Patents

Literature

65 results about "Grain boundary strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain-boundary strengthening (or Hall–Petch strengthening) is a method of strengthening materials by changing their average crystallite (grain) size. It is based on the observation that grain boundaries are insurmountable borders for dislocations and that the number of dislocations within a grain have an effect on how stress builds up in the adjacent grain, which will eventually activate dislocation sources and thus enabling deformation in the neighbouring grain, too. So, by changing grain size one can influence the number of dislocations piled up at the grain boundary and yield strength. For example, heat treatment after plastic deformation and changing the rate of solidification are ways to alter grain size.

Alloy vermicular cast iron glass mold material and preparation method thereof

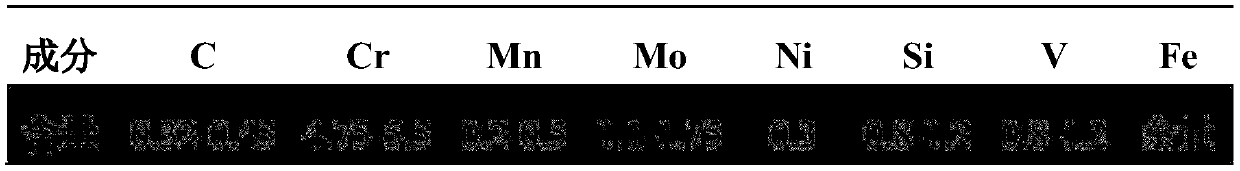

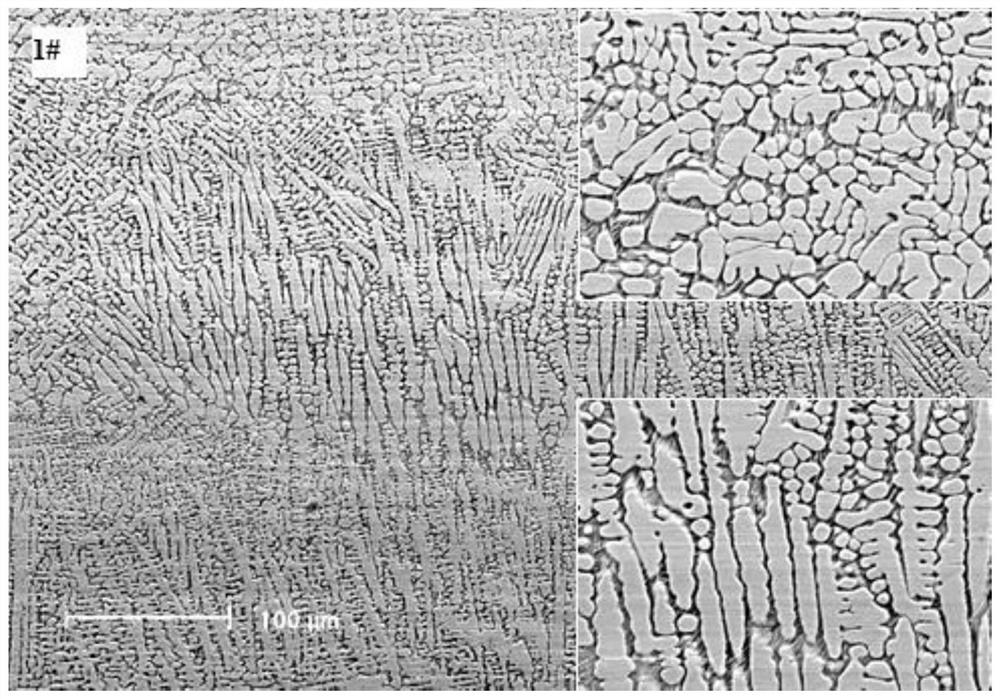

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

Roller surface laser strengthened coating powder material of roller type crusher

The invention relates to a roller surface laser strengthened coating powder material of a roller type crusher, which is characterized by comprising the following components: 0.6-1.2% of C, 11.0-18.0% of Mn, 12.0-18.0% of Cr, 3.0-5.0% of Ni, 4.0-6.0% of W, 0.6-1.4% of Si, 0.06-0.12% of Zr, 0.04-0.08% of Ce, and the balance of Fe. According to the roller surface laser strengthened coating powder material of the roller type crusher disclosed by the invention, an iron-based high-chromium high-manganese alloy powder material, which is lower in melting point and higher in hardness, contains a WC strengthening phase and is applied to laser cladding, is formed by carrying out alloy matrix strengthening by adding Cr, W, Ni and Si and carrying out matrix grain refinement and inter-crystalline strengthening by adding the element Zr and the rare earth microelement Ce on the basis of a high-manganese steel alloy composition; therefore, the impact resistance and the abrasion resistance of the roller surface are greatly increased; and the roller frequent replacing problem of the roller type crusher because of the reduced service life of a roller resulted from abraded abrasive particles on the roller surface is solved.

Owner:上海大陆天瑞激光表面工程有限公司

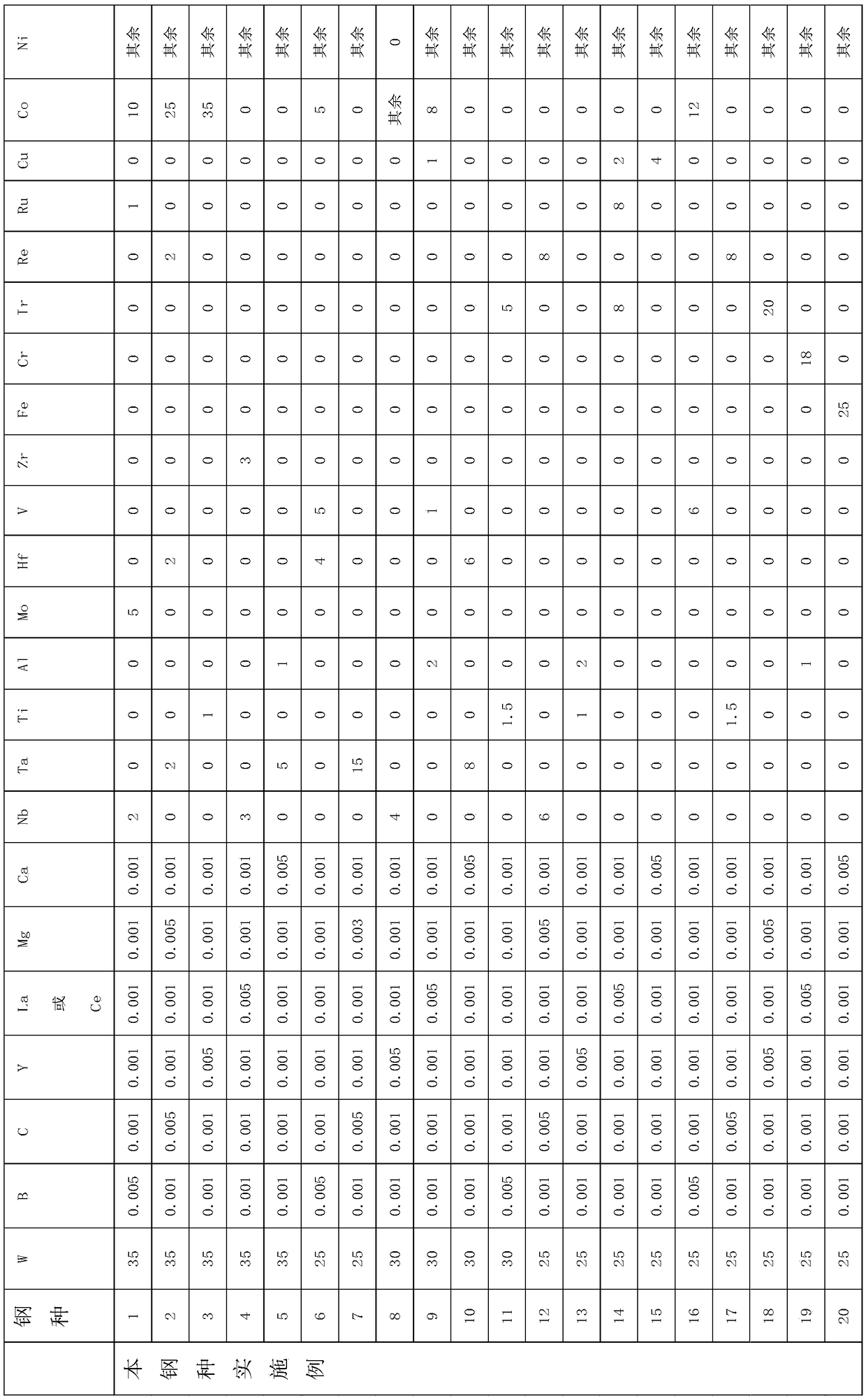

Castable and forgeable solid solution tungsten alloy and preparation method

The invention discloses castable and forgeable solid solution tungsten alloy and a preparation method, and belongs to the technical field of refractory alloy. According to the chemical components, thecastable and forgeable solid solution tungsten alloy comprises, by weight percentage, 20%-75% of W, 0%-20% of Mo, 0%-20% of Nb, 0%-20% of Ta, 0%-10% of Hf, 0%-10% of V, 0%-10% of Zr, 0%-10% of Ti, 0%-10% of Al, 0%-5% of Cu and the balance Ni or Co and inevitable impurity elements and microelements, specifically, the Ni element and the Co element can be partially replaced by one or two or more elements of 0%-50% of Ir, 0%-30% of Fe, 0%-20% of Cr, 0%-20% of Re and 0%-20% of Ru. The castable and forgeable solid solution tungsten alloy further comprises the following one or two or more grain boundary strengthening elements of 0.001%-1.0% of C, 0.001%-1.0% of B, 0.001%-1.0% of Y, 0.001%-1.0% of La or Ce or the rare earth element, 0.001%-1.0% of Mg and 0.001%-1.0% of Ca. The castable and forgeable solid solution tungsten alloy has the advantages of being high in density, ultrahigh in strength, high in toughness and high in hot-working performance. The alloy is castable and forgeable and canbe formed through 3D printing, the density ranges from 11.0g / cm<3> to 15.0g / cm<3>, the impact toughness is 80J / cm<2> or above, and the tensile strength is 1700MPa or above.

