Automatic production line for steel springboard

An automatic production line and springboard technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, complicated production steps, complex production process of steel springboard, etc., and achieve strong adaptability and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-8 The present invention is described in further detail.

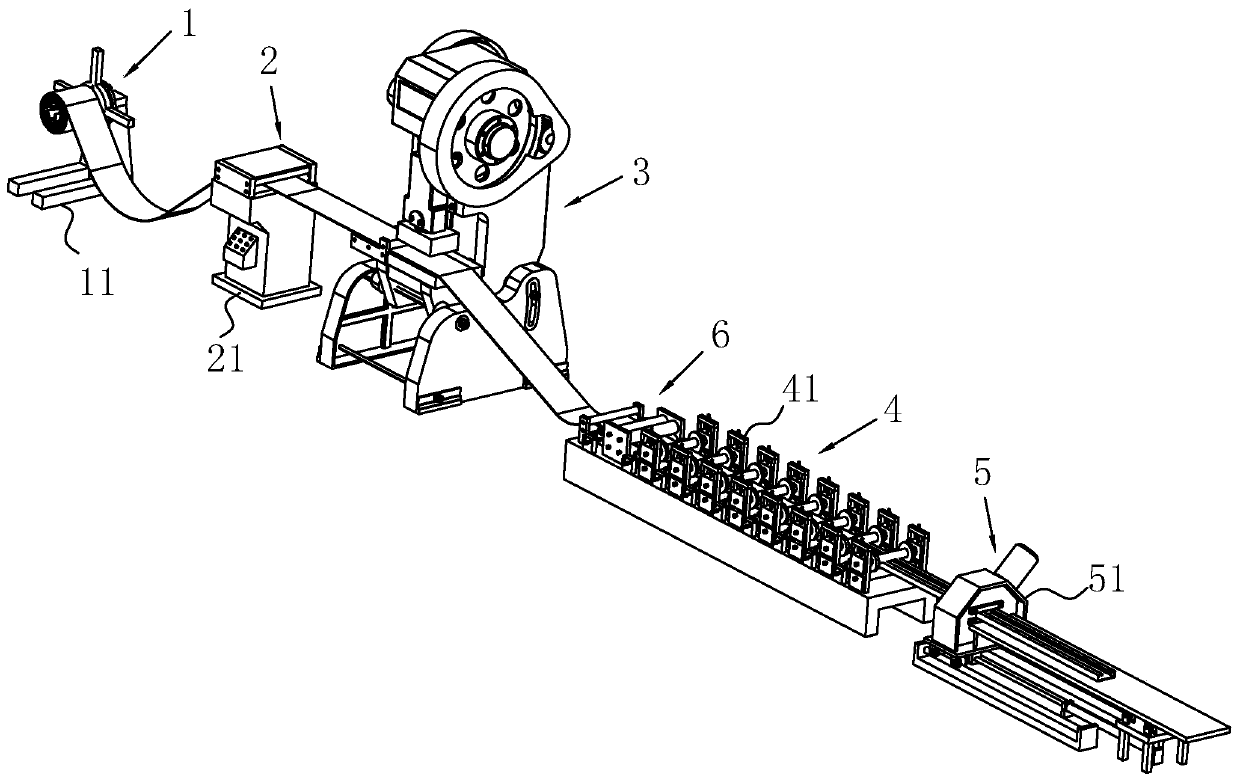

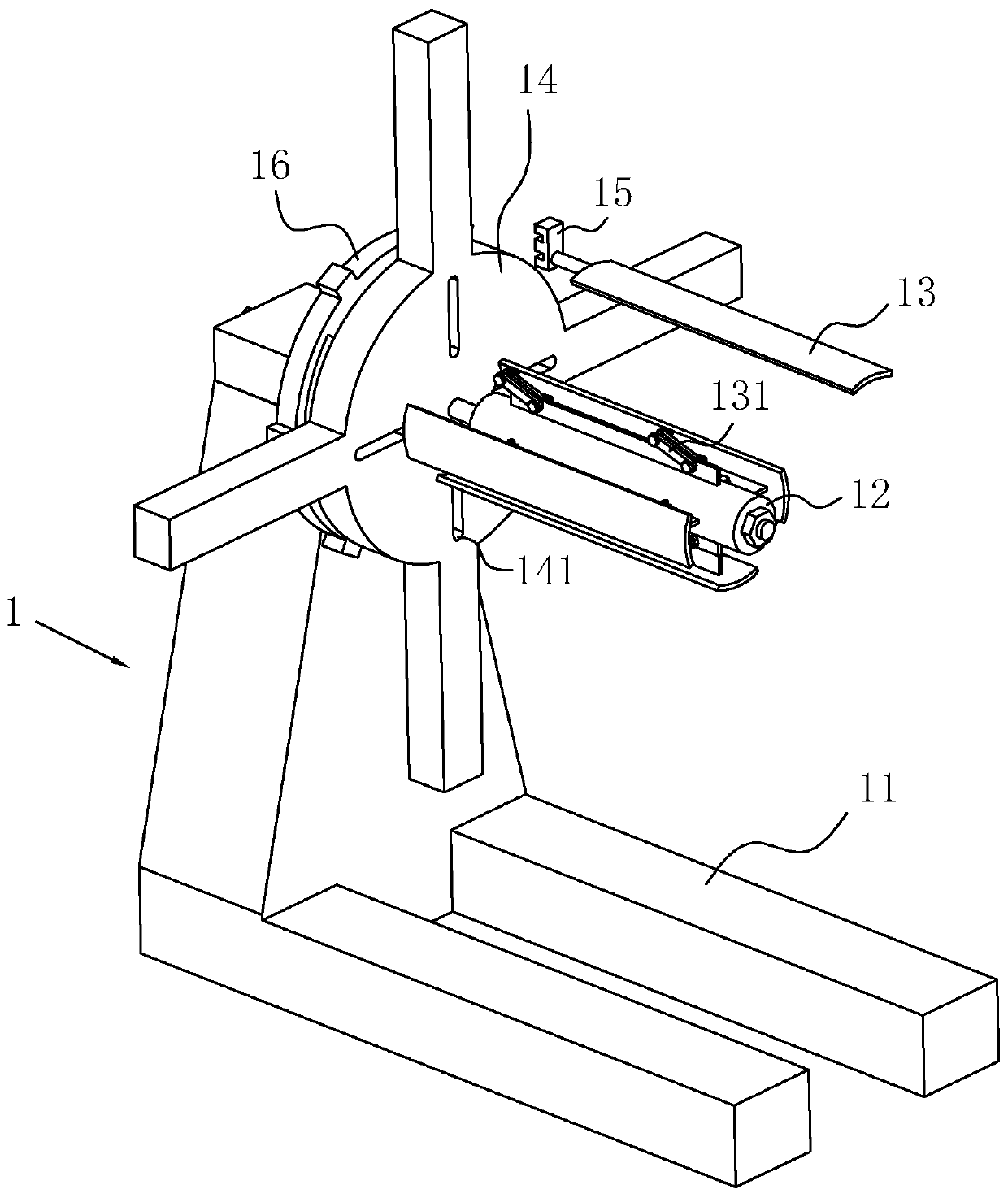

