In-situ preparation method for micrometer scale T1 phase based on Al-Cu-Li alloy

An in-situ preparation, al-cu-li technology, applied in the field of aluminum alloy heat treatment, can solve the problems of uniformity, difference in oxide film alloy matrix, inability to achieve crystal structure and atomic arrangement, etc., to increase the holding temperature and eliminate elements The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

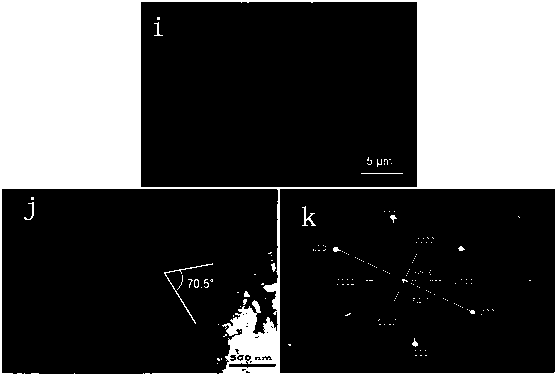

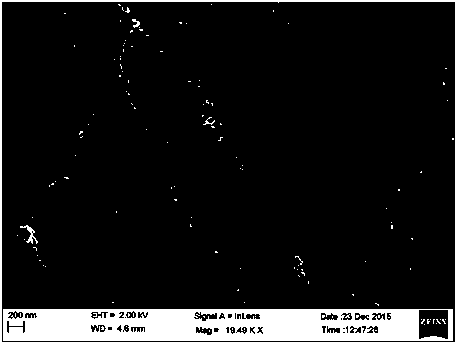

Image

Examples

Embodiment 1

[0028] Embodiment 1, a micron scale T based on Al-Cu-Li alloy 1 The in-situ preparation method of phase, it comprises the steps:

[0029] Step 1: Cut a 30×30×30mm sample from the AA2099 Al-Li alloy ingot by wire cutting method, put the AA2099 Al-Li alloy sample to be treated into a heat treatment furnace for solution treatment, and the solution treatment temperature is 540℃±5℃, solution treatment holding time is 1h;

[0030] Step 2, quenching the AA2099 aluminum-lithium alloy sample that has been solid solution treated, the quenching medium is water at 0°C, and the quenching transfer time is not greater than 10s;

[0031] Step 3: Put the quenched AA2099 aluminum-lithium alloy sample in a heat treatment furnace for graded heat treatment, the first heat treatment temperature is 500°C, the treatment time is 12h, the second heat treatment temperature is 520°C, and the treatment time is 36h, Then cooled to room temperature with the furnace, in situ prepared T with a longitudinal ...

Embodiment 2

[0032] Embodiment 2, a micron scale T based on Al-Cu-Li alloy 1 The in-situ preparation method of phase, it comprises the steps:

[0033] Step 1: Cut a 30×30×30mm sample from the AA2099 Al-Li alloy ingot by wire cutting method, put the AA2099 Al-Li alloy sample to be treated into a heat treatment furnace for solution treatment, and the solution treatment temperature is 540℃±5℃, solution treatment holding time is 3h;

[0034] Step 2, quenching the AA2099 aluminum-lithium alloy sample that has been solid solution treated, the quenching medium is water at 3°C, and the quenching transfer time is not greater than 10s;

[0035] Step 3: put the quenched AA2099 aluminum-lithium alloy sample in a heat treatment furnace for graded heat treatment, the first heat treatment temperature is 480°C, the treatment time is 18h, the second heat treatment temperature is 530°C, and the treatment time is 24h, Then cooled to room temperature with the furnace, in situ prepared T with a longitudinal ...

Embodiment 3

[0036] Example 3, a micron scale T based on Al-Cu-Li alloy 1 The in-situ preparation method of phase, it comprises the steps:

[0037] Step 1: Cut a 30×30×30 mm sample from the AA2055 Al-Li alloy ingot by wire cutting method, put the AA2055 Al-Li alloy sample to be treated into a heat treatment furnace for solution treatment, and the solution treatment temperature is 540℃±5℃, solution treatment holding time is 5h;

[0038] Step 2, quenching the AA2055 aluminum-lithium alloy sample that has undergone solid solution treatment, the quenching medium is water at 5°C, and the quenching transfer time is not greater than 10s;

[0039] Step 3: put the quenched AA2055 aluminum-lithium alloy sample in a heat treatment furnace for graded heat treatment, the first heat treatment temperature is 510°C, the treatment time is 24h, the second heat treatment temperature is 530°C, and the treatment time is 28h, Then cooled to room temperature with the furnace, in situ prepared T with a longitud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com