Owner:CENT IRON & STEEL RES INST

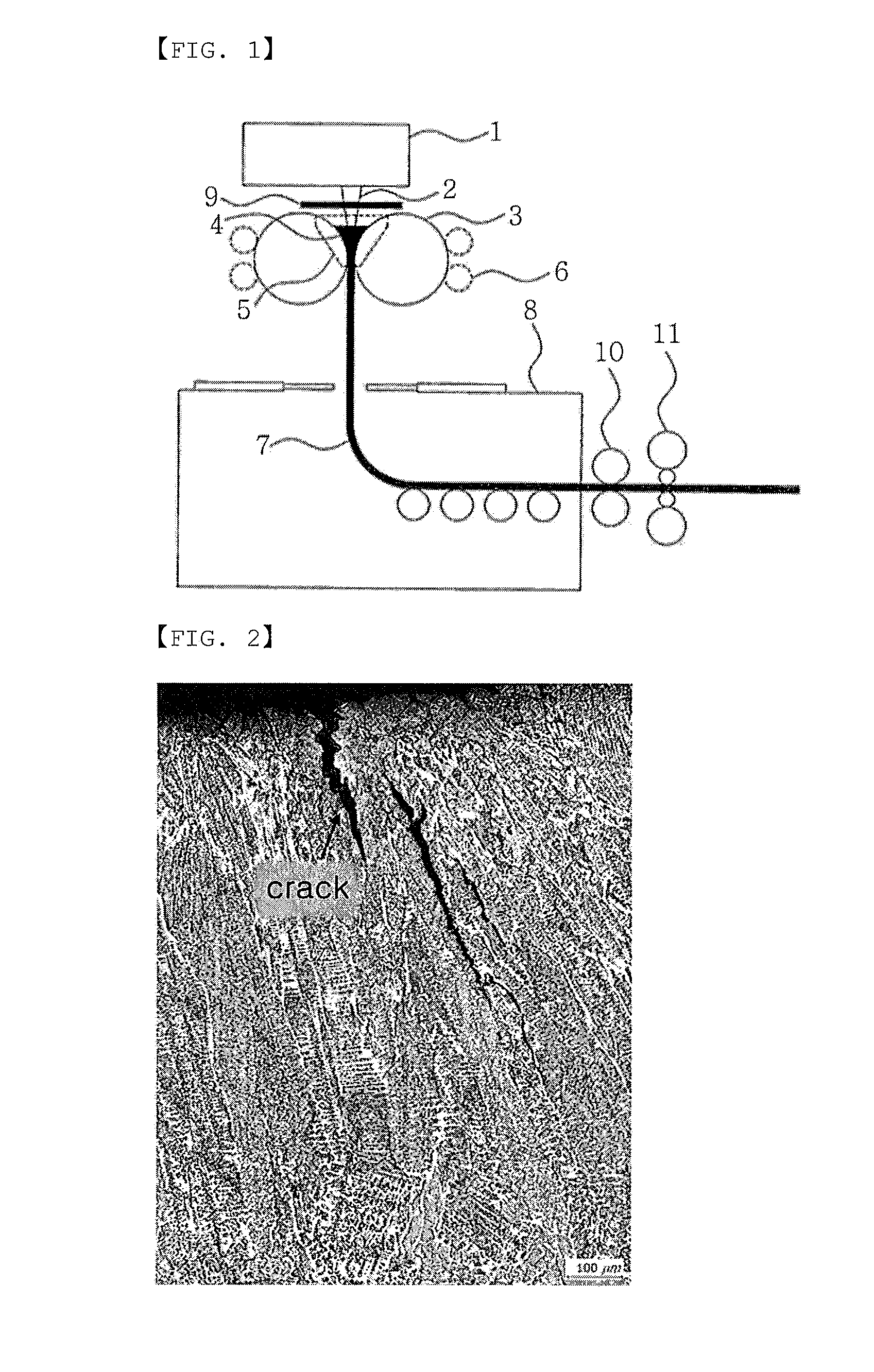

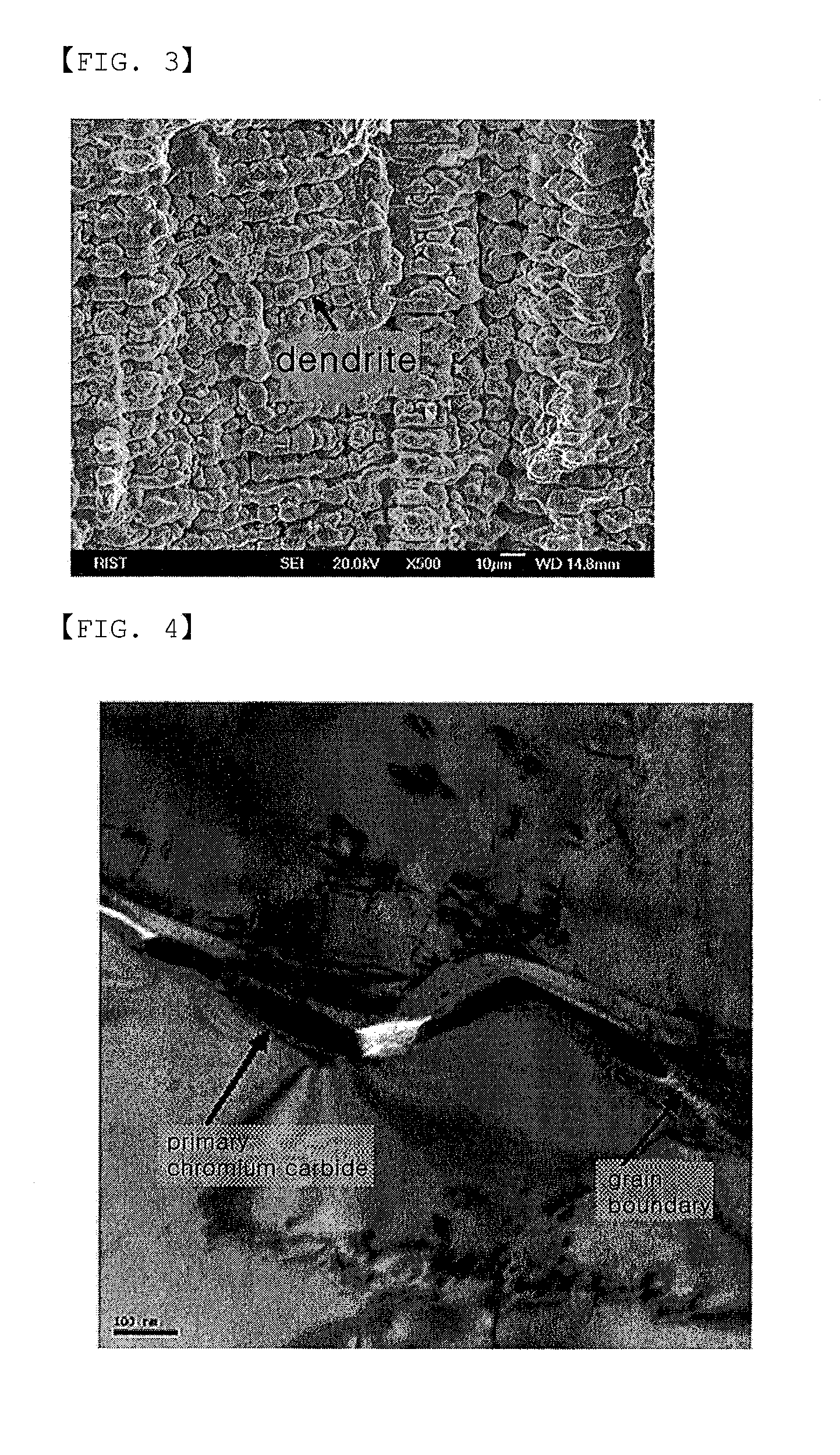

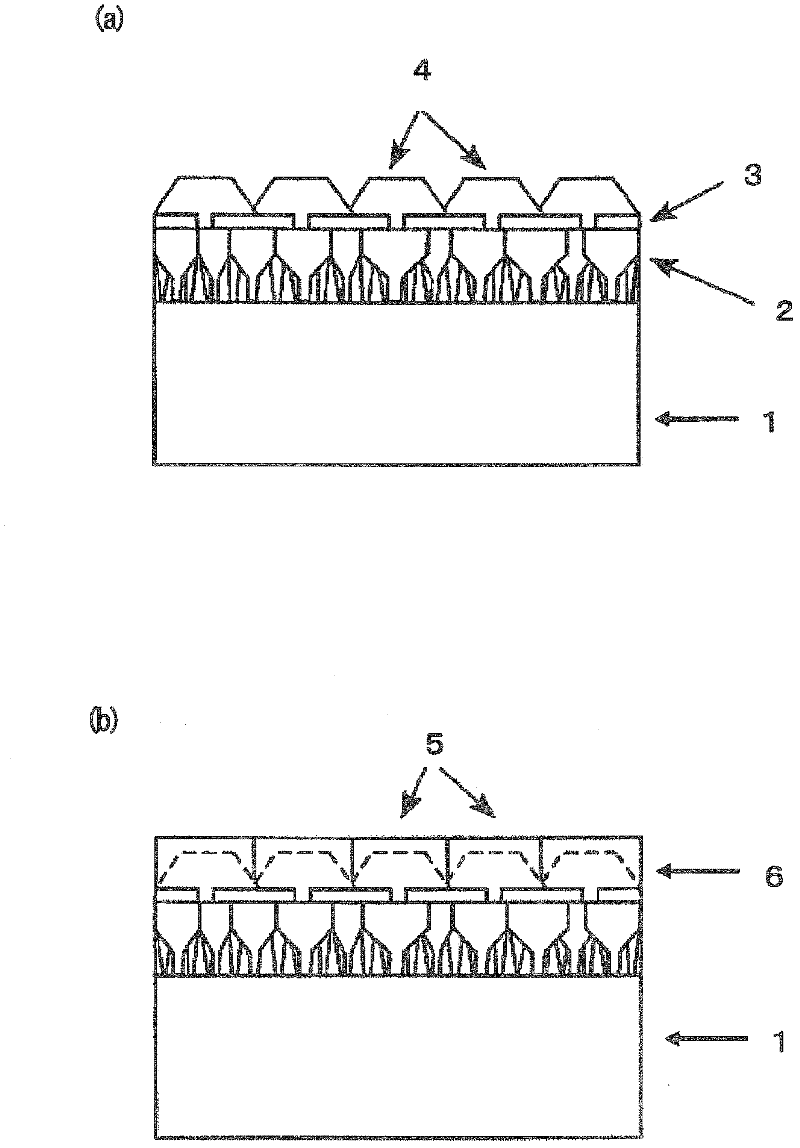

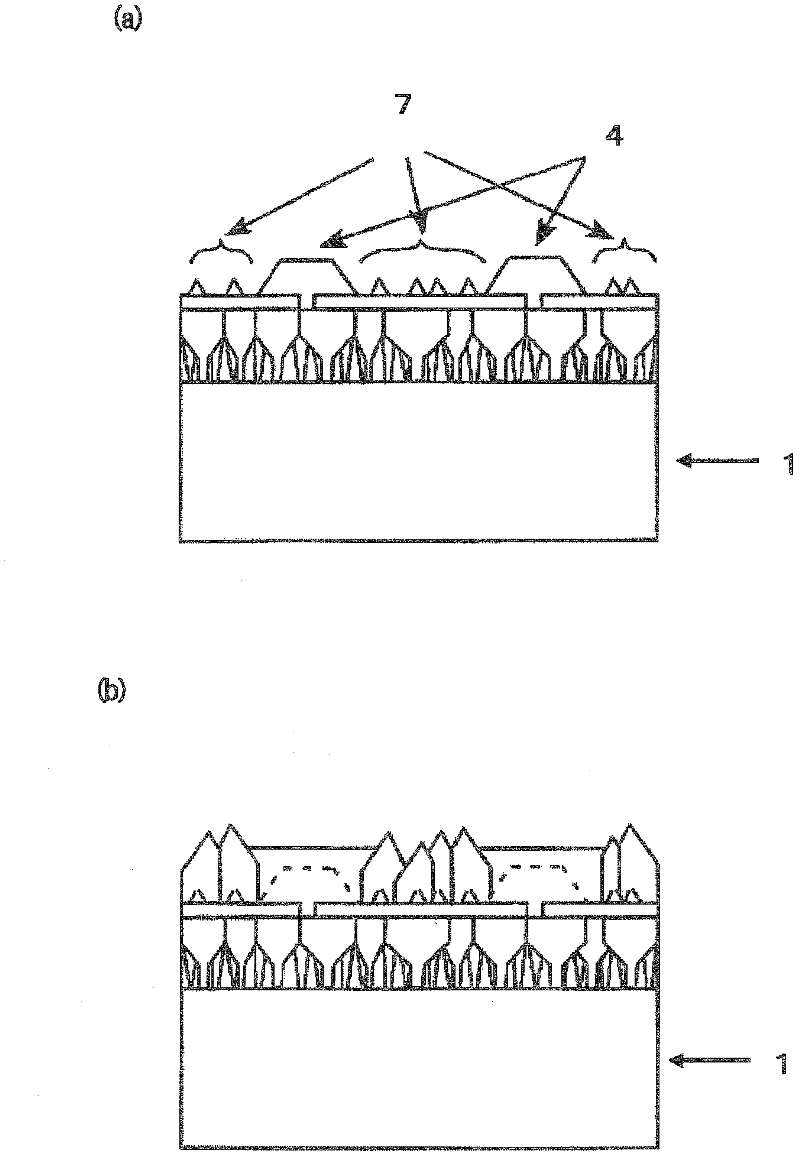

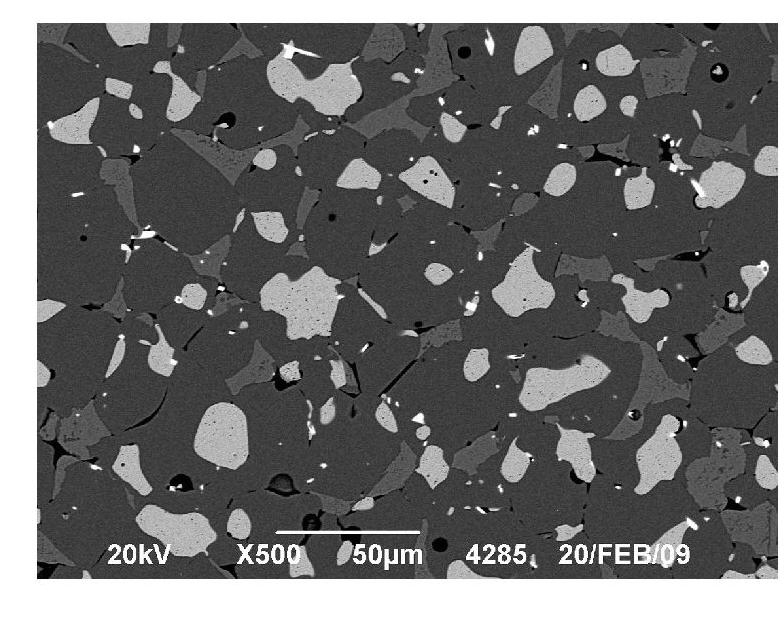

Martensitic Stainless Steel Produced by a Twin Roll Strip Casting Process and Method for Manufacturing Same

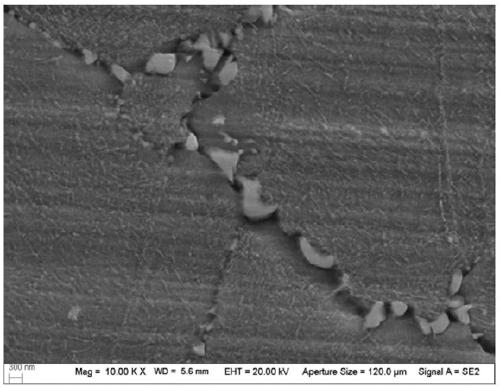

InactiveUS20120237390A1Promotes even distributionHigh hardnessFurnace typesMetal rolling arrangementsCrack resistanceSheet steel

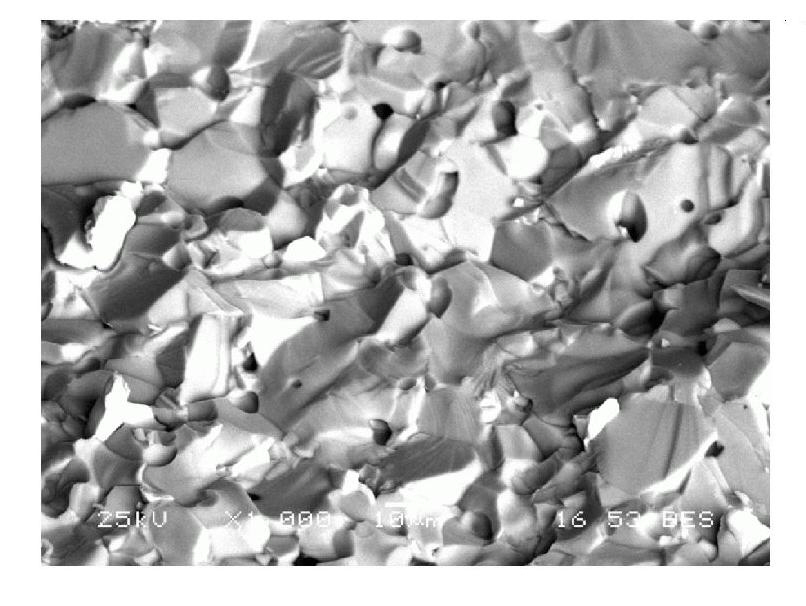

Provided is a martensitic stainless steel produced by a twin roll strip casting process and a method for manufacturing the same, wherein the hot rolled steel has superior crack resistance. The martensitic stainless hot rolled steel sheet comprises, by weight %, C:0.1 to 1.5%, Cr:12 to 15%, Ni:1% or lower, Ti:0.005 to 0.1%, and the balance Fe and unavoidably added impurities, and wherein a primary chrome carbide precipitated at a grain boundary is fragmented and refined. Provided is a high hardness martensitic stainless cold rolled steel sheet manufactured by annealing and cold rolling the hot rolled steel sheet, and a method for manufacturing the same. A twin roll strip casting process is applied, and grain boundary strengthening elements are added to prevent center segregation, crack and strip breakage during casting, thereby ensuring the stability of the casting process.

Owner:POHANG IRON & STEEL CO LTD

Array type diamond film and method for making the same

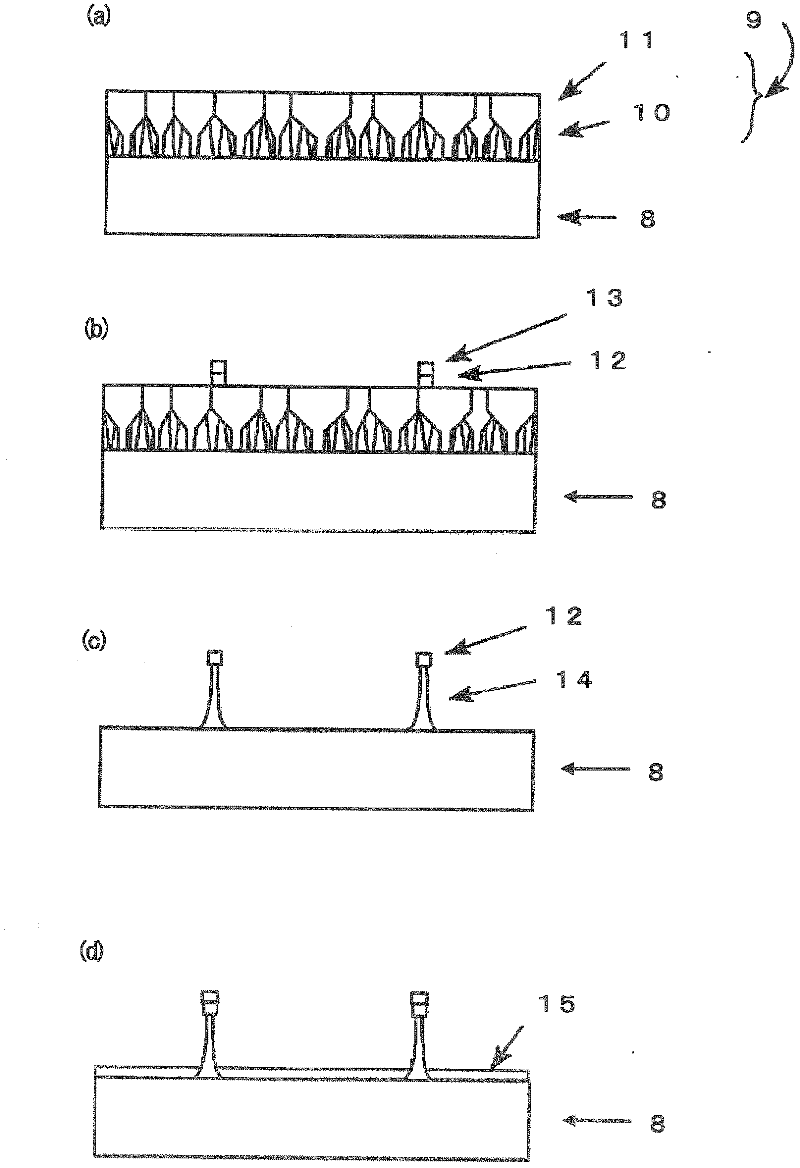

ActiveCN102345169AEfficient preparationEasy to splitPolycrystalline material growthFrom chemically reactive gasesRepeat patternSingle crystal

Provided is an array-type diamond film arranged with large scale polylateral diamond grains, which is configured by elements capable of easily avoiding grain boundary, thereby enable to manufacture the elements of high performance efficiently as upon a monocrystal substrate. Moreover, along the grain boundary segmentation, the element is more easily to be made. The array type diamond film, based on the information on crystallization direction, starts to grow into high orientation diamond film on the crystallized substrate of different material. On the surface, polylateral diamond grains are arranged as per the two-dimension repeating pattern with distance between the centers of gravity beyond 20 microns.

