Alloy powder and application thereof into laser cladding

A technology of alloy powder and laser cladding, which is applied in the coating process and coating of metal materials, can solve the problems of cracks in the cladding layer, easy cracking of multiple layers, unstable performance, etc., and achieve excellent cladding performance , Improve the performance of multi-layer and large-area cladding, and improve the quality of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

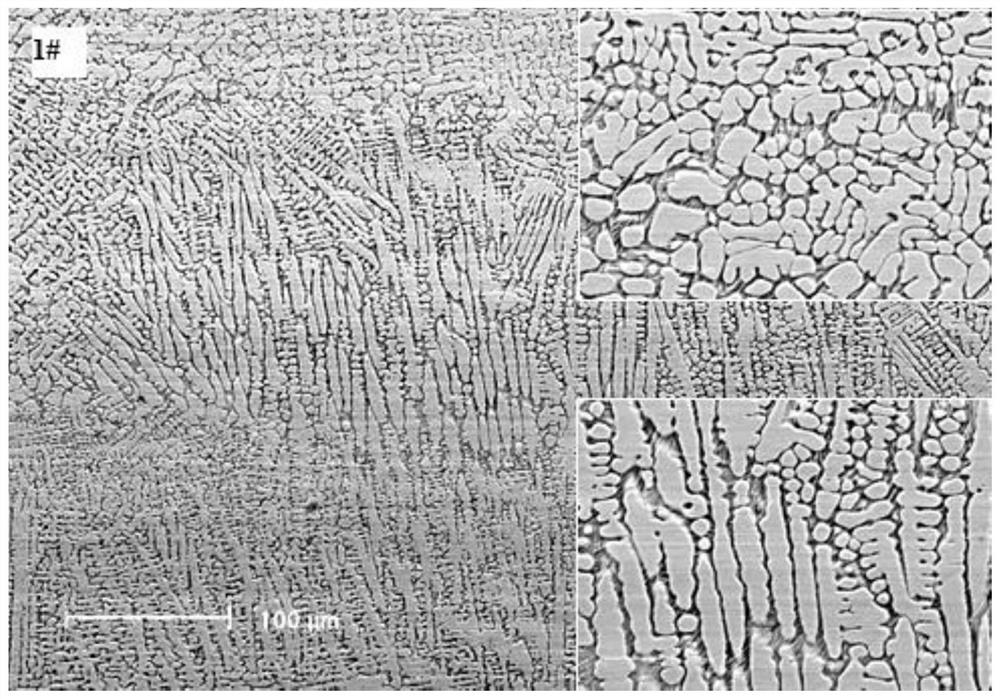

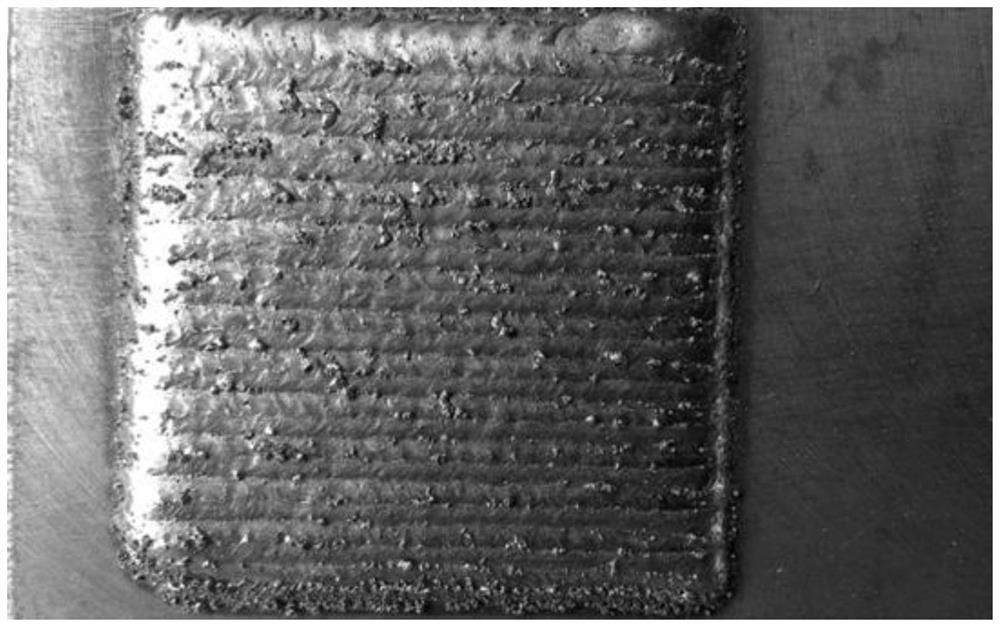

Embodiment 1

[0032] Laser cladding treatment is performed on the surface of the failed hydraulic cylinder (the material is low alloy carbon steel). The alloy powder for laser cladding is composed of the following elements by weight percentage (wt%): C: 0.45; Cr: 15.5; Ni: 2.0 ;Mo:1.6;Nb:1.5;N:0.3;Mn:0.4;V:1.1;Si:1.2;B:1.2;Ce:1.3;Y 2 o 3 : 0.45; the balance is Fe.

[0033] A 4 kilowatt semiconductor laser is used for laser cladding. The parameters of laser cladding are: power 3000W; focal length 280mm; spot diameter 6mm; scanning speed 360mm / min; powder thickness 0.8mm;

[0034] The alloy powder was dried at 120°C for 1.5 hours before cladding.

[0035] Results: There are three cladding layers in total, the total thickness of cladding is 2.5mm; the cladding area is 1.2 square meters; the hardness measured by multi-point testing is HRC55-58; the cladding layer has no cracks or bubbles through non-destructive testing; The machine company installed it in the underground operation area. Afte...

Embodiment 2

[0037] Laser cladding is carried out on the failed structural steel major shaft of the steel company (the material is low alloy structural steel). The alloy powder for laser cladding is composed of the following elements by weight percentage (wt%): C: 0.5; Cr: 16.2; Ni: 2.4;Mo:1.5;Nb:2.4;N:0.35;Mn:0.45;V:1.2;Si:1.3;B:1.1;Ce:1.4;Y 2 o 3 : 0.5; the balance is Fe.

