Multi-arc ion plating cavitation erosion resistant nickel-based metal coating and preparation method thereof

A multi-arc ion plating and base metal technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as weak cavitation resistance, reduced coating protection life, poor mechanical properties, etc. , to achieve the effect of improving the ability to resist plastic deformation, reducing self-damage, and improving grain boundary strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: This embodiment provides a multi-arc ion plating anti-cavitation nickel-based metal coating and a preparation method thereof, which includes the following steps:

[0026] (1) Take by weighing 64.5% of Ni powder, 25% of Cr powder, 10% of Al block, and 0.5% of Y powder according to the formula, put them into a multifunctional vacuum induction melting furnace, and put the aluminum block with low melting point first, The raw materials are smelted by induction heating under vacuum conditions, and smelted into cylindrical ingots under the protection of argon. The cylindrical ingot is then machined into a round ingot with a diameter of 100mm and a height of 40mm;

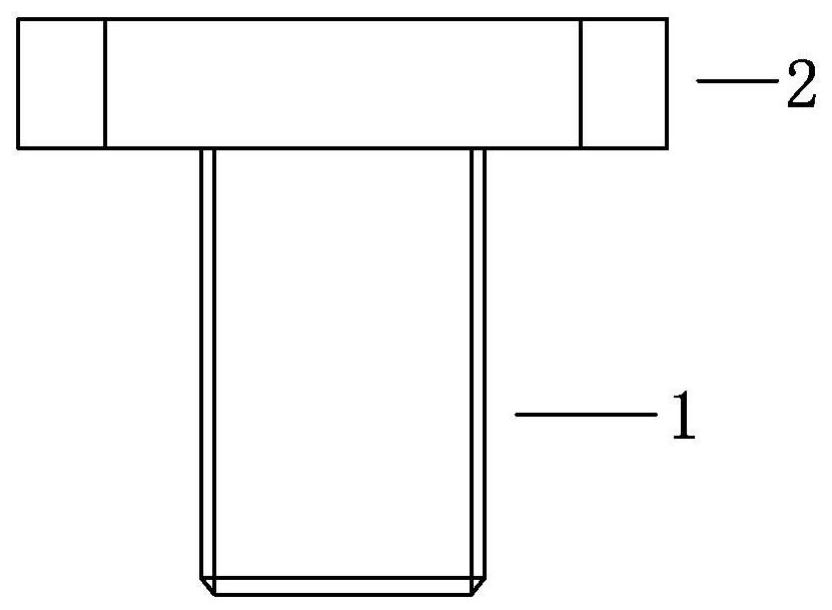

[0027] (2) Process commercial 304L stainless steel into a shape with threads as a sample (substrate), see figure 1, the sample includes a threaded part 1 and a deposition surface 2, and the threaded part 1 facilitates installation on a sample stage of a cavitation erosion machine. Polish the depositi...

Embodiment 2

[0030] Embodiment 2: This embodiment provides a multi-arc ion plating anti-cavitation nickel-based metal coating and a preparation method thereof, which includes the following steps:

[0031] (1) Take by weighing the Ni powder 64.5% of mass fraction ratio, Cr powder 25%, Al block 10%, Y powder 0.5%, put into multifunctional vacuum induction melting furnace, put into the aluminum block of low melting point earlier, The raw materials are smelted by induction heating under vacuum conditions, and smelted into cylindrical ingots under the protection of argon. It was then machined into round ingots with a diameter of 100 mm and a height of 40 mm.

[0032] (2) The commercial 304L stainless steel is processed into a shape with threads as a sample (substrate). The sample includes a threaded part and a deposition surface, and is conveniently installed on the sample stage of a cavitation erosion machine through the threaded part. Polish the deposition surface where the sample needs to b...

Embodiment 3

[0035] Embodiment 3: This embodiment provides a multi-arc ion plating anti-cavitation nickel-based metal coating and its preparation method, which is basically the same as in Embodiment 2, the difference being that the component mass percentage of the coating is: Ni powder 49.5 %, Cr powder 30%, Al block 20%, Y powder 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com