Owner:KOBE STEEL LTD

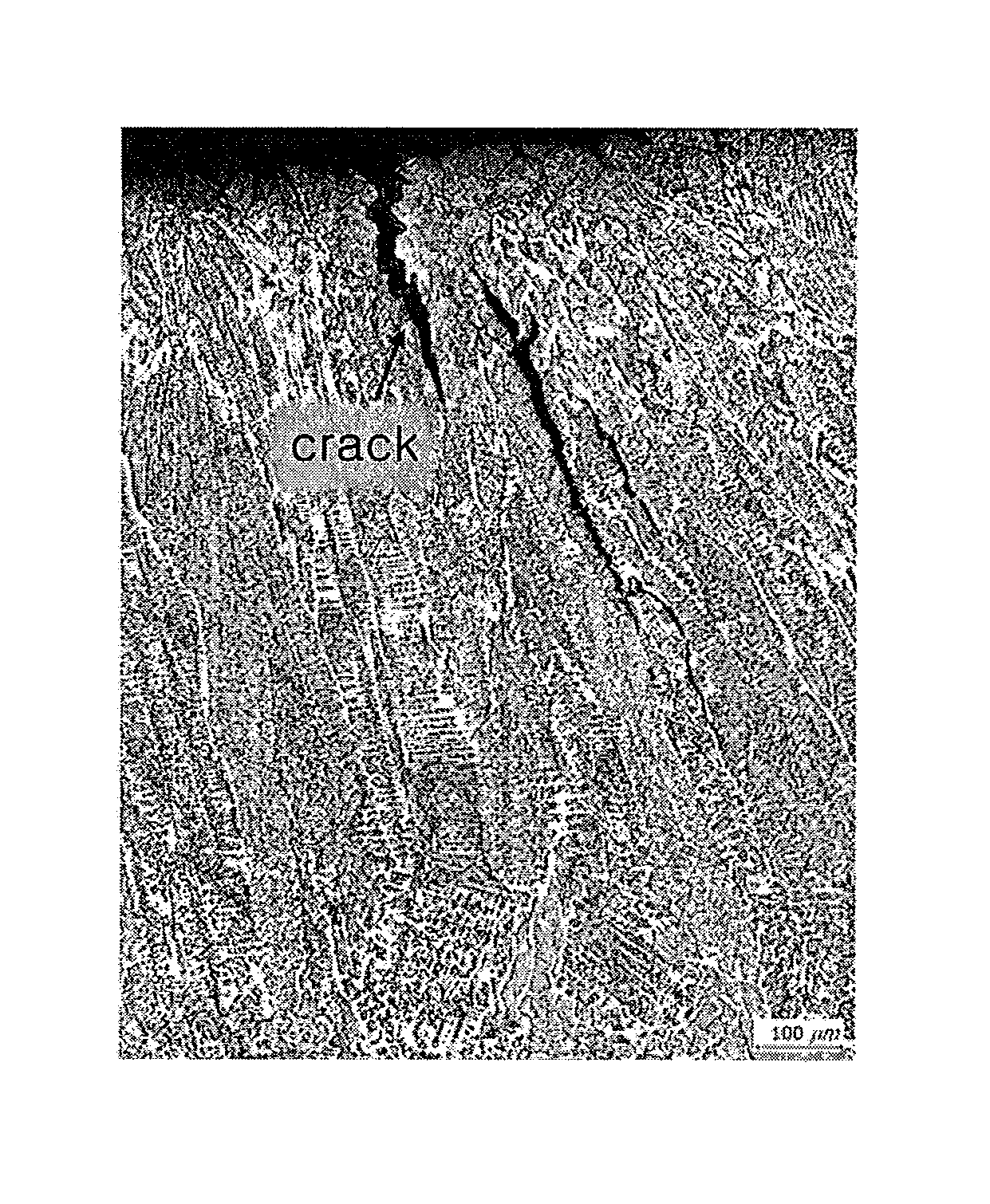

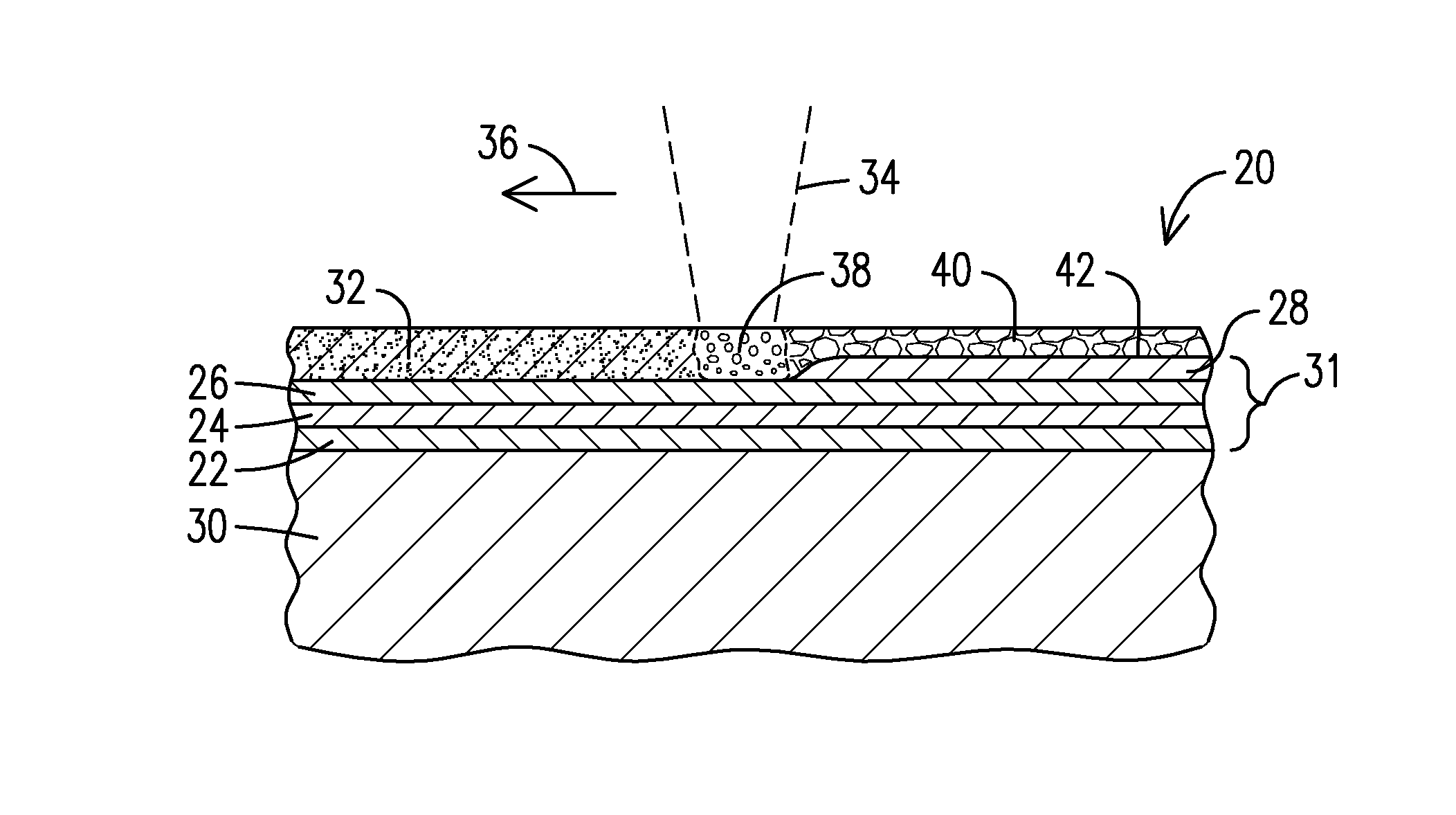

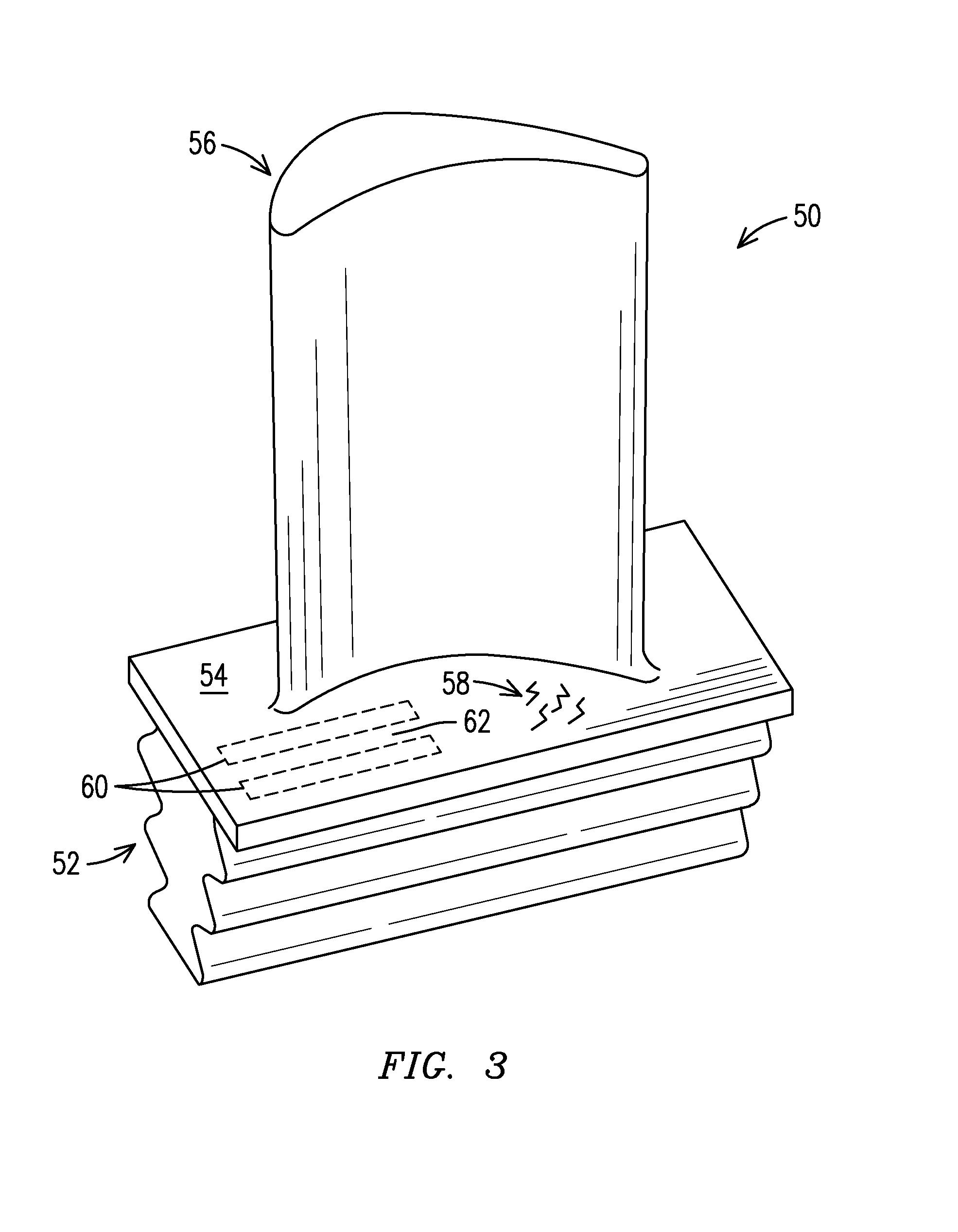

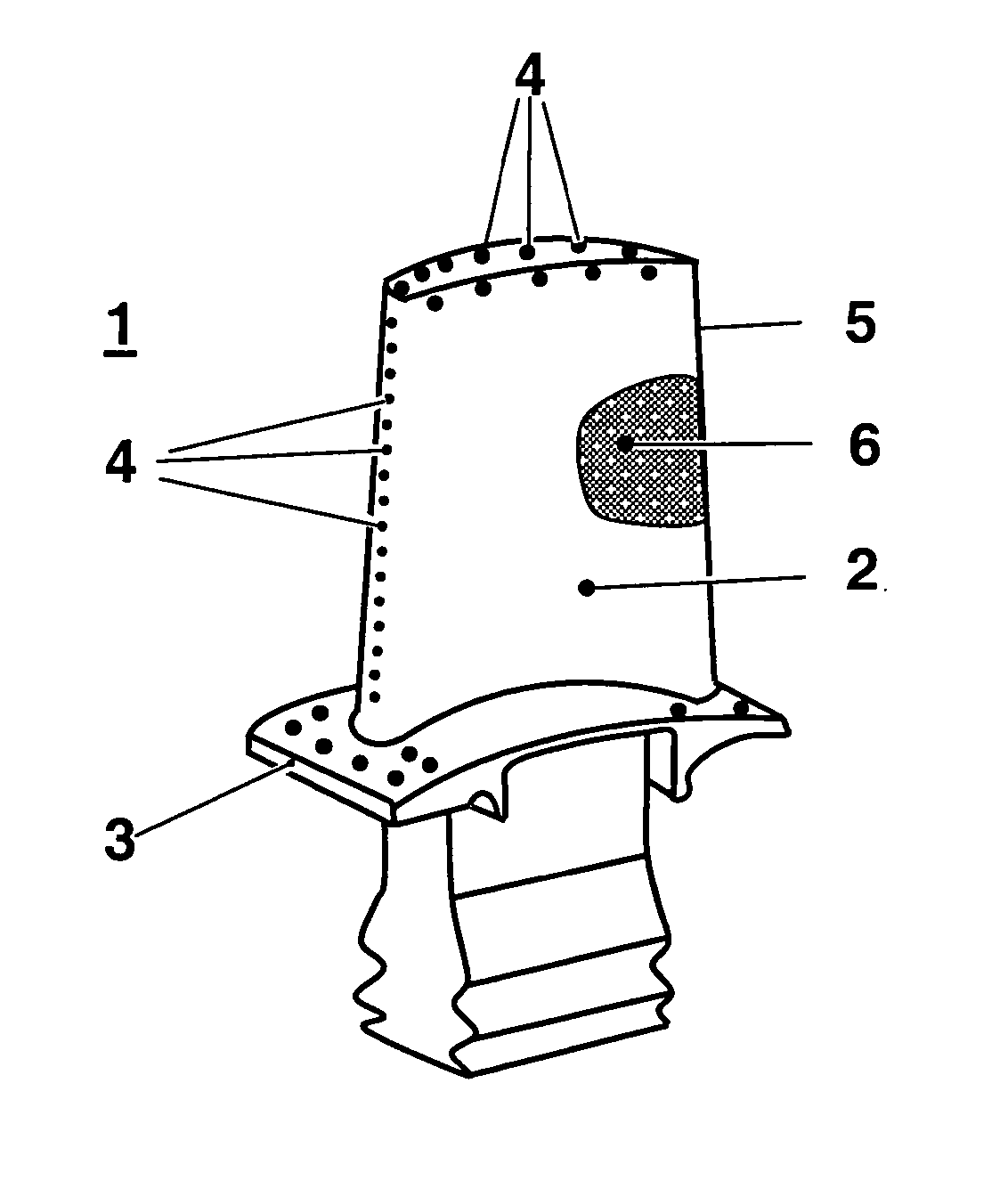

Functional based repair of superalloy components

A method of repairing or manufacturing a superalloy component (50) by depositing a plurality of layers (22, 24, 26, 28) of additive superalloy material having a property that is different than an underlying original superalloy material (30). The property that is changed between the original material and the additive material may be material composition, grain structure, principal grain axis, grain boundary strengthener, and / or porosity, for example. A region (60) of the component formed of the additive material will exhibit an improved performance when compared to the original material, such as a greater resistance to cracking (58).

Owner:SIEMENS ENERGY INC

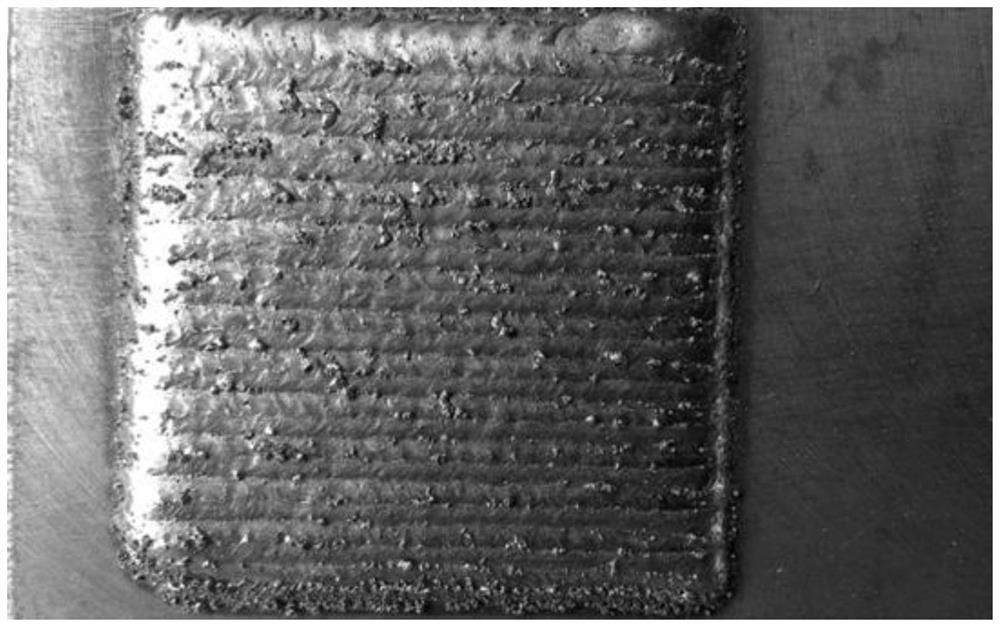

Laser cladding alloy powder and laser cladding method for H13 die steel

PendingCN110066995AImprove wettabilityImprove corrosion resistanceMetallic material coating processesNetwork structureAlloy

The invention discloses laser cladding alloy powder and a laser cladding method for H13 die steel. The the laser cladding method comprises the following steps that re-treating is carried out on a matrix before cladding; H13 plus nickel-clad WC alloy powder is prepared for laser cladding; the matrix is preheated; and a laser cladding machine is adopted, argon is used as protective gas, an optical fiber laser is an emitting laser source, the prepared laser cladding H13 plus nickel-clad WC alloy powder through a conical powder beam coaxial powder feeding mode is subjected to multi-channel lap joint to the matrix for laser cladding, laser cladding is carried out by controlling the laser power, the light spot diameter, the scanning speed and the powder feeding speed of laser cladding, and lasercladding of the H13 die steel is modulated and then is completed. According to the laser cladding method, the cladding layer forms a grain boundary strengthening type network structure, and has the characteristics of low friction coefficient, high wear resistance, high corrosion resistance and the like. The problem of dilution rate is reduced, the thermal stress is reduced, the metallurgical bonding with the matrix is increased, and the problem of easy cracking of large-area multi-channel lap joint is solved.

