High temperature resistant molten salt corrosion ceramet anode material and preparation method thereof

A metal ceramic anode, molten salt corrosion technology, applied in the field of material science, can solve the problem that the corrosion resistance of grain boundaries needs to be improved, and achieve the effects of eliminating the connected pores of grain boundaries, improving sintering density, and low cost

Inactive Publication Date: 2011-01-05

CENT SOUTH UNIV

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a kind of cermet inert anode material and its preparation method that can withstand the corrosion of long-term high-temperature fluoride molten salt, and can ensure the inert anode in aluminum electrolysis run smoothly, solve the problem of existing cermet for aluminum electrolysis Corrosion resistance of inert anode materials, especially the problem that the corrosion resistance of grain boundaries needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

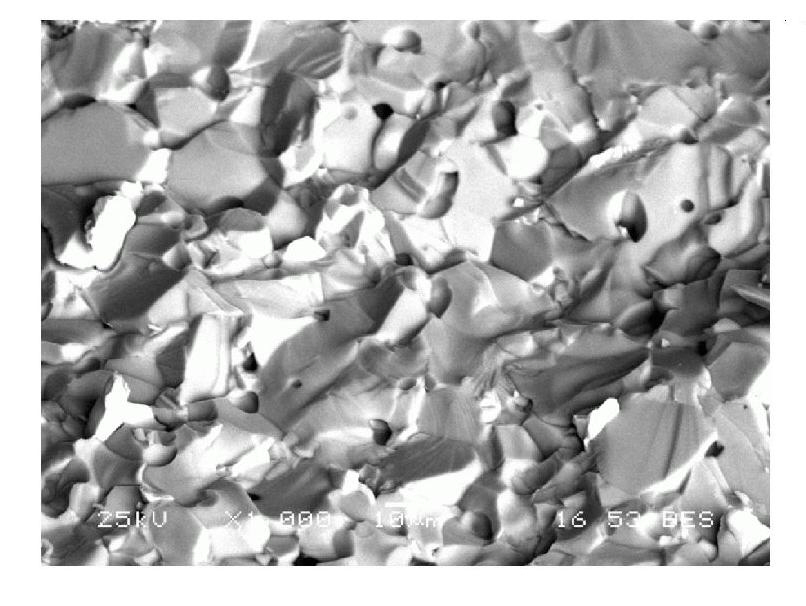

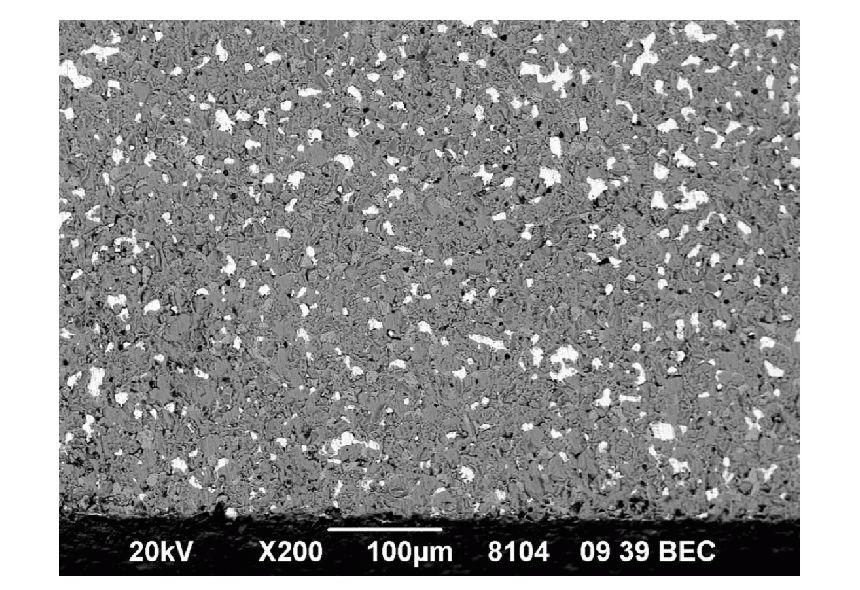

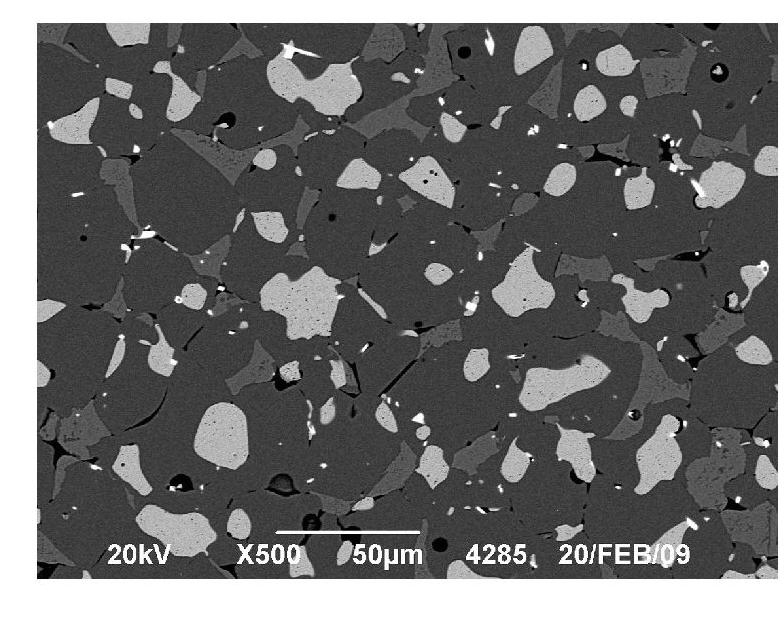

The present invention provides a kind of high temperature resistant molten salt corrosion ceramet anode material and a preparation method thereof. The referred ceramet inertness anode material is composed of the following components by weight: 50% to 95% of spinelle type oxide, 1% to 30% of other oxide, 1% to 30% of metal or alloy, and 0.1% to 2% of grain boundary corrosion resistant energizing agent. The raw material is added with a given amount of +3 value lanthanide series rare-earth oxide powder, the rare-earth oxide and a ceramic matrix react with each other during a sintering process toform high temperature resistant molten salt corrosive ferrate new phase along the grain boundary, and simultaneously accelerate the elimination of communication between the grain boundary and breathing holes as well as densification of the sintering material, so as to improve the high temperature resistant molten salt corrosive performance of the material especially the grain boundary region.

Description

Metal ceramic anode material resistant to high temperature molten salt corrosion and preparation method thereof Technical field The invention belongs to the field of material science and relates to a metal ceramic anode material resistant to high temperature molten salt corrosion and a preparation method thereof. Background technique At present, cermet has good thermochemical stability, strong corrosion resistance, oxidation resistance and excellent electrical conductivity and thermal shock resistance of metal materials, and is considered to be the most promising replacement for carbon anode as molten salt electrolysis ( Such as electrolytic aluminum) one of the inert anode materials. In the high-temperature molten salt electrolyte, due to the difference in chemical composition between the grain interface and the interior, as well as the presence of grain boundary impurities or internal stress, it is easy to cause problems such as electrolyte penetration, material swelling, cr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25C3/12

Inventor 周科朝何汉兵谭占秋李志友甘雪萍张雷

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com