Metal phase of cermet inert anode material capable of resisting corrosion of high-temperature molten salt and preparation method and application thereof

A cermet and inert anode technology, which is applied in the field of material science, can solve the problems such as the high temperature molten salt corrosion resistance of the metal phase needs to be improved, and achieve the effects of improving the molten salt corrosion resistance, smooth operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

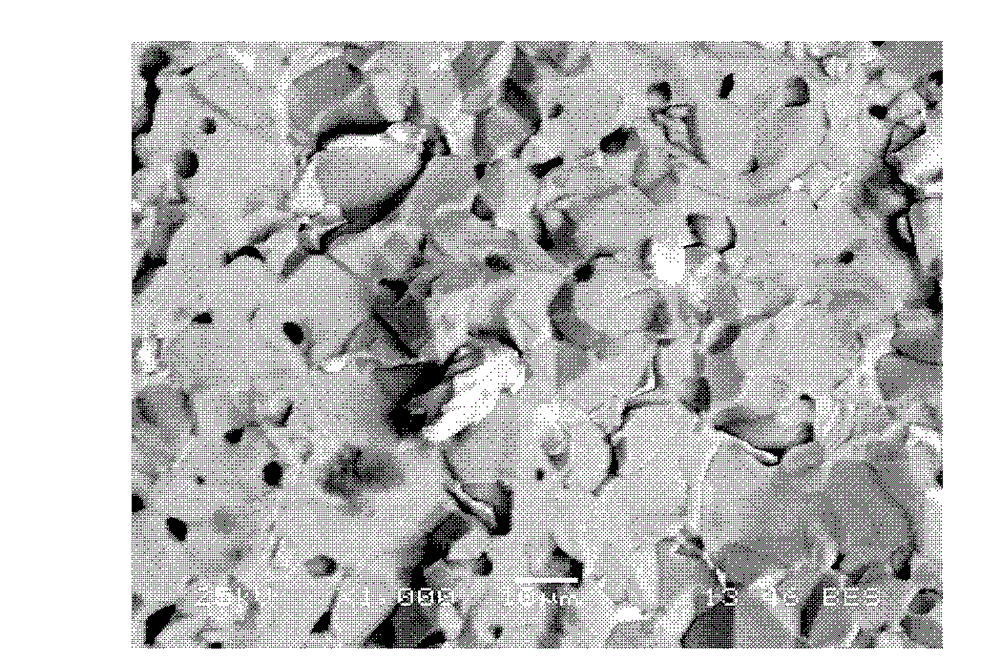

[0038] Embodiment 1: 15 (20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0039] 15(20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formula of cermet inert anode is shown in Table 1.

[0040] Table 115 (20NiFe 2 o 4 -80(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0041] raw material

Mass percentage (%)

20Ni-80Cu

12.0

Coated NiFe 2 o 4

3.0

NiO

8.5

NiFe 2 o 4

76.5

[0042] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of the substances is 4:1, the co-current co-precipitation method is adopted, the ammonia water is used as the precipitating agent, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the r...