Owner:XIAN UNVERSITY OF ARTS & SCI

High-strength magnesium alloy tube

InactiveCN101805865AImprove mechanical properties at room temperatureHigh strengthBand shapeRare earth

The invention relates to a high-strength magnesium alloy tube containing the following components in percent by weight: 7.8%-9.2% of aluminum Al, 0.2%-0.8% of zinc Zn and 0.2%-0.5% of manganese Mn. The high-strength magnesium alloy tube is characterized by also containing 0.5%-2.0% of rare earth RE in percent by weight. Because the rare earth RE can react with the aluminum Al to generate an Al-RE compound, the dispersion-strengthening function of the Al-RE compound can improve the strength of alloy and refine crystal particles so that the amount of a Mg17Al12 phase in the alloy is reduced, the original continuous and semi-continuous net-shaped crystal boundary structure is gradually changed into an interrupted and dispersion-distribution belt-shaped structure so that the fine crystal strengthening and the crystal boundary strengthening are more obvious, and meanwhile, the rare earth RE has the function of strong solid-dissolving strengthening, and the comprehensive mechanical properties of the alloy at room temperature are improved.

Owner:嘉兴中科亚美合金技术有限责任公司

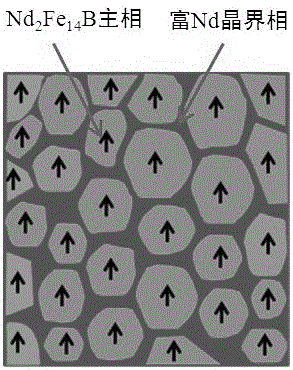

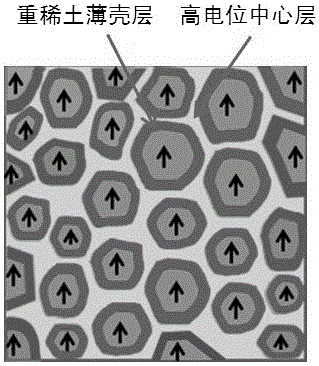

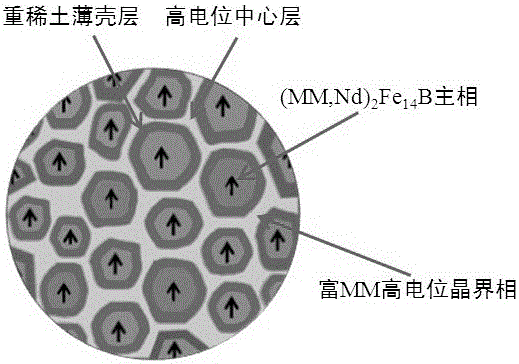

Preparation method of high-performance sintered Nd-Fe-B magnet with multi-layer grain boundary structure and prepared product

ActiveCN106653268AEffectively maintain stabilityImprove magnetic propertiesTransportation and packagingMetal-working apparatusElectrode potentialRare earth

The invention discloses a preparation method of a high-performance sintered Nd-Fe-B magnet with a multi-layer grain boundary structure and a prepared product, and aims at solving the problems of a single grain boundary strengthening effect, serious waste of heavy rare-earth resources and the like due to the fact that fine control on the grain boundary structure cannot be achieved in an existing method. According to the multi-layer grain boundary structure of the prepared magnet, a heavy rare-earth thin shell distributed on a grain boundary of a main phase has a relatively high magnetocrystalline anisotropy field, so that magnetic domain inversion of a weak area of the grain boundary in a reverse magnetic field can be inhibited, thereby improving the coercivity and the high-temperature stability of the magnet. Meanwhile, the heavy rare-earth thin shell is only distributed on the grain boundary of the main phase and is rarely diffused to the main phase and a center area of the grain boundary, so that the dosage of heavy rare earth can be greatly reduced and the production cost of the magnet is reduced. In addition, an electrode potential difference between a grain boundary phase and the Nd2Fe14B main phase can be reduced through formation of a high-potential grain boundary center layer in the magnet, the electrochemical corrosion drive force is reduced and the corrosion resistance of the magnet is obviously improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Low plastic aluminium piston alloy

A low-plasticity Al-alloy for piston is prepared from low-plasticity cast Al-alloy as basic component, As-enriched RE mixture, Sn, Pb, Zn, Cr and Ti. Its advantages are low linear expansibility, dnd high strength, hardness, volume stability and machinability.

Owner:江苏万里活塞轴瓦有限公司

Nickel base alloy powder for manufacturing anticorrosive coating of boiler tube

ActiveCN102021567AImprove performanceHigh hardnessMetallic material coating processesCrack resistanceTemperature resistance

The invention relates to nickel base alloy powder for manufacturing an anticorrosive coating of a boiler tube, which comprises 40 to 45 percent of Cr, 4 to 8 percent of Ti, 0.1 to 0.3 percent of Si, 0.1 to 0.3 percent of Nb, 0.1 to 0.3 percent of Y, 0.1 to 0.3 percent of Hf, 0.1 to 0.3 percent of B and the balance of Ni. The nickel base alloy powder has the excellent comprehensive properties by selecting strengthening elements of an alloy matrix and strengthening elements of a grain boundary of grain refinement and selecting the percentage content of each element preferably, so that the alloy has a higher melting point and higher wear-resisting and corrosion-resisting properties besides moderate rigidity and strength. Therefore, the crack resistance, moldability, process stability and component uniformity of the alloy powder in laser cladding coatings are improved fundamentally, and the requirements of the boiler tube on comprehensive properties of temperature resistance, corrosion resistance, wearing resistance, high strength and the like of the cladding coatings are met.

Owner:四川大成涡轮设备再制造技术有限公司

Alloy powder for gray pig iron laser cladding repair and preparation method thereof

ActiveCN104498774AImprove performanceOverall performance is moderateMetallic material coating processesCrack resistanceChemical composition

The invention provides alloy powder for gray pig iron laser cladding repair and a preparation method of the alloy powder. The alloy powder comprises the chemical components, by weight, 12% to 24% of Cu, 1.5% to 3.5% of C, 0.2% to 2.4% of Si, 0.01% to 0.05% of Al, 0.005% to 0.01% of Ba, 0.001% to 0.01% of Ca, 0.5% to 1.2% of Co, 0.0% to 0.04 % of Y2O3, 0.0% to 0.03% of La2O3, 0.0% to 0.04% of Ce and the balance Ni. According to the alloy powder, because alloy matrix strengthening elements, graphitizing-promoting elements and grain refinement grain boundary strengthening elements are added, and the percentages of the elements are adjusted, alloy acquires the excellent comprehensive performance, the alloy has both the appropriate hardness and the appropriate strength, the possibility of white cast tissue forming is reduced, shock resistance and fatigue resistance are improved, the crack resistance, the formability, the process stability and the component uniformity of the alloy powder in a laser cladding layer are improved, and an effective method convenient to use is provided for successive repair of gray pig iron parts.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

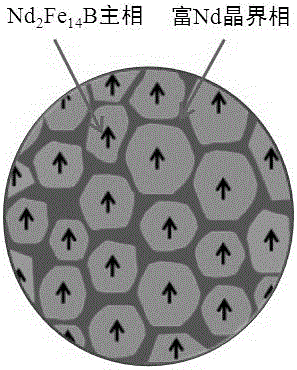

Preparation method of high-abundance rare earth sintered neodymium-iron-boron magnet capable of regulating and controlling grain boundary multi-layer structure and product prepared by preparation method

ActiveCN106601401AImprove coercive forceImprove corrosion resistanceInductances/transformers/magnets manufactureMagnetic materialsThin shellsRare earth

The invention discloses a preparation method of a high-abundance rare earth sintered neodymium-iron-boron magnet capable of regulating and controlling a grain boundary multi-layer structure and a product prepared by the preparation method, and aims at solving the problems that the grain boundary strengthening effect is single and waste of heavy rare earth resources is serious due to the fact that fine regulation and control on the grain crystal structure cannot be achieved by an existing method, and limited rare earth resources are greatly consumed along with a dramatic increase in the dosage of the magnet. According to the preparation method, preparation of the high-abundance rare earth sintered neodymium-iron-boron magnet capable of regulating and controlling the grain boundary multi-layer structure is achieved by adopting a double-alloy process and a second sintering technology. The prepared magnet has a double main phase structure and has an Nd2Fe14B main phase and an (La, Nd)2Fe14B / (Ce, Nd)2Fe14B main phase at the same time; and the grain boundary phase has a multi-layer grain boundary structure of a heavy rare earth thin shell layer / a high-potential grain boundary center layer containing high-abundance rare-earth / another heavy rare earth thin shell layer. According to the preparation method, overall improvement of the magnetic property and the corrosion resistance of the magnet is achieved through fine regulation and control on the grain crystal structure on the basis of achieving full utilization of the high-abundance rare earth; and the preparation method has relatively high application value and economic value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

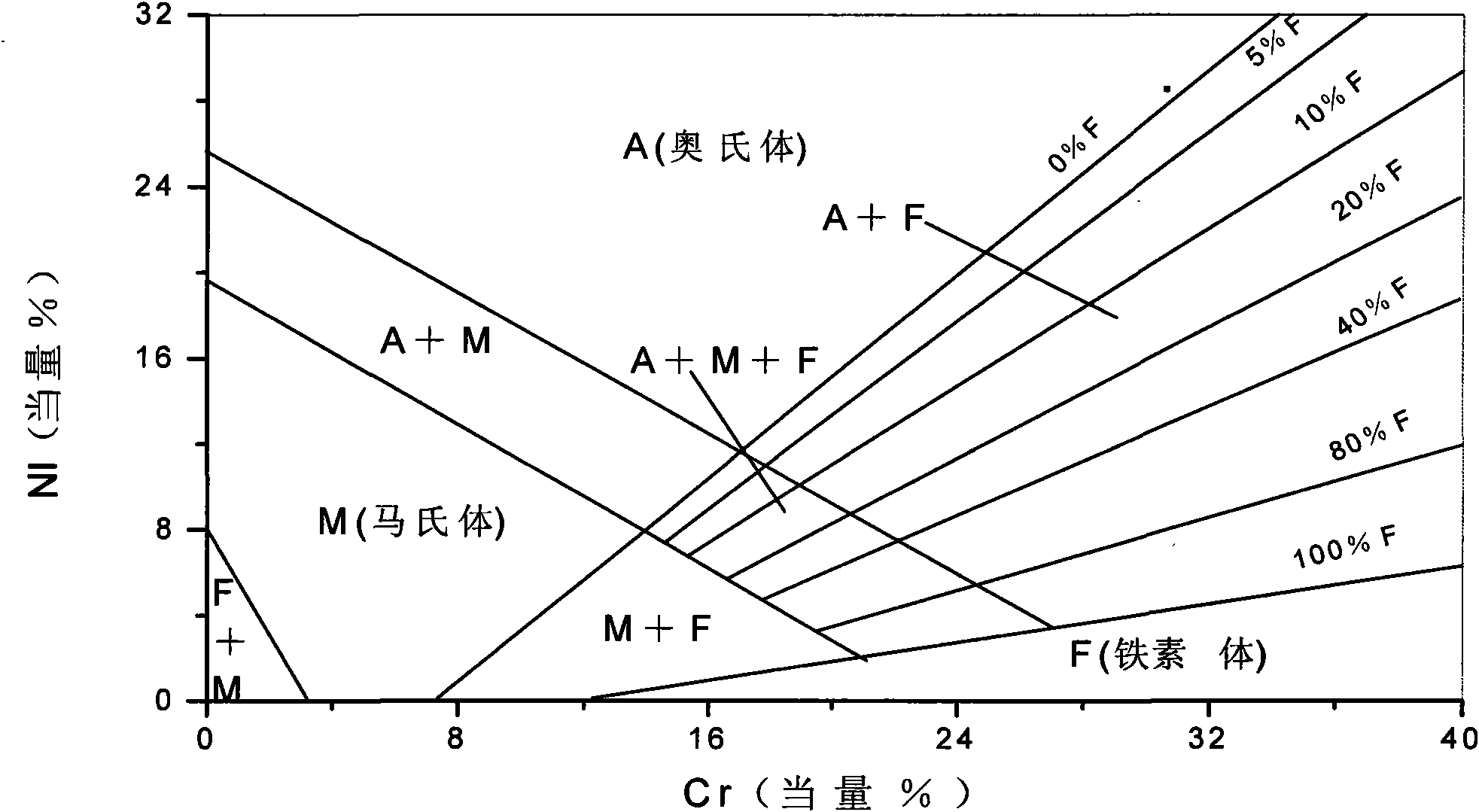

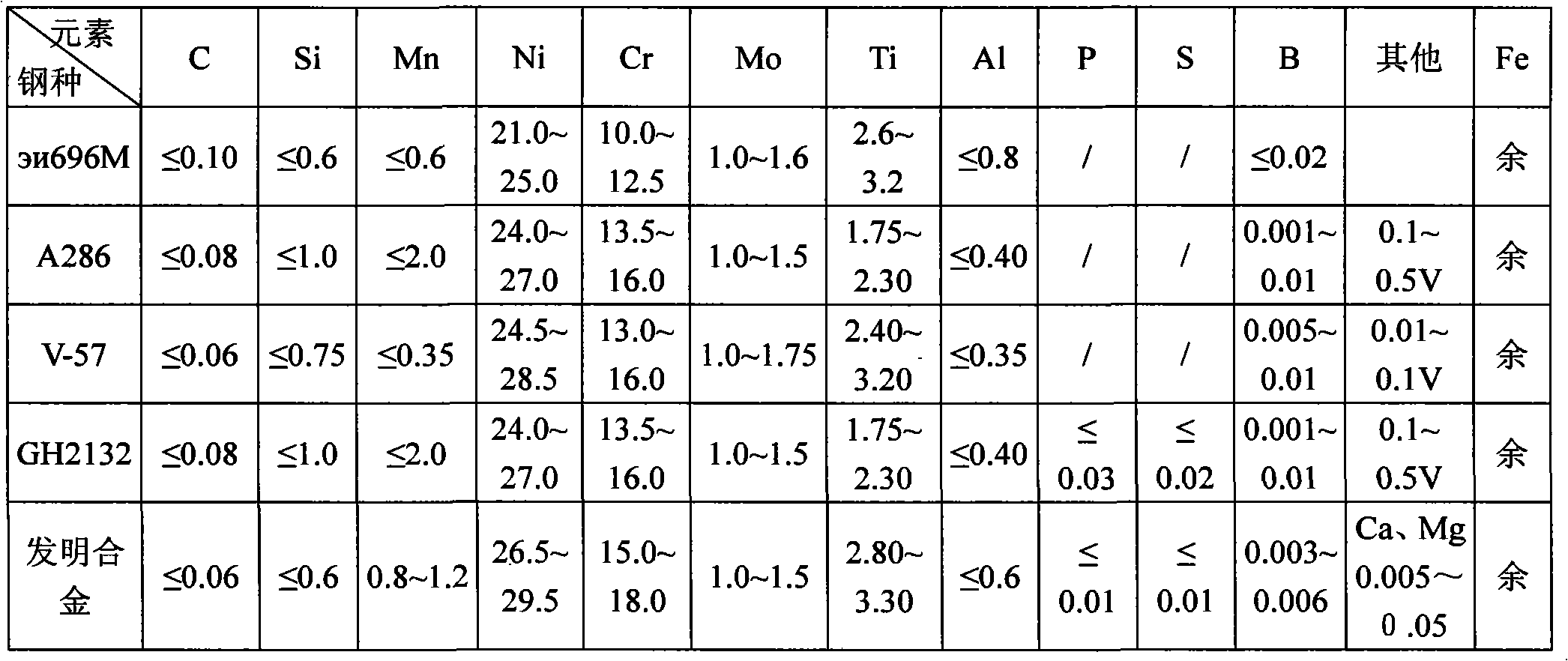

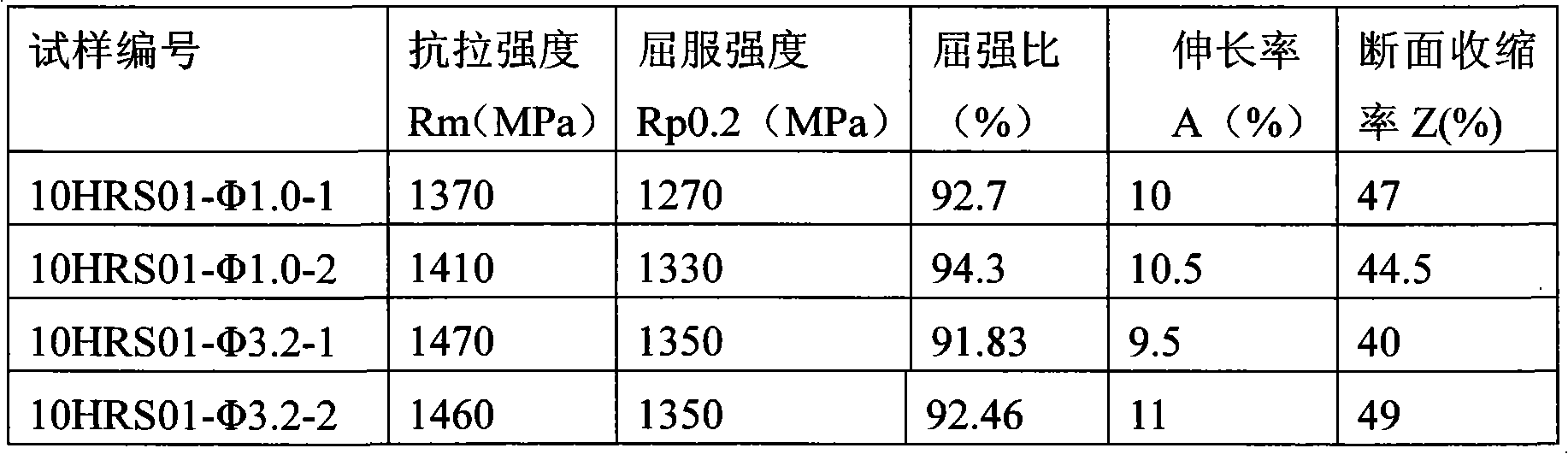

Heat-resisting alloy with high yield ratio, high toughness and long-run elasticity stability

The invention discloses a heat-resisting alloy with high yield ratio, high toughness and long-run elasticity stability, which is characterized by comprising the following components in percentage by weight: less than or equal to 0.06 percent of C, less than or equal to 0.6 percent of Si, 0.8 to1.2 percent of Mn, 26.5 to 29.5 percent of Ni, 15.0 to 18.0 percent of Cr, 1.0 to 1.5 percent of Mo, 2.80 to 3.30 percent of Ti, less than or equal to 0.6 percent of Al, 0.003 to 0.006 percent of B, 0.005 to 0.05 percent of Ca, 0.005 to 0.05 percent of Mg, and the balance of Fe. In the new alloy, alloy elements are added on the basis of Fe-Cr-Ni, the high yield ratio and high toughness are achieved, and the long-run elasticity stability is kept; and by controlling a Ti / Al ratio, optimizing the microstructures of intermetallic compounds and regulating the contents of B, Mo and C, the grain boundary strengthening effect is improved. The new ally fills up a blank on the research of the alloy in China, and meets the property requirements on high yield ratio, high toughness and long-run elasticity stability of the conventional aero high-temperature alloy parts of China.

