Manufacturing method of LED bulb heat dissipation lampshade and manufactured lampshade

A technology of LED bulb lamp and manufacturing method, which is applied in the direction of lampshade, heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity, inability to achieve heat transfer and heat dissipation, and achieve good heat dissipation capability and simple installation. Convenient and avoid the effect of working temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086]42 parts of polypropylene, 32 parts of polymethyl methacrylate, 22 parts of silicone resin, 12 parts of methacryloxysilane, 16 parts of polyethylene glycol, 9 parts of nano zinc oxide, 5 parts of tea green pigment Plastic masterbatch, 0.6 parts of coupling agent, 0.9 parts of heat conduction aid, 0.3 parts of emulsifier, 0.4 parts of composite antioxidant, 0.2 parts of compatibilizer, 1.3 parts of light diffusing agent, 1.2 parts of light stabilizer, 12 parts of graphene ; Fully mixed, heated while stirring in a vacuum environment; when the temperature reaches a certain level, ; Add the mixed material in the hot melt state into the injection molding machine, inject it into the lampshade mold for one-time molding; water-cooled demoulding to obtain the lampshade.

Embodiment 2

[0088] 45 parts of polypropylene, 35 parts of polymethyl methacrylate, 25 parts of silicone resin, 15 parts of methacryloxysilane, 20 parts of polyethylene glycol, 10 parts of nano zinc oxide, 7 parts of tea green pigment Plastic masterbatch, 0.8 parts of coupling agent, 1 part of heat conduction aid, 0.4 parts of emulsifier, 0.5 parts of composite antioxidant, 0.5 parts of compatibilizer, 1.4 parts of light diffusing agent, 1.3 parts of light stabilizer, 12 parts of graphene ; Fully mixed, heated while stirring in a vacuum environment; when the temperature reaches a certain level, add the mixed material in the hot-melt state to the injection molding machine, inject it into the lampshade mold for one-time molding; water-cooled demoulding to obtain the lampshade.

Embodiment 3

[0090] 48 parts of polypropylene, 38 parts of polymethyl methacrylate, 28 parts of silicone resin, 18 parts of methacryloxysilane, 22 parts of polyethylene glycol, 11 parts of nano-zinc oxide, 8 parts of tea green pigment Plastic masterbatch, 0.9 parts of coupling agent, 1.2 parts of heat conduction aid, 0.5 parts of emulsifier, 0.6 parts of composite antioxidant, 0.8 parts of compatibilizer, 1.5 parts of light diffusing agent, 1.4 parts of light stabilizer, 14 parts of graphene ; Fully mixed, heated while stirring in a vacuum environment; when the temperature reaches a certain level, add the mixed material in the hot melt state into the injection molding machine, inject it into the lampshade mold for one-time molding; water-cooled demoulding to obtain the lampshade

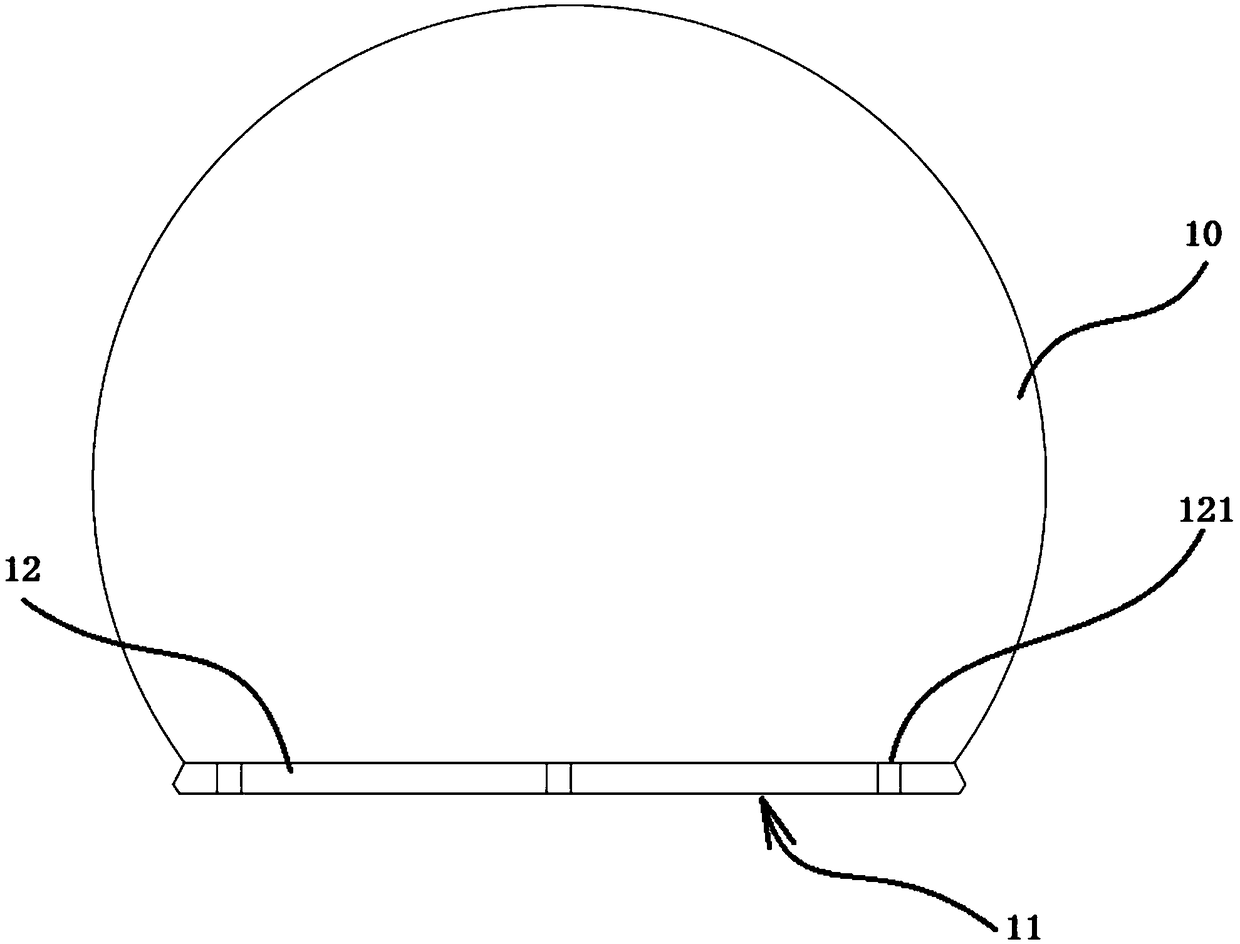

[0091] A heat dissipation lampshade 10 for an LED light bulb, the lampshade has a spherical inner whole body hollow structure, and its shape is two-thirds of a sphere;

[0092] The lampshade opening 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com