Embodiment 2

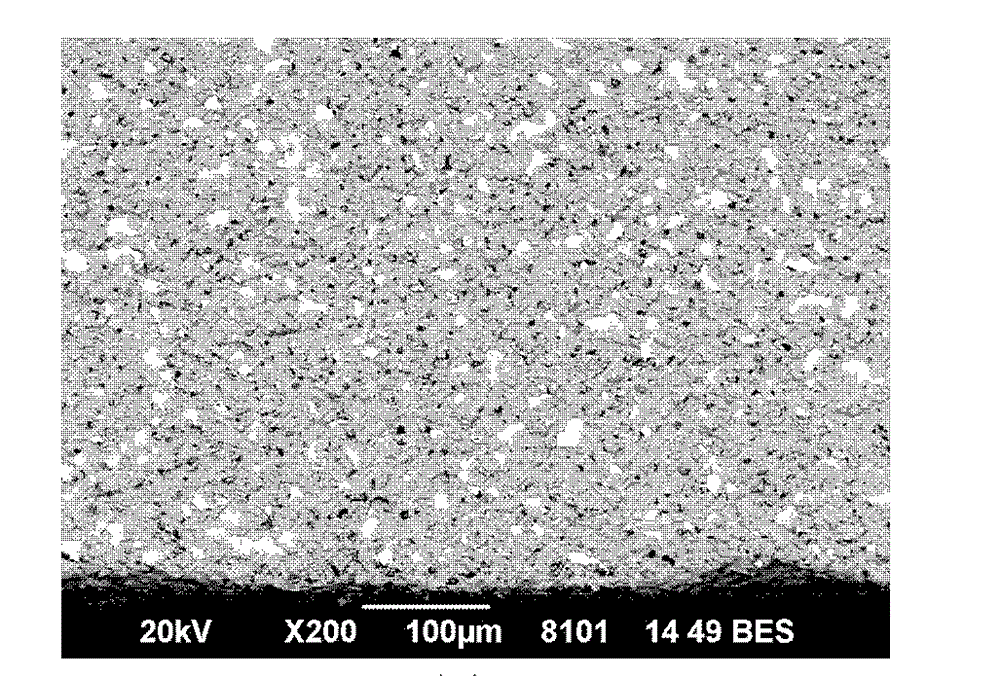

[0044] Embodiment 2: 15 (30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0045] 15(30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 2.

[0046] Table 215 (30NiFe 2 o 4 -70(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0047] raw material

Mass percentage (%)

20Ni-80Cu

10.5

Coated NiFe 2 o 4

4.5

NiO

8.5

NiFe 2 o 4

76.5

[0048] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of substances is 7:3, the co-current co-precipitation method is adopted, ammonia water is used as the precipitating agent, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the r...

Embodiment 3

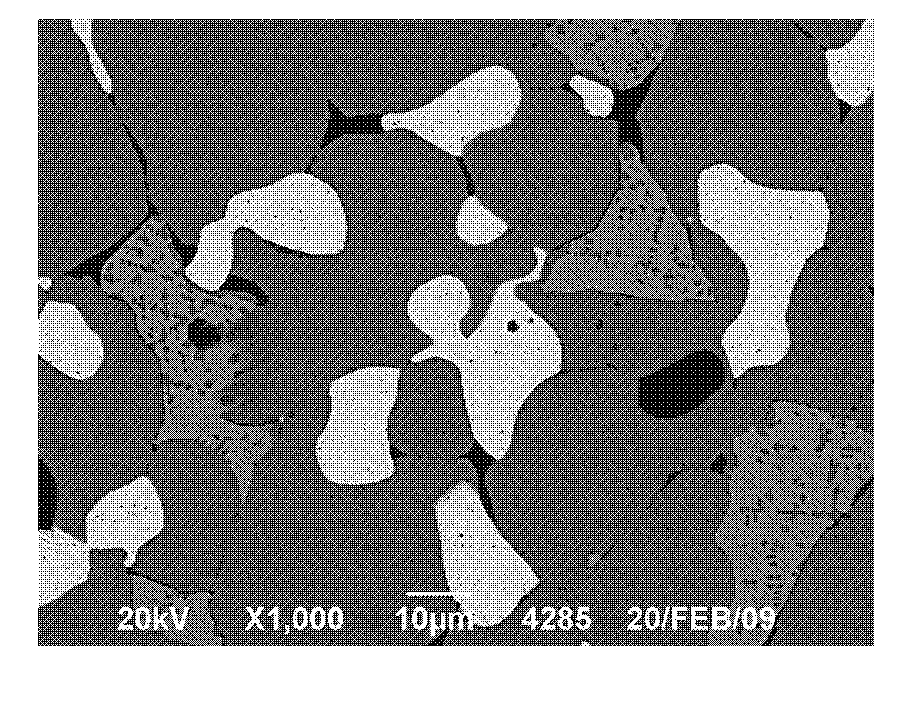

[0050] Embodiment 3: 15 (40NiFe2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) cermet inert anode

[0051] 15 (40NiFe 2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) The raw material formulation of the cermet inert anode is shown in Table 3.

[0052] Table 315 (40NiFe 2 o 4 -60(20Ni-80Cu)) / 85(10NiO-NiFe 2 o 4 ) Raw material formula example of cermet inert anode

[0053] raw material

Mass percentage (%)

20Ni-80Cu

9.0

Coated NiFe 2 o 4

6.0

NiO

8.5

NiFe 2 o 4

76.5

[0054] Put 20Ni-80Cu metal powder into a certain amount of NiCl 2 Aqueous solution and FeCl 3 Aqueous solution (n Ni 2+ : n Fe 3+ =1:2,), its 20Ni-80Cu metal and NiCl 2 The molar ratio of the substances is 3:2, the co-current co-precipitation method is adopted, ammonia water is used as the precipitant, the pH value is controlled to be 12, the reaction temperature is 60° C., and the stirring speed is 200 r / min. Filter the resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com