Heat treatment method of nickel-based single crystal superalloy

A heat treatment method and technology of superalloy, applied in the direction of post-treatment, single crystal growth, single crystal growth, etc., can solve the problem of no specific solution, depletion of Cr on the surface layer of nickel-based alloy, etc., and achieve excellent high temperature strength and Antioxidative properties, eliminate element segregation and eutectic structure, improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Vacuum induction furnace is used to smelt nickel-based single crystal superalloy, and the alloy cast rod is prepared by gravity casting;

[0037] (2) Using the seed crystal method to prepare a Cr-containing nickel-based single crystal superalloy at a temperature gradient of 150K / cm and a pulling rate of 50 μm / s through Bridgeman directional solidification technology; in this embodiment, select the Cr-containing superalloy The diameter of the nickel-based single crystal superalloy is 10 mm, and the length of the Cr-containing nickel-based single crystal superalloy is 5 mm;

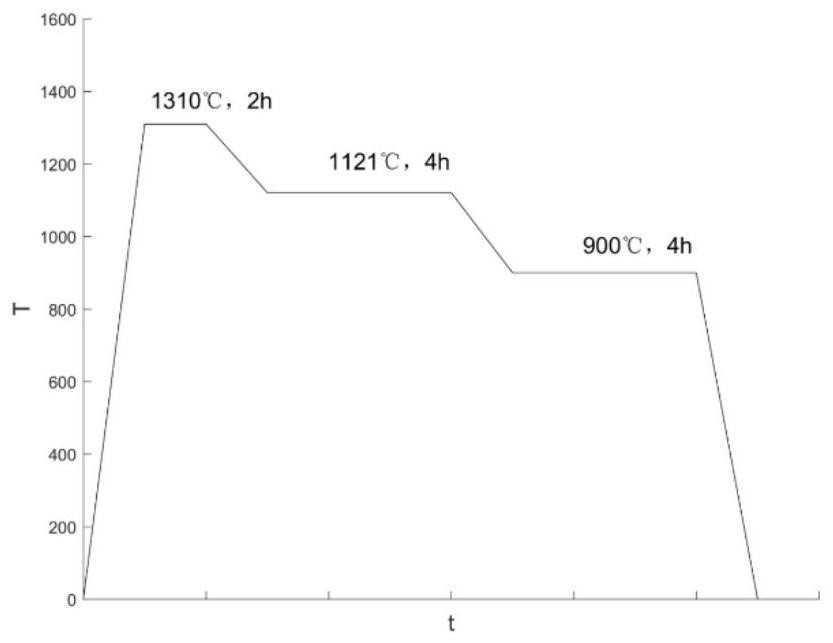

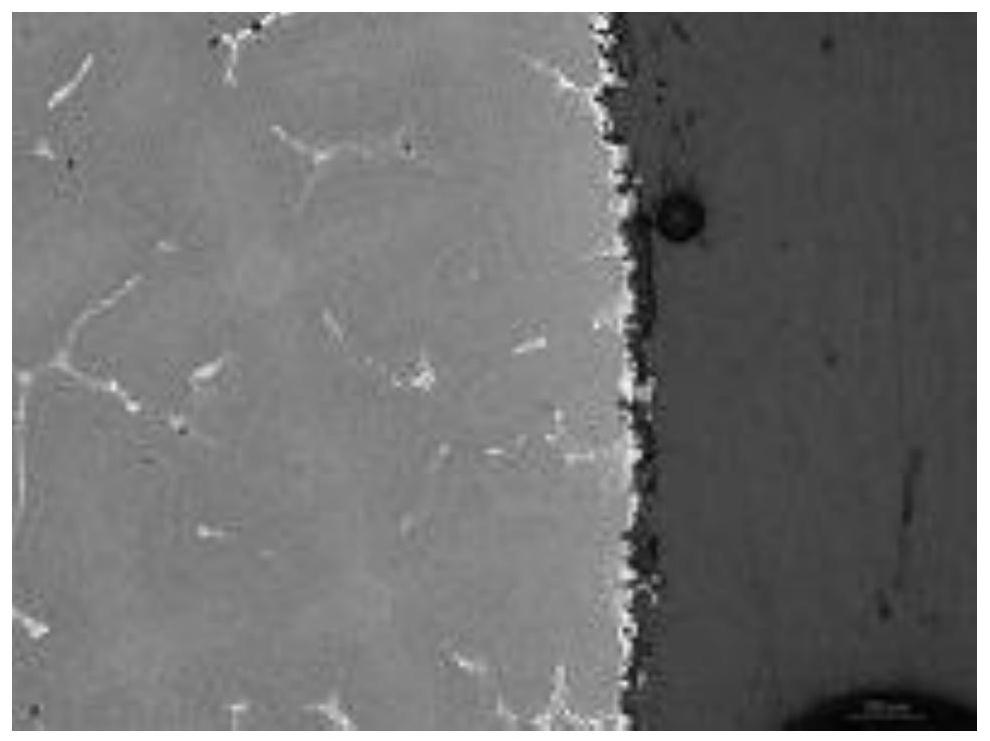

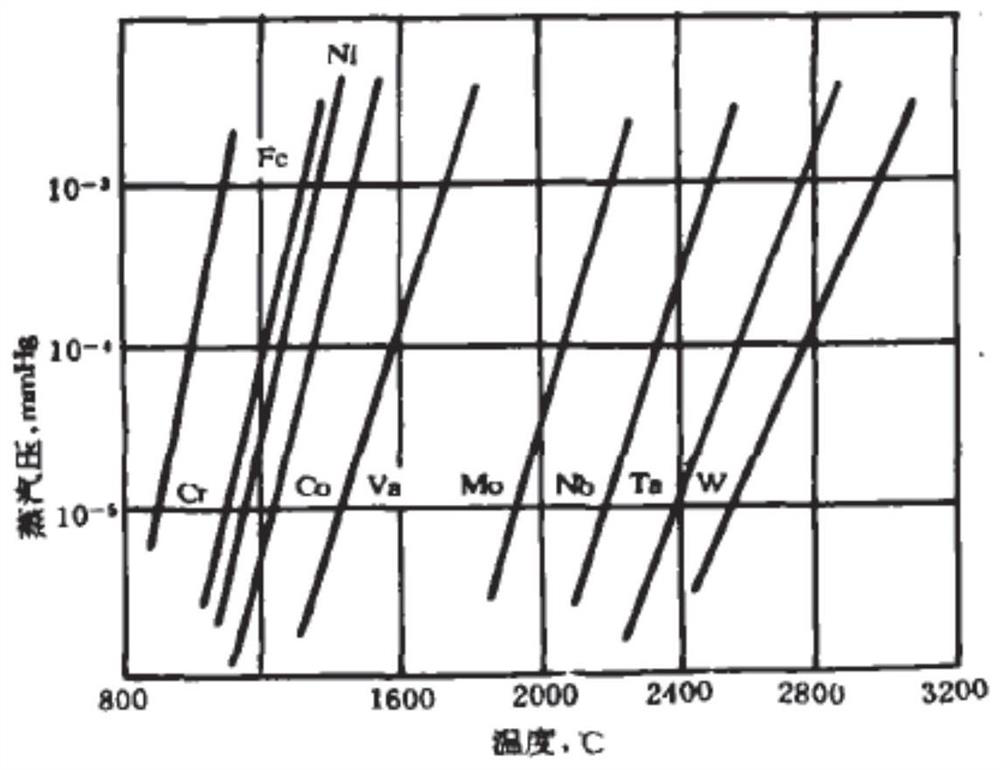

[0038] (3) Determine the initial melting temperature T of the nickel-based single crystal superalloy containing Cr, and determine the heating rate V of the nickel-based single crystal superalloy containing Cr in the solution treatment process; The heating rate of the alloy during the solution treatment process is obtained by Dictra software to obtain the initial distribution of the mass fraction ...

Embodiment 2

[0045] (1) Vacuum induction furnace is used to smelt nickel-based single crystal superalloy, and the alloy cast rod is prepared by gravity casting;

