Full-automatic dryland lotus bean vermicelli production line

A fully automatic, production line technology, applied in applications, food preparation, food science, etc., can solve the problems of low automation level, unrealized continuous production, high labor intensity, etc., achieve high automation level, controllable moisture content, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

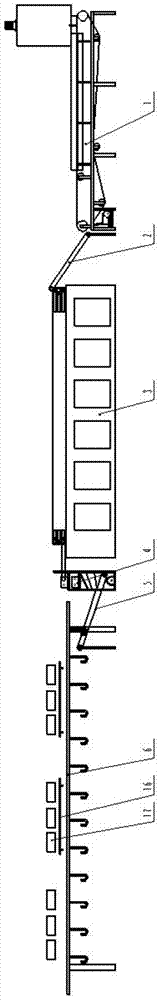

[0027] Such as figure 1 , figure 2 Shown, the present invention comprises vermicelli machine 1, and vermicelli machine 1 is provided with conveyer belt 2, freezer 3, powder cutting machine 4 successively, also is provided with hanger conveyor 5 and drier 6 behind powder cutting machine 4.

[0028] In the present embodiment, when vermicelli is produced, vermicelli machine 1 processes the powder slurry into a powder belt, which is lifted to the freezer 3 through the conveyor belt 2, and the powder belt is frozen and aged in the freezer 3 and then sent to the powder cutter 4, and the powder cutter 4 The powder belt is cut into vermicelli, and the hanger conveyor 5 lifts the vermicelli to the drying machine 6 for final drying to complete the whole production process.

Embodiment 2

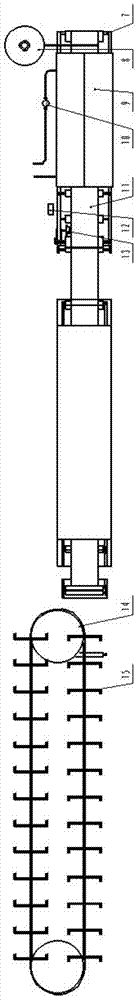

[0030] The difference from Embodiment 1 is that the dryer 6 includes a disc circulation frame 14 on which a hanger 15 is arranged, and a heating pipe 16 and a fan 17 are arranged above the hanger 15 .

[0031] In this embodiment, the vermicelli is hung on the hanger 15, the wind blown by the fan 17 to the vermicelli is heated by the heating pipe 16 and becomes hot air, and the vermicelli gradually passes through different hot air zones, and the moisture inside evaporates gradually, and is processed into final finished product.

Embodiment 3

[0033] The difference from Embodiment 2 is that the dryer 6 also includes a temperature measuring device and a humidity measuring device.

[0034] In this embodiment, the data measured by the temperature measuring device and the humidity measuring device are input into the electric control system, and compared with the set process data, if there is a difference, the electric system will adjust the temperature of the heating pipe or the speed of the fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com