Owner:CHONGQING MATERIALS RES INST

High-strength and high-plasticity high manganese steel material and machining method thereof

ActiveCN105200309AImprove plasticityEnhanced effect of grain boundary strengtheningManganeseMachining

Owner:YANSHAN UNIV

High-nickel ternary positive electrode material as well as preparation method and application thereof

PendingCN114436347APromote circulationImproved grain strengthCell electrodesSecondary cellsPhysical chemistryThermal stability

The invention provides a high-nickel ternary positive electrode material as well as a preparation method and application thereof. The high-nickel ternary positive electrode material is prepared from a high-nickel ternary precursor, a lithium source and an additive for improving the grain strength, the additive for improving the grain strength is enriched at the grain boundary; the preparation method comprises the following steps: a) uniformly mixing a high-nickel ternary precursor and a lithium source in a ball mill at a high speed, and introducing an additive for improving the grain strength through low-speed mixing to obtain mixed powder; the speed of the high-speed mixing is 250 to 600 rpm (revolutions per minute); the speed of the low-speed mixing is 50 rpm to 200 rpm; and b) sintering, washing, drying and re-burning the mixed powder obtained in the step a) in sequence to obtain the high-nickel ternary positive electrode material. Compared with the prior art, the additive can be enriched at the grain boundary, the ternary positive electrode material which is strengthened in grain boundary, excellent in particle pressure resistance and good in chemical stability and thermal stability is obtained, and the cycle performance, the DCR performance and the gas production performance of the positive electrode material are obviously improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Centrifugation device high-temperature alloy used for glass wool production

The invention discloses centrifugation device high-temperature alloy used for glass wool production. The alloy comprises the following chemical components according to the weight percent: 0.65% to 0.75% of C, 28.5% to 30.5% of Cr, 4.0% to 6.5% of Co, 4.5% to 6.0% of W, 3.0% to 5.0% of Mo, 4.8% to 5.9% of Al, 2.0% to 3.0% of Ti, 0.01% to 0.05% of Ce, 0.01% to 0.05% of B and the balance of Ni. Because of unique formulation, the alloy obtains excellent high-temperature mechanical property, high-temperature corrosion-resisting property and high-temperature oxidation resistance property under the composite action of technical means of solid solution strengthening, precipitation strengthening, crystal boundary strengthening, and the like, and the service life is obviously enhanced.

Owner:WUXI YITONG MECHANICAL TECH

High-performance silicon carbide ceramic material and preparation method thereof

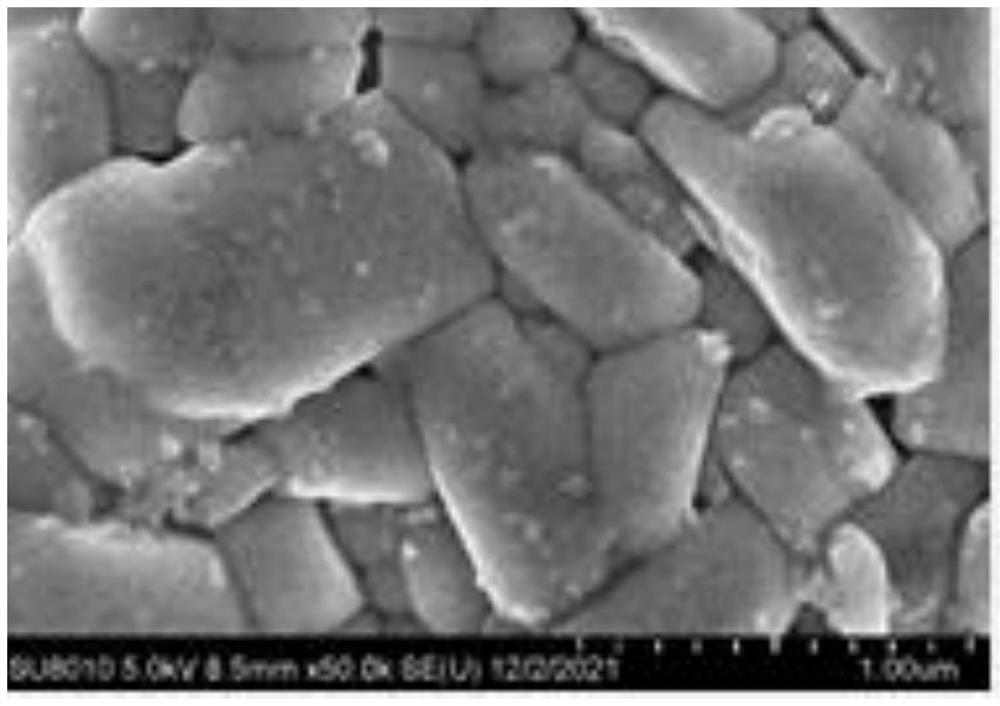

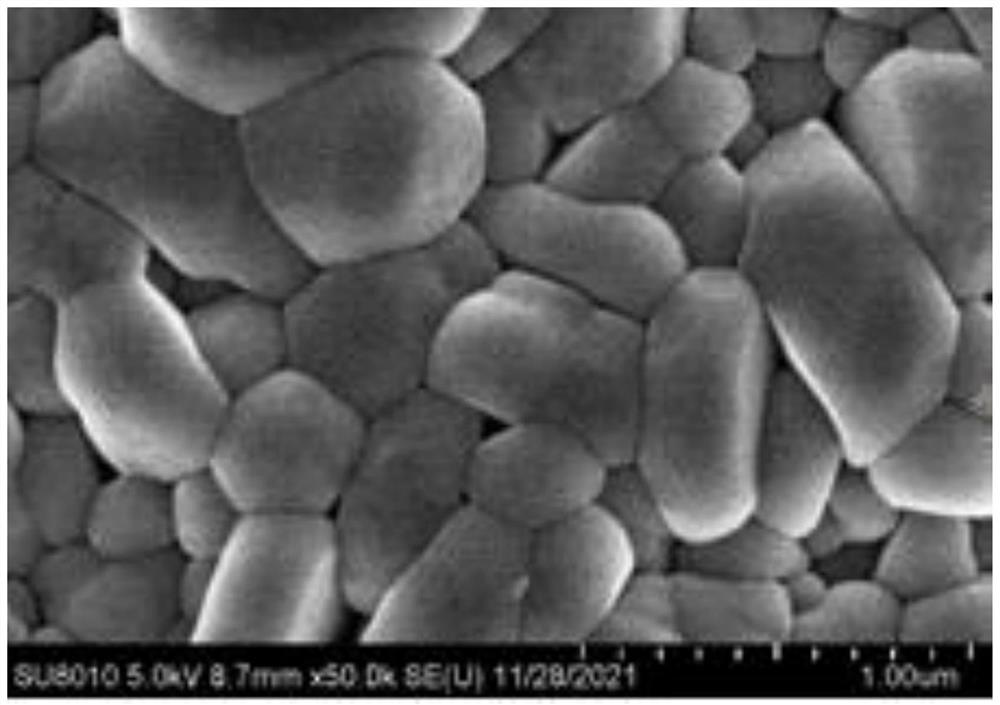

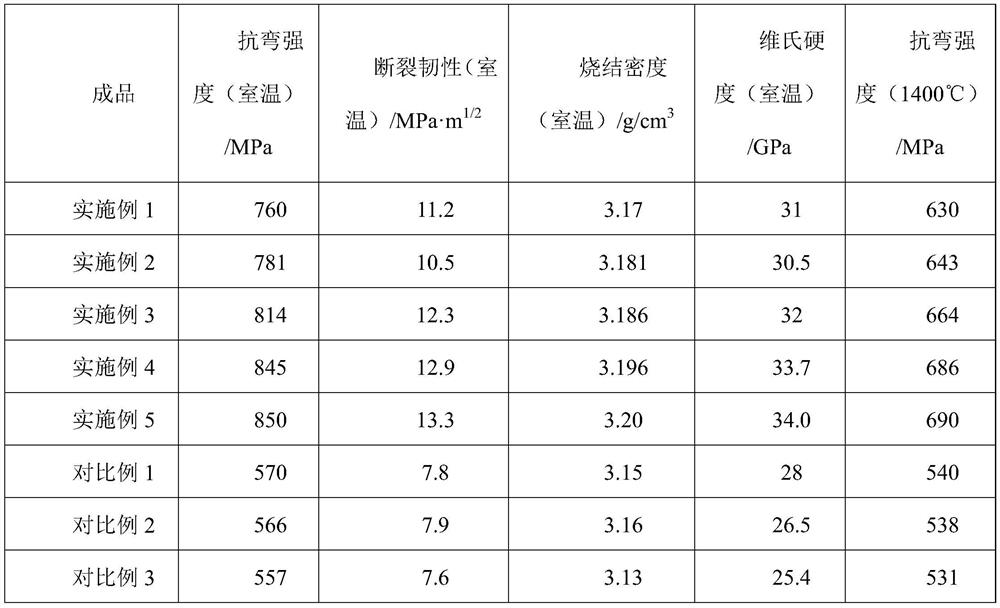

PendingCN112778014AImprove sintered densityImprove toughnessChemical industryCarbide siliconSpray Granulation

The invention relates to a high-performance silicon carbide ceramic material and a preparation method thereof. The preparation method comprises the following steps of raw material preparation, ball-milling mixing, spray granulation, compression molding and sintering. Through the adding proportion of alpha-silicon carbide powder and beta-silicon carbide powder in the raw materials, grain boundary strengthening and grain refinement are facilitated, and further, the obdurability and the hardness of the silicon carbide ceramic are improved. The sintering temperature range can be expanded by proper sintering aid composition, and convenience is brought to process control; the sintering aid is B4C, C and AlN, and when the mass ratio of B4C to C to AlN is (1-2): (1.5-3): (1-3), the sintering aid can better improve the interface bonding strength between silicon carbide grains and promote the improvement of high-temperature strength. When the sintering temperature is 2050 DEG C, the sintering density of the silicon carbide ceramic material is high. The prepared silicon carbide ceramic material has excellent room-temperature and high-temperature mechanical properties.

