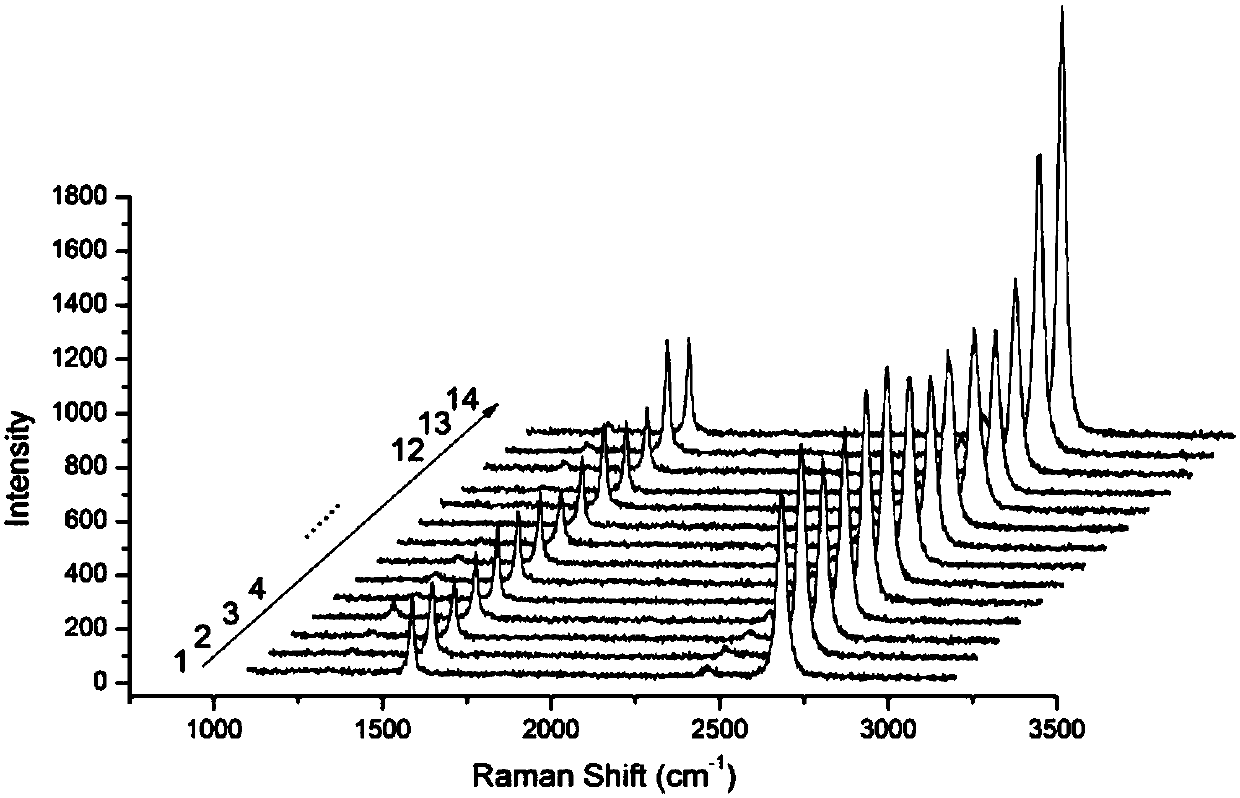

[0150] Select the performance testing method identical with embodiment 1, test result shows, every 70m take points, get 14 points altogether, carry out Raman spectrum scanning, Raman spectrum figur...

Embodiment 3

[0152] Step (1)~step (3) are identical with embodiment 1, carry out following steps after step (3):

[0153] (4) After the copper strip is transferred from the first winding roll 100 to the second winding roll 200, stop the operation of the equipment to obtain a copper strip deposited with one layer of graphene;

[0154] (5) Start the magnetron sputtering unit 900, wait for the vacuum inside the magnetron sputtering unit 900 to reach 1×10-6Torr, feed argon gas at a speed of 500 sccm, and heat up to a temperature of 200° C., the magnetron sputtering unit 900 The sputtering target is a copper target;

[0155] (6) input setting tension to control unit 500 as 8N and moving speed as 15cm / min, start the first winding roller 100 and the second winding roller 200, make the copper strip transfer from the second winding roller 200 to the first winding roller Winding roller 100, carry out magnetron sputtering copper thin film on the graphene surface on the copper strip of growth graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com