Application of hydroxypropyl chitosan/carbon nanotube modified electrochemical sensor

A technology of hydroxypropyl chitosan and carbon nanotubes, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of limited application scope, easy agglomeration, difficulty, etc., and achieves improved sensitivity, high sensitivity, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

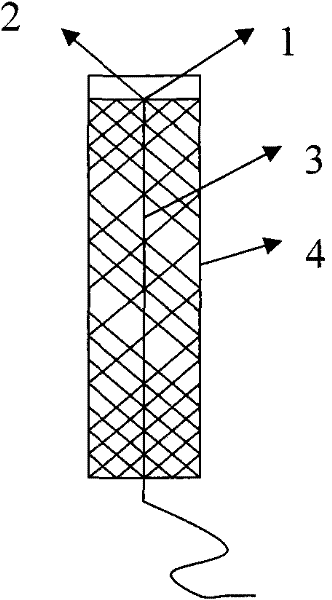

[0044] Such as figure 1 As shown, the working electrode of the electrochemical sensor consists of 1 response film, 2 glassy carbon substrate, 3 electrode leads and 4 insulating layers.

[0045] The preparation method of the working electrode of the electrochemical sensor is as follows:

[0046] 1) Place 5 g of multi-walled carbon nanotubes in 20% nitric acid for reflux oxidation for 5 hours, then wash with double distilled water until neutral and dry to obtain multi-walled carbon nanotubes with functional groups such as carboxyl and hydroxyl groups at the end groups ;

[0047] 2) Preparation of hydroxypropyl chitosan: 1 g of sodium hydroxide solid was weighed, placed in a beaker, 50 ml of distilled water was added to dissolve it, and 25 g of isopropanol was added to fully disperse it. Put into there-necked flask, add 4g chitosan while stirring. After alkalization for 9 hours, 40ml of propylene oxide was added, and the mixture was heated under reflux at 45°C for 14 hours. ...

Embodiment 2

[0052] The working electrode of the electrochemical sensor consists of 1 response membrane, 2 glassy carbon substrate, 3 electrode leads and 4 insulating layers.

[0053] The preparation method of the working electrode of the electrochemical sensor is as follows:

[0054] 1) Place 5 g of multi-walled carbon nanotubes in 30% nitric acid for reflux oxidation for 6 hours, then wash with twice distilled water to neutrality and dry to obtain multi-walled carbon nanotubes with functional groups such as carboxyl and hydroxyl groups at the end groups ;

[0055] 2) Preparation of hydroxypropyl chitosan: 1 g of sodium hydroxide solid was weighed, placed in a beaker, 20 ml of distilled water was added to dissolve it, and 30 g of isopropanol was added to fully disperse it. Put into there-necked flask, add 3g chitosan while stirring. After alkalization for 10 h, 20 ml of propylene oxide was added, and the reaction was heated under reflux at 45° C. for 13 hours. After the product can be ...

Embodiment 3

[0059] The working electrode of the electrochemical sensor consists of 1 response membrane, 2 glassy carbon substrate, 3 electrode leads and 4 insulating layers.

[0060] The preparation method of the working electrode of the electrochemical sensor is as follows:

[0061] 1) Place 5 g of multi-walled carbon nanotubes in 40% nitric acid for reflux oxidation for 8 hours, then wash with double distilled water to neutrality and dry to obtain multi-walled carbon nanotubes with functional groups such as carboxyl and hydroxyl groups at the end groups ;

[0062] 2) Preparation of hydroxypropyl chitosan: 1 g of sodium hydroxide solid was weighed, placed in a beaker, 40 ml of distilled water was added to dissolve it, and 35 g of isopropanol was added to fully disperse it. Put into there-necked flask, add 1g chitosan while stirring. After alkalization for 9 hours, 10 ml of propylene oxide was added, and the mixture was heated under reflux at 45°C for 14 hours. After the product can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com