A connection method for rapid in-situ formation of homogeneous phase alumina ceramics in an atmospheric environment

A technology of alumina ceramics and connection methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effects of reducing production costs, improving connection efficiency, and consuming less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

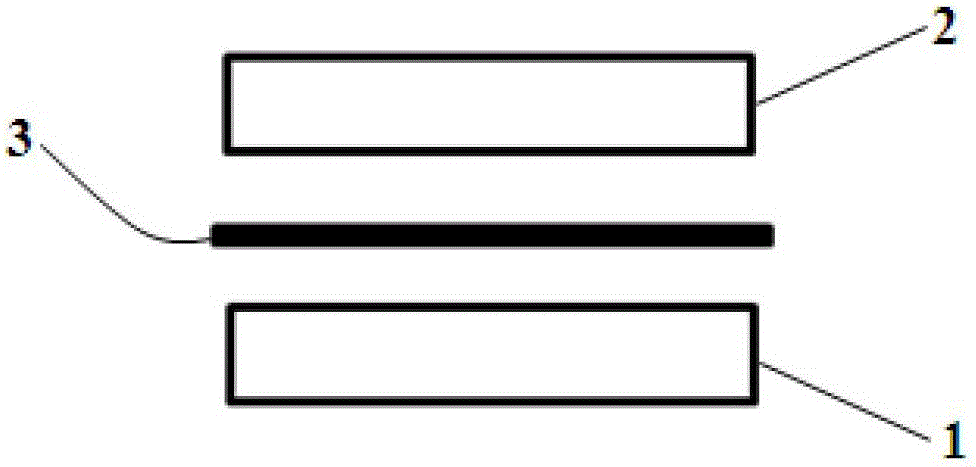

[0041] Embodiment one: see attached figure 1 , 2 , 3, a connection method for rapid in-situ generation of homogeneous or nearly homogeneous alumina ceramics in an atmospheric environment, the connection method includes the following steps:

[0042] 1. Surface treatment of the materials to be connected: mechanically polish the butt joint surfaces of base metal 1 and base material 2 to ensure surface cleanliness and roughness, and use ultrasonic cleaning for the middle layer 3 for 1 to 5 minutes;

[0043] II. The base material 1, the base material 2 2 and the intermediate layer 3 are assembled in a "sandwich" laminated structure to form a connected sample structure;

[0044] III. Applying a pre-pressure relative to the connection interface on the base material 2, the pre-pressure is 0.5-3 MPa, and the pre-pressure is uniformly applied to avoid local concentration;

[0045] IV. Use the high-frequency electromagnetic induction heating coil 6 to locally and rapidly heat the conne...

Embodiment 2

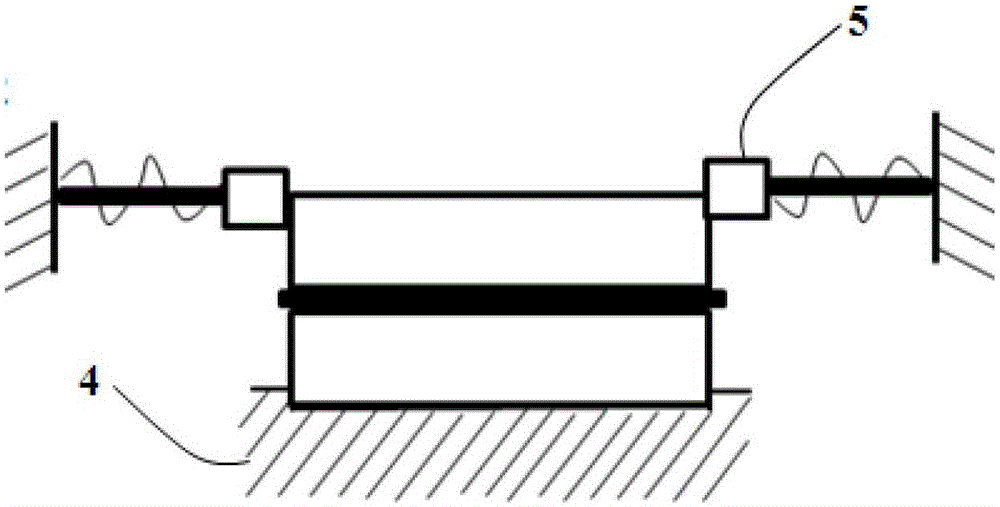

[0059] Embodiment two: see attached figure 2 As shown, a connection method for rapid in-situ generation of homogeneous or near-homogeneous alumina ceramics in an atmospheric environment, the connection method includes the following steps:

