Full-automatic disc-type rubber-insulated wire lamp string production device and production method thereof

A production device, a disc-type technology, applied in the direction of tin feeding device, lighting device, lighting device parts, etc., can solve the problems of low efficiency, achieve the effect of cost reduction, small heating range and powerful function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

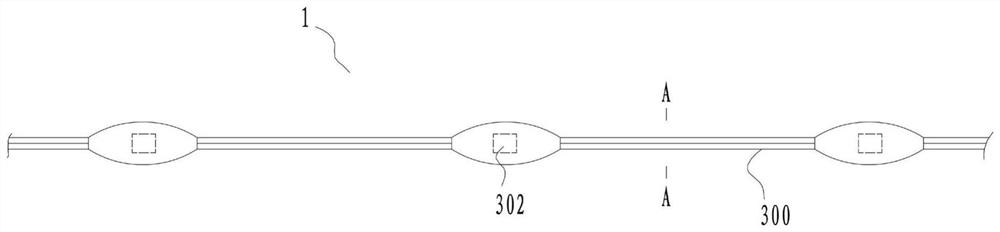

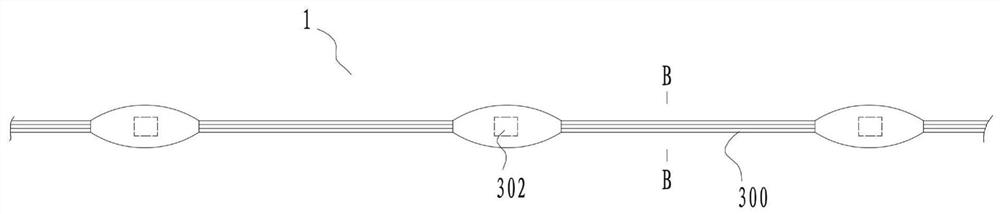

[0057] Such as Figure 1-20 As shown, a fully automatic disc-type leather wire light string production device includes a disc clamping and conveying mechanism 1, a wire mechanism 2 arranged around the disc clamping and conveying mechanism 1, a cutting mechanism 11, and a peeling mechanism 5. The chip welding module, the glue injection mechanism 9 and the workbench 12 for supporting and installing the above-mentioned mechanism, wherein,

[0058]The disc clamping and conveying mechanism is used to clamp the leather thread 300 and intermittently transport the leather thread 300 in a circular route;

[0059] The wire mechanism 2 is used to guide the leather wire 300 into the disc clamping and conveying mechanism 1;

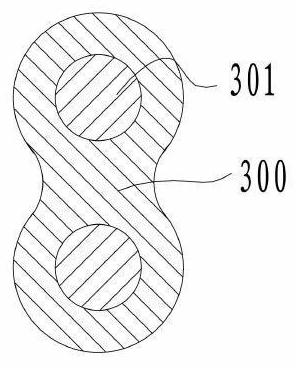

[0060] The cutting mechanism 11 is used to cut the leather wire 300, only the skin wire 300 is cut during cutting, and the copper wire 301 is not cut;

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com