Full-automatic glutinous rice dumpling making device and full-automatic glutinous rice dumpling making method

A fully automatic, zongzi technology, applied in food science and other directions, can solve the problems of inability to realize the process of making zongzi, different technical levels, increased labor costs, etc., and achieve the effect of saving labor costs, compact overall structure, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with accompanying drawing.

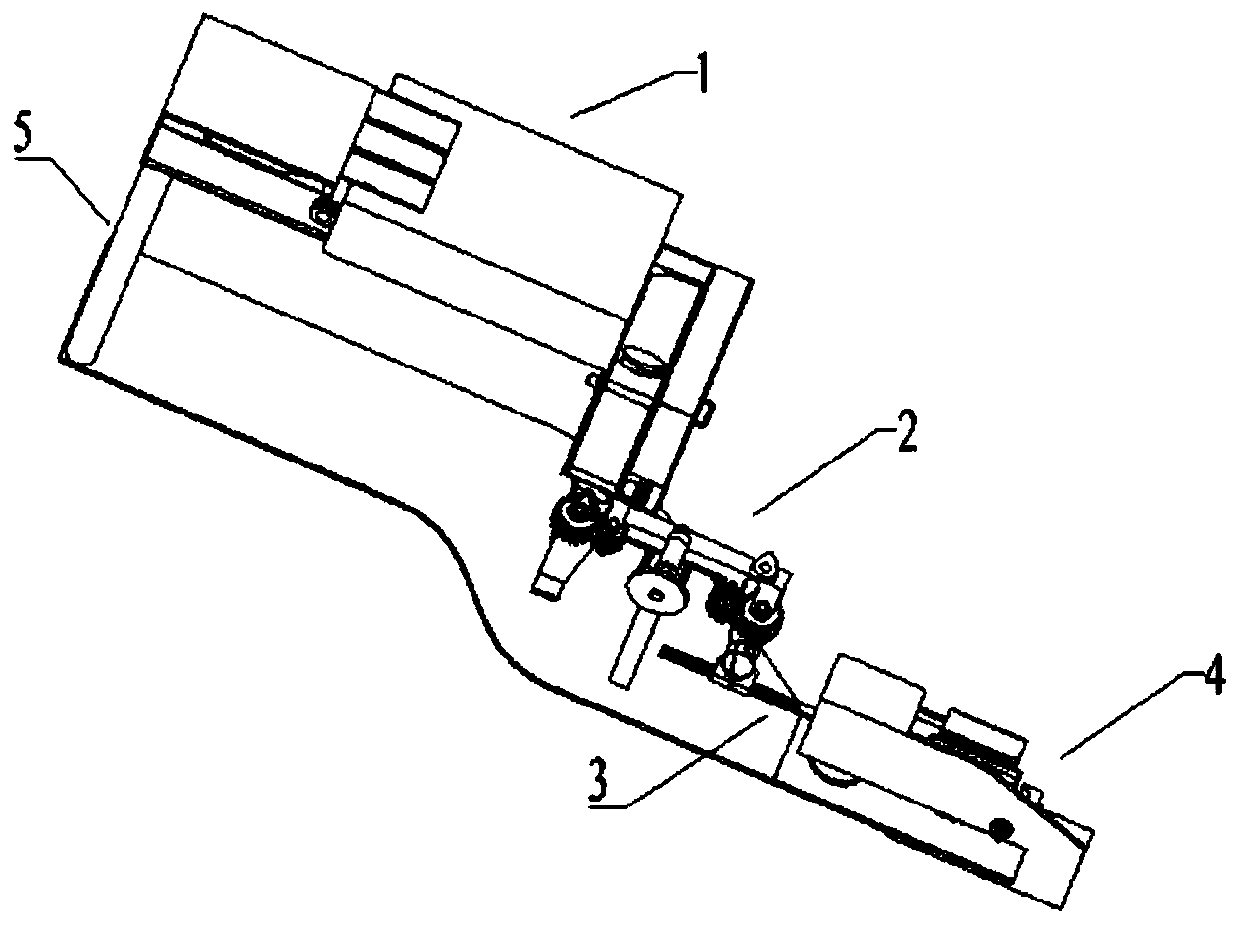

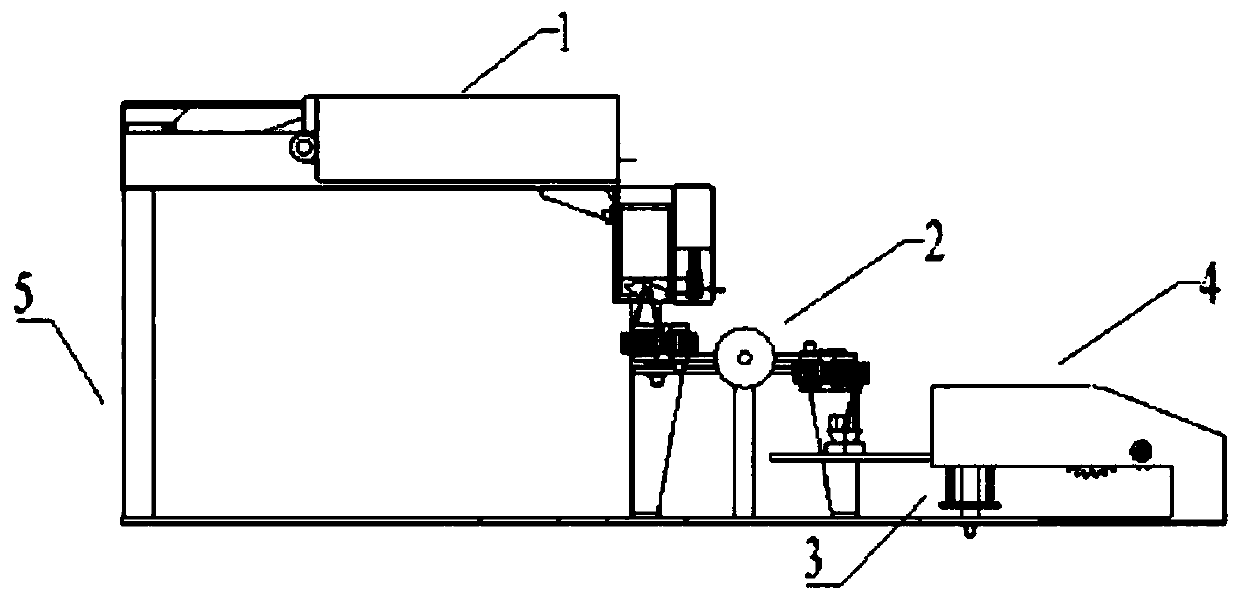

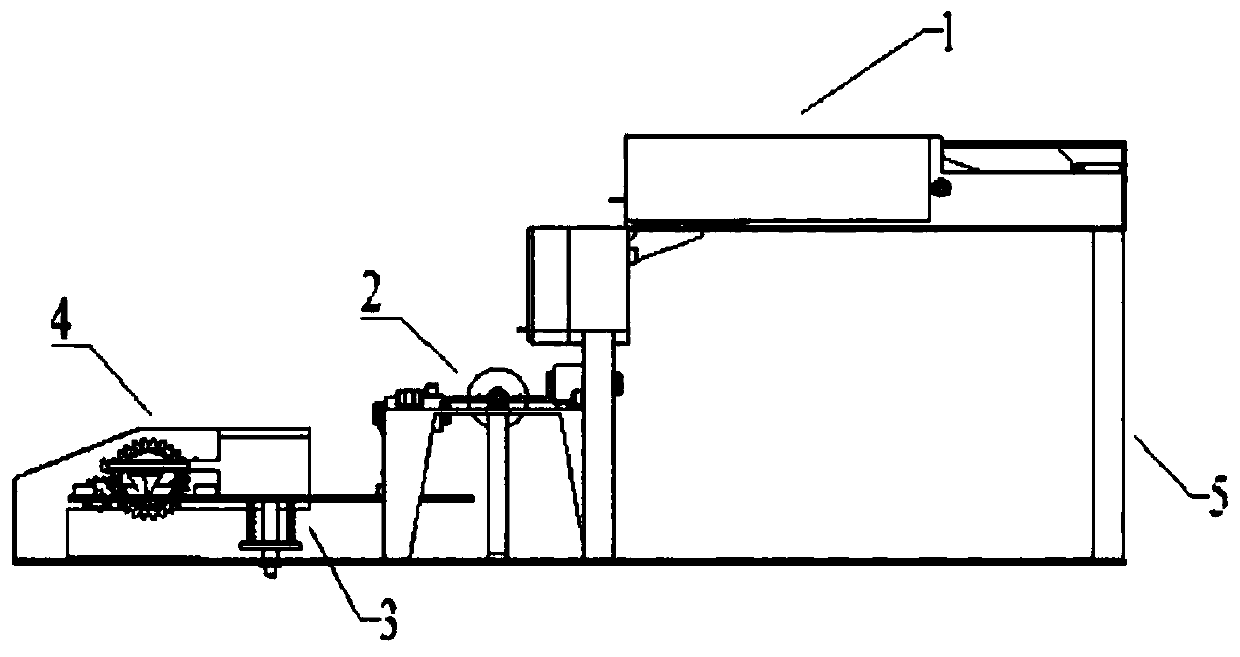

[0068] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a fully automatic zongzi wrapping device, comprising a zongzi leaf separator 1, a zongzi leaf circulation supply device 2, a zongzi conveyor 3, an automatic binding device 4 and a frame 5, the zongzi leaf separator 1 , Zongzi leaf circulating supply device 2, Zongzi conveyer 3 and automatic binding device 4 are fixedly arranged on the frame 5, and described Zongzi leaf circulating supply device 2 is arranged on the discharge opening of Zongzi leaf separator 1, and described Zongzi conveyer 3 one side corresponds to the zongzi leaf circulation supply device 2 and the other side corresponds to the automatic binding device 4.

[0069] 1. Zongye separator

[0070] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9Shown, the rice dumpling leaf separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com