[0060] 1. Surface treatment of the materials to be connected: Grinding the butt joint surfaces of base material 1 and base material 2 to ensure a certain surface cleanliness and roughness, and the middle layer 3 is ultrasonically cleaned for 1 to 5 minutes;

[0061] II. The base material 1, the base material 2 2 and the intermediate layer 3 are assembled in a "sandwich" laminated structure to form a connected sample structure;

[0062] III. Applying a pre-pressure relative to the connection interface on the base material 2, the pre-pressure is 0.5-3 MPa, and the pre-pressure is uniformly applied to avoid local concentration;

[0063] IV. Use the high-frequency electromagnetic induction heating coil 6 to locally and rapidly heat the connec...

Embodiment 3

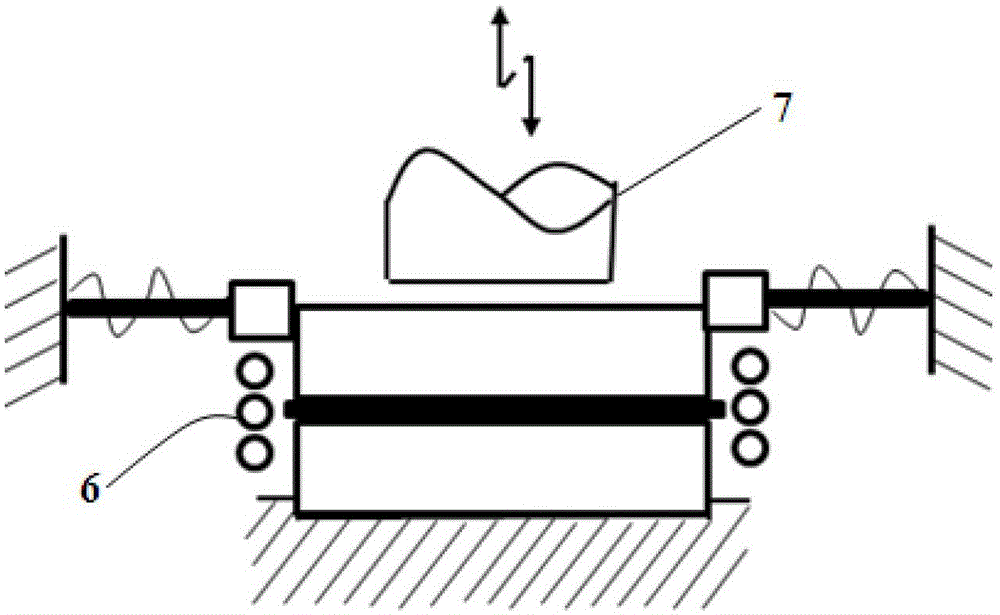

[0077] Embodiment three: see attached image 3 As shown, a connection method for rapid in-situ generation of homogeneous or near-homogeneous alumina ceramics in an atmospheric environment, the connection method includes the following steps:

[0078] 1. Necessary surface treatment for the materials to be connected: polish base material 1 and base material 2 to ensure surface cleanliness and roughness, and use ultrasonic cleaning for the middle layer 3 for 1 to 5 minutes;

[0079] II. The base material 1, the base material 2 2 and the intermediate layer 3 are assembled in a "sandwich" laminated structure to form a connected sample structure;

[0080] III. Applying a pre-pressure relative to the connection interface on the base material 2, the pre-pressure is 0.5-3 MPa, and the pre-pressure is uniformly applied to avoid local concentration;

[0081] IV. Use the high-frequency electromagnetic induction heating coil 6 to locally and rapidly heat the connecting part of the base mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com