[0046] (2) Using the seed crystal method to prepare a Cr-containing nickel-based single crystal superalloy at a temperature gradient of 250K / cm and a pulling rate of 100 μm / s through Bridgeman directional solidification technology; in this embodiment, select the Cr-containing superalloy The diameter of the nickel-based single crystal superalloy is 10 mm, and the length of the Cr-containing nickel-based single crystal superalloy is 5 mm;

[0047](3) determine the initial melting temperature T of the nickel-based single crystal superalloy containing Cr; the heating rate of the nickel-based single crystal superalloy containing Cr in the solution treatment process is obtained by Dictra software. The mass fraction of each element in the dendrite structure is obtained from the initial distribution of the dendrite stem to the dendrite, ...

Embodiment 3

[0054] (1) Vacuum induction furnace is used to smelt nickel-based single crystal superalloy, and the alloy cast rod is prepared by gravity casting;

[0055] (2) adopting the seed crystal method to prepare the nickel-based single crystal superalloy containing Cr in the temperature gradient of 200K / cm and the drawing rate of 50-100 μm / s by Bridgeman directional solidification technology; The diameter of the Cr-containing nickel-based single-crystal superalloy is 10 mm, and the length of the Cr-containing nickel-based single-crystal superalloy is 5 mm;

[0056] (3) Determine the initial melting temperature T of the nickel-based single crystal superalloy containing Cr, and determine the heating rate V of the nickel-based single crystal superalloy containing Cr in the solution treatment process; The heating rate of the alloy in the solution treatment process is obtained by Dictra software to obtain the initial distribution of the mass fraction of each element in the dendrite struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com