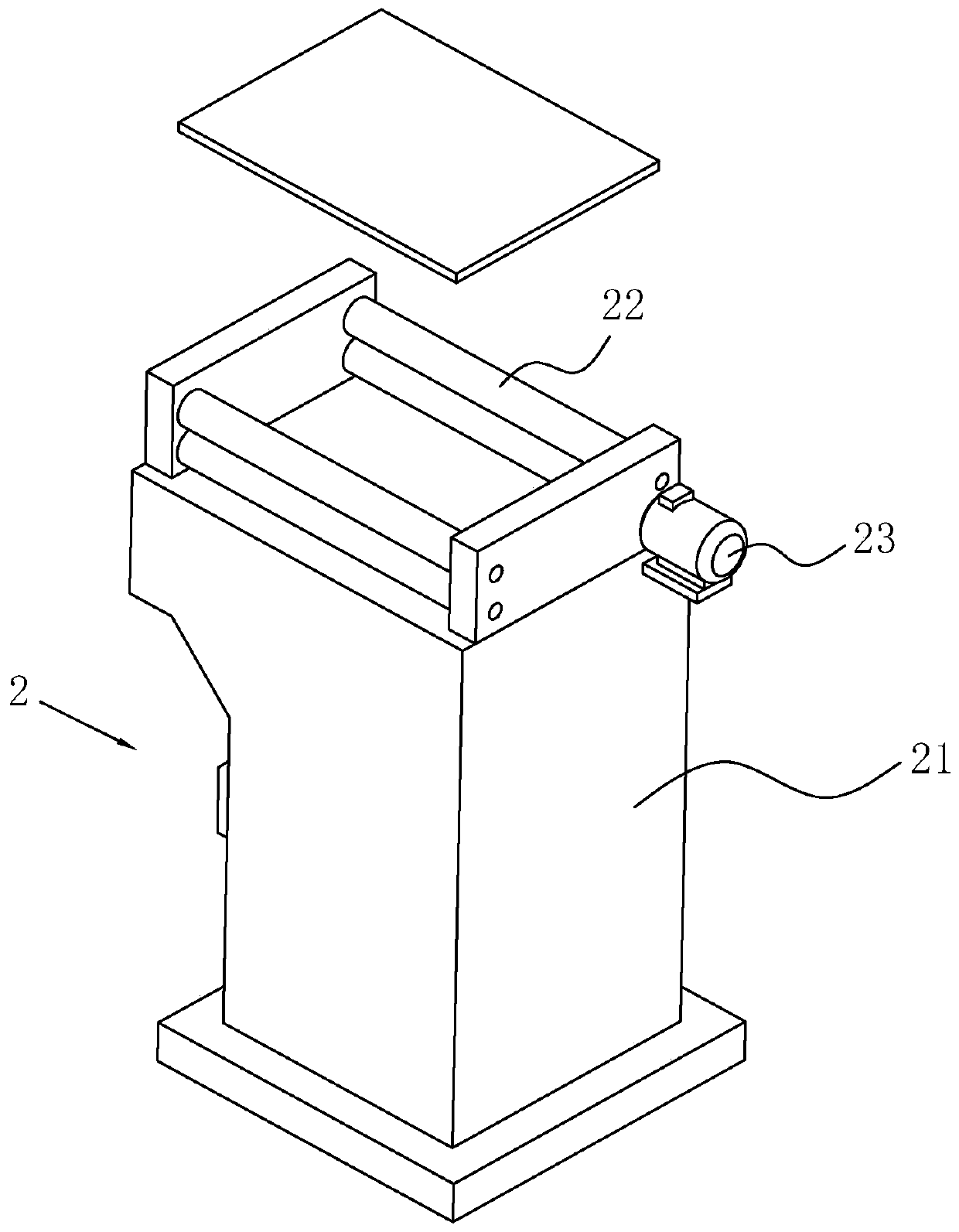

[0036] refer to figure 1 , is a steel springboard production line disclosed in the present invention, comprising a sheet metal feeding machine 1, a leveling machine 2 for leveling the sheet metal is provided downstream of the sheet metal feeding machine 1, and the leveling machine 2 can carry out the leveling of the sheet metal Leveling, stretching the rolled sheet metal to facilitate subsequent stamping. The leveling machine 2 is also the driver of the sheet metal, which drives the sheet metal to move from the sheet metal feeder 1 to the punching machine 3. The punching machine 3 is set Downstream of the leveling machine 2, the sheet metal is punched, and a forming machine 4 is arranged downstream of the punching machine 3, and the forming machine 4 is used to bend the sheet metal to bend the sheet metal into a U shape, and A relative flanging is formed at both ends of the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com