Environmentally responsive comb type polycondensate and preparation thereof

An environment-responsive, polycondensate technology, applied in the field of environment-responsive comb-type polycondensate and its preparation, comb-type polycondensate and its preparation field, can solve the problems of single conditions for inducing phase transition, complex industrial production process, etc. Wide application value, sensitive responsiveness, and the effect of rich response conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

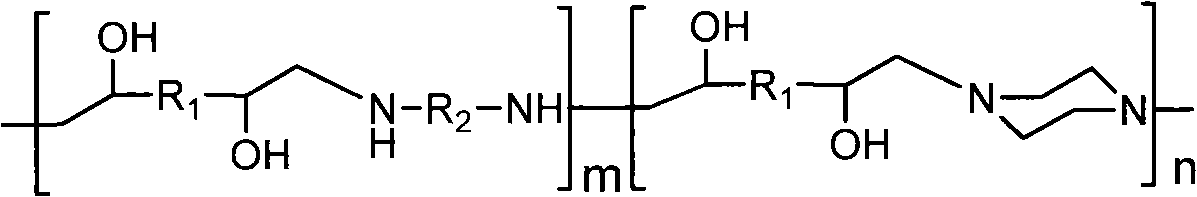

[0018] With stirring, in the reflux condenser flask, add the polyoxypropylene (molecular weight 640g·mol) containing double epoxy functional group -1 ) 5.12g, piperazine 0.52g and L100 (SURFONAMINE amine series product of Huntsman company) 2.10g, then add 15ml ethanol to dissolve the reactant. Under the condition of flowing nitrogen, the reaction was refluxed for 10 hours. After the reaction, ethanol was removed to obtain the target product.

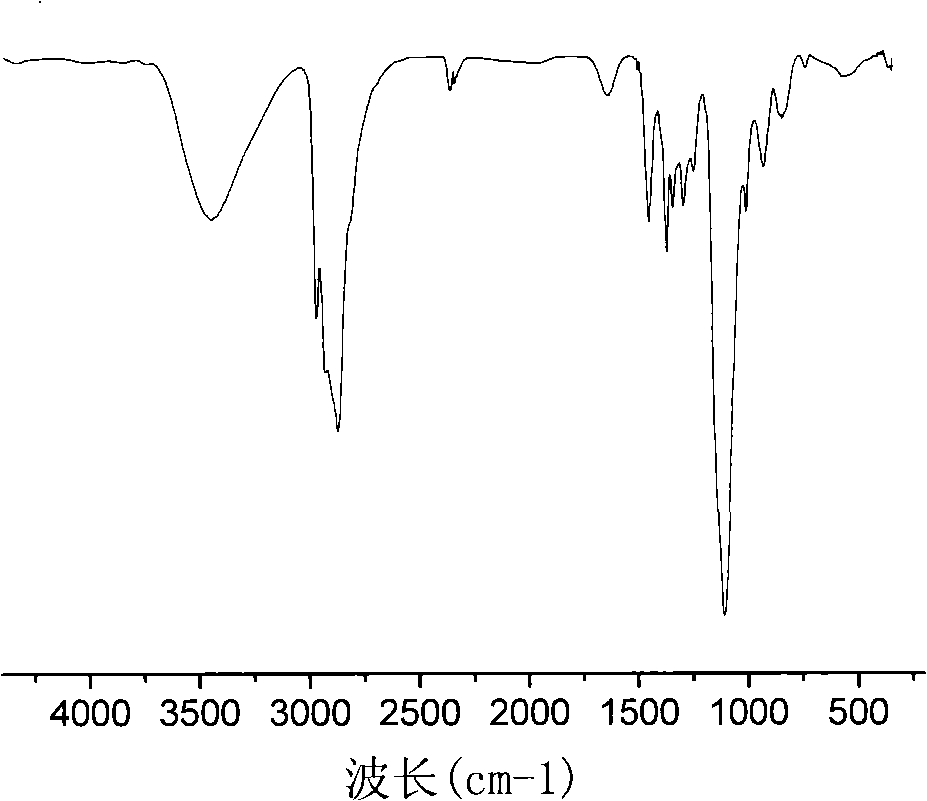

[0019] figure 1 It is the infrared spectrum of the environment-responsive comb polycondensate, measured by the KBr salt flake method. 3448cm in the picture -1 At the absorption peak of hydroxyl group, 2872cm -1 The place is the C-H vibration absorption peak, 1374cm -1 The place is the methyl symmetrical deformation vibration absorption peak, 1110cm -1 At the C-O-C asymmetric stretching vibration absorption peak, 840cm -1 is the CH2O-deformation vibration absorption peak.

