Preparation method of temperature-responsive Janus nanofiber dressing

A nanofiber, temperature-responsive technology, applied in the direction of fiber type, fiber treatment, conjugated synthetic polymer artificial filament, etc., can solve the problems of destroying the humidity balance of the wound healing microenvironment, unfavorable wound healing, etc., and achieve the effect of improving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

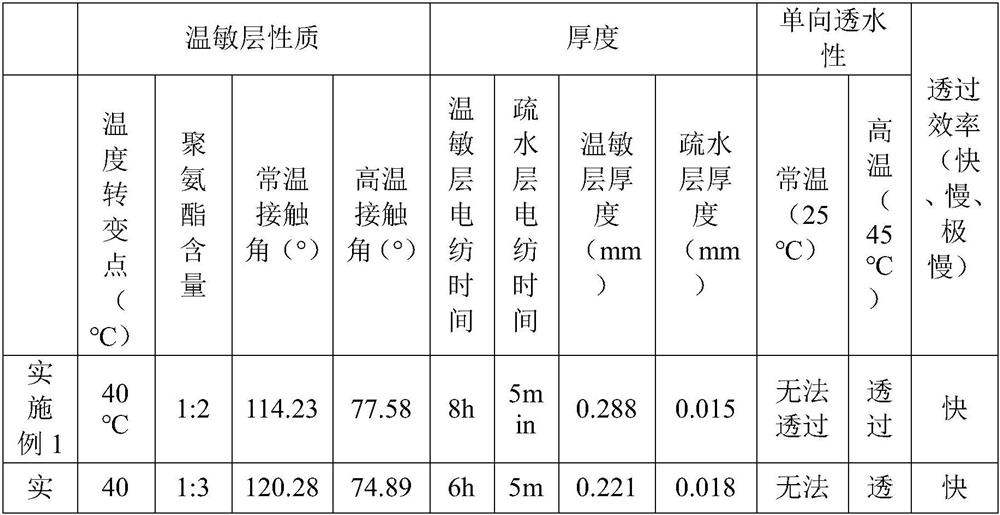

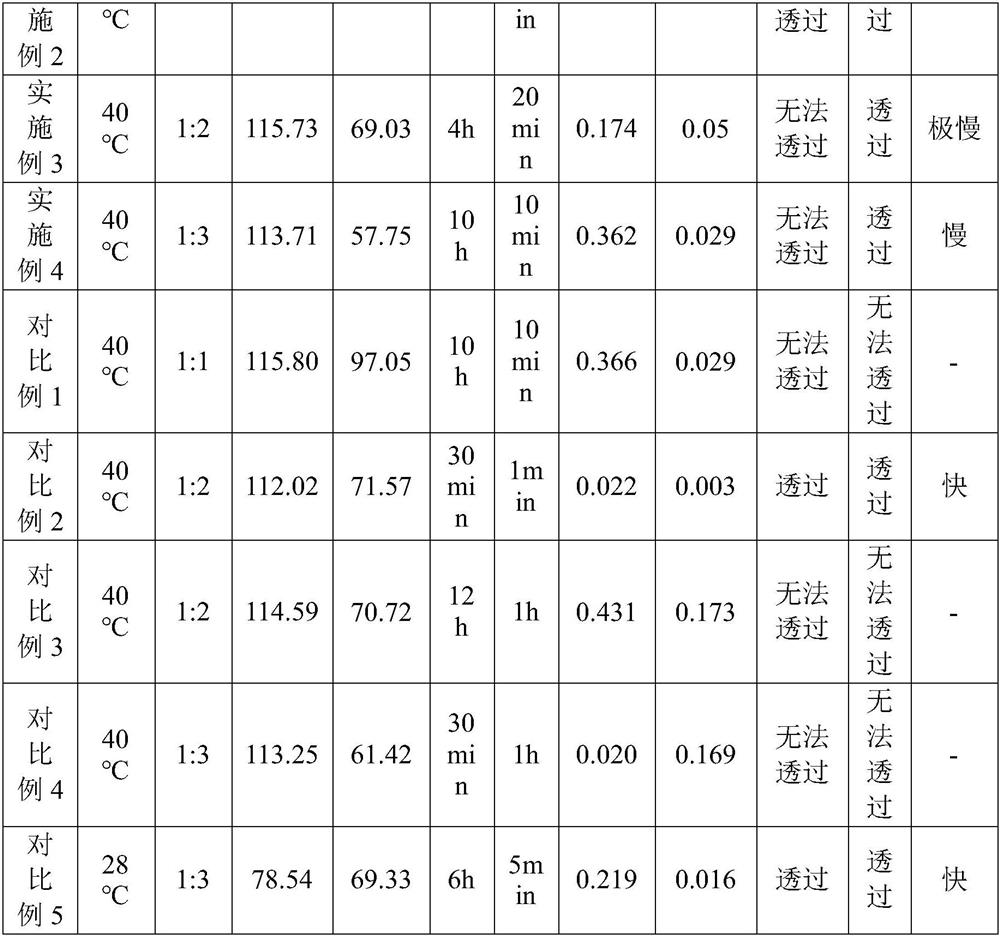

Embodiment 1

[0028] (1) Add 60% of monomer acrylamide, 20% of acrylonitrile, and 20% of N-methylolacrylamide (total concentration: 1mM) into a round-bottomed flask by molar ratio, and add 1% of monomer molar ratio Add azobisisobutyronitrile into dimethyl sulfoxide solution, deoxygenate with nitrogen, and react at 55°C. After the reaction was completed, the solution was cooled to room temperature, then dialyzed in deionized water for 40 h, and freeze-dried to obtain the target product for future use.

[0029] (2) Use N,N-dimethylformamide as a solvent to prepare 15wt% thermosensitive polymer solution and 15wt% polyurethane solution respectively, and then mix the above two solutions into a uniform spinning solution, wherein the polyurethane solution The mass ratio to the temperature-sensitive solution is 1:2. The temperature-sensitive layer was obtained by electrospinning the temperature-sensitive / polyurethane blend solution on cotton fabric by electrospinning. The spinning parameters were:...

Embodiment 2

[0032] (1) Add monomer acrylamide 60%, acrylonitrile 20%, N-methylol acrylamide 20% (total concentration 0.5mM) into the round bottom flask by molar ratio, and add 1% of monomer molar ratio Add azobisisobutyronitrile into dimethyl sulfoxide solution, deoxygenate with nitrogen, and react at 55°C. After the reaction was completed, the solution was cooled to room temperature, then dialyzed in deionized water for 40 h, and freeze-dried to obtain the target product for future use.

