Cold crucible induction smelting method using ultrahigh smelting temperature

A technology of induction smelting and melting temperature, which is applied in cold crucible induction smelting and raised to over 3000°C, which can solve the problems of increasing the electromagnetic field energy of the crucible, increasing equipment, increasing energy consumption and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

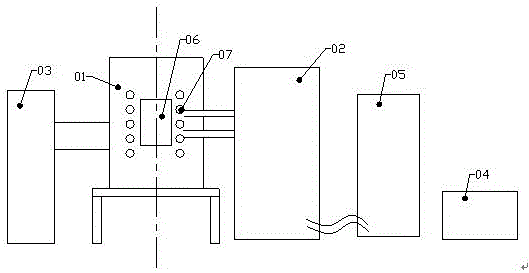

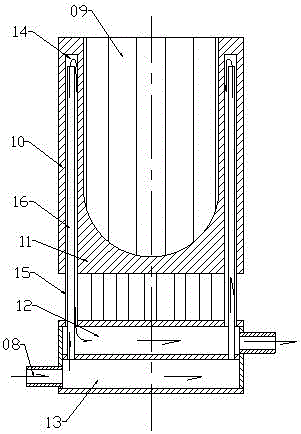

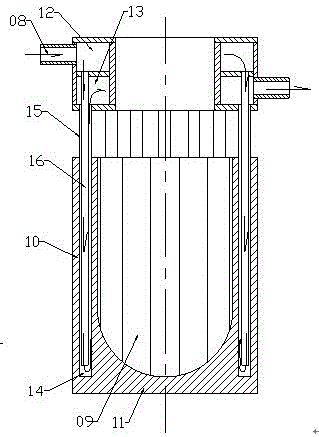

[0097] Cold crucible induction melting equipment is composed of vacuum melting chamber 01, induction power supply 02, vacuum unit 03, cooling system 04, control system 05 and other parts (see figure 1 ). The vacuum melting chamber is equipped with a water-cooled copper crucible 06 and an induction coil 07 surrounding the crucible. The inner diameter of crucible 06 is 120mm, divided into 24 petals, see the structure figure 2 , which is a crucible equipped with cooling water channels only on the crucible wall. In order to improve the melting temperature, a water-cooled red copper crucible cover 17 (see Figure 5 ). The diameter of the crucible cover is 180 mm, and there are four slits with a width of 2 mm. The distance between the crucible cover and the top of the crucible is 20 mm.

[0098] The rated power of the induction power supply 02 is 200kw, the working voltage is 500V, the output frequency is 25kHz, and 5kg of metal vanadium is loaded into the crucible 06. Start t...

Embodiment 2

[0101] The power and frequency of the equipment used, the power supply, and the structure of the crucible cover are all the same as in Example 1. The water-cooled crucible 06 has an inner diameter of 80 mm and is divided into 22 pieces. The cooling water path in the crucible adopts a structure in which radial branch cooling water paths 26 are arranged at the bottom of the crucible in addition to the cooling water path of the crucible wall (see Figure 8 ).

[0102] The crucible contained 2 kg of niobium metal. Start the induction power supply, and when the current intensity reaches 260A, the charge begins to melt. At this time, turn the crucible lid to the top of the crucible, and after 4 minutes of heat preservation, the metal niobium is completely melted (see Figure 14). The results of melting niobium metal showed that the melting temperature reached 2600°C. The crucible remained intact after smelting.

Embodiment 3

[0104] The equipment used, the power and frequency of the power supply, and the structure of the crucible lid are also the same as in Example 1. The inner diameter of the water-cooled crucible is 80mm, divided into 20 pieces. The cooling water path of the crucible flap is also provided with a radial branch cooling water path 26 at the bottom of the crucible (see Figure 8 ). In addition, a circular hole with a diameter of 24 mm is made in the center of the bottom of the crucible, and a red copper crucible plug 27 of a simple structure with a diameter of 24 mm is installed. The structure is shown in Figure 11 . The crucible plug is divided into 12 petals, the height of the petal area 28 is 15 mm, and the cooling water channel area 29 is located below the petal area.

[0105] Crucible 06 was filled with 1.5 kg of molybdenum metal. Start the induction power supply, and when the current intensity reaches 300A, the charge begins to melt. At this time, turn the crucible cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com