Polymer matrix composite and preparation method thereof

A technology for composite materials and polymers, which is applied in the field of preparing "sandwich" structure multi-layer polymer-based composite materials, which can solve the problems of difficult preparation of high thermal conductivity and low dielectric properties, and achieve easy control of process parameters and low manufacturing cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

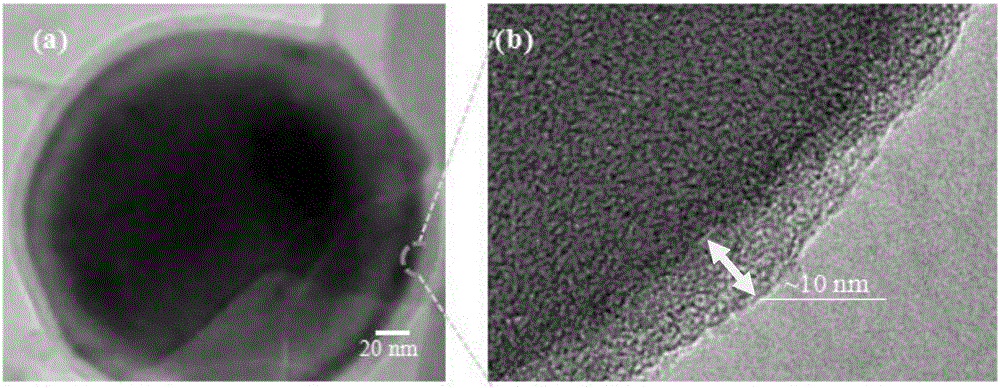

[0049] A polymer-based composite material, using PVA as a polymer matrix, surface-modified silver nanofibers coated with a PDA shell and surface-modified silver nanoparticles coated with a PDA shell as nano-scale metal fillers, nano-scale metal The filler is dispersed in the polymer matrix, wherein, in the polymer matrix composite material, the polymer matrix accounts for 97% by mass, the nanoscale metal filler accounts for 3% by mass, and the nanoscale metal filler contains The mass ratio of silver nanofibers coated with PDA shell to silver nanoparticles coated with PDA shell is 1:1.

Embodiment 2

[0051] Preparation of a single-layer polymer matrix composite with "point-line" structure

[0052] The preparation method of the polymer-based composite material of the "point-line" structure is as follows:

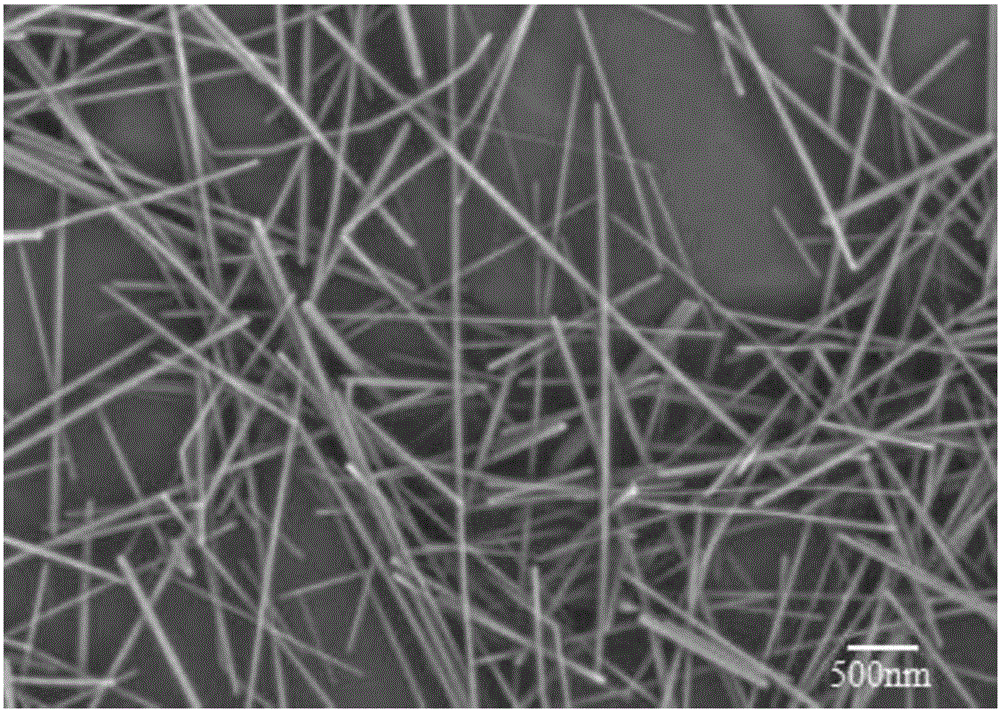

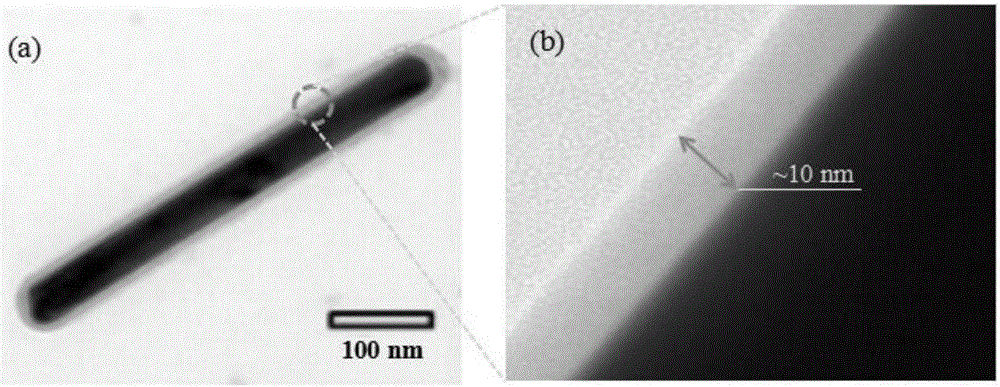

[0053] (1) Synthesis of silver nanofibers, specific synthesis method references: Chen C, Tang Y, Ye Y S, et al. High-performance epoxy / silica coated silver nanowire composites as underfill material for electronic packaging [J]. Composites Science and Technology, 2014, 105:80-85. The diameter of the synthesized silver nanofiber is between 100 nanometers and 200 nanometers, and the aspect ratio is 10:1 to 20:1, and the scanning electron micrograph of the silver nanofiber of gained is as follows figure 1 shown by figure 1 It can be seen that the shape of the prepared silver nanofibers is regular and linear, the average diameter is about 100nm, the aspect ratio is moderate and the dispersion is good, and there is no obvious agglomeration phenomenon;

[0054] (2) Select sui...

Embodiment 3

[0060] Preparation of a "sandwich" structured multilayer polymer matrix composite

[0061] On the basis of Example 2, the single-layer polymer-based composite material prepared in Example 2 was brittlely fractured with liquid nitrogen, and then a composite material with a suitable size was selected for lamination treatment and then placed in a high-temperature heat sink with a diameter of 25 mm. Press the mold into the mold, then put the mold into a vacuum oven and heat it to 180°C, and at the same time slowly apply a vertical pressure of 220MPa to it, keep the pressure for 20min, cool it down to room temperature naturally, and then demould to get a typical "sandwich" structure. Layer polymer matrix composite material, the scanning electron micrograph of the "sandwich" structure of the multilayer polymer matrix composite material is as follows Figure 5 shown by Figure 5 It can be seen that the prepared composite membrane has an obvious "sandwich" structure. From the cross-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com