Owner:东莞市康柏工业陶瓷有限公司

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

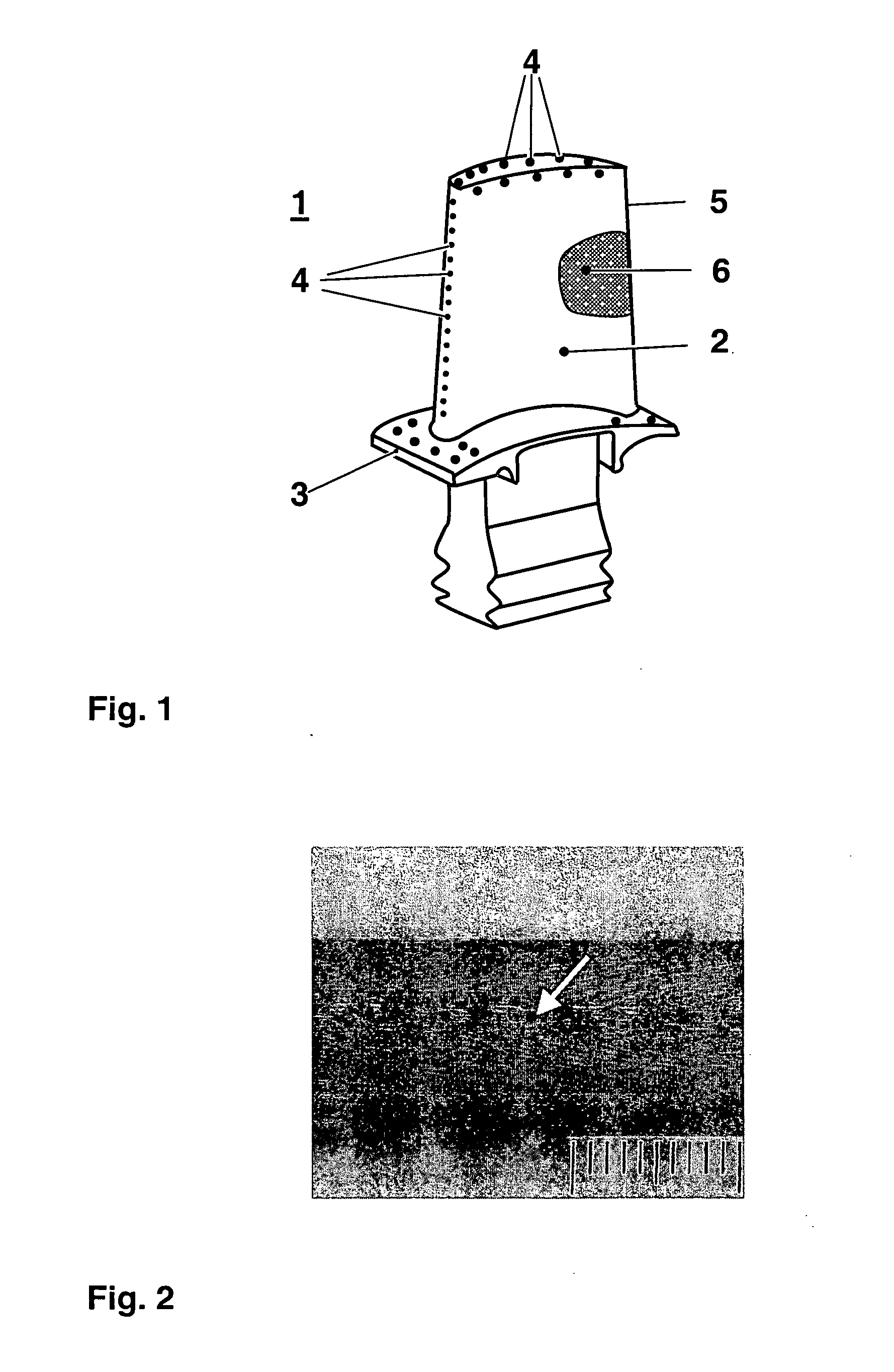

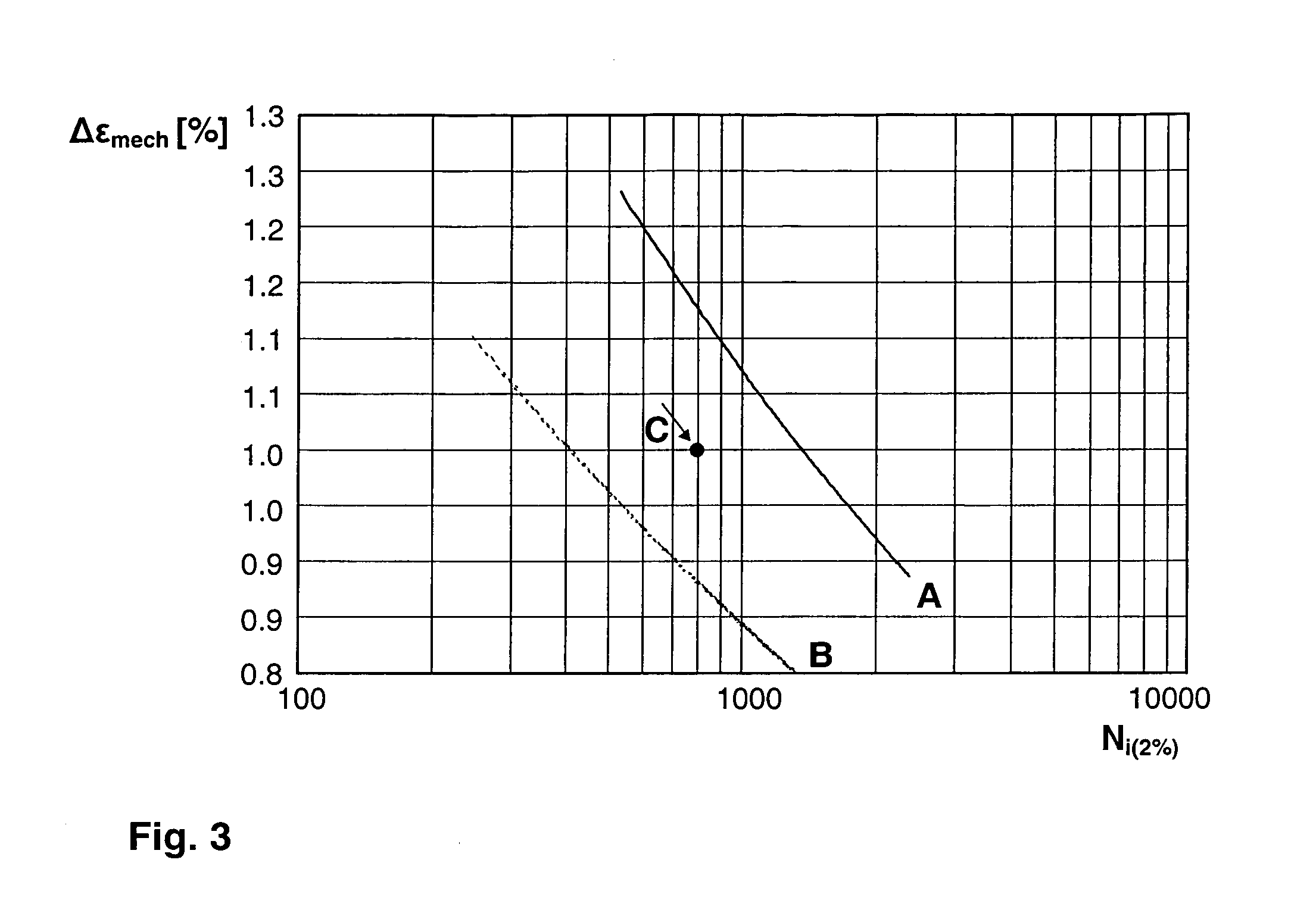

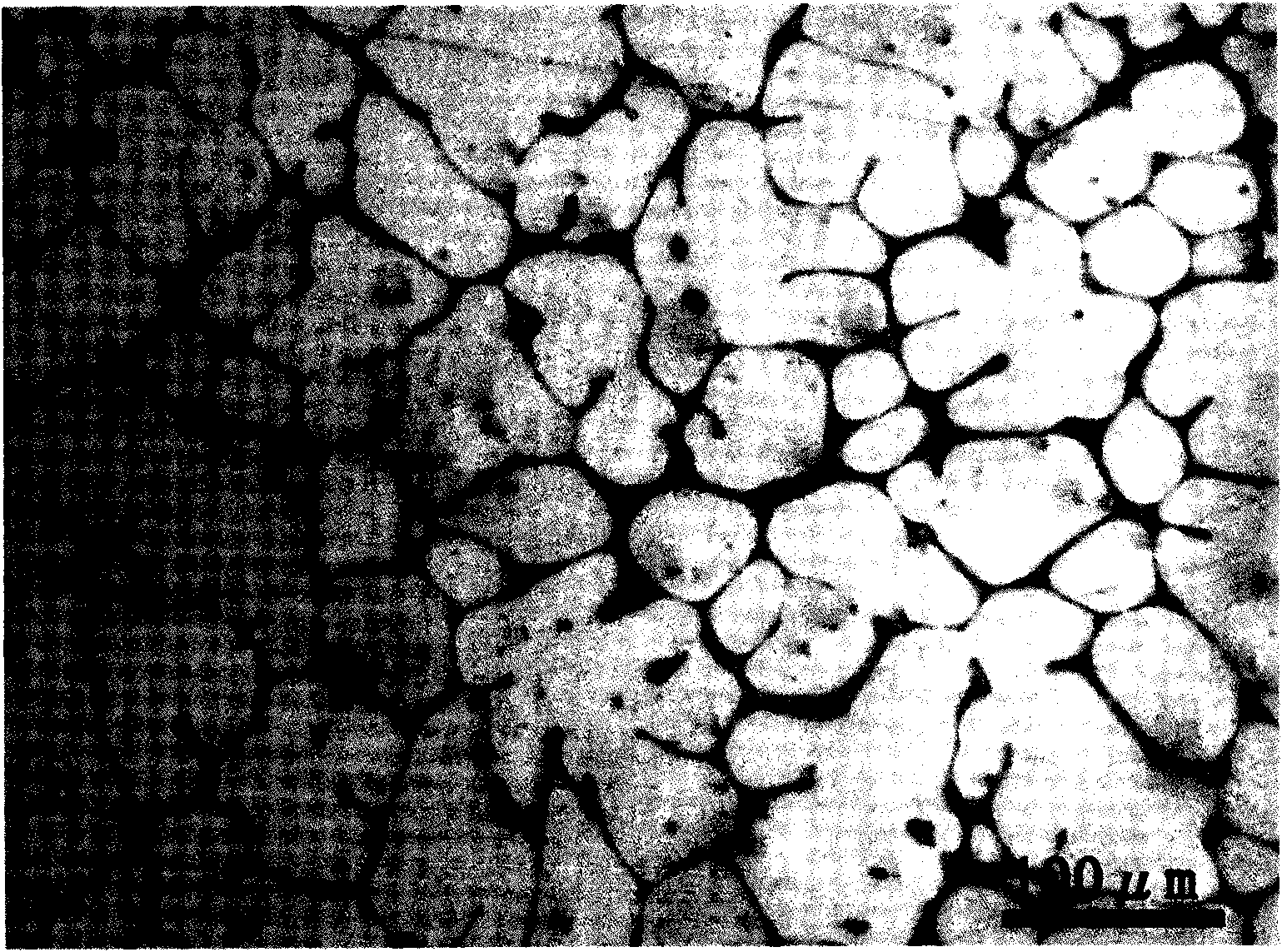

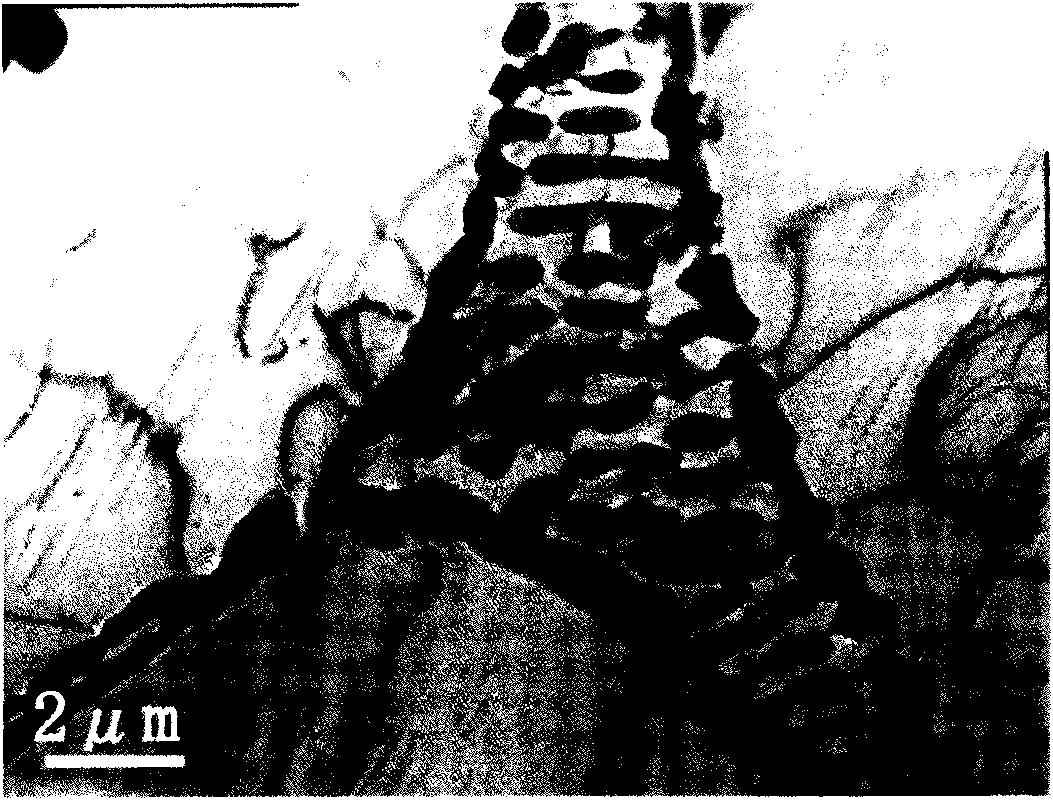

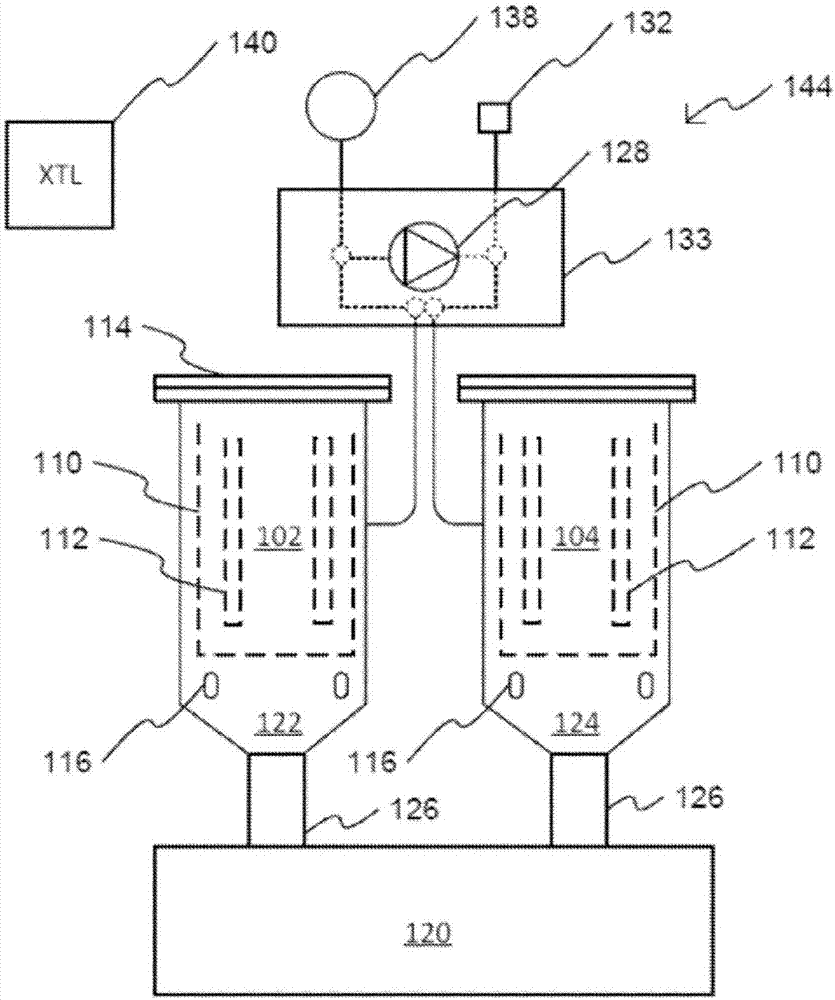

Process for strengthen grain boundaries of an article made from a Ni based superalloy

ActiveUS20050061228A1Defective mechanical propertyEliminate the effects ofPolycrystalline material growthAfter-treatment detailsBorideCarbide

It is disclosed a method for strengthen the grain boundaries of an article (1) made from a Ni based superalloy while the article (1) is in the solid state and containing at least one grain boundary. A surface diffusion process is applied to the article (1) to enrich the at least one grain boundary with grain boundary strengthening elements of one or a combination of boron, hafnium, zirconium without forming brittle precipitates like borides or carbides.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Heat-resistant magnesium alloy

A heat-resistant magnesium alloy comprising Mg as a main component; at least any one selected from among Al and Ni as a first alloy element (M1); at least any one selected from among Mn, Ba, Cr and Feas a second alloy element (M2); and Ca. This heat-resistant magnesium alloy has a metallographic structure containing Mg crystal grains; platelike precipitates having precipitated within the Mg crystal grains; and grain boundary crystallizates having crystallized at boundaries of the Mg crystal grains and forming a microscopically continuous network. By virtue of the presence of the platelike precipitates within the Mg crystal grains, the transfer of dislocation within the Mg crystal grains is blocked to thereby restrict any deformation. Further, by virtue of the microscopically continuous presence of network forming grain boundary crystallizates at boundaries of the Mg crystal grains, the grain boundary strength is enhanced. This magnesium alloy having its Mg crystal grain interiors andboundaries simultaneously strengthened retains high mechanical properties even in high temperature region.

Owner:TOYOTA IND CORP

High temperature resistant molten salt corrosion ceramet anode material and preparation method thereof

InactiveCN101586246BImprove corrosion resistance of molten saltGuaranteed uptimeRare earthLanthanide

The present invention provides a kind of high temperature resistant molten salt corrosion ceramet anode material and a preparation method thereof. The referred ceramet inertness anode material is composed of the following components by weight: 50% to 95% of spinelle type oxide, 1% to 30% of other oxide, 1% to 30% of metal or alloy, and 0.1% to 2% of grain boundary corrosion resistant energizing agent. The raw material is added with a given amount of +3 value lanthanide series rare-earth oxide powder, the rare-earth oxide and a ceramic matrix react with each other during a sintering process toform high temperature resistant molten salt corrosive ferrate new phase along the grain boundary, and simultaneously accelerate the elimination of communication between the grain boundary and breathing holes as well as densification of the sintering material, so as to improve the high temperature resistant molten salt corrosive performance of the material especially the grain boundary region.

