Preparation method of isotropic high-thermal-conductivity carbon nanofiber membrane, and product thereof

A technology of nano-carbon fiber and nano-fiber film, which is applied in the field of new material technology and heat-conducting materials, can solve the problems that the thermal conductivity of the heat-conducting film is not obvious, and the thermal conductivity of the heat-conducting film cannot be realized, so as to achieve good thermal conductivity and good thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

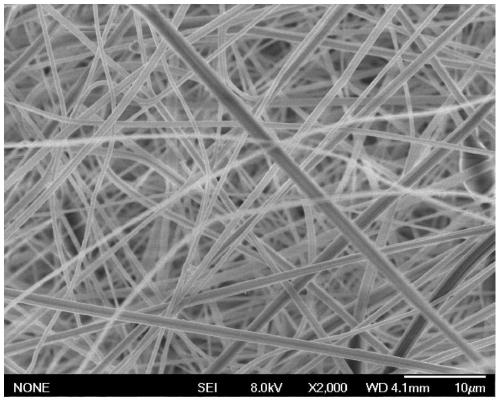

[0023] Embodiment 1: the PAN powder of 6g is dissolved in the DMF of 50mL and the preparation concentration is the PAN solution of 12%, the PAN solution is packed in the injector, the setting spinning distance is 15cm, and the injection speed is 2.5mL / h, The spinning voltage was 15kV, and the PAN nanofiber membrane was prepared by electrospinning; after spinning for 8 hours, a PAN fiber membrane with a thickness of about 150 μm was obtained. figure 1 It is the scanning electron micrograph of the obtained PAN fiber.

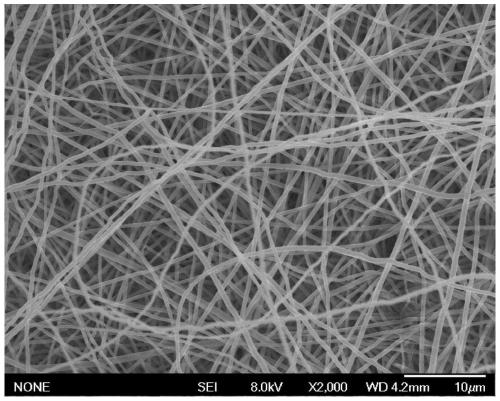

[0024] The prepared PAN nanofiber membrane is placed between the two rollers of the roller press, the distance between the two rollers is adjusted to 75 μm, and the rollers are rotated for rolling to make the PAN fiber membranes cross-linked and densified. figure 2 It is a scanning electron micrograph of the PAN fiber after rolling. It can be seen that the fiber is denser and the contact at the intersection is enhanced.

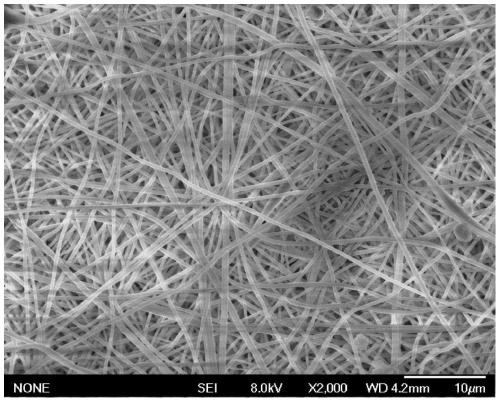

[0025] Place the PAN nanofiber membrane ...

Embodiment 2

[0028] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that the distance between the two rollers is 50 μm during rolling, and other conditions are the same as in Embodiment 1.

[0029] The thermal conductivity of the carbon nanofiber film prepared in this example is 13.1 W / (m·K) in the plane direction, and 12.0 W / (m·K) in the vertical direction.

Embodiment 3

[0030] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that the distance between the two rollers is 100 μm during rolling, and other conditions are the same as in Embodiment 1.

[0031] The thermal conductivity of the carbon nanofiber film prepared in this example is 10.3 W / (m·K) in the plane direction, and 8.7 W / (m·K) in the vertical direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com