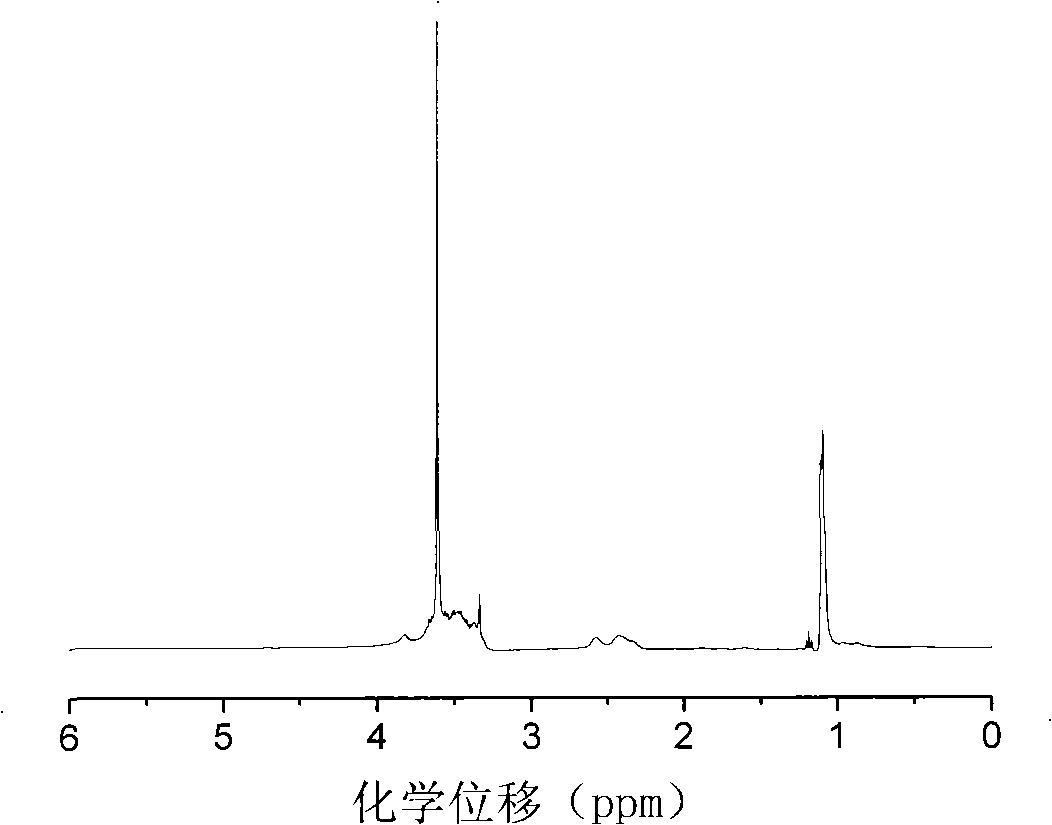

[0020] figure 2 for multiple environment-responsive com...

Embodiment 2

[0022] With stirring, in the reflux condenser flask, add the polyoxypropylene (molecular weight 640g·mol) containing double epoxy functional group -1 ) 6.40g, piperazine 0.75g and L300 (SURFONAMINE amine series product of Huntsman company) 3.96g, then add 17ml chloroform to dissolve the reactant. Under nitrogen, the reaction was refluxed for 11 hours. After the reaction, the trichloromethane was removed to obtain the target product.

Embodiment 3

[0024] With stirring, in the reflux condenser flask, add polyoxypropylene (molecular weight 380g·mol) containing double epoxy functional group -1 ) 1.90g, piperazine 0.21g and B100 (SURFONAMINE amine series product of Huntsman company) 2.63g, then add 12ml methanol to dissolve the reactant. Under nitrogen, the reaction was refluxed for 12 hours. After the reaction, methanol was removed to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com