GH4145 alloy forging and preparation method thereof

A technology of GH4145 and forgings, applied in the field of GH4145 alloy forgings and their preparation, can solve the problems of easily causing defects, large thermal stress, and large temperature gradients on the surface and core of GH4145 alloys, and achieves improved yield, strong hot workability, The effect of element segregation elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

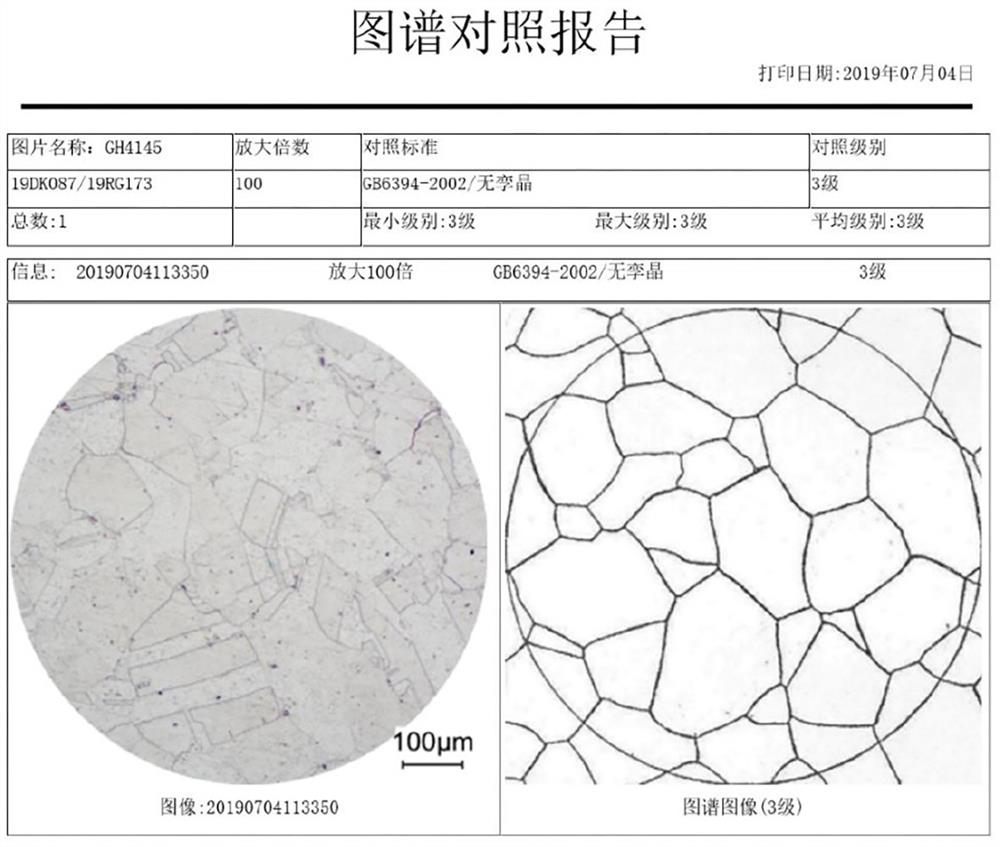

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of a GH4145 alloy forging, comprising the following steps:

[0034] S1: Staged heating of steel ingots: place GH4145 nickel-based alloy steel ingots on cast iron and add them to the furnace, the first stage of heating, the temperature of the steel ingot is raised to 580-620 ° C and maintained, the second stage of heating, the temperature of the steel ingot is raised to 880-920 ℃ and heat preservation; and before the GH4145 nickel-based alloy ingot is added to the furnace, the temperature is lower than 300 ℃;

[0035] S2: Diffusion annealing: the ingot treated by S1 is heated to 1150-1250°C and kept warm;

[0036] S3: Cooling and rewarming of steel ingot: Cool the steel ingot after S2 treatment to 1020-1070℃, then return to 1160-1180℃ and keep it for a period of time;

[0037] S4: Billeting of steel ingots: The steel ingots treated by S3 are processed for unrolling and billeting, and the temperature of final forging is control...

Embodiment 1

[0060] Forging of GH4145 Alloy Forgings

[0061] S1: Staged heating of steel ingots: Place GH4145 alloy steel ingots on cast iron with a size of 200mm*200mm*1500mm and add them to the furnace. The first stage is heated, and the steel ingots are raised to 580°C at a rate of 100°C / hour and kept for 3 hours. , the second stage of heating, the temperature of the ingot is raised to 880°C at a rate of 100°C / hour and kept for 2.5 hours;

[0062] S2: Diffusion annealing: the ingot treated by S1 is heated to 1150°C at a rate of 150°C / hour and kept for 20 hours;

[0063] S3: Cooling and rewarming of steel ingot: Cool the steel ingot after S2 treatment to 1020°C, then return to 1160°C and keep it for 5 hours;

[0064] S4: Billeting of steel ingots: The steel ingots treated in S3 are released from the furnace for billeting treatment, the four sides of the steel ingots are patted and rounded, and then the steel ingots are flattened by a heavy hammer in one direction. The method processes...

Embodiment 2

[0070] Forging of GH4145 Alloy Forgings

[0071] S1: Staged heating of steel ingots: Place GH4145 alloy steel ingots on cast iron with a size of 200mm*200mm*1500mm and add them to the furnace. The first stage is heated, and the steel ingots are raised to 620°C at a speed of 100°C / hour and kept for 3 hours. , the second stage of heating, the temperature of the ingot is raised to 920°C at a rate of 100°C / hour and kept for 2.5 hours;

[0072] S2: Diffusion annealing: the ingot treated by S1 is heated to 1250°C at a rate of 150°C / hour and kept for 20 hours;

[0073] S3: Cooling and rewarming of the steel ingot: The steel ingot treated with S2 is cooled to 1070°C, then returned to 1180°C and kept for 5 hours;

[0074] S4: Billeting of steel ingots: The steel ingots treated in S3 are released from the furnace, and the four sides of the steel ingots are tapped and rounded, and then the steel ingots are flattened by a heavy hammer in one direction. The method processes the steel ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com