Owner:CENT SOUTH UNIV

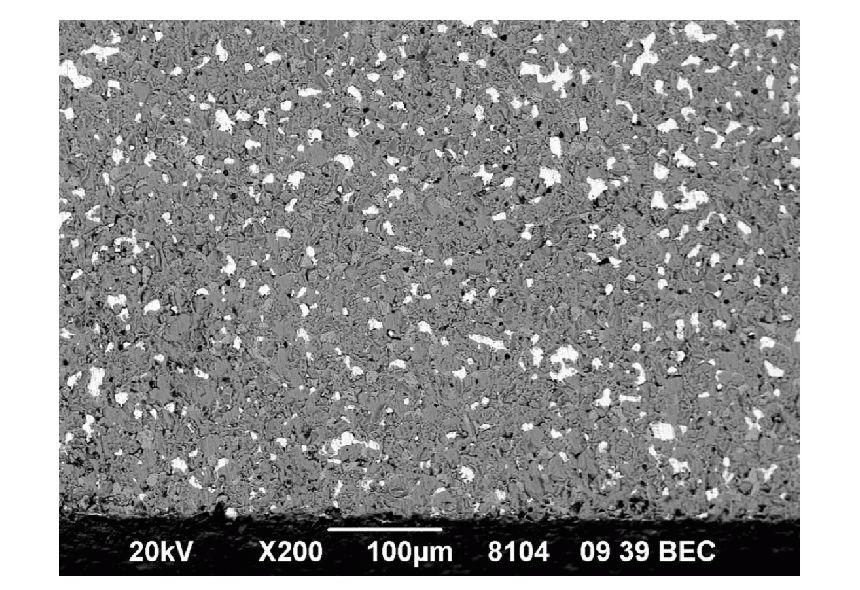

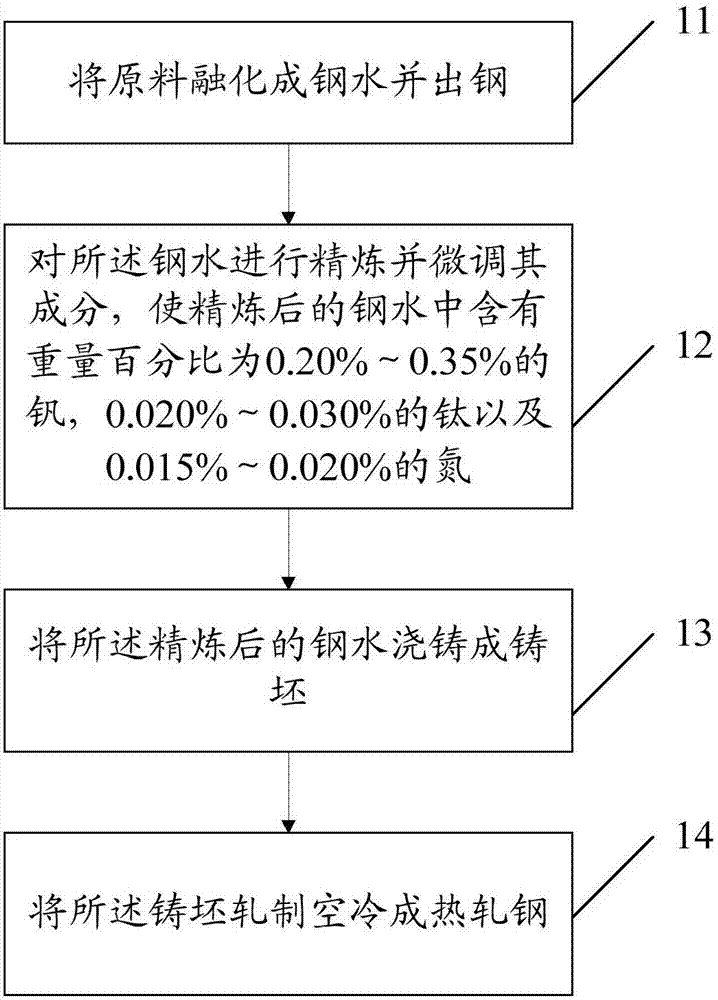

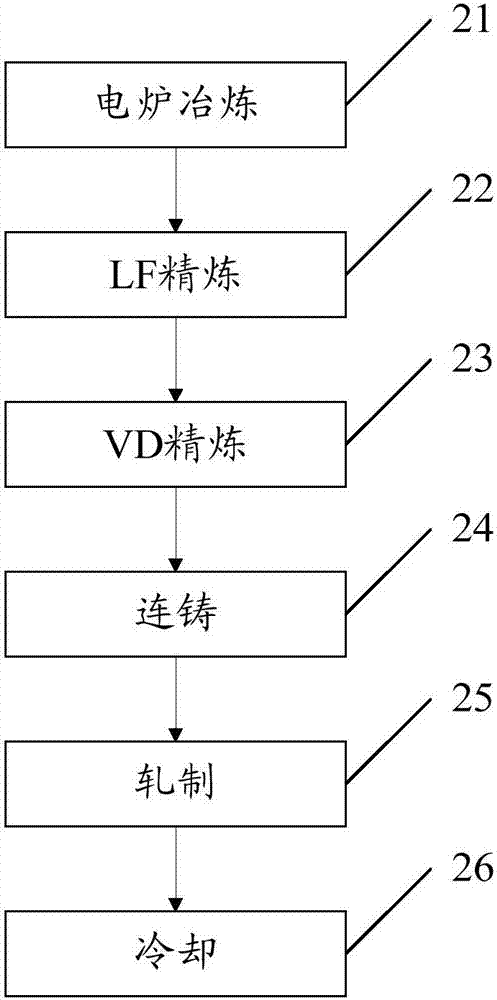

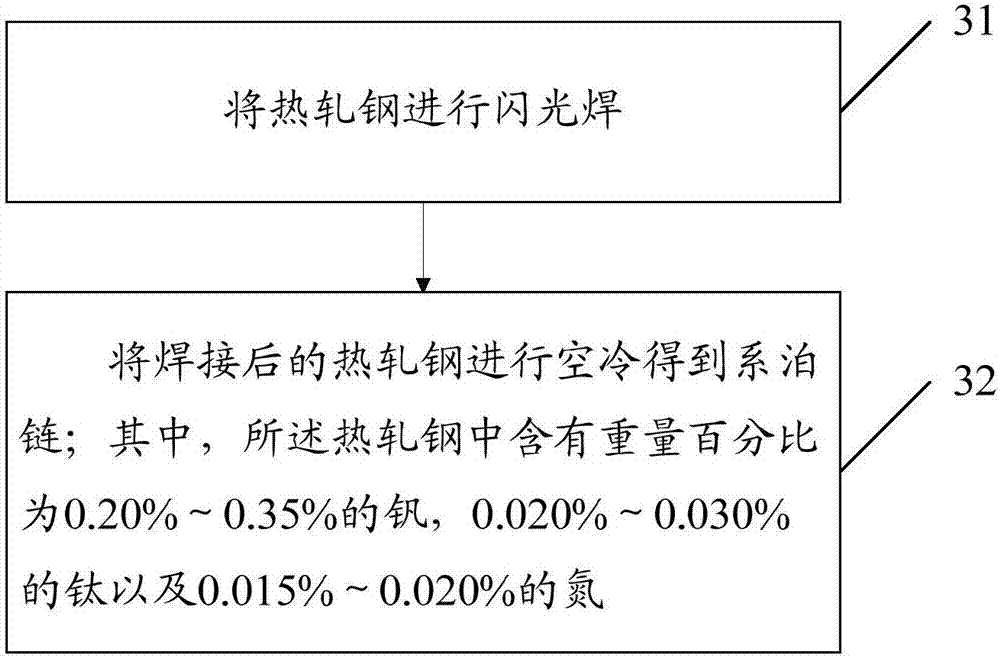

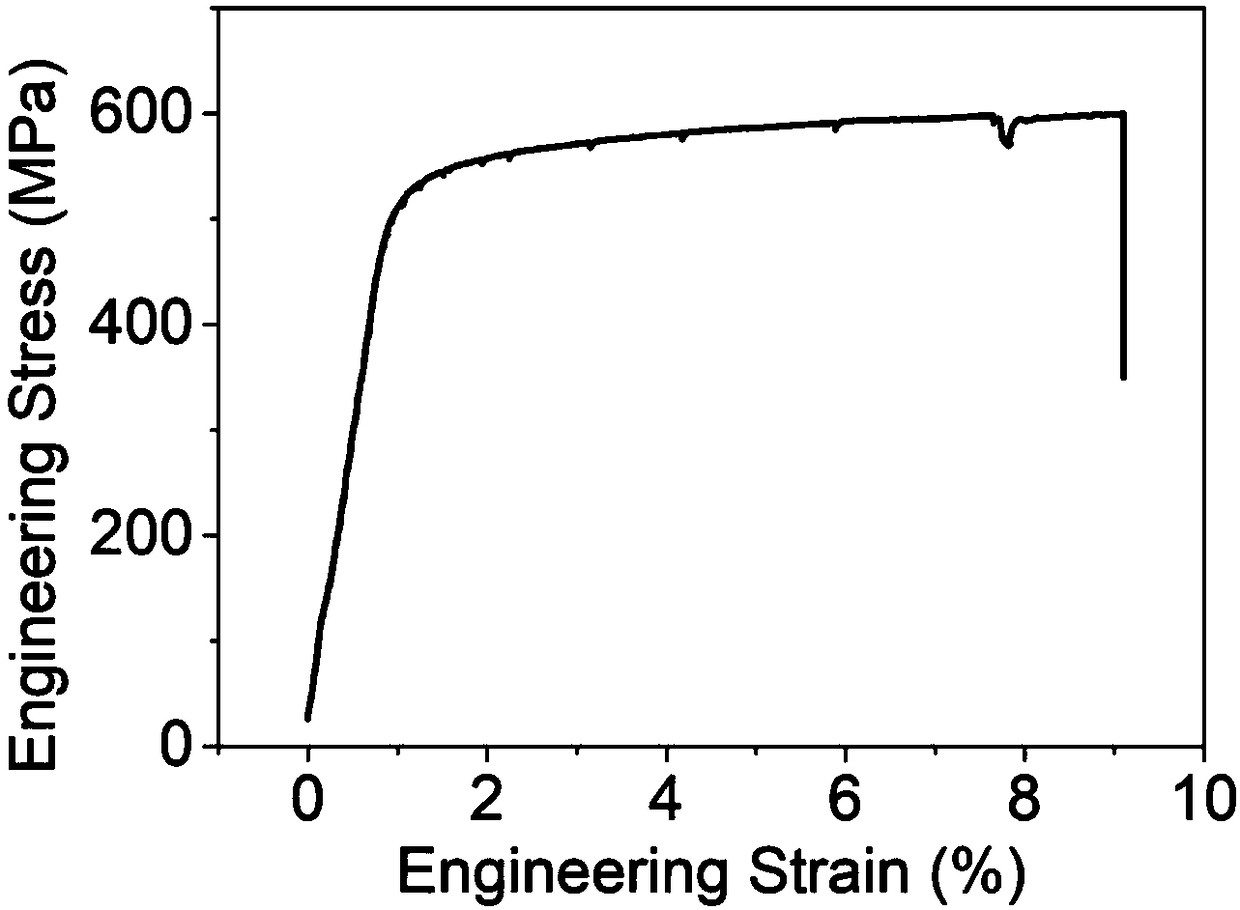

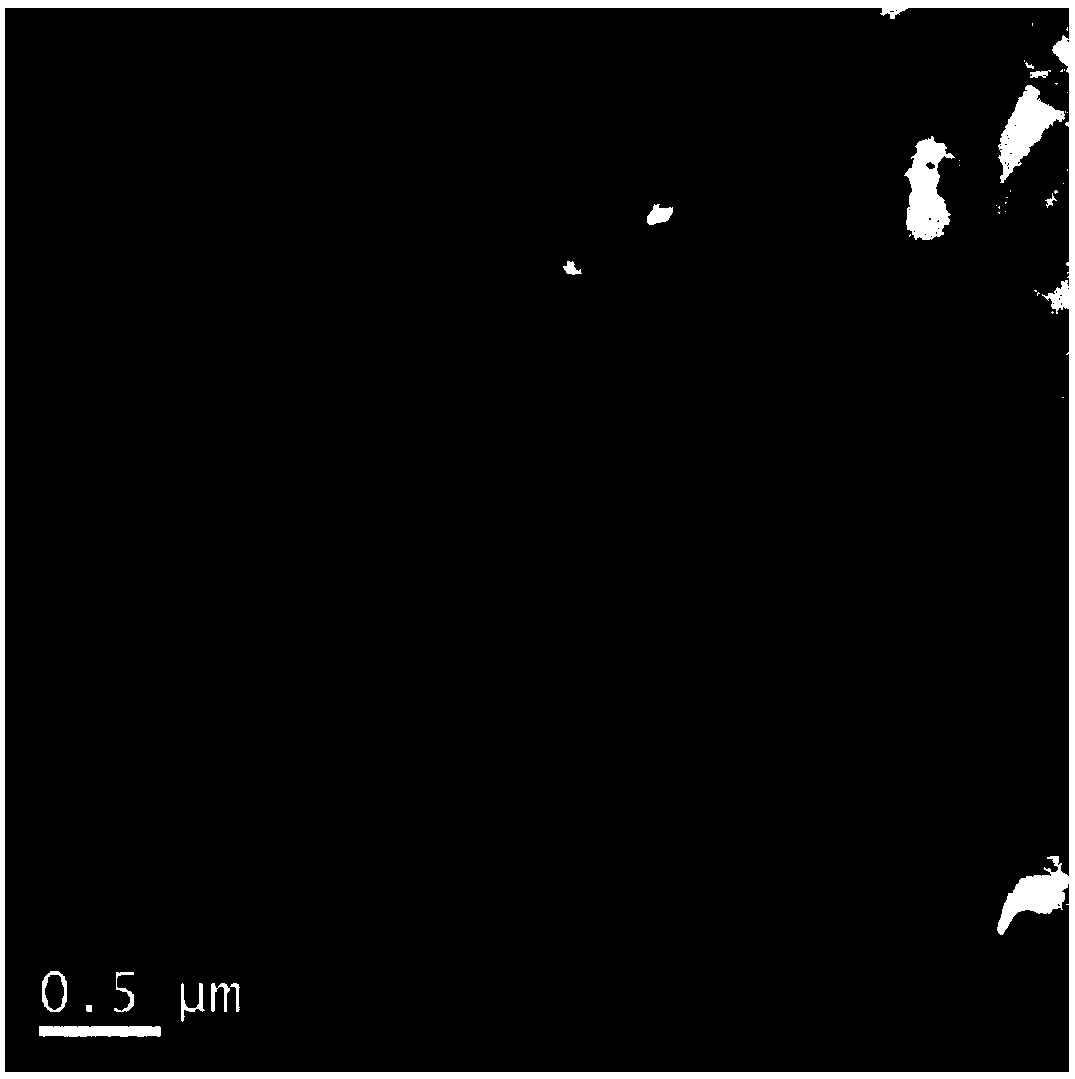

Hot rolled steel, manufacturing method of hot rolled steel, mooring cable and manufacturing method of mooring cable

ActiveCN107304458AReduce manufacturing costReduce energy consumptionWaterborne vesselsPrecipitationHeat treated

The invention provides hot rolled steel, a manufacturing method of the hot rolled steel, a mooring cable and a manufacturing method of the mooring cable. The manufacturing method of the hot rolled steel comprises the steps that raw materials are melted into molten steel, and steel tapping is conducted; the molten steel is refined, constituents of the molten steel are slightly adjusted, and accordingly, the refined molten steel comprises, by weight, 0.20-0.35% of vanadium, 0.020-0.030% of titanium and 0.015-0.020% of nitrogen; the refined molten steel is cast into a cast blank; and the cast blank is rolled and air-cooled into the hot rolled steel. According to the scheme provided by the invention, microalloying (V, Ti and the combination element N of V and Ti are added ) is conducted during steel smelting production, the finish rolling temperature is controlled in the steel rolling process, thus, the precipitation amount of VN and Ti3N4 in the grain boundary and primary-precipitated ferrite is controlled, the purposes of grain boundary strengthening and dispersion strengthening are achieved, and the hot rolled steel with the toughness being identical to that of steel which comprises a large quantity of alloy elements and is subjected to tempering treatment is obtained; and in addition, heat treatment does not need to be conducted in the manufacturing process, the production cost is greatly reduced, and energy consumption is reduced.

Owner:NEW FOUNDER HLDG DEV LLC +2

Preparation method for deforming Al-Mg alloy with ultrahigh Mg content

ActiveCN108330420AImprove solid solution strengtheningEnhanced dislocation strengtheningManufacturing technologyIngot

The invention relates to a preparation method for a deforming Al-Mg alloy with ultrahigh Mg content. The preparation method comprises the following steps of firstly, carrying out component homogenization treatment, densification treatment, and solid solution treatment for forming a single-phase solid solution on an Al-Mg alloy ingot at the temperature of 0-80 DEG C lower than the alloy solidus temperature; then carrying out plastic deformation at the temperature of 20-300 DEG C; and carrying out annealing at the temperature of 50-300 DEG C according to requirements so as to obtain the final deforming Al-Mg alloy with ultrahigh Mg content. Compared with an existing industrialized deforming and casting Al-Mg alloy manufacturing technology, the preparation method has the advantages that solidsolution strengthening, dislocation strengthening and grain boundary strengthening of Mg can be enhanced, and the strength of the Al-Mg alloy can be improved; and compared with a deforming Al-Mg alloy with ultrahigh Mg content prepared through severe plastic deformation and nanocrystalline powder consolidation, the method has the advantages that a large amount of deforming Al-Mg alloys with ultrahigh Mg content can be prepared efficiently at low cost, and a wide industrialization prospect can be achieved.

Owner:WUHAN UNIV OF TECH

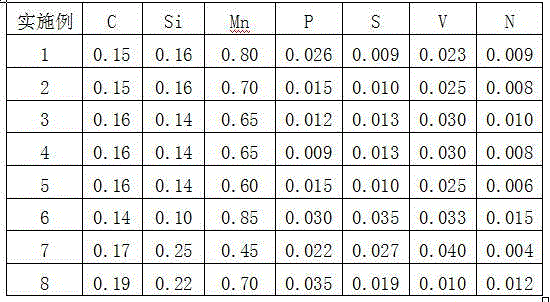

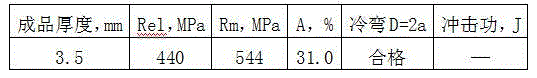

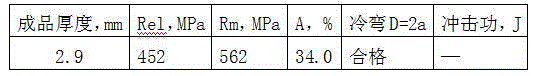

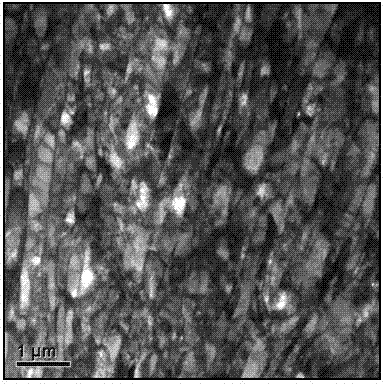

Q345B medium-wide band steel and production method thereof

The invention discloses Q345B medium-wide band steel and a production method thereof. The production method comprises the steps of heating, hot rolling, cooling and winding. A steel billet contains the following ingredients by weight percent: 0.14 to 0.19 percent of C, less than or equal to 0.25 percent of Si, 0.45 to 0.85 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.010 to 0.040 percent of V, 0.004 to 0.015 percent of N, and the balance of Fe and unavoidable impurities. The medium-wide band steel adopts nitrided ferrovanadium to be under microalloying, and the precipitation of vanadium is promoted by increasing the nitrogen, and the crystal grain is refined; trace amount of vanadium is used for substituting a great amount of manganese, and the precipitation strengthening is used for substituting the solution strengthening. The content of Mn in the medium-wide band steel is reduced by about 0.45 percent; meanwhile, by adding V, the cost of the steel per tonnage is effectively reduced; the precipitation strengthening and the fine-grain strengthening are adopted as main strengthening means, so that the content of sulfide impurities is reduced, the internal tissue is improved, and effects for reducing the production cost and improving the quality of the medium-wide band steel product can be achieved. By adopting the method, the addition amount of the alloy element is reduced, the reduction production is realized, the fine-grain strengthening and precipitation strengthening can be better realized, and the comprehensive performance of the product is better.

