Subboundary-reinforced high-strength interstitial free steel containing Ti, and preparation method thereof

An interstitial-free steel and high-strength technology, applied in the field of metallurgy, can solve the problems of low specific mass, low strength, and high processing costs, and achieve strong dislocation absorption capacity, high room temperature tensile strength, and good plastic deformation capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

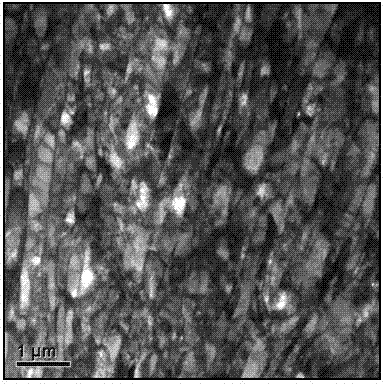

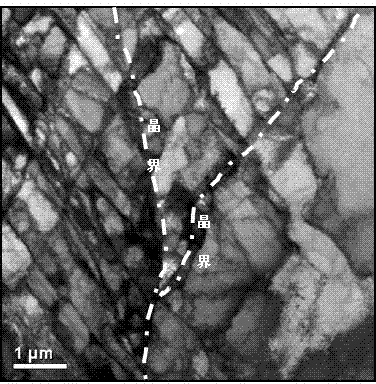

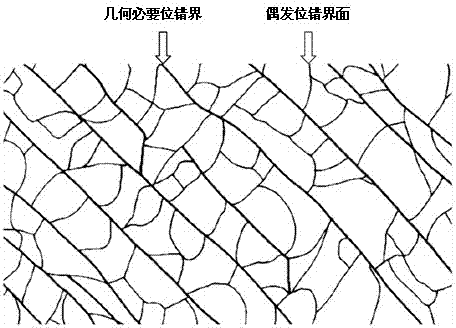

Image

Examples

Embodiment 1

[0036] The chemical composition of the sub-grain boundary strengthened high-strength titanium-containing non-interstitial atom steel of this embodiment is as follows by weight percentage: Mn 0.14%, Ti 0.10%, and the balance is Fe and unavoidable impurities.

[0037] The method for preparing the above-mentioned sub-grain boundary strengthened high-strength titanium-containing interstitial atom-free steel is carried out according to the following steps:

[0038] (1) According to weight percentage, Mn0.14%, Ti0.10%, the balance is Fe. Put metallic Fe, metallic Mn and metallic Ti in a smelting furnace, smelt under protective gas, and then cast into ingots ;

[0039] The impurity components in the ingot are Ni0.01%, Cu0.04%, Si0.176%, Al0.002%, Nb0.019%, V0.075%, Co0.019%, P0.018% in weight percentage, B0.004%, W0.028%, N0.002%, S0.007%;

[0040] (2) Heat the ingot to 1040°C for 1 hour for solution treatment, perform hot rolling at 840°C, with a deformation of 63%, and control the final r...

Embodiment 2

[0045] The chemical composition of the sub-grain boundary strengthened high-strength titanium-containing non-interstitial atom steel in this embodiment is as follows by weight percentage: Mn 0.16%, Ti 0.09%, and the balance is Fe and unavoidable impurities.

[0046] The method for preparing the above-mentioned sub-grain boundary strengthened high-strength titanium-containing interstitial atom-free steel is carried out according to the following steps:

[0047] (1) According to weight percentage, Mn0.16%, Ti0.09%, the balance is Fe. Put metallic Fe, metallic Mn and metallic Ti in a smelting furnace, smelt under protective gas, and then cast into ingots ;

[0048] The impurity components in the ingot are Ni0.02%, Cu0.03%, Si0.176%, Al0.003%, Nb0.021%, V0.079%, Co0.014%, P0.015%, B0 in weight percentage .003%, W0.026%, N0.003%, S0.006%;

[0049] (2) Heat the ingot to 1050°C for 1.2h for solution treatment, perform hot rolling at 850°C, with a deformation of 70%, and control the final ro...

Embodiment 3

[0054] The chemical composition of the sub-grain boundary strengthened high-strength titanium-containing non-interstitial atom steel in this embodiment is as follows by weight percentage: Mn 0.12%, Ti 0.08%, and the balance is Fe and unavoidable impurities.

[0055] The method for preparing the above-mentioned sub-grain boundary strengthened high-strength titanium-containing interstitial atom-free steel is carried out according to the following steps:

[0056] (1) According to the weight percentage, Mn0.12%, Ti0.08%, the balance is Fe. Put metallic Fe, metallic Mn and metallic Ti in a smelting furnace, smelt under protective gas, and then cast into ingots ;

[0057] The impurity components in the ingot are Ni0.03%, Cu0.03%, Si0.16%, Al0.004%, Nb0.027%, V0.065%, Co0.013%, P0.018%, B0 .008%, W0.029%, N0.002%, S0.007%;

[0058] (2) Heat the ingot to 1060°C and hold for 1.5h for solution treatment, perform hot rolling at 860°C, with a deformation of 72%, and control the final rolling tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com