Hot rolled steel, manufacturing method of hot rolled steel, mooring cable and manufacturing method of mooring cable

A manufacturing method and hot-rolled steel technology, which are applied to ships and other directions, can solve the problems of high energy consumption and high cost, and achieve the effect of saving production costs and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

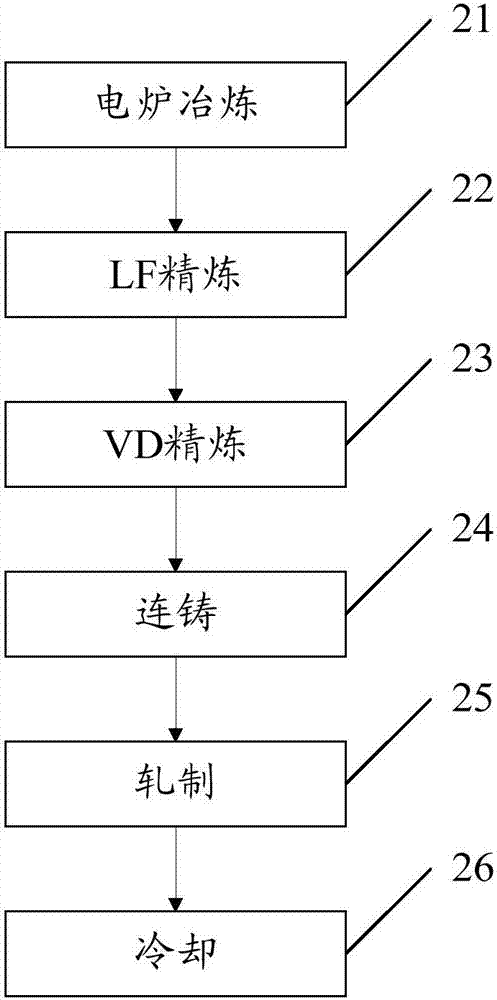

[0045] The process route for manufacturing hot-rolled steel provided by the present invention includes the following steps: FAF (electric furnace steelmaking) → LF refining (ladle refining) → VD refining (vacuum refining) → continuous casting → cutting → cooling (slow cooling) → inspection → judgment →heating→rolling→cutting→air cooling→ultrasonic + magnetic particle inspection→(finishing)→judgment→packaging→weighing→storage. The main steps in the above steps are described below.

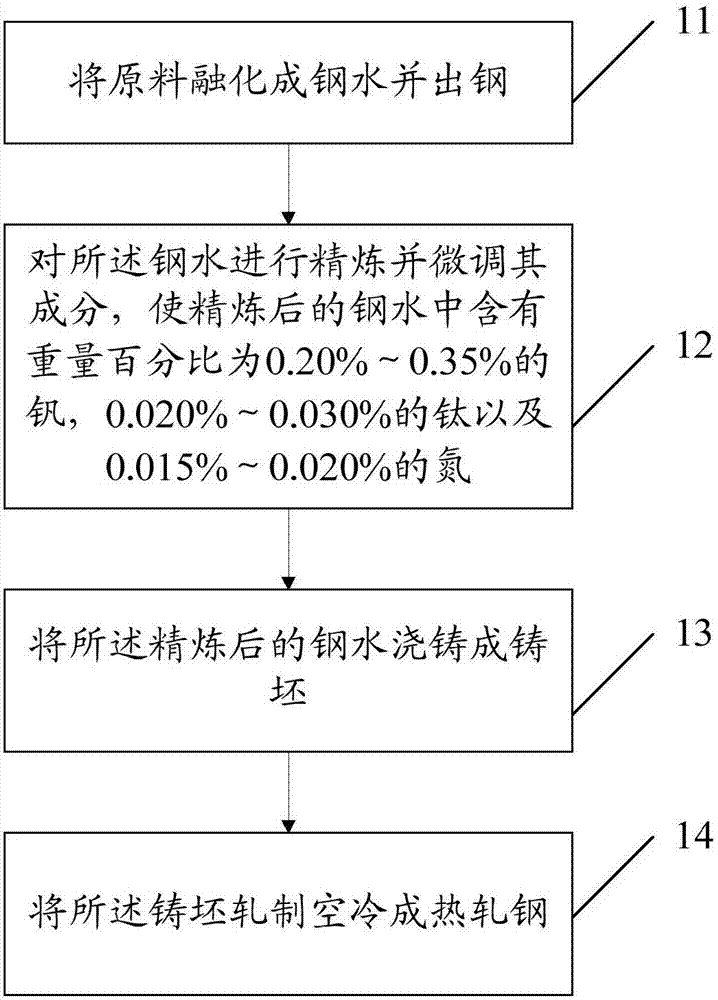

[0046] Such as figure 1 As shown, the manufacturing method of the hot-rolled steel provided by Embodiment 1 of the present invention includes:

[0047] Step 11: melting raw materials into molten steel and tapping;

[0048] The raw materials include main materials and auxiliary materials. The main materials include pig iron and steel scrap. Of course, pig iron can also be replaced by molten iron, or pig iron and molten iron can be added at the same time. Pig iron and molten iron should meet the re...