Owner:HEBEI IRON AND STEEL

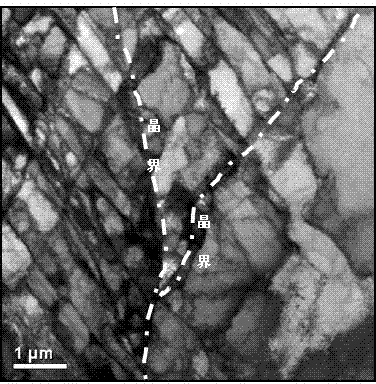

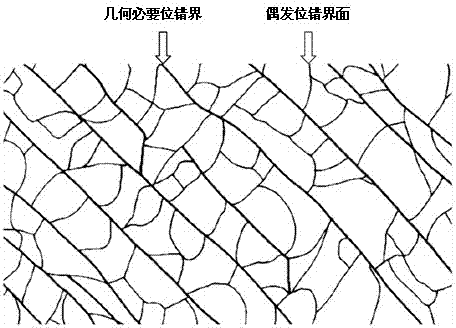

Subboundary-reinforced high-strength interstitial free steel containing Ti, and preparation method thereof

ActiveCN103540843AHigh strengthImprove plastic deformation abilityImpurityGrain boundary strengthening

The invention belongs to the field of metallurgical technology, and especially relates to subboundary-reinforced high-strength interstitial free steel containing Ti, and a preparation method thereof. The subboundary-reinforced high-strength interstitial free steel comprises 0.12 to 0.16wt% of Mn, 0.08 to 0.10wt% of Ti, the balance Fe and unavoidable impurities. Tensile strength is 540 to 710MPa, and yield strength is 510 to 600MPa. Microstructure of the subboundary-reinforced high-strength interstitial free steel containing Ti is formed by equiaxed ferritic grains, diameter of the equiaxed ferritic grains ranges from 20 to 30 <mu>m, separation distance between geometrically necessary dislocation boundaries ranges from 300 to 500nm, and the size of a cellular structure ranges from 400 to 800nm. The preparation method comprises following steps: Fe, Mn and Ti are subjected to melting and casting so as to obtain ingot casting; the ingot casting is subjected to solution treatment, and hot rolling so as to obtain hot rolled plates; thin steel plates are obtained after further processing; and the thin steel plates are subjected to annealing treatment so as to obtain the subboundary-reinforced high-strength interstitial free steel containing Ti. The subboundary-reinforced high-strength interstitial free steel containing Ti possesses high strength and relatively excellent plasticity and deformability, and possesses significant values for development of the fields of rapid developed automobile industry and machine building industry.

Owner:NORTHEASTERN UNIV

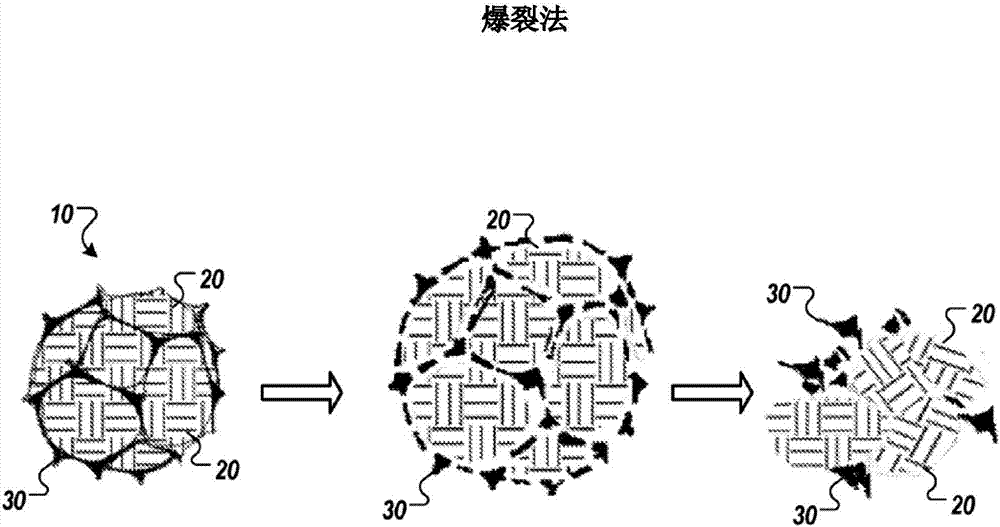

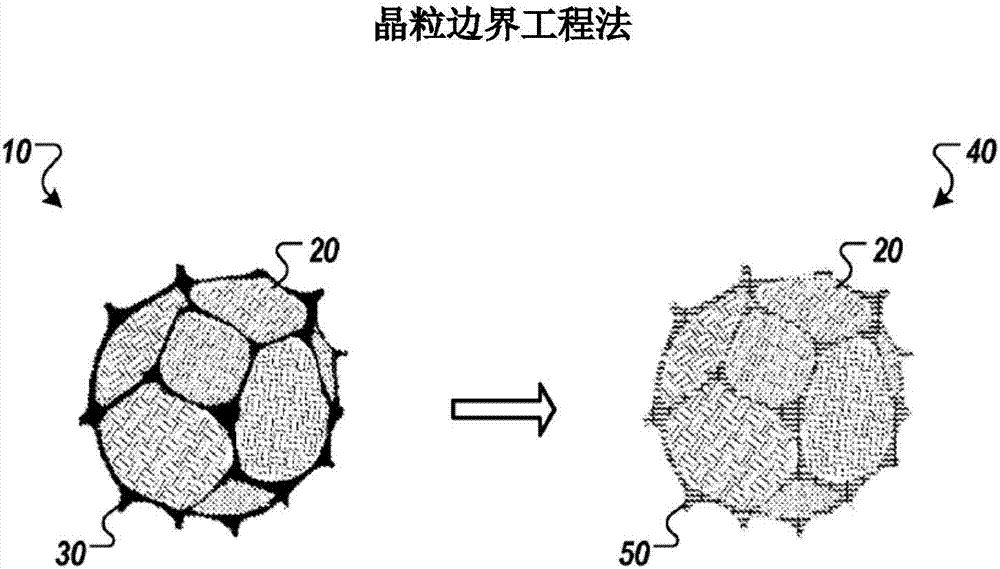

Grain boundary engineering

InactiveCN107000051AReduce consumptionReduce magnetismTransportation and packagingMetal-working apparatusRare earthComputer program

Methods, systems, and apparatus, including computer programs encoded on computer storage media, for creating magnetic material. One of the methods includes melting magnetic elements to create a molten alloy, forming cast alloy flakes that comprise 2:14:1 phase grains, pulverizing the cast alloy flakes to create a first powder while maintaining at least some of the 2:14:1 phase grains, pressing and aligning particles in the first powder to create a first compact, sintering the first compact to create a sintered compact, fragmenting the sintered compact to form a second powder while maintaining at least some of the 2:14:1 phase grains from the sintered compact, mixing the second powder with a rare earth material and an elemental additive to produce a homogeneous powder while maintaining at least some of the 2:14:1 phase grains from the second powder, and sintering and magnetizing the homogeneous powder to form an Nd-Fe-B magnetic product.

Owner:URBAN MINING CO

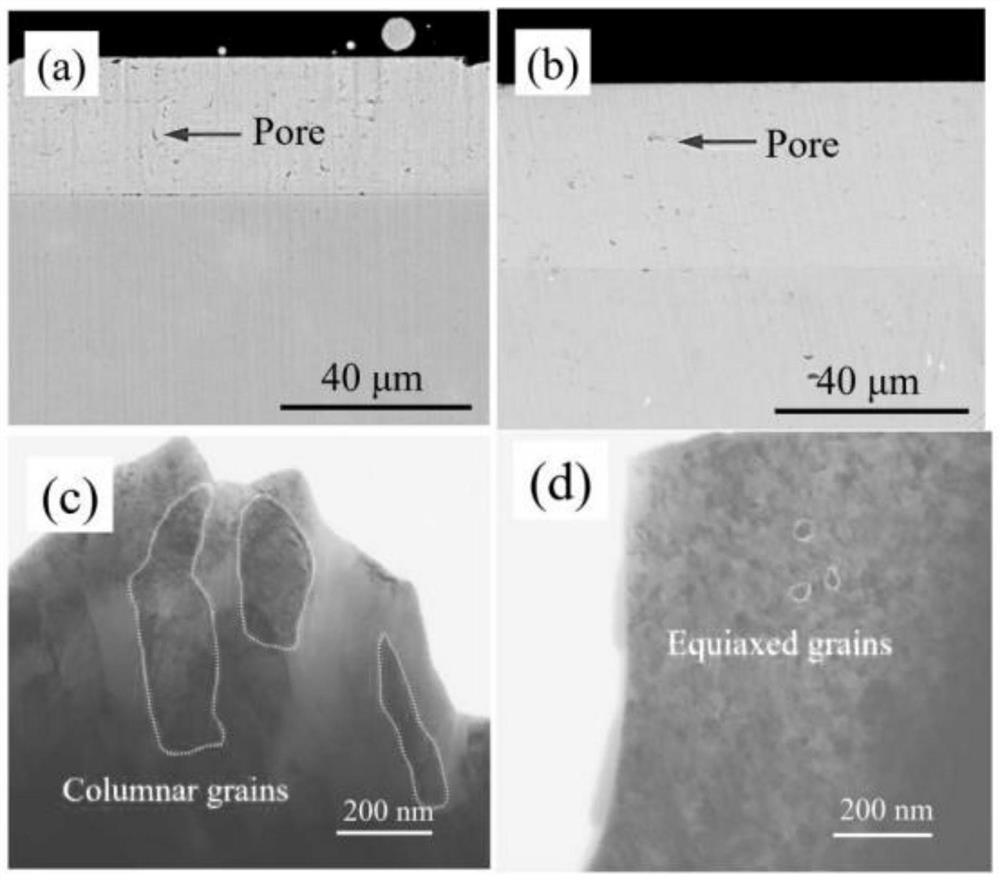

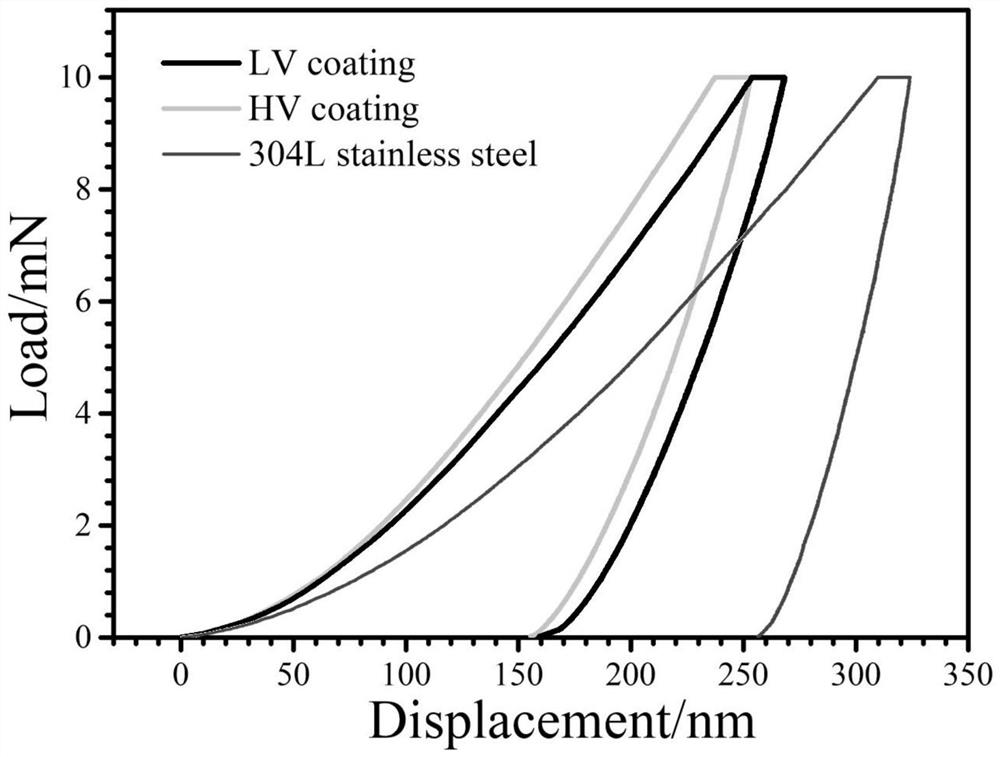

Multi-arc ion plating cavitation erosion resistant nickel-based metal coating and preparation method thereof

PendingCN113718208AImprove bindingHigh hardnessVacuum evaporation coatingSputtering coatingMetal coatingCrazing

The invention discloses a multi-arc ion plating cavitation erosion resistant nickel-based metal coating and a preparation method thereof. The coating comprises the following components in percentage by mass: 49.5%-80% of Ni, 10%-30% of Cr, 10%-20% of Al and 0-0.5% of Y. The preparation method is simple and easy to operate, high in controllability and low in cost, the nanocrystalline coating with the phase composition of gamma / gamma' is prepared through the multi-arc ion plating technology, the hardness of the coating is greatly improved through grain boundary strengthening and precipitation strengthening and can reach 9.88 GPa, and then the plastic deformation resistance is improved; and nano-pores exist in the coating and have elastic deformation capacity, so that cavitation impact energy is partially dissipated, self-damage is reduced, cavitation crack initiation and expansion are restrained, the cavitation rate is reduced, the cavitation resistance is excellent, in addition, the application range is wide, the coating is suitable for being deposited on iron-based, nickel-based, copper-based, aluminum-based and other materials, and economical efficiency and application prospects are good.

Owner:SONGSHAN LAKE MATERIALS LAB

Alloy powder and application thereof into laser cladding

InactiveCN113416953AHigh melting pointHigh hardnessMetallic material coating processesMetallic materialsMetal

The invention discloses alloy powder and application thereof into laser cladding, and belongs to the technical field of metal materials and laser cladding. The alloy powder is composed of elements and compounds of C, Cr, Ni, Mo, Nb, N, Mn, V, Si, B, Ce, Fe and Y2O3. Alloy matrix strengthening elements (Nb, Mn and N), grain boundary strengthening elements (Ce and Y2O3) and various element materials (V, Si and B) capable of reducing the melting point and improving the performance are added into a designed iron-chromium-nickel-molybdenum alloy, the proper content of all the elements is designed and adjusted, so that the alloy powder forms a coherent and stable intermetallic compound gamma'-Ni3Nb, a matrix containing a dispersed phase and a second-phase strengthened structure after cladding and solidification, and under the condition that the hardness of the cladding layer is guaranteed, the technical problems that multiple laser cladding layers are generated, and large-area cracking is prone to happening are solved.

Owner:沈阳稀有金属研究所

Ultrafine zinc alloy powder and preparation method thereof

ActiveCN104972108AGrain refinementReduce grain boundary energyMaterial nanotechnologyAnti-corrosive paintsRare-earth elementIndium

The invention provides a ultrafine zinc alloy powder and a preparation method thereof, wherein the particle size range of the ultrafine zinc alloy powder is 1-100nm. The ultrafine zinc alloy powder comprises light rare earth element lanthanum, cerium and heavy rare earth element gadolinium, wherein the light rare earth element lanthanum, and the cerium and the heavy rare earth element gadolinium can restrain crystal particles to grow on one hand and form a fine crystal particle grain boundary strengthening mechanism, can play the role of degassing and removing impunities on the other hand, thereby reducing damage to alloy. Simultaneously, less nickel, cobalt and stibium are added into the ultrafine zinc alloy powder, can obviously improve anti-corrosion and oxidation resistance. Trace amount of indium, bismuth, aluminum and calcium metal are added into the ultrafine zinc alloy powder, and the alloy performance of the ultrafine zinc alloy powder is enhanced. The ultrafine zinc alloy powder does not comprise poisonous and harmful elements such as mercury, lead and cadmium, can not cause environment pollution and ecological damage, and is green and environmentally friendly.

Owner:JIANGSU YEJIAN ZINC IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com