[0038] A 3 kilowatt semiconductor laser is used for laser cladding. The parameters of laser cladding are: power 2600W; focal length 280mm; spot diameter 4mm; scanning speed 240mm / min; powder thickness 1.1mm;

[0039] The alloy powder was dried at 150°C for 1.5 hours before cladding.

[0040] Results: There are three cladding layers in total, and the total cladding thickness is 3mm; the cladding area is 1.2 square meters; the hardness measured by multi-point testing is HRC52-55; the cladding layer has no cracks or bubbles through non-destructive testing; resume the machine The use effect is good, the wear resistance i...

Embodiment 3

[0042] Laser cladding is performed on the intermediate flange shaft (the material is 42CrMo steel). The alloy powder for laser cladding is composed of the following elements by weight percentage (wt%): C: 0.6; Cr: 12.0; Ni: 1.2; Mo: 3.0; Nb: 2.8; N: 0.5; Mn: 0.3; V: 0.8; Si: 2.0; B: 0.8; Ce: 1.6; 2 o 3 : 0.4; the balance is Fe.

[0043] A 3 kilowatt semiconductor laser is used for on-site laser cladding. The parameters of laser cladding are: power 3800W; focal length 300mm; spot diameter 6mm; scanning speed 400mm / min; powder thickness 1.2mm;

[0044] The alloy powder was dried at 150°C for 1.8 hours before cladding.

[0045] Results: A total of four cladding layers were clad, with a total cladding thickness of 4.8 mm; cladding area of 1.5 square meters; the hardness measured by multi-point testing was HRC47-50; the cladding layer had no defects such as cracks and bubbles through non-destructive testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com