A 3D printer capable of printing continuous fibers, a printer nozzle and a printer feed structure

A 3D printer, continuous technology, applied in the fields of fiber chemical characteristics, textile and papermaking, additive processing, etc., can solve the problems of limited 3D printing materials, reduce friction, prevent nozzle blockage, and reduce heating range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

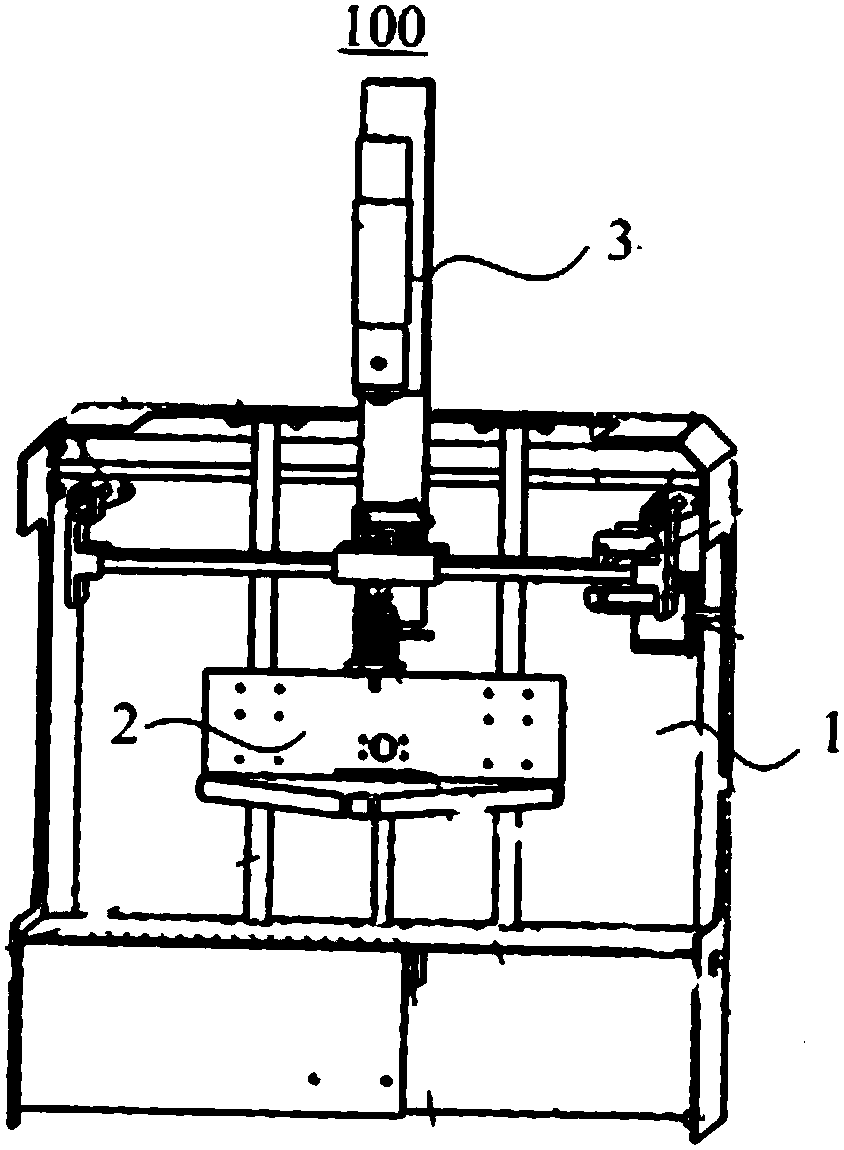

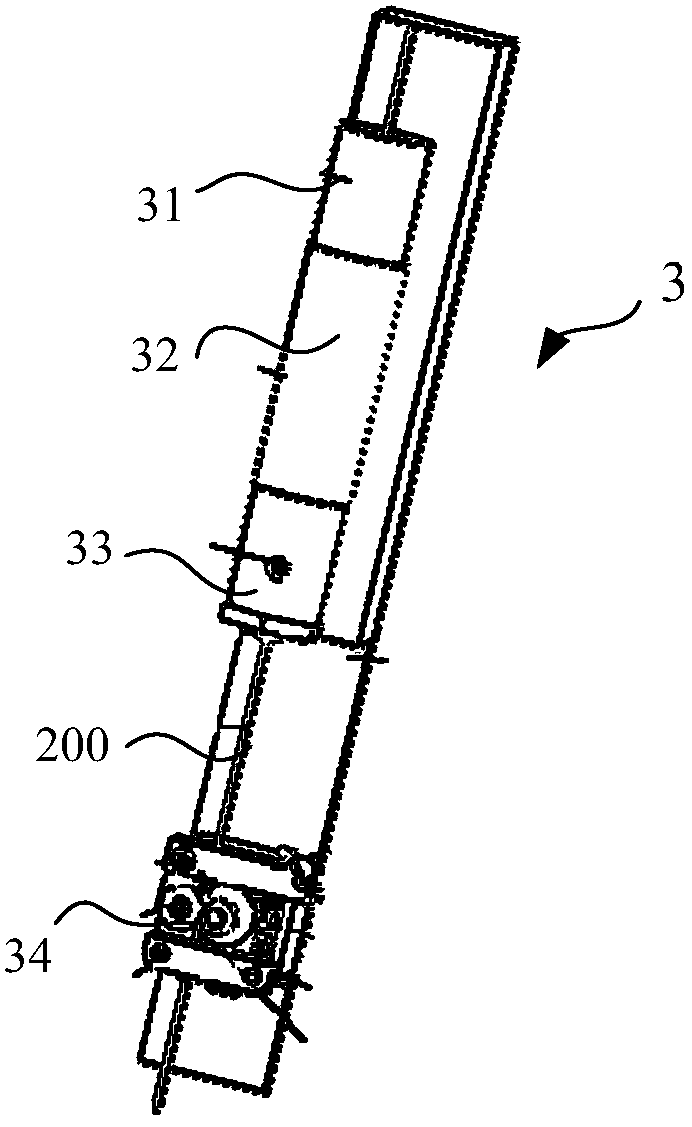

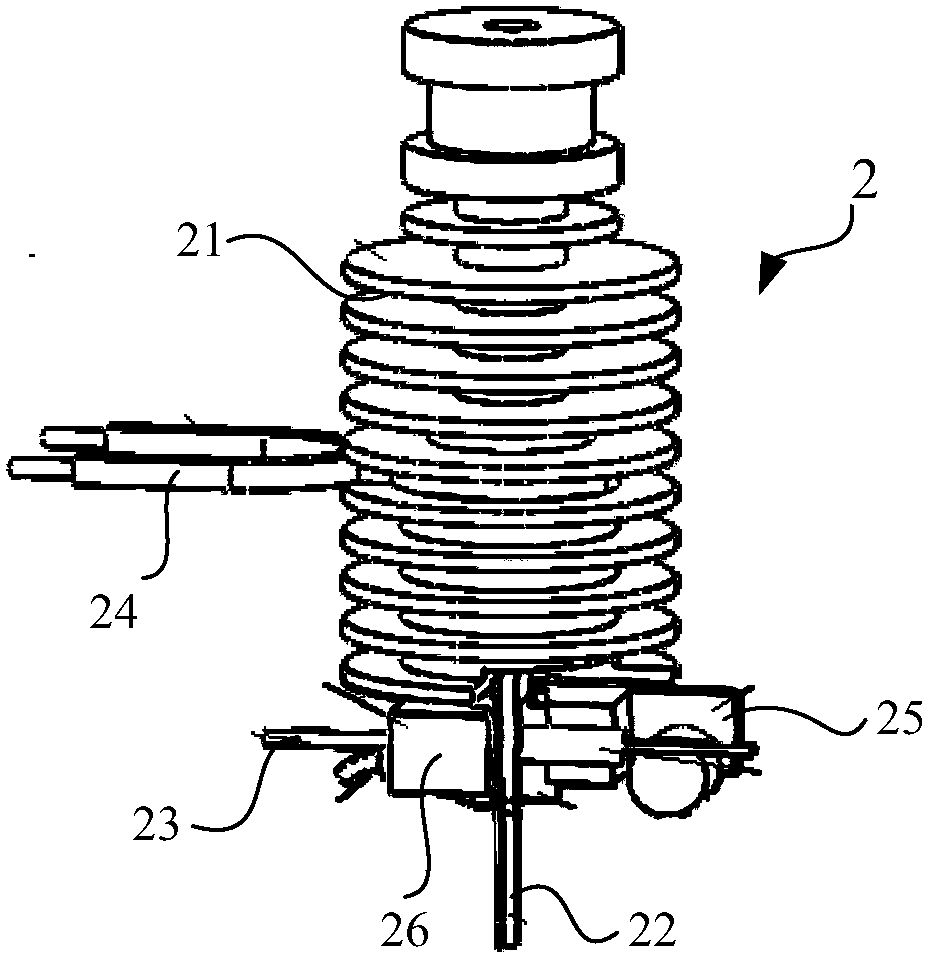

[0040] figure 1 It is a schematic structural diagram of a 3D printer capable of printing continuous fibers according to a preferred embodiment of the present application. Please also see figure 1 , the 3D printer 100 provided in this application includes a fixed frame 1 , a feeding part 3 and a nozzle part 2 .

[0041] Wherein, the fixing frame 1 is used for fixing and supporting the spray head 2 and the feeding part 3 . The fixed frame 1 includes an X-axis transmission rod, a Y-axis transmission rod and a Z-axis transmission rod, the nozzle head 2 and the feeding part 3 are fixed on the X-axis transmission rod by fasteners, and are driven drive the displacement of the X-axis transmission rod in the X-axis direction; the nozzle head 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com