[0033](2) Use N,N-dimethylformamide as a solvent to prepare 18wt% thermosensitive polymer solution and 16wt% polyurethane solution respectively, and then mix the above two solutions into a uniform spinning solution, wherein the polyurethane solution The mass ratio to the temperature-sensitive solution is 1:3. The temperature-sensitive layer was obtained by electrospinning the temperature-sensitive / polyurethane blend solution on cotton fabric by electrospinning. The spinning parameters were: spinning sp...

Embodiment 3

[0036] (1) Add 60% of monomer acrylamide, 20% of acrylonitrile, and 20% of N-methylolacrylamide (total concentration is 2mM) into a round bottom flask by molar ratio, and add 1% of monomer molar ratio Add azobisisobutyronitrile into dimethyl sulfoxide solution, deoxygenate with nitrogen, and react at 55°C. After the reaction was completed, the solution was cooled to room temperature, then dialyzed in deionized water for 40 h, and freeze-dried to obtain the target product for future use.

[0037] (2) Use N,N-dimethylformamide as a solvent to prepare 18wt% thermosensitive polymer solution and 15wt% polyurethane solution respectively, and then mix the above two solutions into a uniform spinning solution, wherein the polyurethane solution The mass ratio to the temperature-sensitive solution is 1:2. The temperature-sensitive layer was obtained by electrospinning the temperature-sensitive / polyurethane blend solution on cotton fabrics by electrospinning. The spinning parameters were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com