Embodiment 2

[0108] In order to better solve the above technical problems, Embodiment 2 of the present invention provides a hot-rolled steel, which contains 0.20% to 0.35% by weight of vanadium, 0.020% to 0.030% of titanium and 0.015% ~0.020% nitrogen.

[0109] Of course, the hot-rolled steel also includes: 0.30%-0.50% chromium, 0.20%-0.50% nickel and 0.20%-0.30% molybdenum.

[0110] It can be seen that the proportion of precious metal elements such as chromium, molybdenum, nickel, niobium and titanium is smaller than that of existing hot-rolled steel, which greatly reduces the production cost.

[0111] The hot-rolled steel also includes: 0.27%-0.34% carbon by weight, 0.17%-0.37% silicon, 1.40%-1.80% manganese, 0.020%-0.065% aluminum, and 0.00%-0.20% copper , 0.000% to 0.025% of phosphorus, 0.000% to 0.015% of sulfur, 0.0000% to 0.0015% of oxygen, 0.00000% to 0.00020% of hydrogen, and the balance is iron.

[0112] The hot-rolled steel with this chemical composition and content has high s...

Embodiment 3

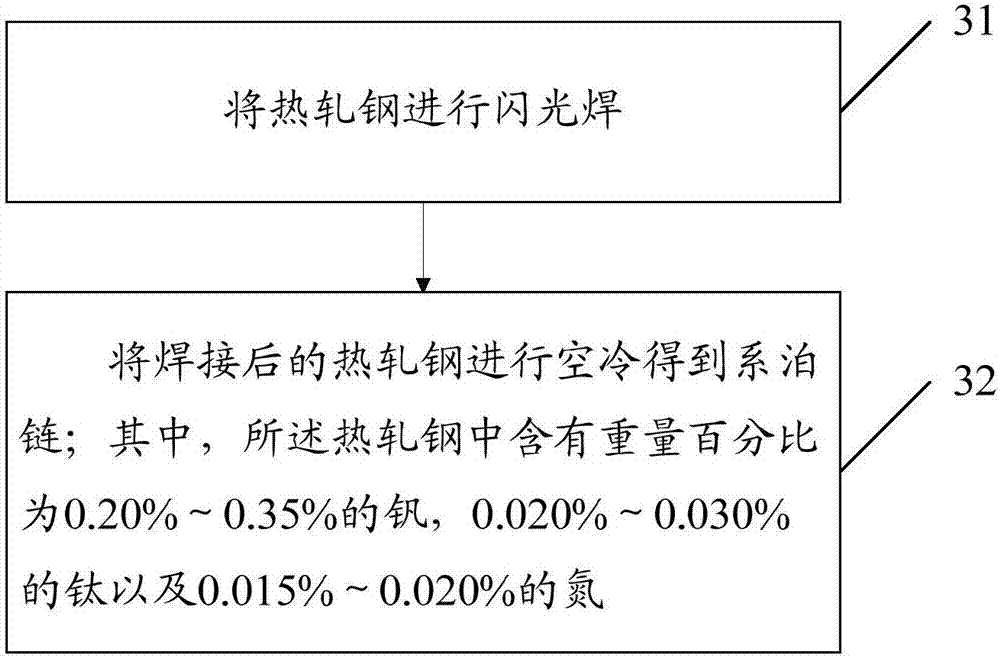

[0117] Correspondingly, Embodiment 3 of the present invention provides a method for manufacturing a mooring chain, such as image 3 shown, including:

[0118] Step 31: flash welding the hot-rolled steel;

[0119] Step 32: air-cool the welded hot-rolled steel to obtain a mooring chain;

[0120] Wherein, the hot-rolled steel contains 0.20% to 0.35% of vanadium, 0.020% to 0.030% of titanium and 0.015% to 0.020% of nitrogen by weight.

[0121] The mooring chain manufacturing method provided by Embodiment 3 of the present invention not only ensures the strength of the mooring chain, but also cancels the heat treatment process in the chain manufacturing process, reduces energy consumption, and saves production costs.

[0122] Specifically, the step of performing flash welding on the hot-rolled steel includes: performing flash welding on the hot-rolled steel at a temperature of 800°C to 950°C.

[0123] It can also be said that the manufacturing method of the mooring chain provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com