Array type diamond film and method for making the same

A technology of diamond film and manufacturing method, which is applied in chemical instruments and methods, gaseous chemical plating, metal material coating technology, etc., and can solve problems such as not easy to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Hereinafter, the present invention will be described in more detail with examples, but the present invention is not limited to the following examples, and can be appropriately changed and implemented within the scope of the purpose described above and below, and these are all included in the technical scope of the present invention .

[0086] (1) Fabrication of highly oriented diamond film as the base layer

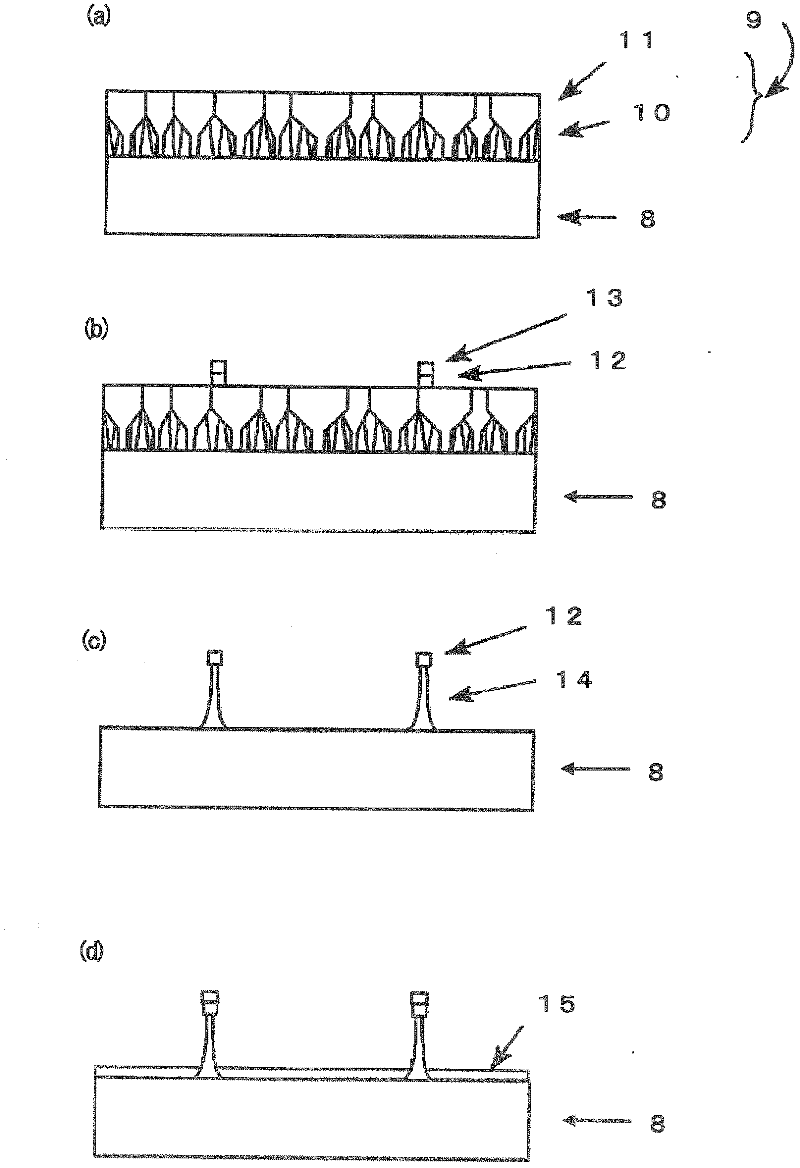

[0087] The highly oriented diamond film serving as the base layer was synthesized by the three-stage vapor phase synthesis method described in Patent Document 3. Specifically, using a Si (100) wafer as the substrate 8, surface carbonization, partial nucleus generation (first stage), orientation growth (second stage) and crystal grain Expand growth (third stage), synthesize highly oriented diamond film 9 ( image 3 (a)).

[0088] Table 1

[0089]

[0090] When the highly oriented diamond film 9 is observed by a scanning electron microscope, it is confirmed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com